Understanding the inner workings and the structure of mechanical tools can significantly extend their lifespan and ensure optimal performance. In this section, we’ll explore the essential elements that make up a versatile and reliable tool. By focusing on these crucial aspects, users can gain a deeper insight into how everything operates seamlessly together.

Whether you’re performing regular maintenance or looking to replace specific elements, having a clear and detailed overview of the various components is crucial. This allows for better care and easier identification when repairs or adjustments are needed. With this knowledge, you can maintain peak efficiency and keep your equipment in top shape for years to come.

Husqvarna Chainsaw Model Overview

When it comes to versatile and reliable cutting tools, few can match the performance and adaptability offered by various models in this category. Each version is designed with unique features tailored to suit different tasks, ensuring users have the right equipment for any job, from light pruning to heavy-duty forestry work.

Power and Efficiency: Each unit combines robust power output with fuel efficiency, allowing operators to work for extended periods without compromising on performance. Advanced technology helps maintain smooth operation, reducing vibrations and improving handling.

Durability and Maintenance: Built to withstand tough conditions, these tools offer enhanced durability. Easy-to-replace components and minimal upkeep requirements make them a practical choice for both professionals and hobbyists.

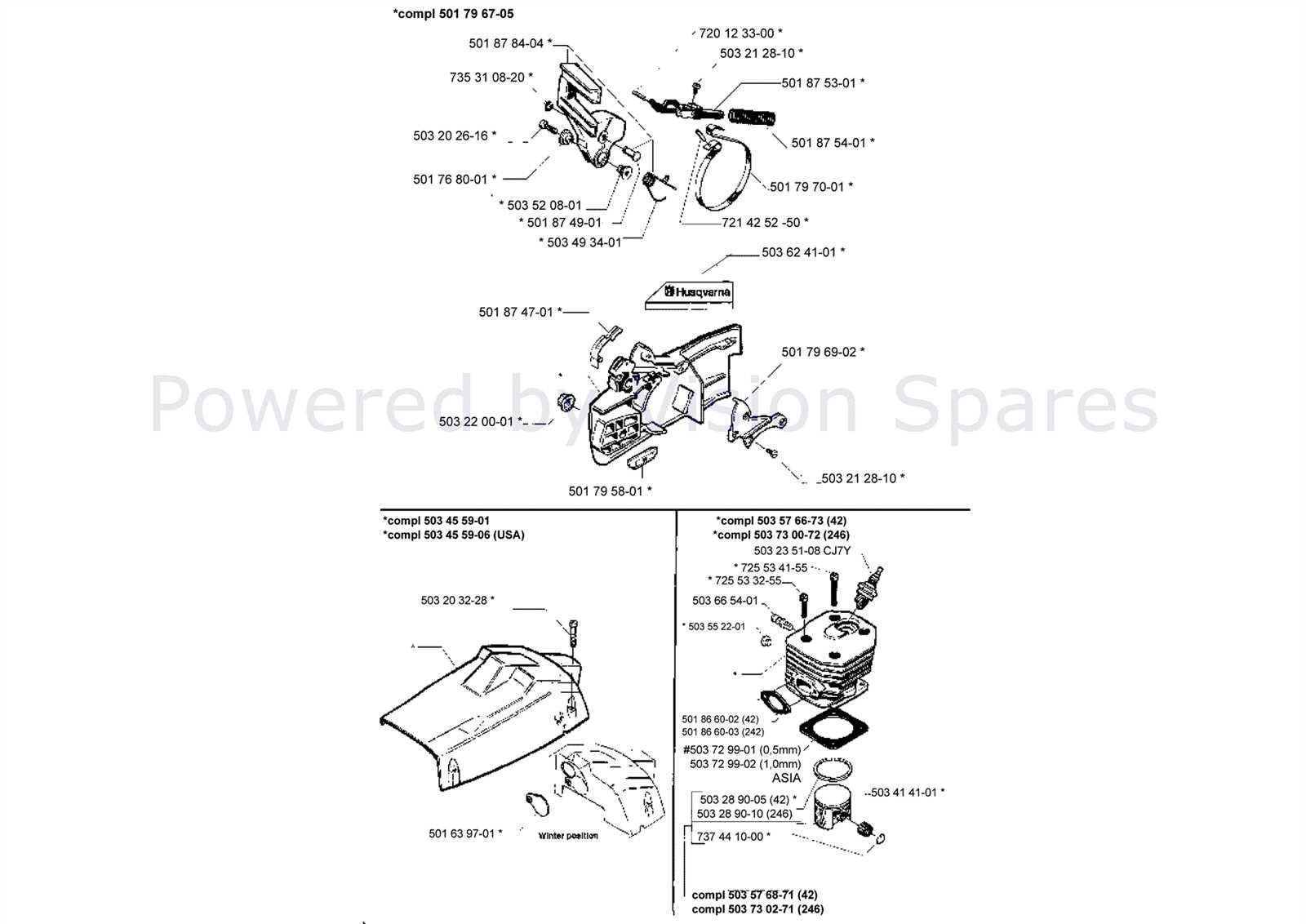

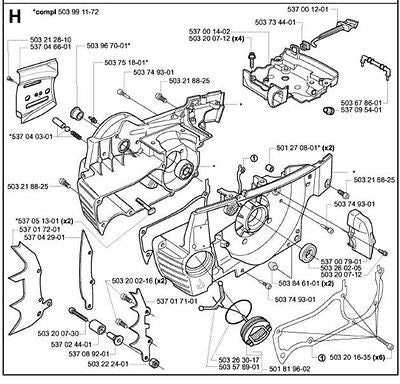

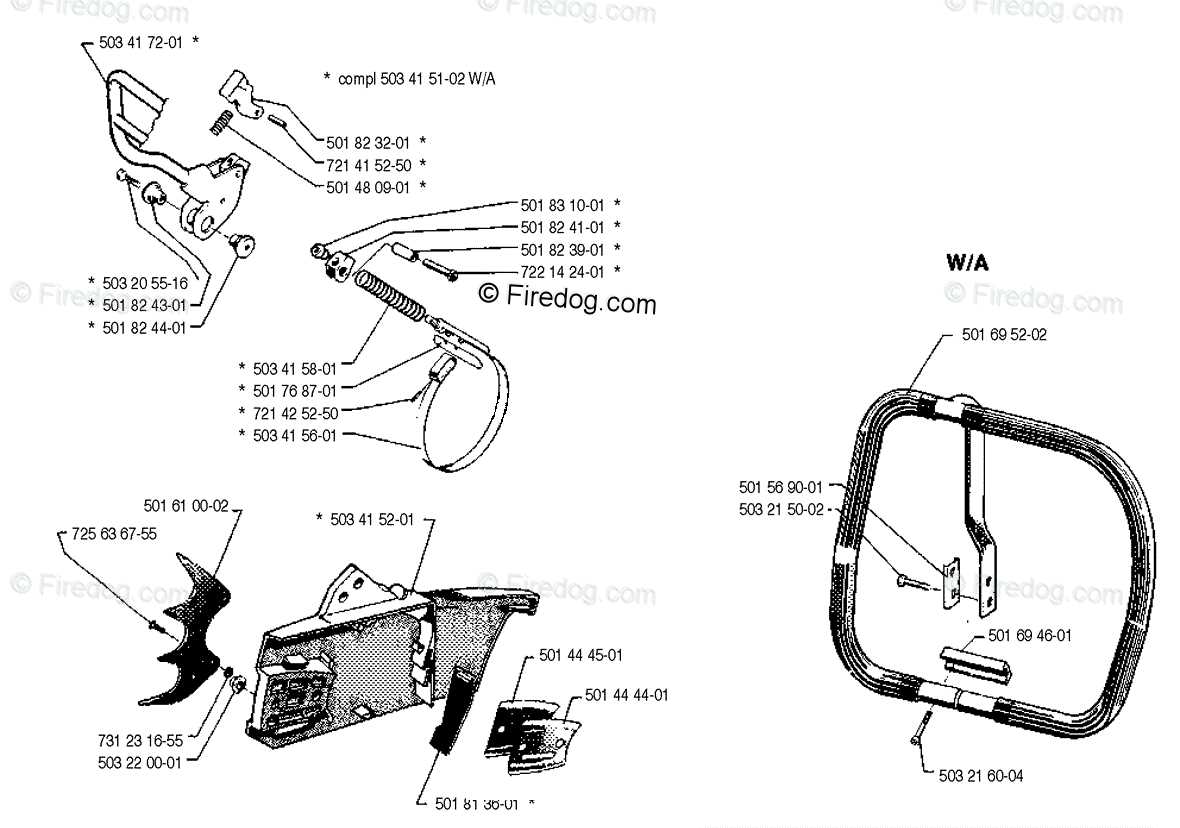

Main Components of the Model 55

This section provides an overview of the essential elements that contribute to the smooth operation and durability of the device. Understanding these elements helps users perform maintenance tasks and ensures efficient use of the equipment in various conditions.

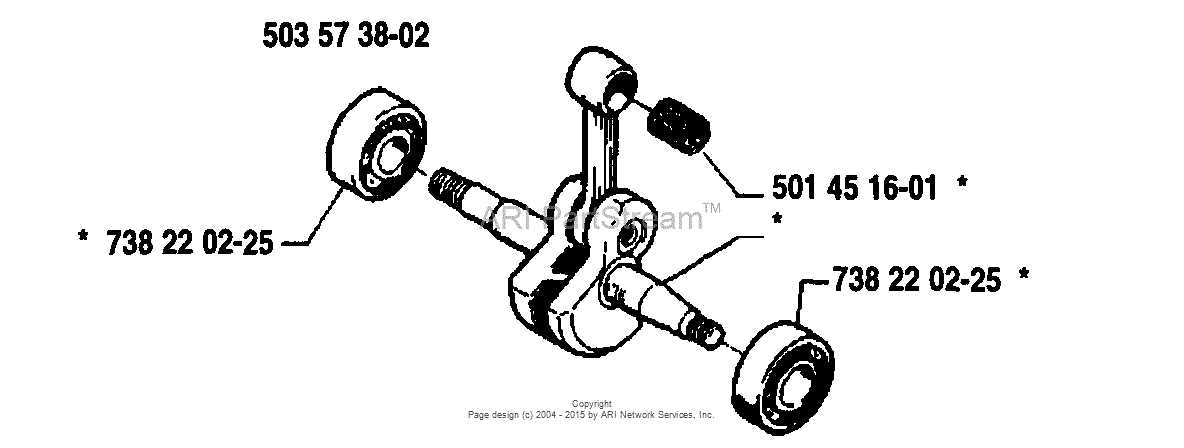

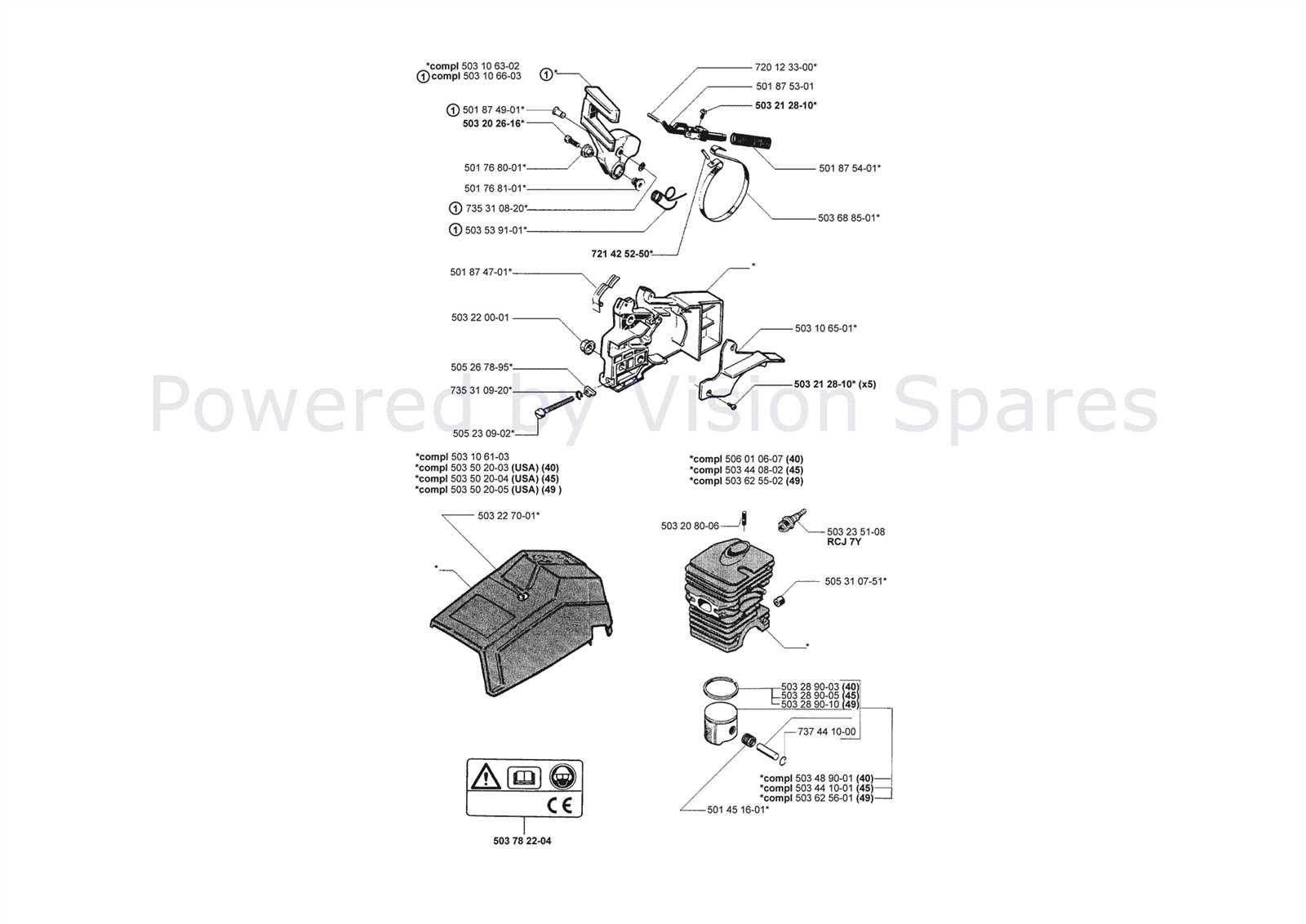

Engine and Power System

The core driving force of this machine is its engine, designed for consistent performance. It includes a fuel-efficient system that powers the internal mechanisms, ensuring optimal operation. The balance between fuel consumption and power output allows users to handle demanding tasks with ease.

Cutting Mechanism

The cutting mechanism is central to the device’s functionality. It consists of a blade system that rotates with precision, providing effective and clean cuts. This component is supported by tensioners and guide systems, ensuring stability and control during use.

| Component | Function | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Component | Description |

|---|---|

| Cylinder | Houses the combustion process, where fuel and air mix to generate power. |

| Piston | Moves within the cylinder to transfer energy from the combustion process. |

| Crankshaft | Transforms the linear motion of the piston into rotational energy. |

| Carburetor |

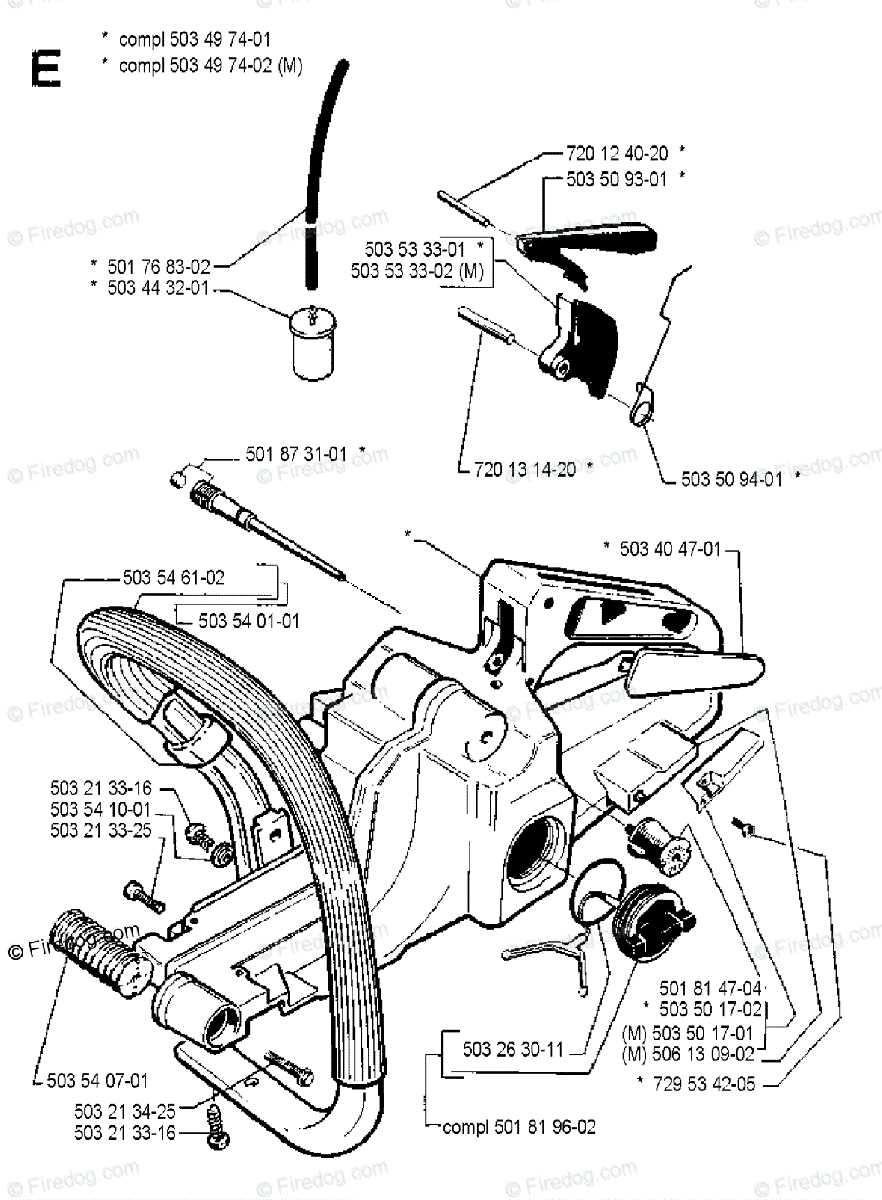

Guide Bar and Chain Mechanism

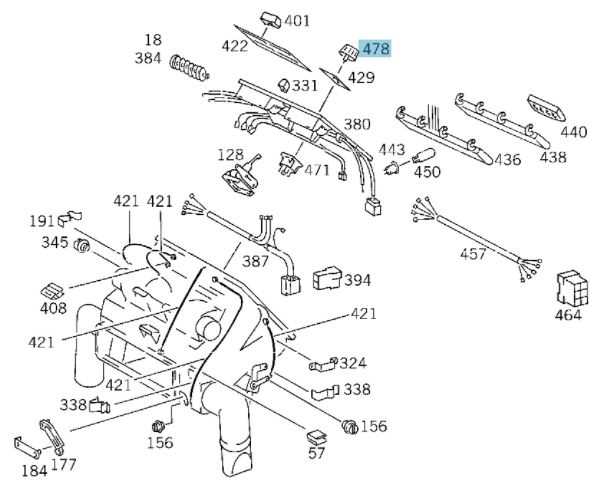

The guide bar and chain work together to deliver precise cutting performance. This mechanism ensures smooth operation by maintaining the balance between the moving parts, allowing for efficient and accurate cuts. Understanding how these components interact can help in maintaining their functionality over time. The guide bar serves as the track for the chain, ensuring stability as it moves. It is essential for directing the cutting action and keeping the chain aligned during use. Regular inspection of the guide bar for wear or damage helps prevent operational issues. The chain, powered by the engine, revolves around the guide bar, creating the motion necessary for cutting. Proper tension and lubrication are key to its smooth performance. Adjustments to the chain tension should be made to ensure safe and efficient operation, as a loose or tight chain can affect cutting Ignition System Configuration

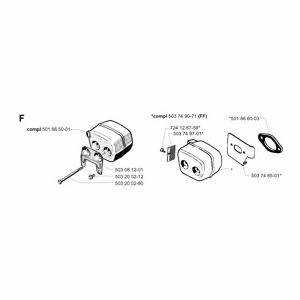

The ignition system plays a critical role in ensuring smooth engine operation by controlling the spark needed for combustion. This component manages the timing and distribution of electrical currents, allowing the engine to start efficiently and maintain performance under various conditions. A well-configured ignition system ensures optimal fuel efficiency and reduces wear on other components. Key elements of the ignition system include the coil, flywheel, and wiring, all working together to generate and deliver the spark at the right moment. Regular maintenance and proper alignment of these parts are essential for consistent performance. Adjusting and replacing ignition components when necessary helps avoid potential engine issues. Fuel Tank and Carburetor SetupThe proper configuration of the fuel system is crucial for ensuring the smooth operation of any cutting tool. By paying attention to both the fuel container and the mechanism that mixes air and fuel, you can guarantee efficient energy transfer and reliable performance. Fuel Tank ComponentsIn this section, we will look at the key components that make up the fuel storage and supply system. Understanding each element helps in maintaining fuel flow and preventing blockages.

|