Anti-Kickback Pawls: Small teeth that grip the material and prevent it from being thrown back toward the user during a cut.

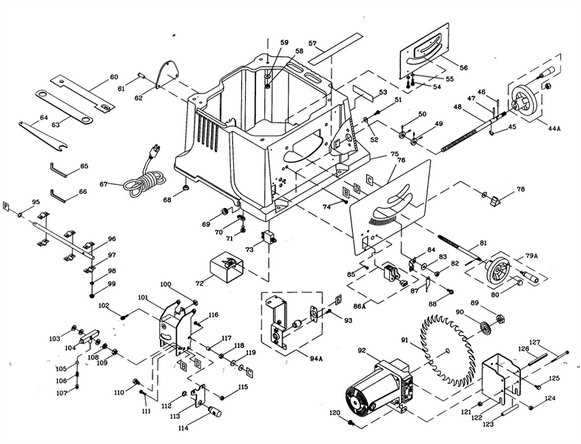

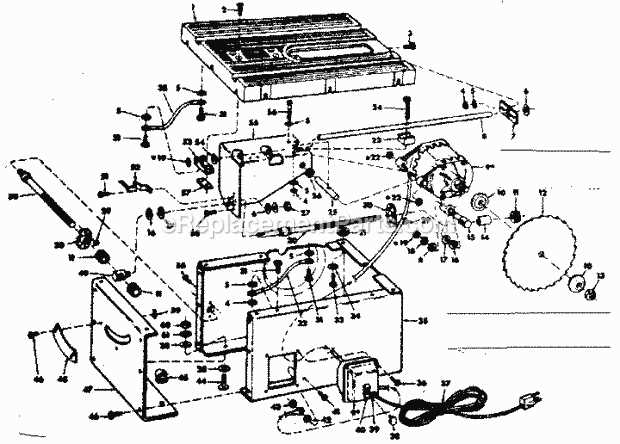

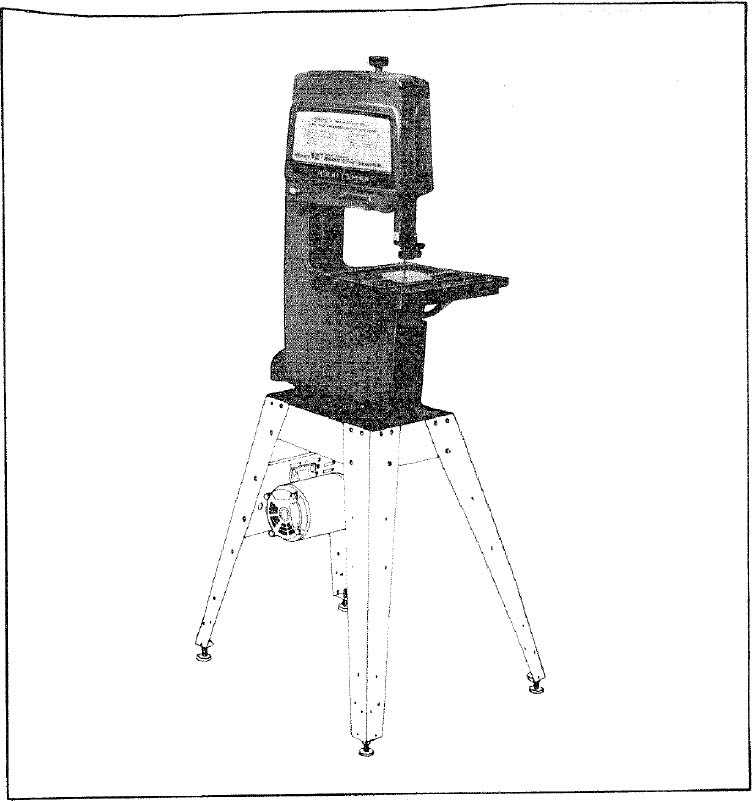

Motor Assembly Breakdown

The motor unit consists of several interconnected components, each playing a crucial role in the operation and performance. Understanding the arrangement of these elements can help in identifying issues, performing maintenance, or replacing individual parts. This section provides a comprehensive look at the key components involved in the motor assembly.

Armature and Field Windings: The armature, along with the field windings, generates the electromagnetic forces that

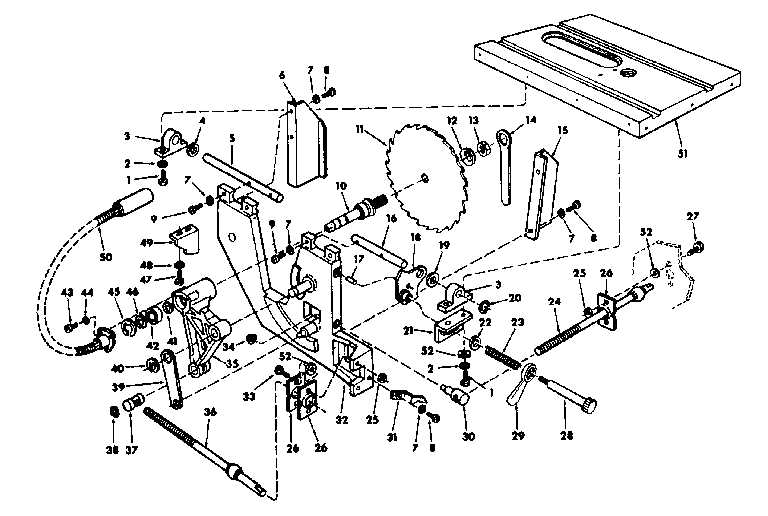

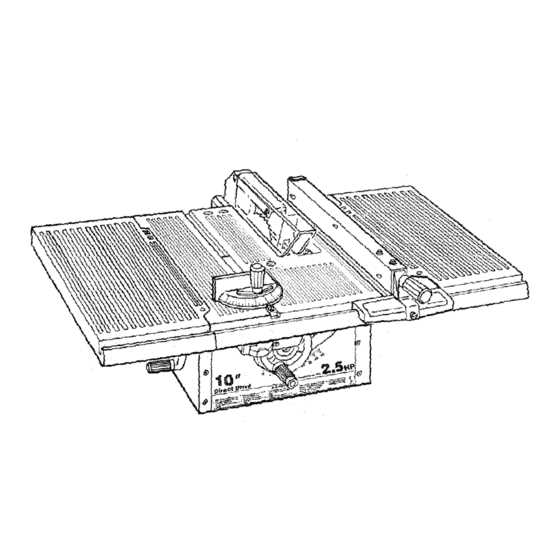

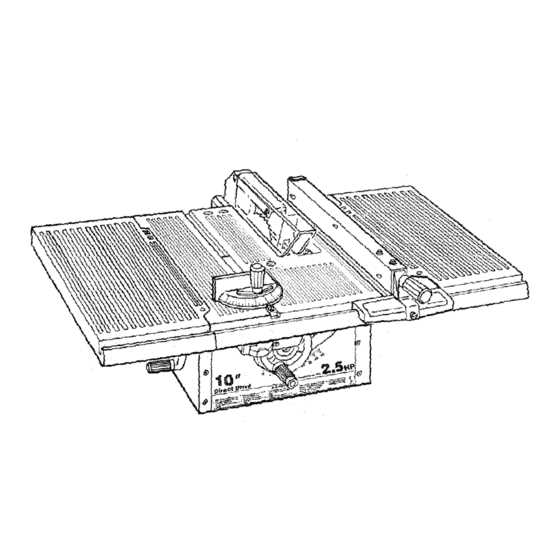

Fence and Rail System Details

The fence and rail system is essential for ensuring precise and consistent cuts, allowing for better control over the material being processed. It provides a stable guide that helps maintain accuracy, even when working with longer or wider pieces. The overall design contributes to smoother operation and enhanced safety during use.

Adjustability and Locking Mechanism

A key feature of the system is its adjustability, which allows users to fine-tune the alignment for various cutting tasks. The locking mechanism secures the guide in place, preventing any unwanted movement. This ensures that the material stays on the intended path throughout the entire cut, resulting in a cleaner and more precise finish.

Rail Length and Extension Options

The rails can vary in length to accommodate different sizes

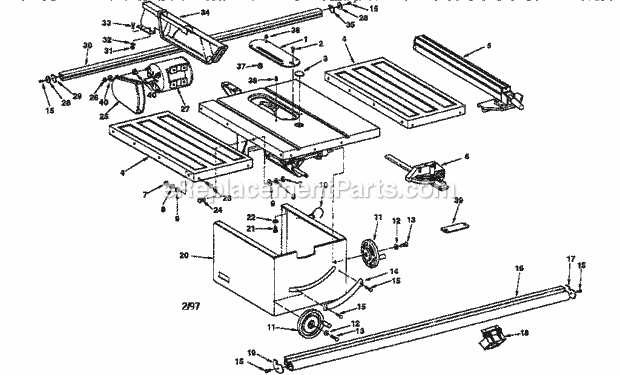

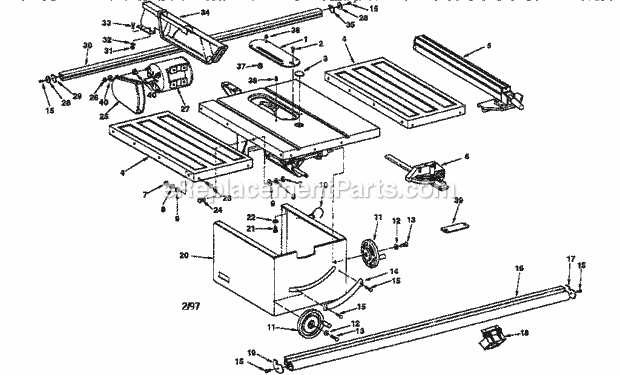

Blade Adjustment Mechanism Overview

The mechanism responsible for modifying the cutting tool’s position plays a vital role in ensuring precision and adaptability during operation. This system allows users to alter the height and angle of the blade, enabling adjustments based on the material being worked on and the desired cut. A well-functioning adjustment mechanism is essential for achieving accurate results and maintaining safety standards.

Understanding the components involved in this mechanism is crucial for effective usage. Typically, it includes a series of levers, gears, and locking devices designed to facilitate smooth operation. Users should familiarize themselves with these elements to ensure proper functionality and to perform any necessary maintenance.

Regular checks and adjustments to this system are recommended to maintain optimal performance. Over time, wear and tear may affect the precision of adjustments, making it important to inspect and calibrate the mechanism periodically. Ensuring that all parts are clean and free from debris will further enhance the efficiency of the adjustment process.

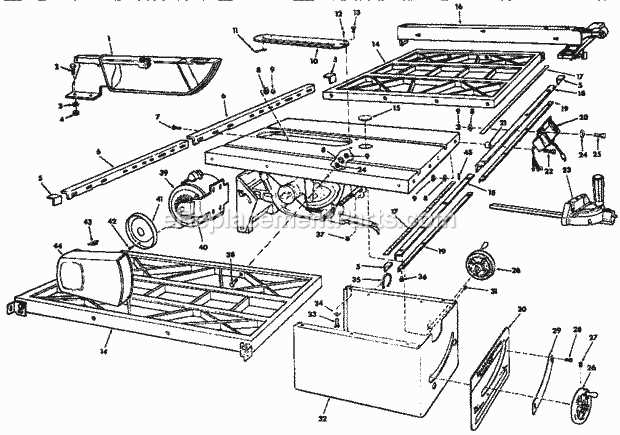

Miter Gauge and Slot Information

The miter gauge serves as an essential tool for making precise angled cuts. Understanding its features and the corresponding slot is crucial for achieving optimal results during woodworking projects. This section delves into the specifics of the miter gauge and the slot’s dimensions and functions.

Key aspects to consider include:

- Gauge Construction: The design and materials influence the stability and accuracy of cuts.

- Slot Dimensions: Accurate measurements ensure the gauge fits properly, facilitating smooth adjustments.

- Adjustability: Features that allow for fine-tuning angles enhance versatility for various projects.

Furthermore, the compatibility between the miter gauge and the slot can impact overall performance. Ensuring that the gauge slides effortlessly within the slot can lead to improved precision and ease of use.

Ultimately, understanding the intricacies of the miter gauge and its corresponding slot enables users to execute complex cuts with confidence, resulting in high-quality finishes in their woodworking endeavors.

Dust Collection System Explained

A dust collection system plays a vital role in maintaining a clean and safe workspace, particularly in environments where wood or other materials are processed. These systems are designed to capture and filter airborne particles, preventing them from accumulating on surfaces and being inhaled by users. Understanding how these systems function can significantly enhance both the efficiency of operations and the overall health of individuals working in such spaces.

Key components of an effective dust collection setup include:

- Collector Unit: The central hub that generates suction to draw in dust and debris.

- Ductwork: A network of tubes that transport the collected materials from the source to the collector.

- Filters: Devices that separate fine particles from the air, ensuring that clean air is released back into the environment.

- Hoses and Fittings: Flexible components that connect tools to the collection system, allowing for easy maneuverability.

Implementing a well-designed collection system not only improves air quality but also enhances the precision of work by minimizing distractions caused by dust. For optimal performance, regular maintenance is essential, which includes cleaning or replacing filters and inspecting ductwork for blockages.

By prioritizing a robust dust collection strategy, individuals can create a healthier and more efficient workspace, ultimately leading to improved productivity and safety.

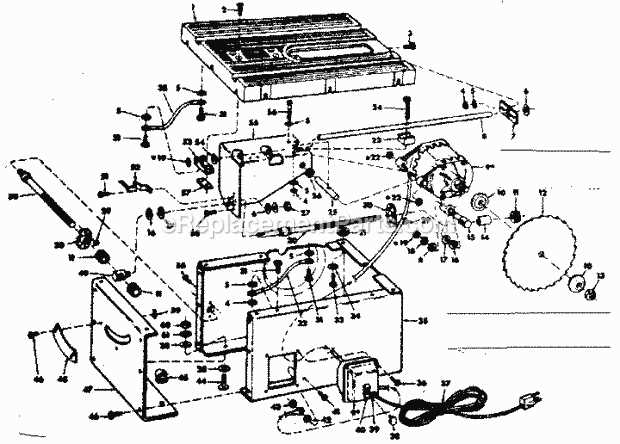

Switch and Power Connections

Understanding the mechanism and layout of electrical components is essential for efficient operation. Properly managing these connections ensures optimal performance and safety during usage. This section explores the critical elements involved in electrical control and power delivery for woodworking equipment.

At the core of these devices is the switch, responsible for regulating power flow. A reliable switch contributes to user convenience and safety, minimizing the risk of electrical failures. It is crucial to recognize how to connect the switch to the power source effectively.

| Component |

Description |

| Power Switch |

Controls the flow of electricity to the device, allowing it to start and stop. |

| Power Cord |

Transfers electrical energy from the outlet to the equipment, connecting it to the power source. |

| Electrical Connector |

Joins wires securely, ensuring reliable connections that withstand operational stress. |

| Fuse |

Provides overcurrent protection by interrupting the circuit if the current exceeds safe levels. |

| Ground Wire |

Enhances safety by redirecting excess current away from the user and equipment. |

Understanding these elements can significantly improve maintenance practices and troubleshooting capabilities. Familiarity with wiring and connections will aid users in ensuring a safe and efficient work environment.