When it comes to maintaining and operating a reliable cutting device, familiarity with its internal structure is essential. Each component plays a critical role in ensuring the efficiency and longevity of the equipment. By comprehending how these elements interact, users can enhance performance and troubleshoot issues more effectively.

In this section, we will delve into the intricate assembly of one popular model. We will explore its various components, highlighting their functions and how they contribute to the overall operation. This knowledge is invaluable for both seasoned users and newcomers alike, empowering them to make informed decisions regarding maintenance and repairs.

Moreover, understanding the arrangement and design of these essential elements allows for better care and optimization of the tool’s capabilities. Whether you are looking to replace a worn-out piece or simply aiming to gain a deeper appreciation for the machinery, a clear insight into its construction is indispensable.

Understanding Husqvarna 50 Chainsaw Components

Every piece of equipment is built from a variety of essential elements that contribute to its functionality and performance. Grasping the roles and interactions of these components is crucial for effective operation and maintenance. This knowledge enhances the user experience and ensures longevity, allowing for optimal results during usage.

The engine serves as the powerhouse, providing the necessary energy for operation. Coupled with the fuel system, it ensures a consistent flow of power. The cutting mechanism, with its sharp teeth, is designed for efficiency, while the guide bar plays a pivotal role in directing the cutting path. Furthermore, the safety features are indispensable, safeguarding the user during operation.

Regular inspection of these components can prevent issues and promote smoother performance. Understanding the assembly of each element allows for better troubleshooting and repairs, ultimately extending the life of the equipment. Knowledge of these critical features empowers users to manage their tools effectively and confidently.

Overview of Chainsaw Parts

The inner workings of a cutting tool consist of several essential components that work in harmony to deliver optimal performance. Each element plays a crucial role in the overall functionality, ensuring efficient operation and user safety.

Power Unit: This is the heart of the machine, providing the energy needed for operation. Typically powered by an engine, it converts fuel into motion.

Guide Bar: A long metal strip that supports the cutting mechanism. Its length and design affect the depth and precision of cuts.

Cutting Chain: The loop of sharp teeth that does the actual cutting. Its quality and sharpness are vital for effective performance.

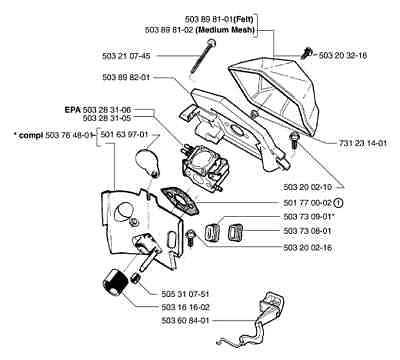

Fuel System: This includes the tank and lines that deliver fuel to the engine. Proper maintenance ensures optimal fuel flow and engine efficiency.

Oiling Mechanism: A system that lubricates the cutting chain to reduce friction and heat, extending the life of both the chain and the guide bar.

Handle and Safety Features: Designed for user comfort and safety, these components help maintain control and prevent accidents during operation.

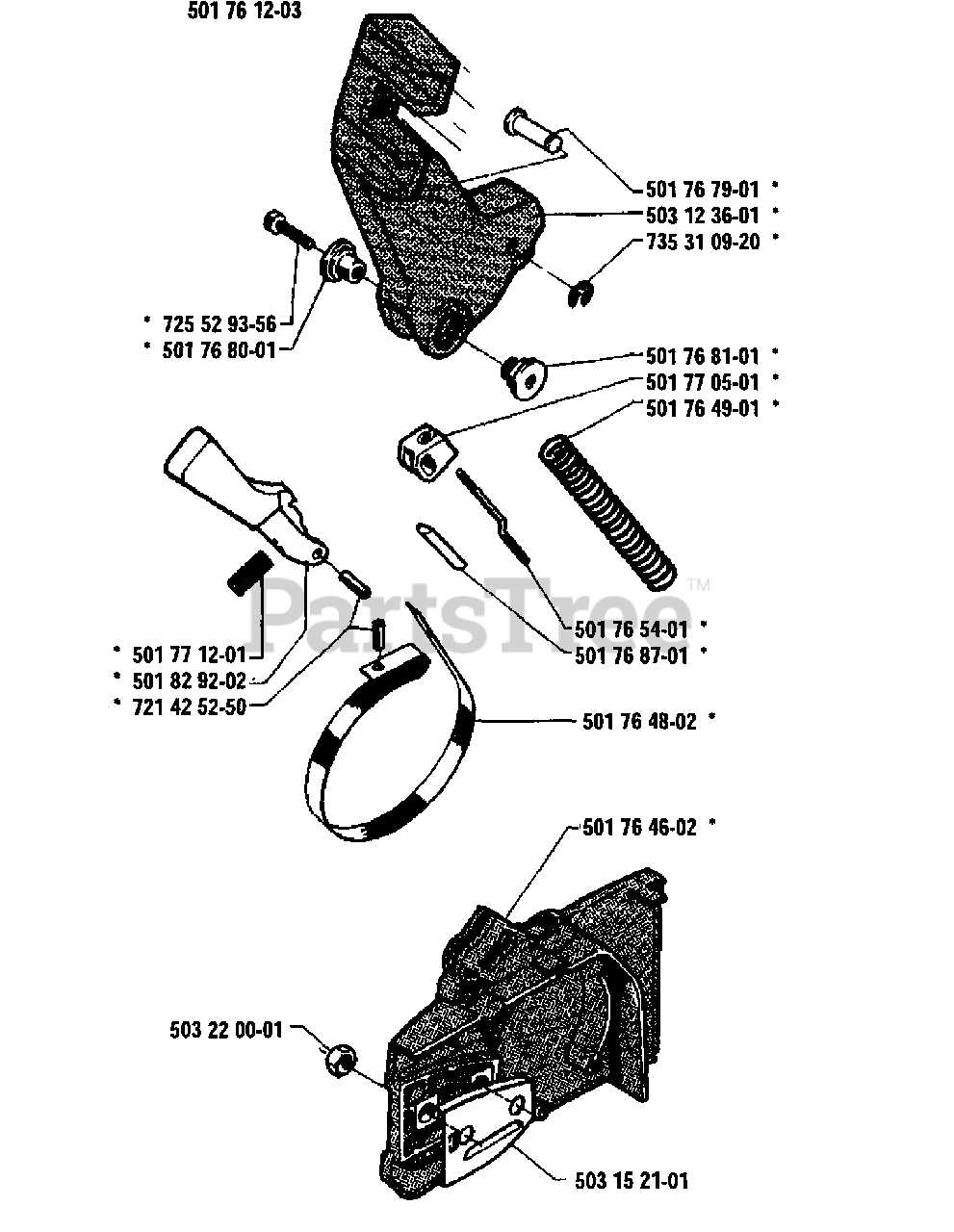

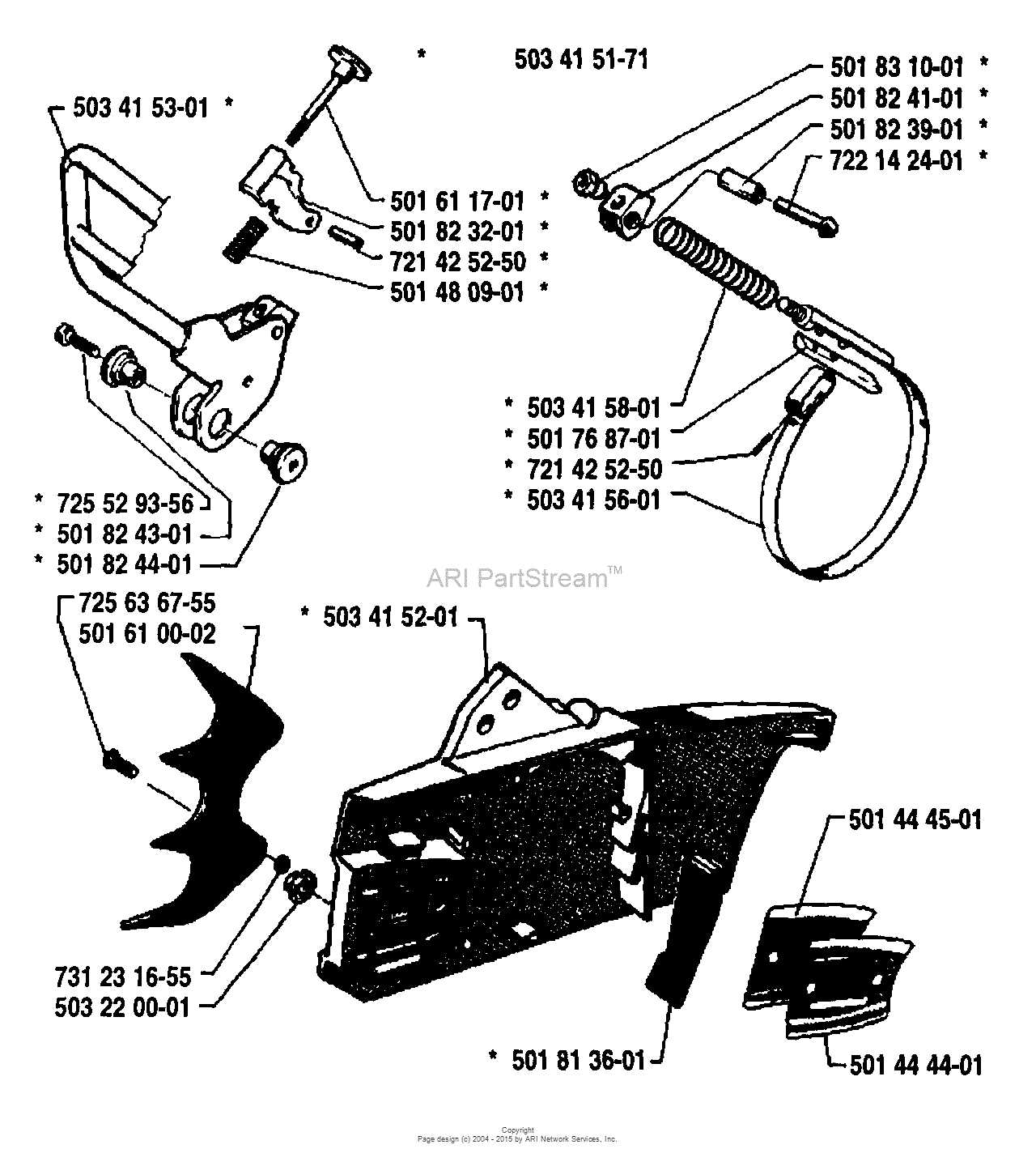

Importance of Diagrams for Maintenance

Visual representations of machinery components play a crucial role in the upkeep and repair of equipment. These illustrations provide clear guidance on assembly, disassembly, and troubleshooting, enabling users to understand complex systems with ease. By utilizing such resources, individuals can enhance their efficiency and accuracy during maintenance tasks.

Enhanced Understanding

Detailed visual aids simplify the comprehension of intricate mechanisms. They help technicians identify specific elements quickly, reducing the likelihood of errors during repairs. A well-structured visual guide allows for a more intuitive approach, making it easier to locate and assess individual elements within the equipment.

Efficient Troubleshooting

When issues arise, having access to comprehensive visual references can significantly expedite the diagnostic process. Technicians can match symptoms with components more effectively, leading to quicker resolutions. This efficiency not only saves time but also minimizes downtime, ensuring that the equipment remains operational for longer periods.

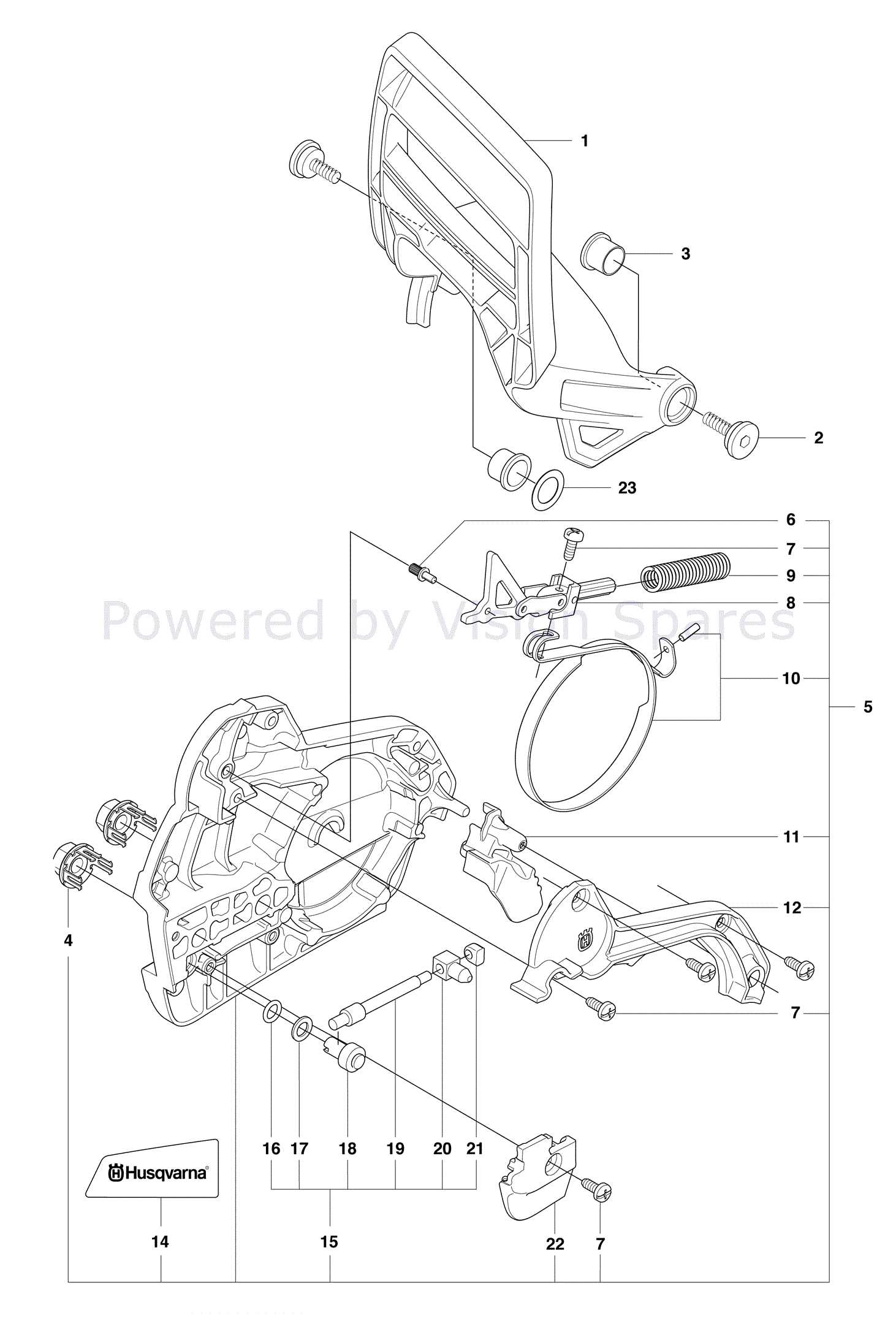

Identifying Key Components in Diagrams

Understanding the layout and functionality of machinery can greatly enhance maintenance and repair processes. By familiarizing oneself with various elements depicted in technical illustrations, users can efficiently locate and address issues, ensuring optimal performance. Each component plays a specific role, and recognizing these can streamline troubleshooting and part replacement.

Common Elements to Recognize

When analyzing technical illustrations, several fundamental components are frequently highlighted. For instance, the power unit typically indicates the source of energy, while the cutting mechanism represents the primary tool for operation. Auxiliary elements, such as safety features and support structures, are equally crucial for safe and effective usage. Recognizing these components allows for a comprehensive understanding of how the equipment functions as a whole.

Interpreting Symbolism and Labels

Many technical illustrations include symbols and labels that convey vital information about each part. Understanding these symbols can prevent misinterpretation and facilitate correct assembly or disassembly. Additionally, labels often indicate specifications, such as dimensions and materials, which are essential for selecting appropriate replacements or upgrades. Mastering these elements can enhance one’s capability to manage the equipment proficiently.

Common Issues with Husqvarna 50 Parts

When it comes to outdoor power tools, several components may experience wear and tear over time. Identifying these common challenges can help users maintain optimal performance and extend the life of their equipment. Addressing these issues promptly is crucial to ensure smooth operation and prevent further damage.

| Component | Common Issues | Signs of Failure |

|---|---|---|

| Fuel System | Clogs and leaks | Poor starting, erratic performance |

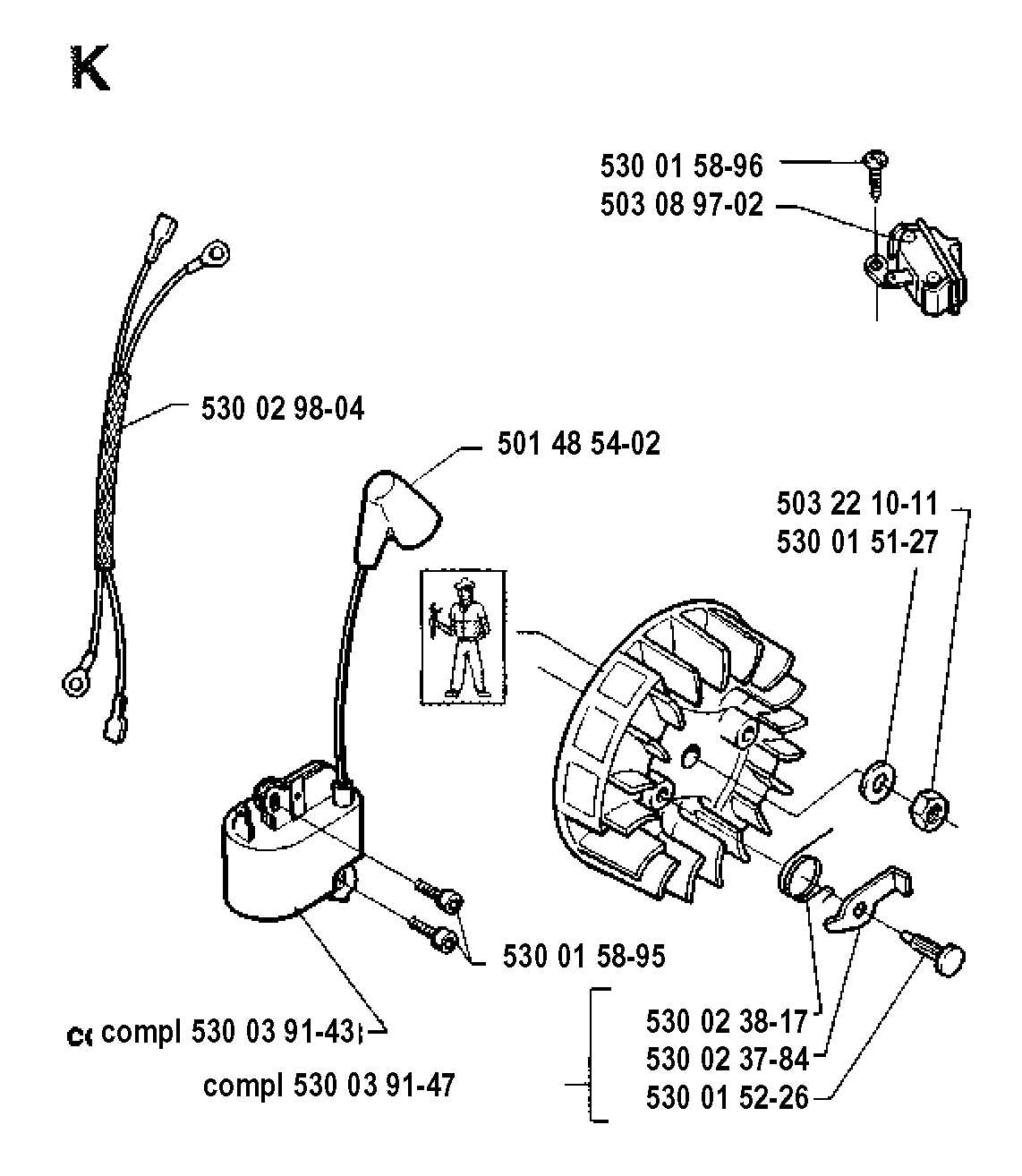

| Ignition | Weak spark, damaged coil | Engine misfires, difficulty starting |

| Bar and Chain | Worn teeth, improper tension | Increased vibration, cutting inefficiency |

| Air Filter | Blockages from debris | Reduced power, overheating |

| Oiler System | Clogs or malfunctions | Excessive wear on bar and chain |

Regular inspections and maintenance can help mitigate these issues, ensuring that your equipment runs smoothly and efficiently. By being aware of potential problems, users can take proactive measures to keep their tools in top condition.

How to Read a Parts Diagram

Understanding an illustration that showcases components can significantly enhance your ability to identify and source replacements. This guide will provide insights into interpreting these visual aids effectively, making your repair process smoother.

Start by familiarizing yourself with the layout. Each section typically represents a different assembly, allowing you to pinpoint specific elements quickly. Look for labels and numbers that correlate with a list, which often details the names and part numbers of each item.

Pay attention to the relationships between components. Some may depend on others for functionality, so recognizing how they connect will help you grasp their overall purpose. This knowledge is crucial when deciding what needs replacement or repair.

Lastly, take note of any unique features indicated in the illustration. Special markings can highlight variations or upgrades in certain models, which may affect compatibility with parts you plan to acquire. By following these steps, you’ll master the art of deciphering these helpful resources.

Finding Replacement Parts Easily

Locating essential components for your outdoor equipment can be a straightforward task if you know where to look. With various resources available, enthusiasts and professionals alike can streamline the process, ensuring minimal downtime and optimal performance.

Online Retailers offer an extensive selection, often featuring detailed descriptions and images. Utilizing advanced search filters can help you quickly pinpoint the exact items you need.

Local Dealers are invaluable for personalized assistance. Establishing a relationship with them can lead to helpful recommendations and exclusive deals.

Forums and Communities allow users to share experiences and advice. Engaging with fellow enthusiasts can provide insights on where to find hard-to-source items.

Catalogs from manufacturers can also be a reliable source of information. They often provide comprehensive listings, making it easier to understand compatibility and specifications.

Tools Needed for Chainsaw Repair

To effectively maintain and fix your power tool, having the right equipment is essential. A well-equipped workspace not only simplifies the process but also enhances safety and efficiency during repairs. Here’s a look at some key implements that will help you tackle common issues.

Essential Hand Tools

Basic hand tools such as screwdrivers, wrenches, and pliers are fundamental for disassembling and reassembling components. Socket sets and hex keys are also invaluable for reaching various fasteners. Having a reliable toolbox to keep these items organized can significantly streamline your repair tasks.

Specialized Equipment

In addition to general tools, certain specialized items may be necessary. A tensioning tool for adjusting the drive mechanism is crucial for optimal performance. A file for sharpening cutting edges will prolong the life of the unit, ensuring it runs smoothly and efficiently. Investing in quality equipment can lead to more effective repairs and longevity of your gear.

Assembly Instructions for Husqvarna 50

Proper assembly is crucial for optimal performance and safety of your equipment. Following a systematic approach ensures that each component fits seamlessly, allowing for efficient operation.

Step 1: Begin by organizing all components in a clear workspace. Check each item against the list to confirm everything is present.

Step 2: Assemble the main housing first. Secure the necessary fasteners, ensuring they are tightened appropriately but not overtightened to avoid damage.

Step 3: Next, attach the power unit. Align it correctly with the housing and fasten it securely. This step is essential for maintaining stability during use.

Step 4: Connect the guide mechanism carefully. Make sure all moving parts are lubricated adequately to ensure smooth operation.

Step 5: Finally, conduct a thorough inspection of the assembled unit. Check for any loose connections or misalignments. Testing the equipment before full operation is advisable to guarantee safety and functionality.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your equipment and ensuring optimal performance. Regular attention to maintenance tasks can prevent costly repairs and enhance efficiency, allowing for a more enjoyable experience during operation.

1. Clean Regularly: Dirt and debris can accumulate, affecting functionality. Ensure to clean the exterior and any accessible internal components after each use.

2. Check Lubrication: Adequate lubrication is crucial. Regularly inspect and refill oil levels to reduce friction and wear on moving parts.

3. Sharpen Blades: Dull blades require more effort and can cause strain on the motor. Keep them sharp to ensure smooth operation and better results.

4. Inspect for Wear: Periodically examine all components for signs of wear or damage. Early detection can prevent more severe issues from developing.

5. Store Properly: When not in use, store your equipment in a dry, cool place. This will protect it from environmental factors that could lead to deterioration.

By following these guidelines, you can significantly enhance the performance and longevity of your machinery, ultimately leading to more successful projects.

Where to Buy Genuine Parts

Finding authentic components for your equipment is essential for maintaining its performance and longevity. Opting for original items ensures reliability and compatibility, ultimately enhancing your machine’s efficiency. Below are some recommended sources to procure these quality items.

| Source | Description |

|---|---|

| Official Retailers | Authorized dealers often carry a comprehensive selection of genuine components, along with knowledgeable staff to assist you. |

| Online Marketplaces | Reputable e-commerce sites offer a wide variety of original items, often with customer reviews to guide your purchase. |

| Manufacturer’s Website | Direct purchases from the official site guarantee authenticity and may offer exclusive deals or promotions. |

| Local Repair Shops | Experienced technicians may stock or can order original items for you, providing valuable advice on installation. |

Safety Precautions During Repair

When engaging in maintenance or repairs on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Implementing proper precautions ensures a secure working environment and helps maintain the longevity of the equipment.

Personal Protective Equipment

Always wear appropriate protective gear, including gloves, goggles, and hearing protection. This gear is essential for shielding against potential hazards such as flying debris and loud noises.

Workspace Organization

Keep your workspace tidy and well-lit. Ensure that all tools are within reach and that any flammable materials are stored safely away from the area of repair. Proper organization minimizes the risk of accidents and improves efficiency during the task.

Upgrading Your Chainsaw: What to Consider

When enhancing your cutting tool, several factors come into play to ensure optimal performance and longevity. Evaluating your current equipment’s capabilities and identifying areas for improvement can lead to a more efficient and powerful experience.

| Consideration | Description |

|---|---|

| Power | Assess the engine strength and choose a model that meets your cutting needs. |

| Weight | Balance between power and maneuverability; lighter options may reduce fatigue. |

| Features | Look for additional functionalities such as anti-vibration systems or tool-free chain adjustments. |

| Maintenance | Select models that offer easy access for repairs and part replacements. |