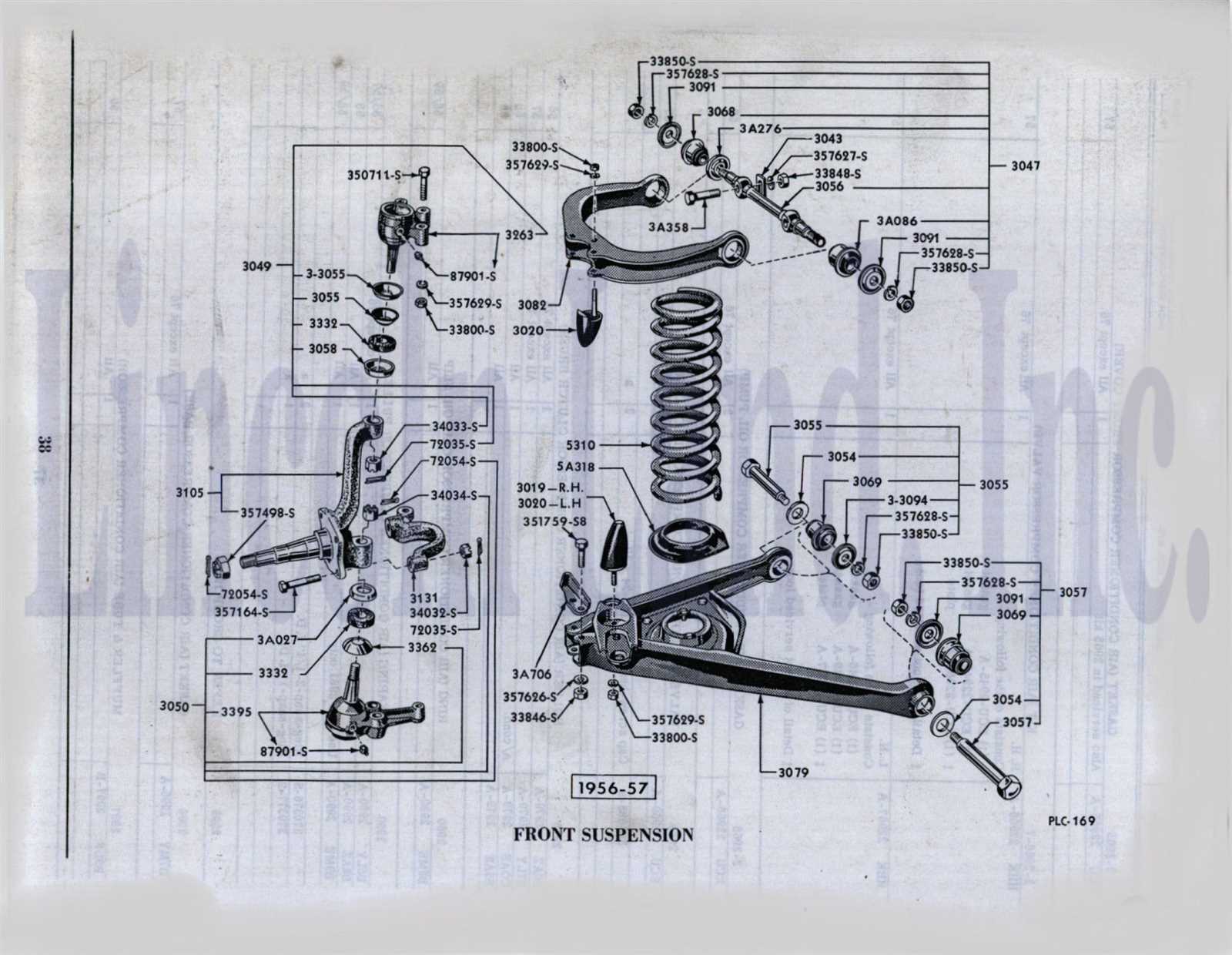

When it comes to maintaining and restoring vintage vehicles, having a comprehensive overview of the mechanical structure is essential. Such visual representations can significantly aid enthusiasts and technicians alike in identifying individual elements and their relationships within the larger assembly. This section delves into the intricate arrangements found in a specific automotive model, providing clarity on how various parts interact to ensure optimal functionality.

Every vehicle consists of a myriad of components, each serving a unique purpose, contributing to the overall performance and reliability of the system. By exploring these arrangements, one can gain insights into the engineering and design considerations that have shaped the vehicle over time. Understanding the layout not only simplifies repairs but also enhances the appreciation for the craftsmanship involved in automotive engineering.

Furthermore, detailed illustrations serve as a valuable reference for sourcing replacements or upgrades, enabling owners to make informed decisions about their vehicle’s upkeep. This visual guide fosters a deeper connection between the user and their automobile, transforming the routine process of maintenance into an engaging exploration of mechanical artistry.

Understanding Lincoln Classic 300D Components

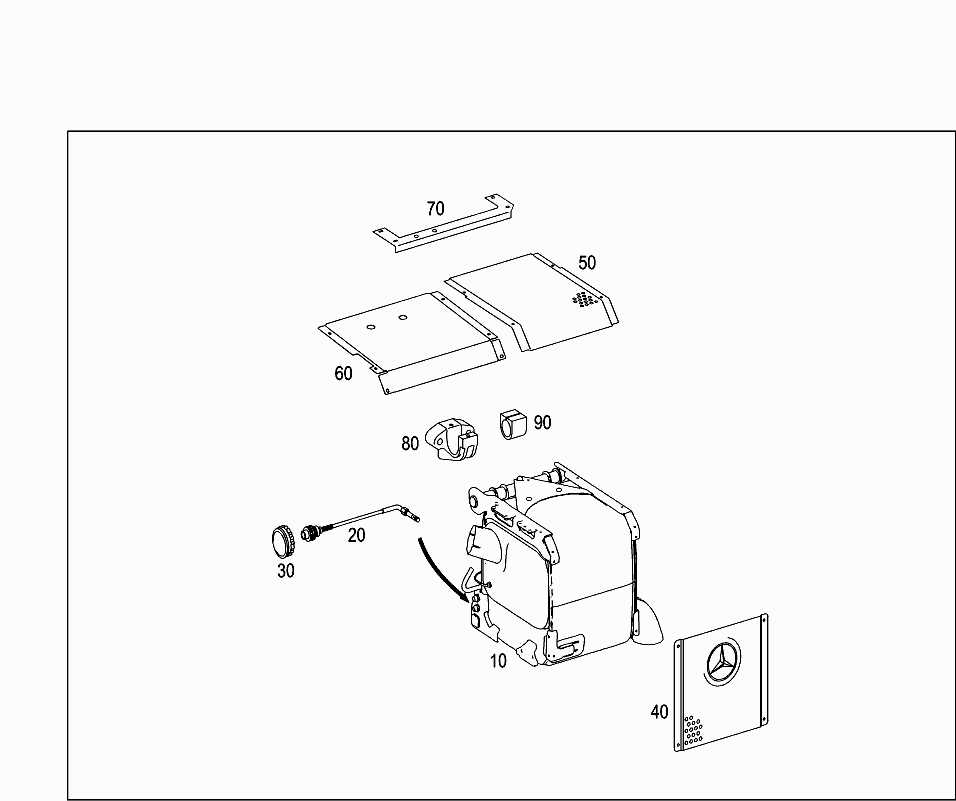

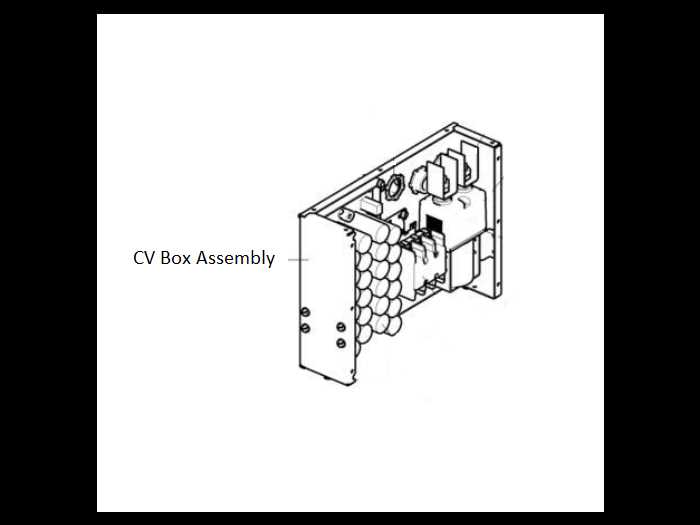

The assembly of a welding machine consists of various essential elements that work in harmony to ensure efficient performance. Each component plays a crucial role, contributing to the overall functionality and reliability of the system. Familiarity with these elements can enhance the user experience and facilitate maintenance and repairs when necessary.

Key Elements of the Welding Machine

One of the primary aspects is the power source, which provides the energy required for the welding process. Additionally, control mechanisms are integral, allowing the operator to adjust settings for optimal results. Moreover, the cooling system is vital for preventing overheating, ensuring the machine operates smoothly during prolonged use.

Importance of Maintenance

Regular upkeep of these components is essential for prolonging the lifespan of the equipment. Routine inspections help identify wear and tear, allowing for timely replacements. Understanding the function of each element aids in recognizing issues early, preventing costly repairs and ensuring consistent performance.

Key Features of Lincoln Classic 300D

This section explores the essential attributes of a renowned welding machine known for its durability and versatility in various applications. It combines advanced technology with user-friendly operation, making it a preferred choice among professionals in the industry. The following highlights showcase its impressive capabilities and design elements.

Durability and Build Quality

Engineered to withstand tough working conditions, this machine features a robust construction that enhances its longevity. The materials used are resistant to wear and tear, ensuring reliable performance over time.

Advanced Technology

Equipped with state-of-the-art technology, this unit offers various welding processes, allowing for efficient and precise work. Its intuitive controls and settings make it easy for users to adjust parameters according to specific requirements.

| Feature | Description |

|---|---|

| Welding Processes | MIG, TIG, and Stick welding capabilities for versatile applications. |

| Power Output | High-performance output for handling a range of materials. |

| Portability | Compact design with wheels for easy transportation. |

| Cooling System | Efficient cooling mechanism to prevent overheating during prolonged use. |

Importance of Parts Diagrams

Visual representations of components play a crucial role in the understanding and maintenance of machinery. They serve as essential tools for technicians and hobbyists alike, providing clarity on how various elements interact within a system. By breaking down complex assemblies into more manageable views, these illustrations facilitate better comprehension and enhance troubleshooting efficiency.

Enhancing Understanding

These visual aids allow users to familiarize themselves with the intricate layouts of different systems. Understanding the relationships between various elements enables more effective repairs and modifications. With a clear view of where each piece fits, users can identify issues more rapidly, reducing downtime and improving overall functionality.

Streamlining Maintenance and Repairs

Having access to these illustrations significantly streamlines the process of upkeep and repairs. By consulting a well-structured visual guide, users can pinpoint specific areas that require attention or replacement. This not only saves time but also minimizes the likelihood of errors during reassembly, ultimately leading to enhanced performance and longevity of the equipment.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visuals provide a detailed representation of components, their arrangement, and how they interact within a system. Familiarity with these illustrations can significantly enhance troubleshooting and assembly processes.

To interpret these visuals, start by identifying the various sections and symbols used. Each section typically corresponds to specific areas of the machinery, making it easier to locate components. Symbols may indicate different types of parts, such as electrical or mechanical elements, and it’s crucial to familiarize yourself with these conventions for accurate understanding.

Next, pay attention to the labeling associated with each element. Labels often include part numbers, specifications, and descriptions, providing valuable information for sourcing replacements or upgrades. Cross-referencing this information with manuals or catalogs can facilitate efficient procurement of necessary components.

Additionally, it is helpful to understand the overall assembly or disassembly process outlined in these illustrations. Often, arrows and connection lines demonstrate how components link and function together. This knowledge can assist in recognizing potential issues and ensuring proper installation.

Lastly, practice makes perfect. The more you engage with these technical visuals, the more intuitive reading them will become. Over time, this skill will aid you in diagnosing problems and executing repairs with confidence.

Common Issues with Lincoln Classic 300D

Welders in various settings often encounter a range of challenges that can impact performance and efficiency. Understanding these potential problems is crucial for maintaining optimal functionality and ensuring longevity. Below are some prevalent concerns associated with these machines, along with suggestions for troubleshooting and prevention.

Overheating

One of the most frequent issues observed is overheating, which can lead to significant damage if not addressed promptly. This situation usually arises from prolonged use without adequate cooling or from blocked ventilation. Regular maintenance and monitoring of the cooling system can help mitigate this problem.

Electrical Failures

Electrical malfunctions are another common challenge, often manifested through erratic power supply or failure to start. Such issues may stem from worn connections, blown fuses, or internal circuit problems. Regular inspection of electrical components and timely replacement of faulty parts can enhance reliability.

| Issue | Symptoms | Solution |

|---|---|---|

| Overheating | Excessive heat, shutdown | Check cooling system, clean vents |

| Electrical Failures | Power irregularities, failure to start | Inspect connections, replace fuses |

Essential Replacement Parts Overview

Understanding the critical components necessary for optimal functionality is vital for any machinery. This section provides insights into the key elements that require attention over time, ensuring reliability and performance. Regular maintenance and timely replacements can significantly enhance the longevity of the equipment.

| Component | Description | Function |

|---|---|---|

| Fuel Filter | Prevents contaminants from entering the fuel system. | Ensures clean fuel reaches the engine, improving efficiency. |

| Air Filter | Traps dirt and debris from the intake air. | Enhances engine performance by allowing clean air for combustion. |

| Oil Filter | Removes impurities from engine oil. | Maintains oil cleanliness, promoting smoother engine operation. |

| Batteries | Provides electrical power for starting the engine. | Ensures reliable ignition and operation of electronic systems. |

| Belts | Transfers power between moving parts. | Facilitates the operation of various engine components. |

| Hoses | Conduits for fluid movement. | Ensures proper circulation of coolant and other fluids. |

Finding Genuine Parts Sources

When it comes to maintaining or restoring any vehicle, locating authentic components is essential for ensuring optimal performance and longevity. Quality replacements can make a significant difference in the overall reliability of the machine, and utilizing trustworthy sources can save time and money in the long run.

Researching Authorized Dealers

One of the most reliable methods to acquire authentic components is through authorized distributors. These vendors typically offer products that meet the manufacturer’s specifications and standards. Additionally, they often provide warranties and customer support, which can be invaluable for those undertaking restoration projects.

Exploring Online Marketplaces

Another avenue to consider is online marketplaces that specialize in automotive components. These platforms often feature a wide range of options, allowing users to compare prices and quality easily. However, it’s crucial to verify the seller’s reputation and check for customer reviews to ensure the authenticity of the items being purchased.

Maintenance Tips for Optimal Performance

To ensure the best functionality and longevity of your equipment, regular upkeep is essential. Implementing effective care strategies can prevent issues and enhance overall efficiency, ultimately saving time and resources in the long run.

Here are some vital recommendations for maintaining your machinery:

| Tip | Description |

|---|---|

| Regular Inspections | Perform frequent evaluations to identify wear and tear before it leads to significant problems. |

| Lubrication | Ensure all moving components are adequately lubricated to reduce friction and prevent overheating. |

| Cleaning | Keep the equipment free of dirt and debris, which can hinder performance and lead to malfunctions. |

| Calibration | Regularly check and calibrate settings to maintain accuracy and functionality during operation. |

| Component Replacement | Timely replace worn-out parts to prevent breakdowns and ensure optimal performance. |

Following these guidelines will help maintain your machinery’s efficiency and prolong its operational life.

Upgrades for Enhanced Functionality

Enhancing the capabilities of your machinery can significantly improve its overall performance and efficiency. By incorporating modern components and technologies, users can achieve a level of functionality that meets contemporary demands. Upgrades not only optimize existing systems but also extend the lifespan of the equipment, making it a worthwhile investment.

One of the primary enhancements involves the implementation of advanced control systems. These systems provide better precision and responsiveness, allowing for more accurate operation and reduced energy consumption. Additionally, integrating high-performance components can lead to improvements in power output and efficiency, facilitating smoother and more effective operation.

Another critical area for enhancement is the addition of improved filtration and cooling systems. Upgrading these elements ensures that the equipment operates under optimal conditions, thereby reducing wear and tear on essential components. This proactive approach helps in maintaining the functionality of the system over time, resulting in lower maintenance costs and increased reliability.

Lastly, incorporating smart technology can revolutionize how users interact with their machinery. Remote monitoring and control capabilities enable real-time assessment and adjustments, providing invaluable insights into operational performance. This level of connectivity not only boosts productivity but also allows for timely interventions, minimizing downtime and maximizing efficiency.

Community Resources and Support

Engaging with a vibrant community can significantly enhance your understanding and experience with automotive restoration and maintenance. Resources such as forums, local clubs, and online groups provide invaluable insights, advice, and assistance. Collaborating with fellow enthusiasts fosters a sense of camaraderie and encourages knowledge sharing, making it easier to tackle various challenges.

Many individuals find great value in tapping into local networks and online platforms that focus on vintage vehicle restoration. These communities often host events, workshops, and meet-ups, where members can exchange ideas and techniques. Additionally, accessing shared resources, such as manuals and reference materials, can streamline the restoration process.

| Resource Type | Description | Examples |

|---|---|---|

| Online Forums | Discussion boards where enthusiasts share experiences and advice. | ClassicCarRestorationForum.com, VintageAutoClub.org |

| Local Clubs | Groups that meet regularly to discuss projects and share knowledge. | Vintage Vehicle Enthusiasts, Classic Car Collectors Association |

| Workshops | Hands-on sessions that teach specific skills and techniques. | Restoration Basics Workshop, Advanced Repair Techniques |

| Social Media Groups | Online communities that connect members through social platforms. | Facebook Groups, Reddit Communities |