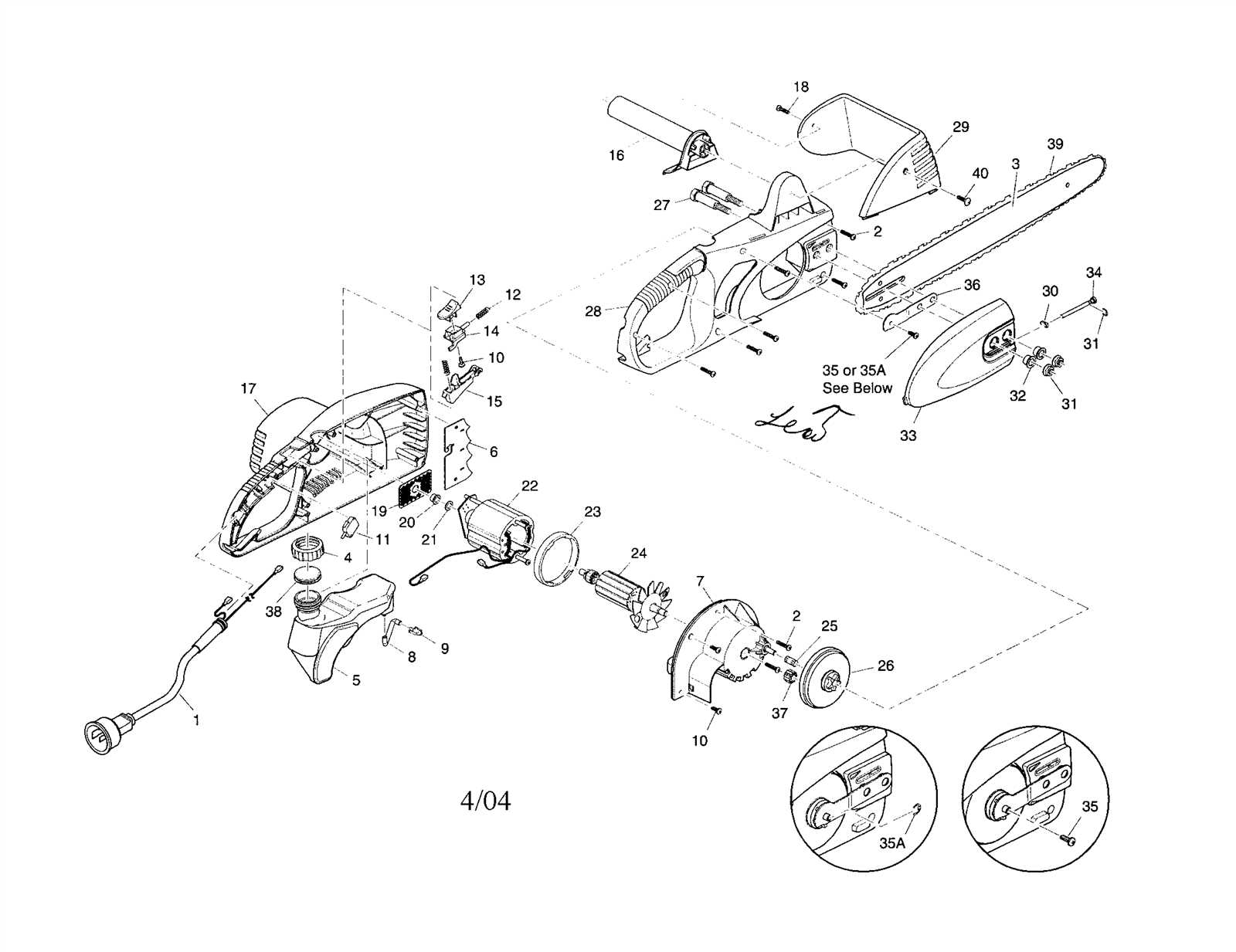

Every cutting instrument consists of a variety of essential elements that work in harmony to ensure optimal performance. Knowing how these components interact can greatly enhance the efficiency and longevity of your equipment. By exploring the intricate arrangement of these parts, users can gain invaluable insights into maintenance and troubleshooting.

Visual representations of these assemblies are vital for both novice and experienced users. They provide clarity, making it easier to identify specific pieces and comprehend their functions. Such knowledge is not just beneficial for repairs but also empowers users to make informed decisions when purchasing replacements.

In this section, we will delve into the various segments of your tool, illustrating their ultimate purpose and interconnections. Understanding these elements will enhance your overall experience and ensure that your instrument remains in top-notch condition for all your cutting tasks.

Understanding Remington Chainsaw Anatomy

To fully grasp the mechanics of a power saw, it is essential to familiarize oneself with its various components and their functions. Each element plays a critical role in ensuring efficient operation, safety, and longevity of the tool. A thorough understanding of these parts not only aids in maintenance but also enhances overall performance.

Core Components

The primary elements of the tool include the motor, guide bar, and cutting chain. The motor serves as the powerhouse, converting fuel or electrical energy into mechanical force. The guide bar provides a stable platform for the cutting chain, while the chain itself is responsible for the actual cutting action. Understanding how these components interact is key to optimizing usage and troubleshooting potential issues.

Safety Features

Safety mechanisms are integral to the design, ensuring user protection during operation. Features such as chain brakes, safety switches, and hand guards minimize the risk of accidents. Knowing where these safety elements are located and how they function can significantly enhance the user experience and reduce hazards associated with cutting tasks.

Key Components of Remington Chainsaws

The efficiency and performance of these cutting tools hinge on several crucial elements, each contributing to their overall functionality. Understanding these components is essential for maintenance and optimal use.

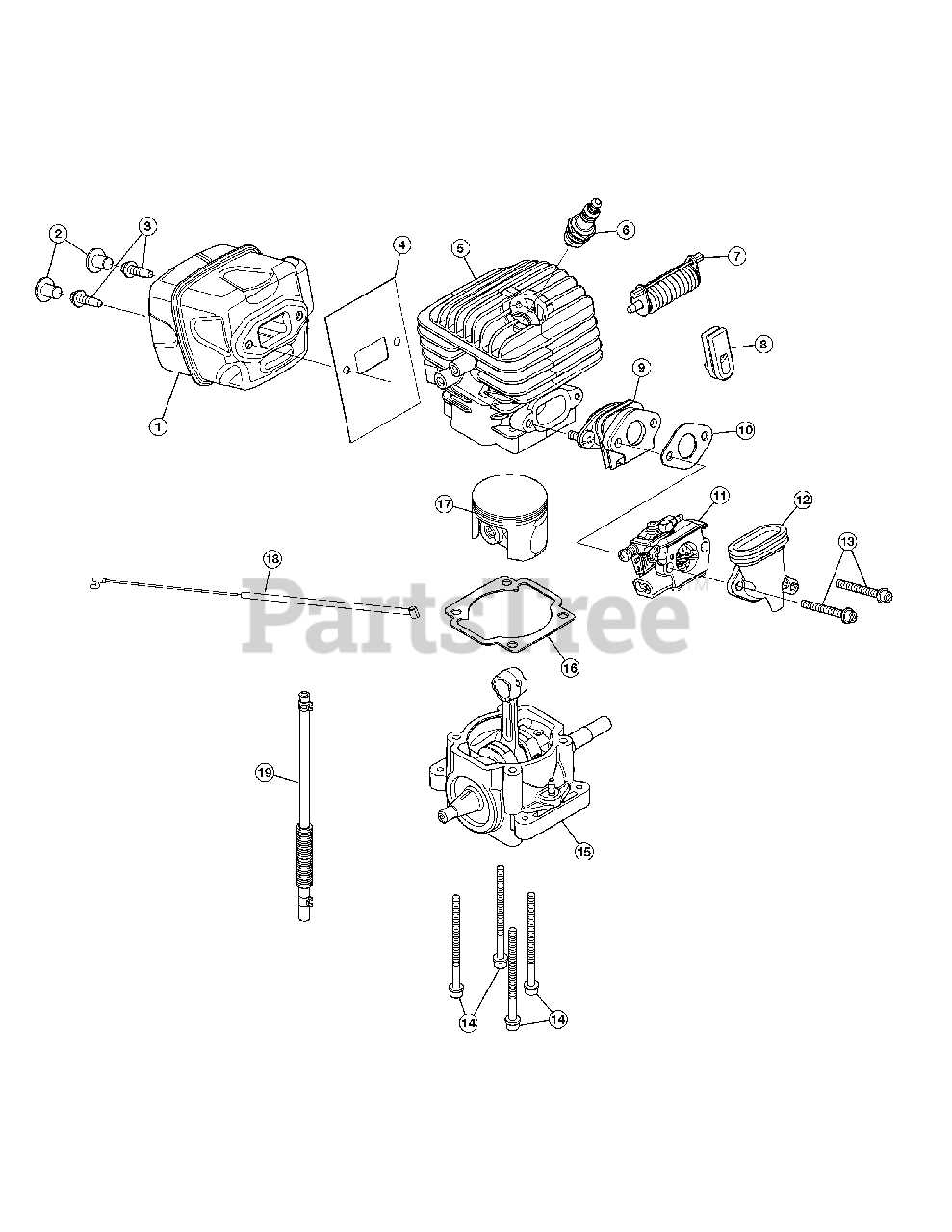

Power Unit: This serves as the heart of the device, providing the necessary energy for operation. A well-functioning engine ensures consistent performance.

Cutting Mechanism: Comprising the blade and the drive system, this element is fundamental for achieving precise cuts. The design and sharpness directly influence the tool’s effectiveness.

Safety Features: Various built-in mechanisms, such as chain brakes and guards, are vital for user protection. They help mitigate risks during operation.

Lubrication System: Proper oil distribution to the cutting mechanism is necessary for reducing friction and wear. This ensures longevity and smooth performance.

Handle and Control: Ergonomically designed handles provide comfort and enhance maneuverability, allowing for better control during use.

Fuel and Air System: A balanced mixture of fuel and air is crucial for optimal combustion, directly affecting performance and efficiency.

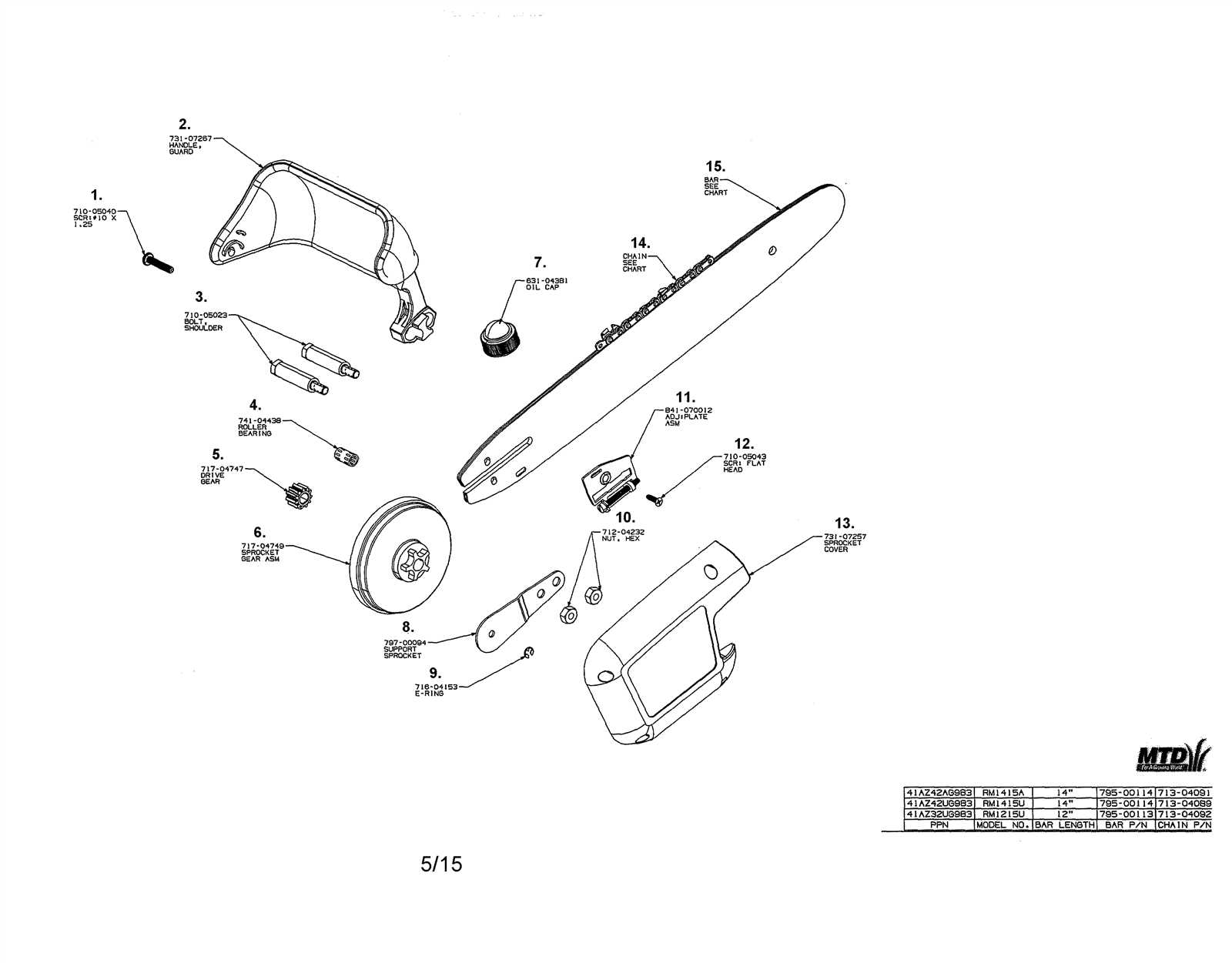

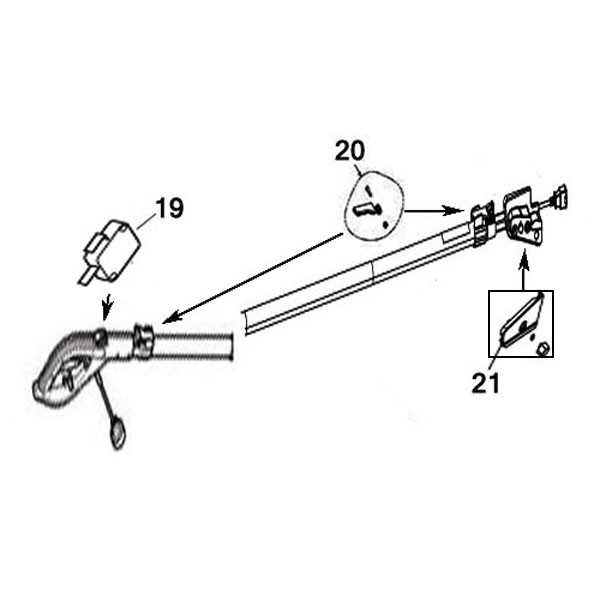

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a structured view of various elements, helping users identify each item and its role within the assembly.

Familiarize Yourself with Symbols

Each component typically has a unique symbol or label that corresponds to its function. Learning these identifiers can significantly streamline the process of locating specific pieces when performing repairs or replacements.

Refer to the Legend

Most visual guides include a legend that explains the symbols used. This reference is crucial for ensuring clarity and accuracy, allowing you to delve deeper into the assembly and understand how each piece interacts with others.

Identifying Common Chainsaw Issues

Understanding the frequent problems encountered with power tools is essential for effective maintenance and optimal performance. Recognizing these issues early can save time and resources, ensuring your equipment operates smoothly when needed.

Common Symptoms

Several signs may indicate that your tool requires attention. Look out for the following:

- Difficulty starting or frequent stalling

- Inconsistent cutting performance

- Excessive vibrations during operation

- Strange noises or smells

- Visible wear on components

Possible Causes

Understanding the underlying causes of these symptoms can help you address issues effectively. Here are some common culprits:

- Fuel quality or mixture problems

- Clogged air filters or spark plugs

- Worn or damaged cutting elements

- Chain tensioning issues

- Lubrication deficiencies

By identifying these symptoms and their possible causes, users can take appropriate steps to maintain their equipment and ensure efficient operation. Regular inspections and prompt repairs can significantly extend the lifespan of your tools.

Essential Tools for Chainsaw Maintenance

Proper upkeep of your cutting tool is crucial for its performance and longevity. Having the right equipment on hand can make all the difference in ensuring that your device operates smoothly and efficiently. This section outlines the key instruments you will need to keep your machinery in top condition.

Basic Maintenance Tools

To start, you’ll need a selection of fundamental instruments such as screwdrivers, wrenches, and pliers. These tools will help you tighten or adjust various components, ensuring everything is securely in place. Additionally, a cleaning brush and cloth are indispensable for removing sawdust and debris that accumulate during operation.

Sharpening and Lubrication Supplies

Sharp blades are essential for effective cutting. A quality sharpening kit, including files and guides, will help you maintain the edge of your blades. Furthermore, a reliable oiling system is vital for reducing friction and wear on moving parts, prolonging the life of your device. Regular application of lubricant ensures smooth operation and prevents overheating.

Step-by-Step Parts Replacement Guide

This section provides a detailed approach to efficiently swapping out components in your equipment. Understanding each step is crucial for maintaining optimal performance and ensuring safety during the process.

Preparation Before Replacement

Before starting, gather the necessary tools and a clean workspace. Make sure to disconnect the power source to avoid any accidents. Review the manual for specific guidance related to your model.

Replacement Process

Begin by removing the old component. Take note of the arrangement to ensure proper reassembly. Insert the new piece, ensuring a snug fit, and secure it with the appropriate fasteners. Finally, double-check all connections before restoring power to the device.

Safety Precautions When Repairing

Engaging in maintenance and repair tasks requires a keen awareness of safety to prevent accidents and injuries. Proper precautions ensure not only personal safety but also the protection of equipment and surroundings.

Essential Safety Gear

- Wear protective eyewear to shield against debris.

- Use gloves to protect hands from sharp components.

- Don sturdy footwear to prevent slips and injuries.

Work Environment

- Ensure the workspace is well-lit and organized.

- Keep flammable materials away from the area.

- Make sure to have a first-aid kit readily available.

By adhering to these guidelines, individuals can mitigate risks and engage confidently in their repair endeavors.

Choosing Quality Replacement Parts

When it comes to maintaining your equipment, selecting high-quality components is essential for ensuring optimal performance and longevity. The right choices not only enhance functionality but also prevent potential issues that could arise from inferior alternatives.

Durability is a key factor to consider. Opt for materials that are resistant to wear and tear, as they will withstand the rigors of regular use. Investing in robust components means fewer replacements and reduced overall costs in the long run.

Additionally, compatibility is crucial. Always verify that the new components are designed to fit seamlessly with your existing setup. Mismatched elements can lead to inefficiencies and possible damage. Research and compare specifications before making a purchase.

Furthermore, consider the manufacturer’s reputation. Established brands often provide reliable products backed by warranties and customer support. Reading reviews and seeking recommendations can guide you toward trustworthy options.

Finally, don’t underestimate the importance of cost-effectiveness. While it may be tempting to choose the cheapest option available, balancing price with quality will yield the best results. Sometimes, a slightly higher initial investment can lead to significant savings over time.

Maintenance Tips for Longevity

To ensure the extended lifespan of your outdoor cutting tool, regular upkeep and care are essential. Proper maintenance not only enhances performance but also prevents costly repairs and replacements. Following a consistent routine will keep your equipment in optimal condition, allowing it to serve you effectively over the years.

1. Regular Cleaning: After each use, remove debris and residues from the machine. Keeping the exterior clean helps prevent rust and other forms of damage.

2. Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and wear, promoting smoother operation and prolonging the life of essential components.

3. Sharp Edges: Regularly inspect and sharpen cutting edges. Dull tools can lead to increased strain on the motor, causing premature wear and inefficiency.

4. Proper Storage: Store the equipment in a dry, protected environment. Extreme weather conditions can lead to deterioration, so using a cover or a dedicated storage area is advisable.

5. Check for Wear: Periodically inspect all components for signs of wear and tear. Early detection of issues can prevent further damage and costly repairs.

6. Follow Manufacturer Guidelines: Always adhere to the maintenance schedule and recommendations provided by the manufacturer. This ensures that you are taking the appropriate steps to care for your specific model.

Implementing these practices will help maintain efficiency and reliability, ensuring that your tool remains a dependable companion for years to come.

Comparing Remington Models and Parts

When evaluating various models from a particular manufacturer, it’s essential to understand how each design incorporates specific components. This analysis reveals not only the uniqueness of each model but also highlights similarities that may simplify maintenance and upgrades. By exploring the distinctions in construction and functionality, users can make informed decisions based on their needs and preferences.

Key Features Across Models

Different iterations often showcase a range of features tailored for various applications. For instance, certain models prioritize lightweight materials for easy handling, while others focus on enhanced power for demanding tasks. Understanding these characteristics is crucial when selecting the right tool for the job. Additionally, common elements like the drive system and cutting mechanisms can influence overall performance, making it important to compare these aspects.

Interchangeability of Components

Another significant factor in this comparison is the interchangeability of components between different designs. Many tools share compatible elements, allowing users to mix and match as needed. This flexibility can be particularly beneficial for those looking to upgrade or replace specific functionalities without investing in entirely new equipment. Familiarizing oneself with the compatibility of various models can enhance user experience and optimize performance.

Resources for Further Learning

Exploring the intricacies of mechanical devices can enhance your understanding and improve your skills in maintenance and repair. Access to various educational materials is essential for anyone looking to deepen their knowledge and gain practical expertise. Below are some valuable resources that can guide you in your learning journey.

| Resource Type | Title/Link | Description |

|---|---|---|

| Books | Mechanics of Equipment | A comprehensive guide covering the fundamentals of mechanical systems and their maintenance. |

| Online Courses | Advanced Maintenance Techniques | An in-depth course focused on the latest maintenance practices and troubleshooting methods. |

| Videos | How to Disassemble and Reassemble | A step-by-step video tutorial demonstrating the disassembly and reassembly of mechanical units. |

| Forums | Mechanics Community Forum | An online community where enthusiasts discuss techniques, share experiences, and offer advice. |