In vehicles designed with an open-top feature, the operation of the retractable cover involves a complex system of interconnected elements. These components work together to provide a smooth, seamless experience when transitioning between open-air driving and a fully covered state.

Whether you are looking to maintain or replace certain elements in this system, it is essential to have a clear understanding of how each part functions and interacts with others. By exploring the assembly, you can ensure better upkeep and improved longevity of the entire mechanism.

This guide offers an in-depth look at the essential components involved in the system, helping to clarify their roles and how they contribute to the overall functionality of the setup. Understanding these elements is key to performing effective maintenance or identifying potential issues.

Soft-Top Mechanism Components Overview

The fabric-covered opening system is comprised of multiple mechanical and structural elements that work in unison to provide a seamless transition between open and closed modes. Each element plays a critical role in ensuring smooth functionality, safety, and durability during operation.

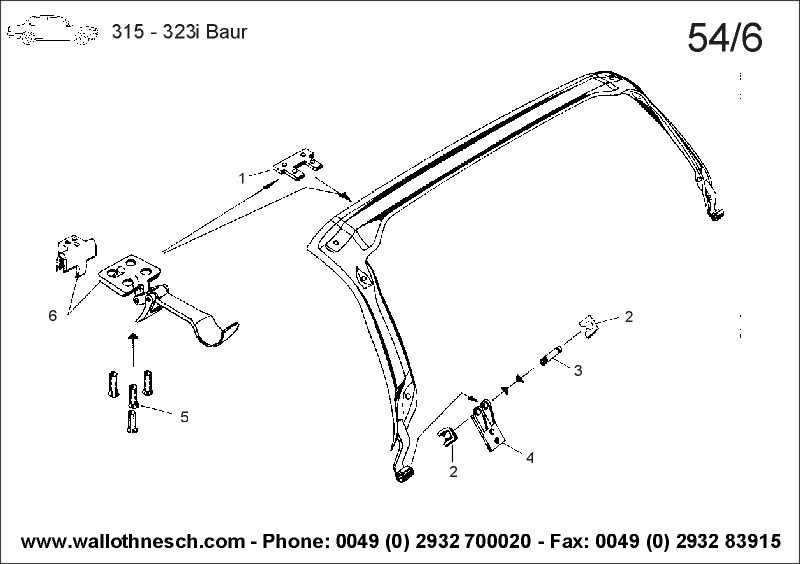

Primary Structural Elements

The framework consists of reinforced bars and pivots designed to support the fabric cover and guide its movement. These elements maintain stability, ensuring that the opening system can withstand various weather conditions without compromising its integrity.

Motion Control Mechanisms

The automated movement is controlled by a series of hydraulic or motor-driven systems. These mechanisms are engineered to provide smooth, reliable transitions, allowing effortless retraction or deployment with minimal user effort.

| Component | Function |

|---|

| Material Type | Function |

|---|---|

| EPDM Rubber | Offers excellent resistance to UV rays and temperature fluctuations, ensuring longevity. |

| Foam Sealants | Provides effective soundproofing and thermal insulation, reducing cabin noise. |

| Butyl Sealants | Ensures a watertight seal, preventing moisture infiltration and related damage. |

| Fleece Insulation | Enhances thermal insulation, maintaining a stable interior temperature. |

Choosing the right combination of seals and insulation materials is essential for achieving the desired performance and comfort level in the vehicle’s interior. Regular inspection and maintenance of these components can significantly impact their effectiveness and durability.

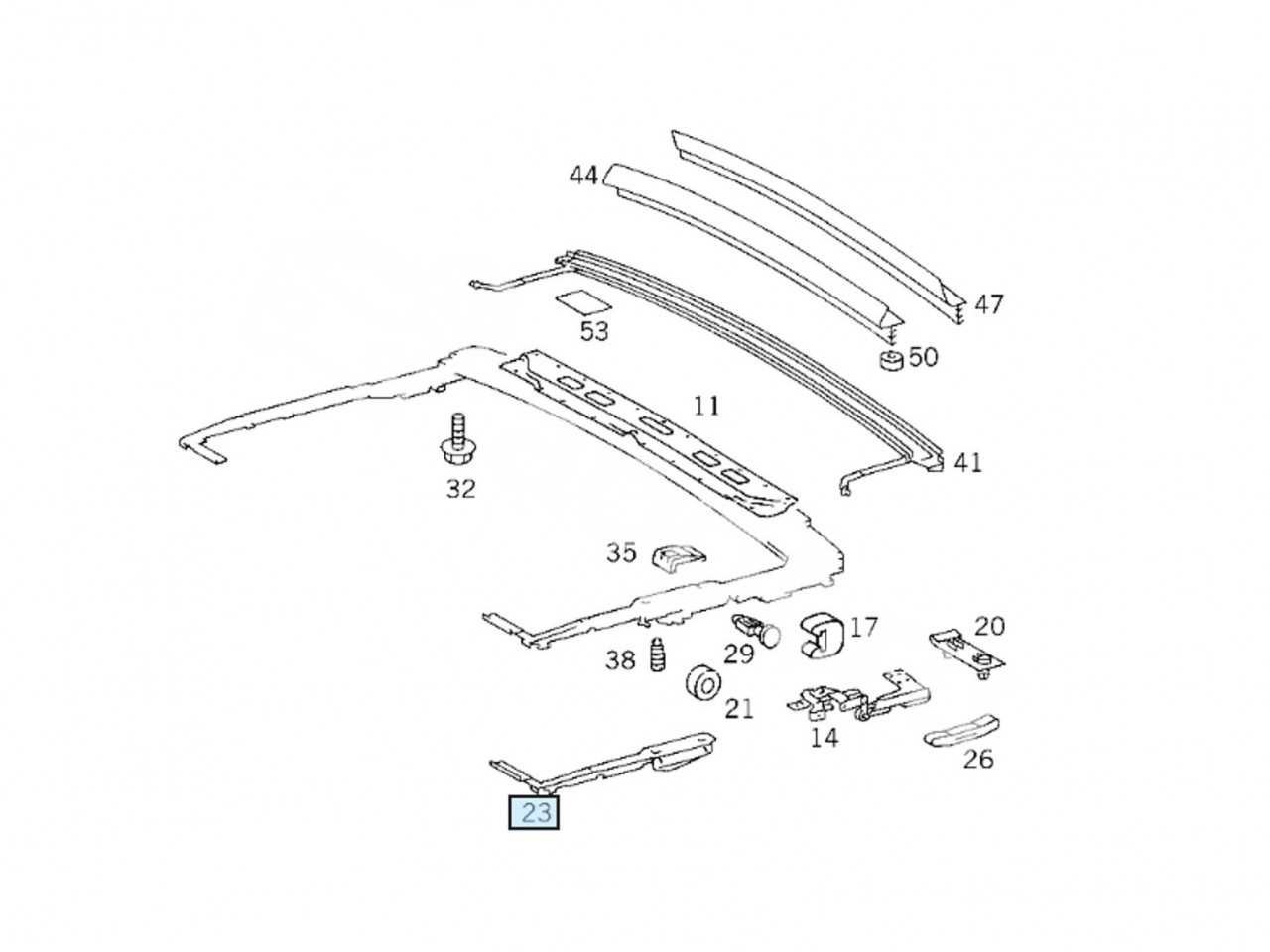

Roof Latch System and Fasteners

The mechanism responsible for securing the upper covering of an automobile plays a crucial role in ensuring both safety and functionality. This system is designed to hold the structure firmly in place during operation while allowing for quick access when needed. Various components work together to achieve this, employing a combination of locks and connectors that guarantee reliability and ease of use.

Components of the Latching Mechanism

The latching mechanism comprises several essential elements that contribute to its overall performance. These components include latches, rods, and securing devices that interact seamlessly to facilitate the opening and closing process. Understanding the function of each part can enhance the appreciation of the system’s complexity and efficiency.

Types of Fasteners Used

Fasteners play a pivotal role in the stability and durability of the latching system. Various types of fasteners are employed, each selected for its specific characteristics and applications. Below is a table outlining the common fasteners used in this system:

| Fastener Type | Function | Material |

|---|---|---|

| Bolts | Secure components together | Steel |

| Nuts | Hold bolts in place | Steel |

| Screws | Attach smaller components | Stainless Steel |

| Washers | Distribute load and reduce wear | Various |

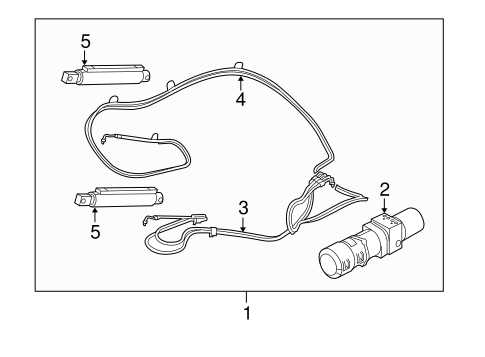

Motor and Drive Units of the Roof

The functionality of a retractable canopy relies heavily on its propulsion and control mechanisms. These components work in tandem to ensure smooth operation and reliable performance, allowing for seamless opening and closing actions.

At the core of this system is the motor, which provides the necessary torque to facilitate movement. It is crucial for this element to possess adequate power to handle the weight of the structure while ensuring speed is appropriate for safe operation.

In addition to the motor, the drive units play a pivotal role in translating the motor’s rotational force into linear motion. These assemblies consist of gears, linkages, and sometimes hydraulic elements, which all contribute to the efficient transfer of energy, ultimately leading to the desired adjustments of the assembly.

Regular maintenance of these components is essential for longevity and optimal performance. Ensuring that all elements are properly lubricated and free of debris can prevent potential malfunctions and enhance the overall reliability of the system.

Convertible Roof Control Module

The control module is a critical component in the operation of the retractable top mechanism, ensuring seamless functionality and coordination among various systems. This unit plays a vital role in managing the electronic signals that dictate how the canopy operates, providing both safety and convenience for users.

Understanding the structure and operation of this module can enhance maintenance and troubleshooting efforts, contributing to the longevity of the entire assembly.

| Function | Description |

|---|---|

| Signal Processing | Interprets inputs from sensors and user commands to control the opening and closing sequence. |

| System Integration | Coordinates with other electronic systems for optimal performance, such as locking mechanisms and safety features. |

| Diagnostic Capability | Provides error codes and diagnostic information for troubleshooting issues related to the operation. |

| Safety Management | Monitors the operation to prevent damage or injury during the movement of the assembly. |

Common Roof Mechanism Issues

The operation of an open-top vehicle’s canopy can be compromised by various mechanical problems. These issues may lead to malfunctions, resulting in inconvenience and potential damage if not addressed promptly. Understanding the typical complications can help owners take proactive measures to maintain the functionality and longevity of their vehicle’s system.

Frequent Mechanical Failures

One of the most common issues involves the failure of the actuators that control the movement of the canopy. These components can wear out over time due to repeated use, leading to sluggish or unresponsive operation. Additionally, misalignment of the framework can occur, preventing the mechanism from sealing properly when closed.

Hydraulic and Electrical Problems

Another prevalent concern is related to hydraulic leaks or electrical faults. Leaks can diminish the pressure required for smooth operation, while electrical issues may disrupt the communication between the control switch and the mechanism. Regular inspections and maintenance can help identify these problems before they escalate.

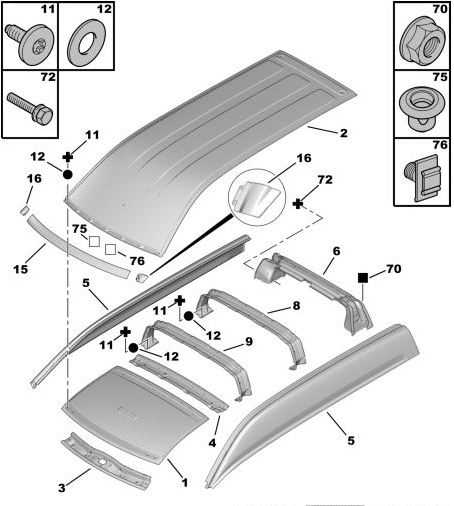

Replacement Parts for Roof Maintenance

Ensuring the proper functioning of a vehicle’s overhead mechanism requires attention to various components that may wear out or become damaged over time. Regular inspections and timely replacements of these elements can significantly enhance the longevity and performance of the system.

Essential Components for Maintenance

- Seals and Weather Strips

- Hydraulic Cylinders

- Control Modules

- Electrical Connections

- Motor Assemblies

Replacement Tips

- Regularly check seals for signs of wear or damage.

- Ensure hydraulic fluid levels are adequate to prevent system failure.

- Inspect electrical connections for corrosion or loose wires.

- Use OEM (Original Equipment Manufacturer) components for reliable performance.

By proactively managing the upkeep of these critical elements, vehicle owners can avoid costly repairs and enjoy a smooth operation.

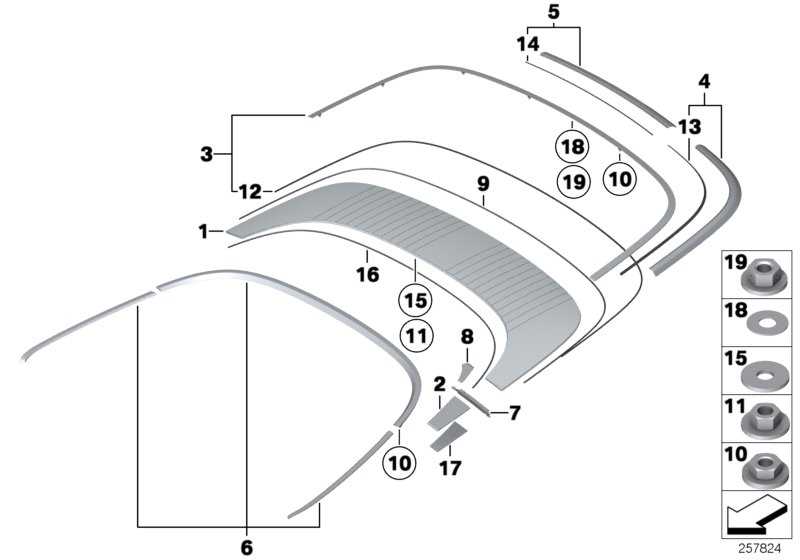

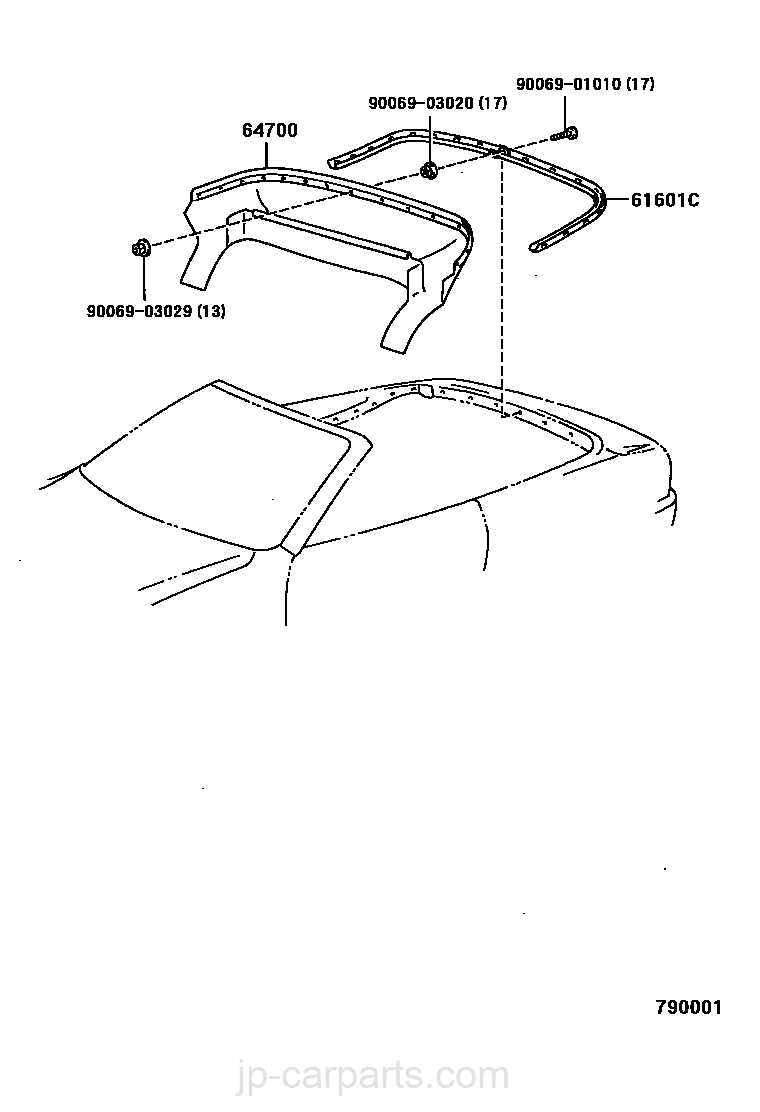

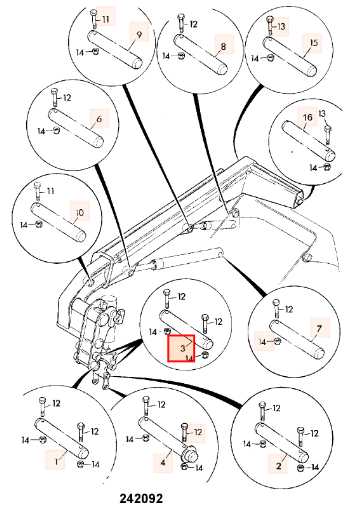

Diagram of Roof Components Layout

This section provides an overview of the arrangement of essential elements involved in the top mechanism of a vehicle. Understanding the layout of these components is crucial for effective maintenance and troubleshooting.

Key Components Overview

The following elements play a significant role in the functionality and operation of the top mechanism:

- Support Framework

- Sealing Strips

- Hydraulic Actuators

- Control Module

- Weather Stripping

Functional Interrelations

Each of these components contributes to the overall performance of the top system. Here’s a brief description of their interactions:

- The support framework provides stability and shape.

- Sealing strips ensure protection against the elements.

- Hydraulic actuators enable smooth opening and closing.

- The control module coordinates operation.

- Weather stripping enhances insulation and reduces noise.