Exploring the inner workings of a powerful cutting device reveals the intricate relationship between its various elements. Each component plays a crucial role in ensuring optimal performance and durability. Familiarizing oneself with these essential parts can enhance both maintenance practices and operational efficiency.

Visual representations serve as invaluable resources for identifying the arrangement and function of each piece within the mechanism. By studying these illustrations, users can gain insights into assembly processes, troubleshooting, and repair techniques. Moreover, this knowledge empowers operators to make informed decisions regarding upgrades and replacements, thereby prolonging the lifespan of their equipment.

In summary, understanding the structure of this type of tool is not merely about knowing how it operates but also about appreciating the craftsmanship behind its design. By taking the time to learn about each component, users can ensure a smoother, more effective experience with their equipment, ultimately leading to better results in their tasks.

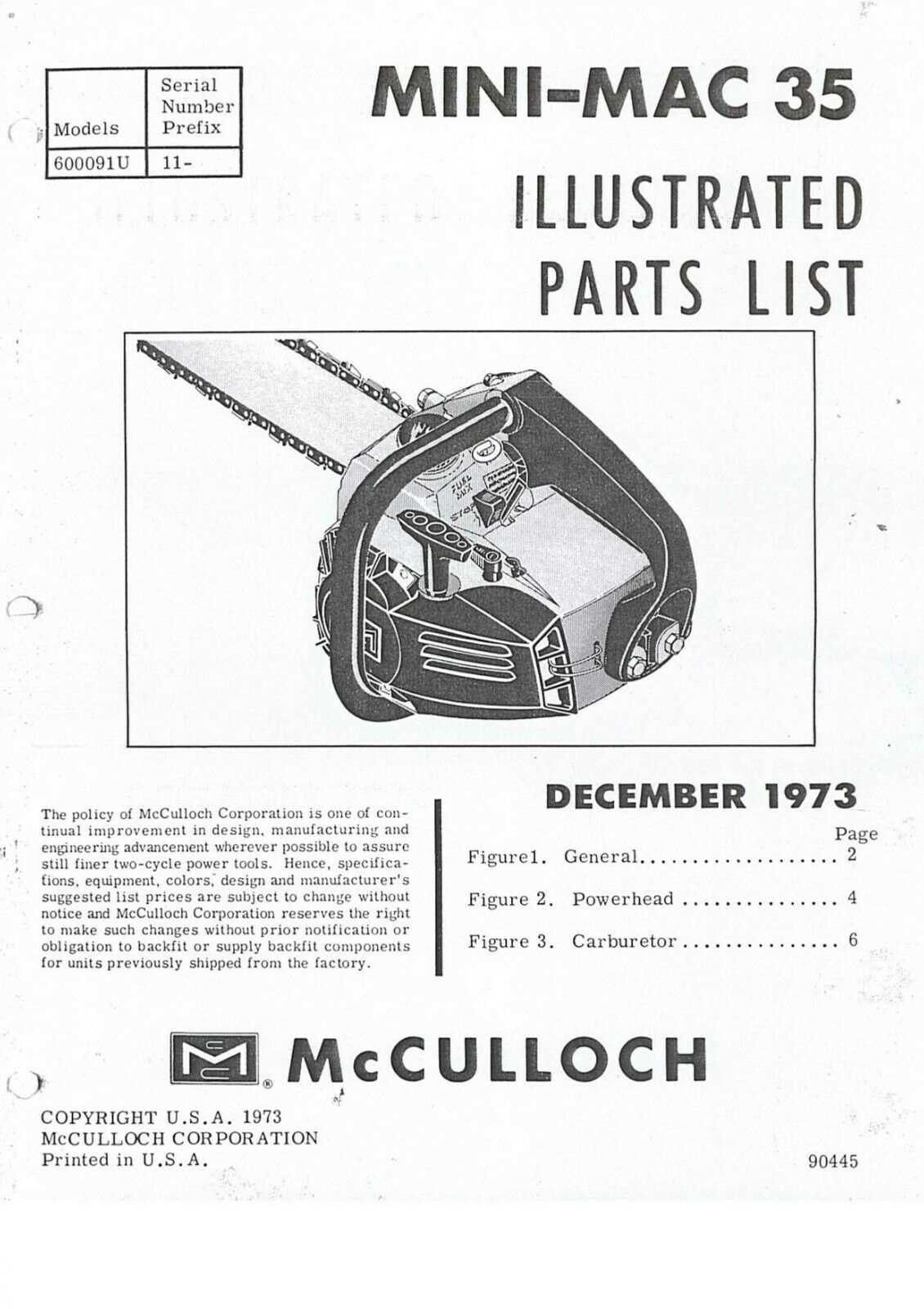

Understanding McCulloch 3516 Chainsaw Components

To effectively operate and maintain a power tool designed for cutting through wood, it’s crucial to have a comprehensive understanding of its various elements. Each component plays a significant role in the overall functionality, ensuring optimal performance and safety during use. Familiarity with these parts not only enhances efficiency but also aids in troubleshooting and repairs.

Main Functional Elements

The primary functional elements of this cutting tool include the motor, guide bar, and cutting chain. The motor is the heart of the device, providing the necessary power to drive the chain at high speeds. The guide bar acts as a support, allowing for precise cutting angles and control, while the cutting chain is designed with sharp teeth that slice through wood effectively. Together, these components create a powerful synergy for tackling various cutting tasks.

In addition to the main components, several accessories enhance the usability of the tool. Features such as safety guards, vibration dampeners, and lubrication systems contribute to a smoother operation and increased user safety. Understanding these additional elements allows for better maintenance practices and ensures the longevity of the equipment. Proper care and awareness of how each component functions can greatly improve the overall experience of using this essential tool.

Detailed Parts Breakdown for Maintenance

Understanding the various components of your cutting tool is essential for effective upkeep. A comprehensive examination of each segment ensures optimal functionality and longevity, enabling users to address potential issues promptly.

Regular inspection and maintenance can significantly enhance performance. Below are the key elements to focus on:

- Power Unit: This serves as the heart of the equipment, converting fuel into mechanical energy.

- Guide Bar: This critical component aids in directing the cutting motion and should be regularly checked for wear.

- Cutting Chain: Ensuring sharpness and proper tension is vital for efficient operation.

- Chain Brake: A safety feature that must be inspected for responsiveness to prevent accidents.

- Air Filter: Keeping this clean allows for efficient airflow and optimal engine performance.

- Fuel System: Regularly examine the fuel lines and filters to avoid clogs and ensure proper fuel flow.

- Starter Mechanism: Inspect for smooth operation, as a faulty starter can impede use.

Each component plays a crucial role in the overall performance of the tool. Regular assessments and timely replacements can prevent unexpected breakdowns and extend the lifespan of the equipment.

Identifying Key Components of the Chainsaw

Understanding the essential elements of a cutting tool is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance and safety. By familiarizing oneself with these vital parts, users can enhance their experience and extend the tool’s lifespan.

The engine serves as the heart of the device, providing the necessary power to drive the cutting mechanism. This central unit is complemented by a fuel system, which supplies energy for operation. Additionally, the cutting assembly, which typically consists of a bar and a chain, is responsible for the actual cutting action.

Another important aspect is the safety features, designed to protect the user during operation. These can include chain brakes and throttle controls, which help prevent accidents. Understanding how each of these components interacts can greatly improve the overall effectiveness and safety of the tool.

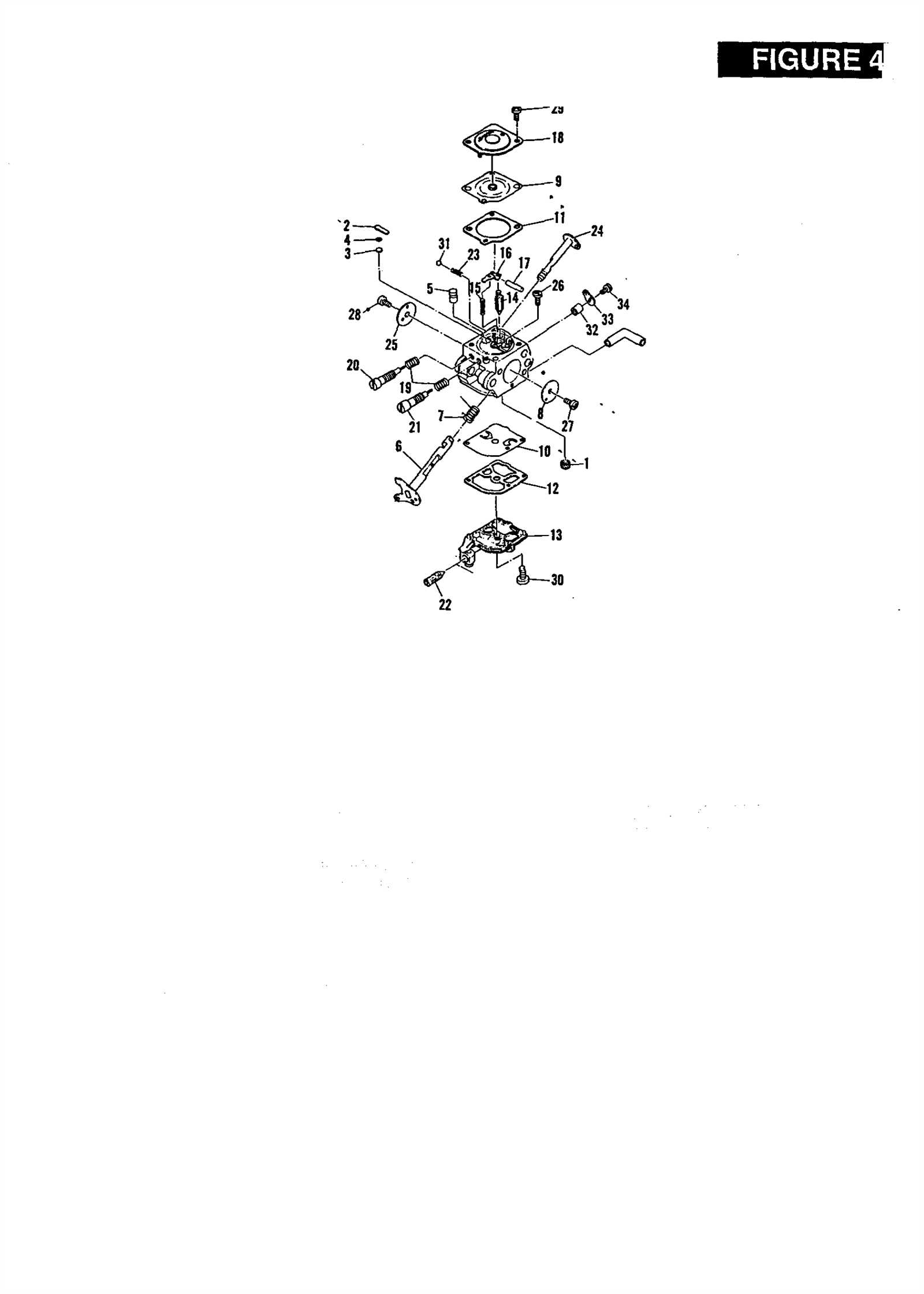

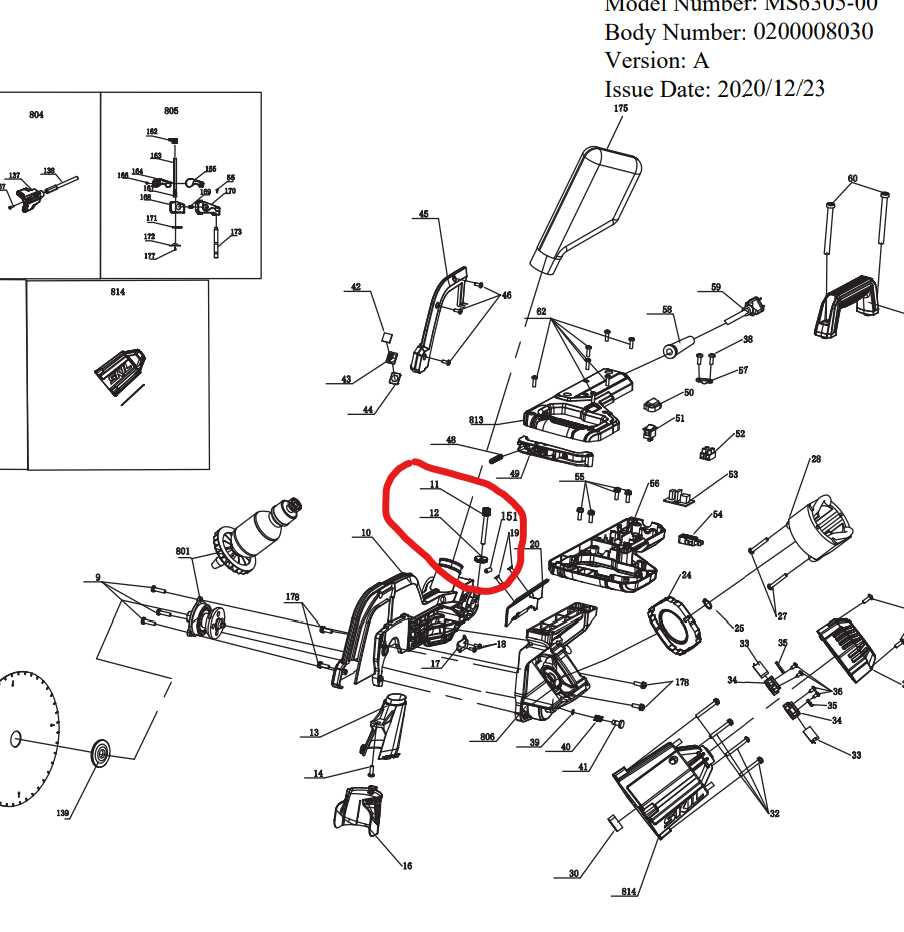

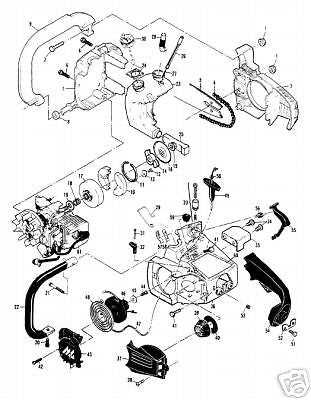

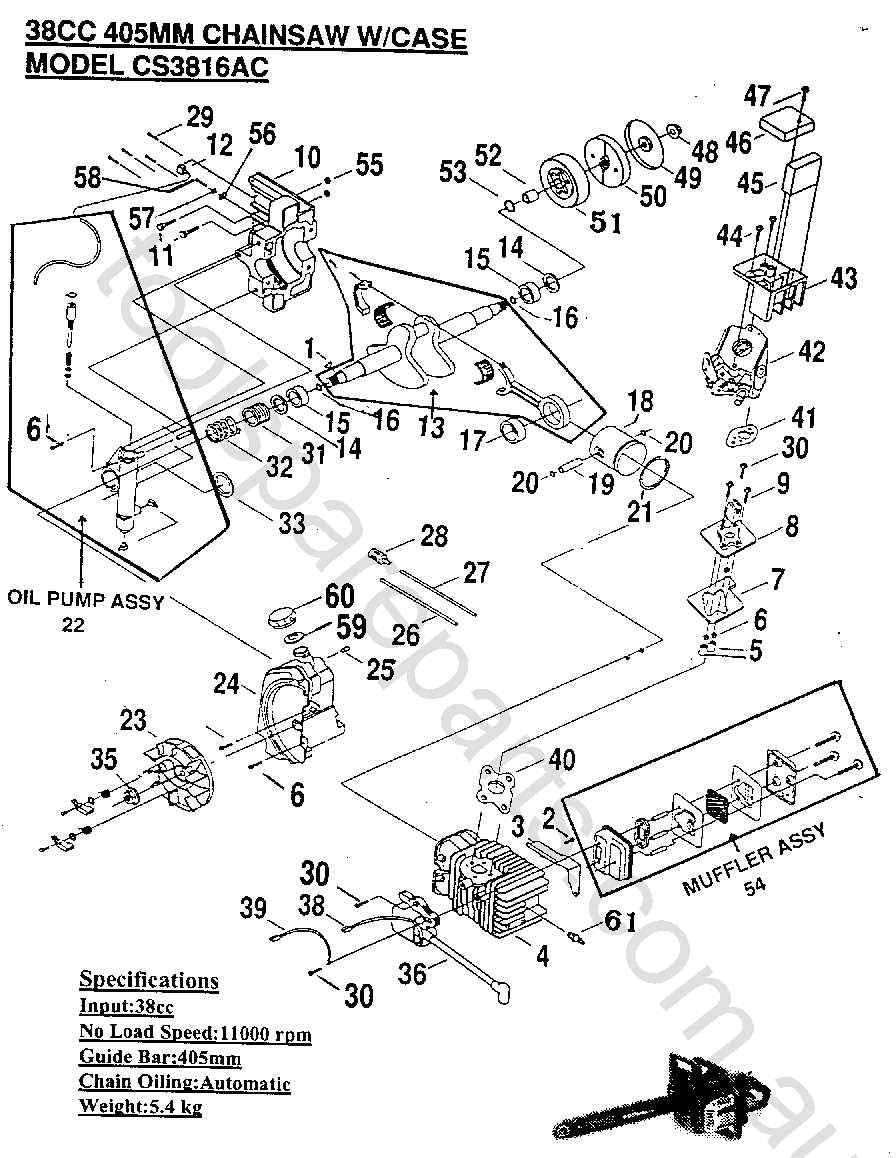

Visual Representation of Parts Diagram

In this section, we explore a graphical overview that illustrates the components of a specific power tool model. This visual guide serves as a valuable resource for understanding how each element fits together and functions within the overall assembly. By examining this representation, users can gain insight into the tool’s structure and the interconnections between various elements.

Understanding the Visual Layout

The layout provides a clear view of the individual segments, making it easier to identify and locate each piece. With labeled sections, users can quickly reference and understand the role of each component, enhancing their ability to perform maintenance or repairs effectively.

Benefits of a Graphical Overview

Utilizing a graphical representation simplifies the learning process for users, whether they are novices or experienced individuals. It not only aids in identifying parts but also fosters a deeper comprehension of the tool’s mechanics, ensuring better care and operational efficiency.

Importance of Regular Parts Inspection

Routine evaluation of essential components is crucial for maintaining optimal performance and safety in machinery. Regular checks can help identify wear and tear, ensuring that every element functions effectively and contributes to the overall reliability of the equipment. By prioritizing this practice, operators can prevent potential failures and enhance the longevity of their tools.

Benefits of Frequent Evaluations

Conducting regular assessments allows for early detection of issues, reducing the likelihood of significant breakdowns. This proactive approach not only saves time but also minimizes repair costs, leading to increased efficiency in operations.

Key Components to Monitor

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Blades | Chips or dull edges | Sharpen or replace |

| Filters | Clogging or dirt buildup | Clean or change |

| Lubrication System | Low fluid levels | Refill and check for leaks |

| Battery | Slow charging or short life | Test and replace if necessary |

Common Issues and Replacement Parts

When working with cutting equipment, users may encounter several frequent challenges that can impact performance and efficiency. Understanding these issues is crucial for maintaining optimal functionality and prolonging the lifespan of the device. Timely identification and resolution of these problems can save both time and resources.

One of the most common complications arises from insufficient lubrication, which can lead to overheating and excessive wear. Regularly checking and replacing the oil is essential to prevent such damage. Additionally, dull blades can hinder cutting efficiency and may require sharpening or replacement to ensure smooth operation.

Another prevalent concern is the malfunction of the ignition system, which may cause difficulty in starting the device. In this case, inspecting the spark plug and ignition coil is advisable, as they often need replacement to restore proper functionality. Furthermore, air filter clogs can restrict airflow, affecting the engine’s performance. Cleaning or replacing the filter can resolve this issue and enhance efficiency.

For those looking to maintain their equipment effectively, knowing which components to replace regularly can make a significant difference. By staying informed about these common problems and potential solutions, users can ensure their equipment remains in excellent condition for all cutting tasks.

How to Order Replacement Components

When it comes to maintaining outdoor power equipment, acquiring suitable replacement elements is crucial for optimal performance. Ensuring that the correct components are selected not only enhances functionality but also prolongs the lifespan of the device. This guide outlines the essential steps to effectively order the necessary items.

Identify Required Components

The first step in the ordering process is to determine which elements need to be replaced. This can be achieved through the following methods:

- Refer to the user manual for specific component details.

- Inspect the equipment for any visible signs of wear or damage.

- Consult online resources or forums for common issues related to similar devices.

Choosing the Right Supplier

Selecting a reputable supplier is vital to ensure the authenticity and quality of the components. Consider the following when choosing where to purchase:

- Look for authorized dealers or official websites that provide genuine parts.

- Read customer reviews to gauge the reliability of the supplier.

- Check for warranty and return policies to safeguard your purchase.

Once the necessary elements are identified and a supplier is selected, proceed to place the order, ensuring that all details are accurate to avoid complications during installation.

Tools Needed for Parts Replacement

Replacing components in a power tool requires specific instruments to ensure a smooth and efficient process. Having the right tools on hand not only makes the job easier but also minimizes the risk of damage to the device. Here are essential tools that will help facilitate the replacement of various elements effectively.

Essential Instruments

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for removing and securing screws.

- Socket Wrench Set: A set of socket wrenches will assist in loosening and tightening bolts.

- Pliers: These are useful for gripping and manipulating small parts.

- Replacement Components: Always have the new pieces ready for installation to ensure a seamless transition.

Safety Equipment

- Safety Glasses: Protect your eyes from debris while working.

- Gloves: Use gloves to maintain grip and protect your hands from sharp edges.

- Work Mat: A clean and organized workspace helps in managing small parts and tools.

Equipping yourself with these tools and safety measures will streamline the replacement process, ensuring efficiency and effectiveness while working on your device.

Step-by-Step Parts Replacement Guide

This guide provides a comprehensive approach to replacing components in your cutting tool. By following these detailed instructions, you can ensure that your equipment operates at peak performance. Regular maintenance and timely replacements can significantly enhance the longevity and efficiency of your device.

Begin by gathering the necessary tools and replacement elements before starting the process. Ensure your equipment is powered down and disconnected from any power sources to guarantee safety. Carefully review the user manual for specific details related to the components involved.

Next, remove any protective covers to access the components. Take note of how each part is installed, as this will aid in the correct reassembly. Use appropriate tools to detach the worn elements, ensuring you do not damage surrounding areas.

Once the old components are removed, align the new ones according to the layout observed earlier. Secure each piece firmly, following the manufacturer’s recommendations. After replacing all necessary components, reattach any covers and perform a final check to ensure everything is in place.

Finally, conduct a test run to verify that your equipment functions correctly. Pay attention to any unusual noises or vibrations, as these may indicate improper installation. Regular checks and maintenance will keep your tool operating smoothly for years to come.

Maintaining Your McCulloch Chainsaw

Proper upkeep of your cutting tool is essential for ensuring its longevity and efficiency. Regular maintenance not only enhances performance but also promotes safety during usage. A few simple practices can significantly extend the life of your equipment while providing a smooth and effective operation.

Routine Cleaning

Keeping the tool clean is a fundamental aspect of maintenance. After each use, remove debris, sawdust, and oil residue from the exterior. Pay special attention to air intake and cooling vents to prevent overheating. A clean machine operates more efficiently and reduces the risk of malfunctions.

Lubrication and Chain Tension

Frequent lubrication of moving parts is crucial. Ensure that the bar and chain are adequately lubricated to minimize wear. Additionally, check the tension of the cutting chain regularly. A properly adjusted chain enhances cutting performance and reduces the risk of accidents.

| Maintenance Task | Frequency |

|---|---|

| Clean exterior and air vents | After each use |

| Lubricate moving parts | Every 5 hours of use |

| Check chain tension | Before each use |

| Inspect spark plug | Every 10 hours of use |

Upgrading Parts for Better Performance

Enhancing the functionality of a cutting tool can lead to significant improvements in its efficiency and overall effectiveness. By replacing standard components with high-quality alternatives, users can achieve enhanced power, reduced vibration, and prolonged service life. This section will explore various upgrades that can be implemented to optimize performance.

Improving the Engine’s Efficiency

One of the most impactful upgrades involves the engine’s components. Installing a high-performance air filter can increase airflow, resulting in better combustion and increased power output. Additionally, a tuned exhaust system can improve exhaust flow, allowing the engine to operate more smoothly and efficiently. These modifications not only enhance performance but can also contribute to lower fuel consumption.

Upgrading the Cutting Mechanism

The cutting mechanism is crucial for achieving precise results. Upgrading to a premium-quality blade can significantly improve cutting speed and accuracy. Opting for a lightweight yet durable material can reduce fatigue during use. Furthermore, ensuring the cutting head is properly maintained and sharp will maximize efficiency, making each task easier and more effective.

Frequently Asked Questions on Parts

This section addresses common inquiries related to the components of outdoor power equipment. Understanding these elements can enhance maintenance and facilitate repairs, ensuring optimal performance of the machinery.

Common Inquiries

- What should I consider when replacing components?

When looking to replace any element, ensure compatibility with your specific model. It’s essential to check specifications and consult the user manual.

- How do I identify the right component for my equipment?

Identification can often be done by referring to the user guide or checking online resources. You can also contact a dealer for assistance.

- Are aftermarket options reliable?

Aftermarket components can vary in quality. It’s advisable to research and choose reputable brands to ensure durability and reliability.

Maintenance and Care

- How can I extend the lifespan of my equipment?

Regular maintenance, including cleaning and timely replacement of worn-out elements, is crucial for longevity.

- What are the signs that a component needs replacement?

Common signs include unusual noises, decreased performance, and visible damage. Addressing these issues promptly can prevent further complications.

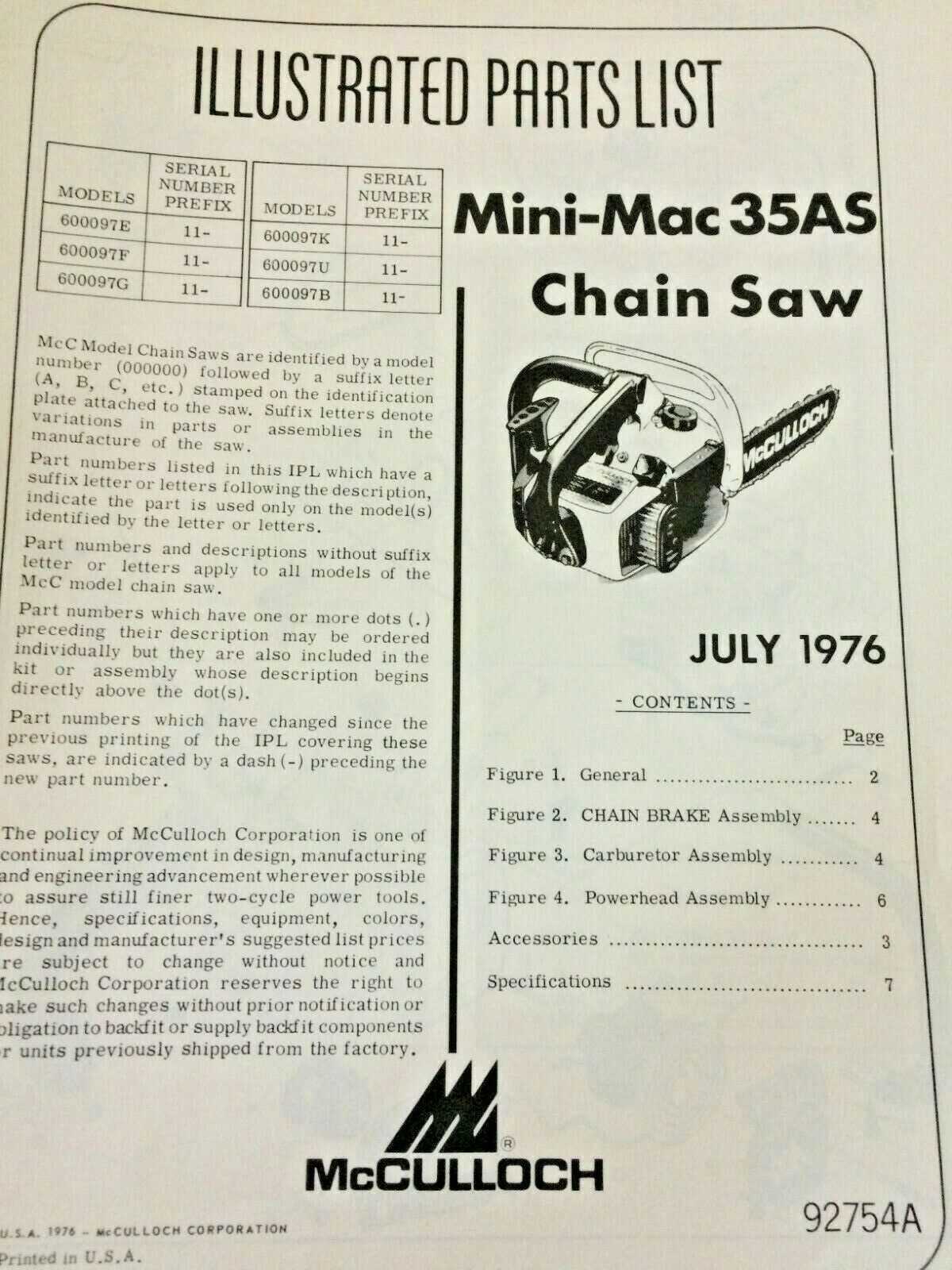

Resources for McCulloch Chainsaw Owners

For those who own this specific type of power tool, having access to reliable information and support resources is essential for optimal maintenance and performance. A variety of guides, manuals, and online forums are available to assist users in understanding their equipment better, troubleshooting issues, and accessing replacement components when necessary.

User Manuals and Guides

Manuals provide comprehensive information about operation, safety, and maintenance procedures. Owners can find downloadable versions of these documents online, which are invaluable for understanding the specifications and features of their tools.

Online Communities and Forums

Engaging with fellow enthusiasts through online forums can be beneficial. These platforms allow owners to share experiences, ask questions, and receive advice from seasoned users who have encountered similar challenges.

| Resource Type | Where to Find |

|---|---|

| User Manuals | Official brand websites |

| Replacement Parts | Authorized retailers and online marketplaces |

| Support Forums | Online community platforms |

| Tutorial Videos | Video sharing websites |