In the world of lawn care, having the right equipment can make all the difference. Each component plays a vital role in ensuring smooth operation, and understanding the configuration of these elements is key to maintaining efficient performance. Whether you’re looking to enhance longevity or boost efficiency, getting to know the inner workings of your machine can help you achieve optimal results.

Proper maintenance involves more than just occasional cleaning or sharpening. Each piece of the system contributes to the overall functionality, and a clear understanding of how these components connect and operate is essential for troubleshooting and upkeep. By gaining insight into the detailed arrangement of individual elements, you empower yourself to address potential issues before they become major problems.

This guide will help you navigate the complex interplay of mechanical parts, explaining how each section functions and interacts with others. From the larger elements that control movement to the finer details that ensure precision, you’ll be equipped with the knowledge necessary to keep your equipment running smoothly and efficiently.

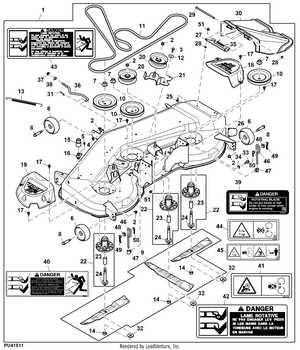

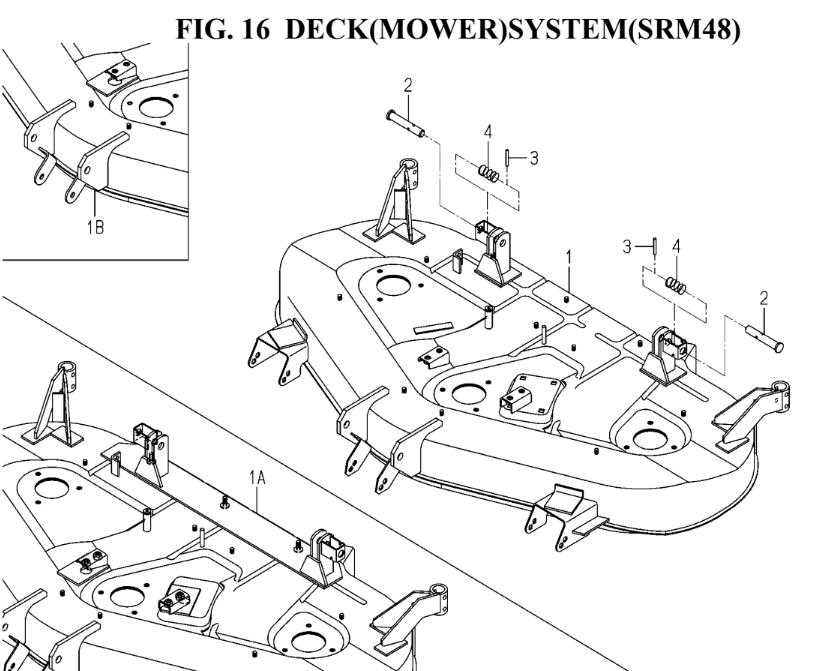

Overview of 54” Deck Components

Understanding the structure and function of the key elements in a cutting platform is essential for proper maintenance and operation. These components work together to ensure an efficient cutting process and extend the longevity of the machine. Here, we’ll take a closer look at the primary features that make up the cutting system and how they contribute to overall performance.

- Blades: These are responsible for cutting the grass. Their sharpness and condition directly impact the quality of the cut.

- Spindles: These hold the blades in place and allow them to spin. They are critical for smooth operation and maintaining proper rotation speed.

- Belts: The belts transfer power from the engine to the blades. A well-functioning belt ensures efficient power delivery and prevents slipping.

- Pulleys: These guide the belt movement, keeping it properly aligned and ensuring the correct tension for optimal performance.

- Anti-scalp wheels: These prevent the cutting platform from making direct contact with uneven ground, protecting both the machine and the lawn from damage.

- Deck shell: The main body that houses all the elements, providing structural sup

Key Features of Craftsman Mower Decks

Effective lawn maintenance tools come with specific attributes designed to enhance performance, durability, and user convenience. These platforms are engineered to optimize grass-cutting precision, ensure long-term operation, and provide consistent results on a variety of terrains.

Durability and Longevity: The construction of these cutting systems prioritizes resilience. High-quality materials, reinforced with protective finishes, guard against corrosion and wear, ensuring they remain functional across seasons.

Precision and Performance: Blades are crafted for efficient cutting, producing clean, even trims. Whether dealing with overgrown grass or uneven ground, these systems adapt, maintaining steady performance to deliver a smooth, polished finish.

Maintenance Accessibility: Designed with user ease in mind, these platforms incorporate intuitive access points. This simplifies upkeep, from cleaning to blade replacements, minimizing downtime and keeping the equipment in top condition.

Terrain Adaptability: Equipped with adjustable settings, these devices handle varying ground levels and vegetation types. Users can easily modify cutting height, ensuring optimal results whether working on flat lawns or sloped areas.

In summary, the innovative design, robust construction, and adaptability of these cutting platforms ensure they stand out in terms of both performance and ease of maintenance.

Common Issues with 54-Inch Mower Decks

Operating large cutting platforms often presents certain challenges related to performance and durability. These problems can reduce efficiency and lead to uneven results or require frequent maintenance. Addressing these concerns early can help avoid major repairs and extend the lifespan of the equipment.

Uneven Cutting Patterns

One of the most frequent complaints involves inconsistent trimming across the lawn, often due to misalignment or imbalance in the blades. This can happen if the blades become dull or damaged over time, or if the platform is not leveled correctly. Regular inspection of the blade’s sharpness and alignment is crucial for maintaining consistent operation.

Clogging and Grass Build-up

Another common issue is the build-up of grass and debris beneath the cutting platform. This can obstruct airflow, which in turn diminishes the machine’s cutting power and can cause clumps of grass to be left behind. To prevent this, it’s important to clean the underside regularly and ensure that the discharge chute remains clear.

Regular maintenance and proper operation techniques can significantly reduce these issues and improve the overall functionality of the equipment. Paying attention to these common concerns helps ensure smooth and efficient performance throughout the season.

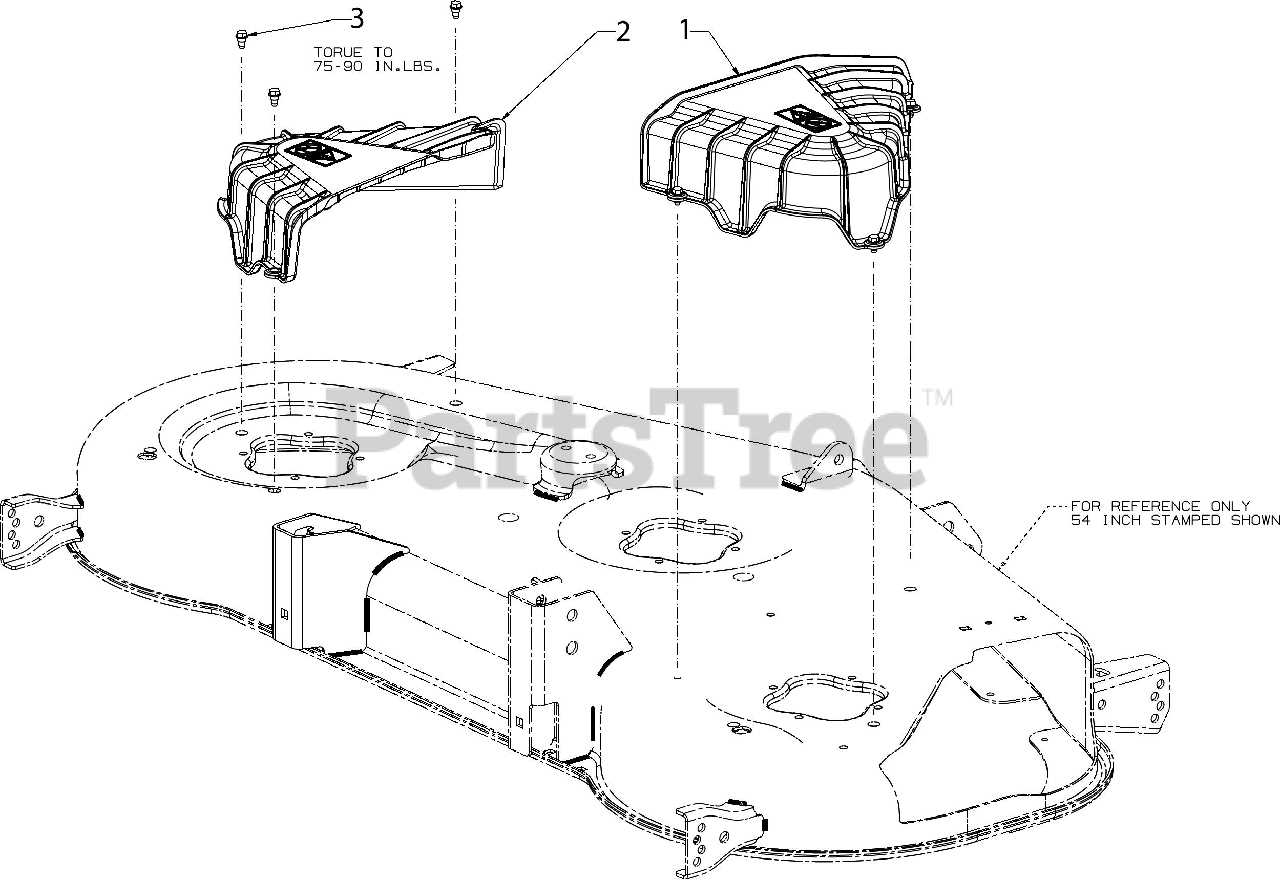

How to Effectively Replace Components of the 54-Inch Cutting Mechanism

To ensure optimal performance and longevity of your cutting apparatus, periodic replacement of its components is essential. This section guides you through the systematic process of swapping out worn or damaged pieces, ensuring seamless operation and prolonged durability.

Begin by carefully inspecting each element of the cutting mechanism, identifying any signs of wear, rust, or misalignment. This meticulous examination ensures that all necessary replacements are promptly addressed, mitigating potential operational disruptions.

Next, disassemble the assembly methodically, keeping track of each component’s orientation and function. Clear documentation or labeling of parts facilitates an efficient replacement process, reducing errors and unnecessary downtime.

When installing new components, adhere strictly to manufacturer guidelines and recommended torque specifications. Proper alignment and secure fastening prevent premature wear and maintain the integrity of the cutting system, promoting consistent cutting performance.

Finally, conduct a comprehensive operational test post-replacement to verify functionality and ensure optimal alignment and performance. Address any anomalies promptly to avoid compounding issues and maintain peak cutting efficiency.

Maintenance Tips for Craftsman Mower Decks

Regular upkeep of your cutting equipment is essential to ensure longevity, optimal performance, and even grass trimming. By following a few simple maintenance routines, you can prevent many common issues and keep your machine running smoothly for years. Let’s explore some best practices for preserving the condition of your equipment.

One of the key tasks is to keep the blades in top condition. Regular sharpening of the cutting tools ensures clean cuts, reducing strain on the engine. Inspect the blades for any nicks or damage, and replace them if needed. Worn or damaged components not only affect the quality of your lawn’s appearance but can also cause vibrations that harm the overall machinery.

Another critical aspect is keeping the underside of the cutting platform clean. Grass clippings and debris can build up over time, leading to blockages and rust. After each use, it’s important to clear out any clumps and rinse the area to avoid corrosion and maintain proper airflow.

Checking belt tension is equally important. Over time, belts may stretch or wear out, leading to slippage or inefficient power transfer. Regular inspection and timely replacement of worn belts are crucial for the smooth operation of the drive system.

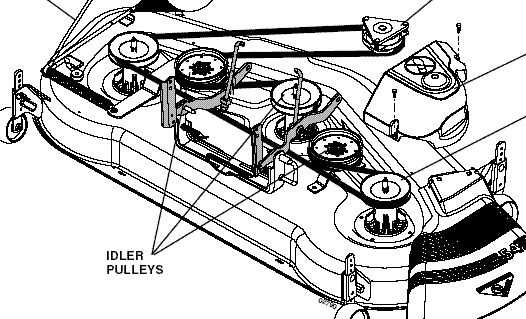

Understanding the Belt Drive Mechanism of the Lawn Machinery Component

In this section, we delve into the intricate network of pulleys, belts, and tensioners that comprise the essential link between the power source and the cutting apparatus of your outdoor equipment. The belt drive system, a critical component of the cutting mechanism, efficiently transfers rotational energy from the engine to the blades.

The Pulley Configuration: Central to Power Transmission

The heart of this system lies in its pulleys, which are meticulously configured to ensure optimal power distribution across the cutting assembly. These pulleys, often equipped with adjustable sheaves, play a pivotal role in maintaining tension and routing the belt along its designated path.

Ensuring Reliable Performance: Tension and Alignment

Proper tension and alignment of the belt are paramount for consistent and effective operation. Tensioners, strategically positioned within the system, maintain the requisite tautness to prevent slippage and ensure seamless power transmission. Alignment guides facilitate the correct positioning of the belt, reducing wear and extending the operational lifespan of the components.

Identifying Worn-Out Mower Deck Components

Over time, various components responsible for the performance of a grass-cutting machine may experience wear and tear, leading to reduced efficiency and potential damage. Regularly inspecting key parts helps to avoid breakdowns and ensures smooth operation. Recognizing the signs of deterioration early can save time and maintenance costs.

- Blades: Look for uneven wear, nicks, or bends. A dull or damaged cutting edge affects the quality of the cut and places additional stress on the motor.

- Belts: Worn-out belts may exhibit cracks, fraying, or glazing. This can cause slipping or loss of power transfer, impacting performance.

- Pulleys: Check for wobbling, noise, or visible damage. Misaligned or worn pulleys can lead to uneven belt tension, reducing efficiency.

- Spindles: Listen for unusual noises during operation. Damaged spindles may vibrate excessively or result in uneven rotation, affecting the cutting process.

- Bearings: Excessive play, grinding noises, or heat can indicate failing bearings. This can cause friction, reducing overall performance and causing further damage.

- Springs: Inspect for stretching or loss of tension. Worn springs may fail to

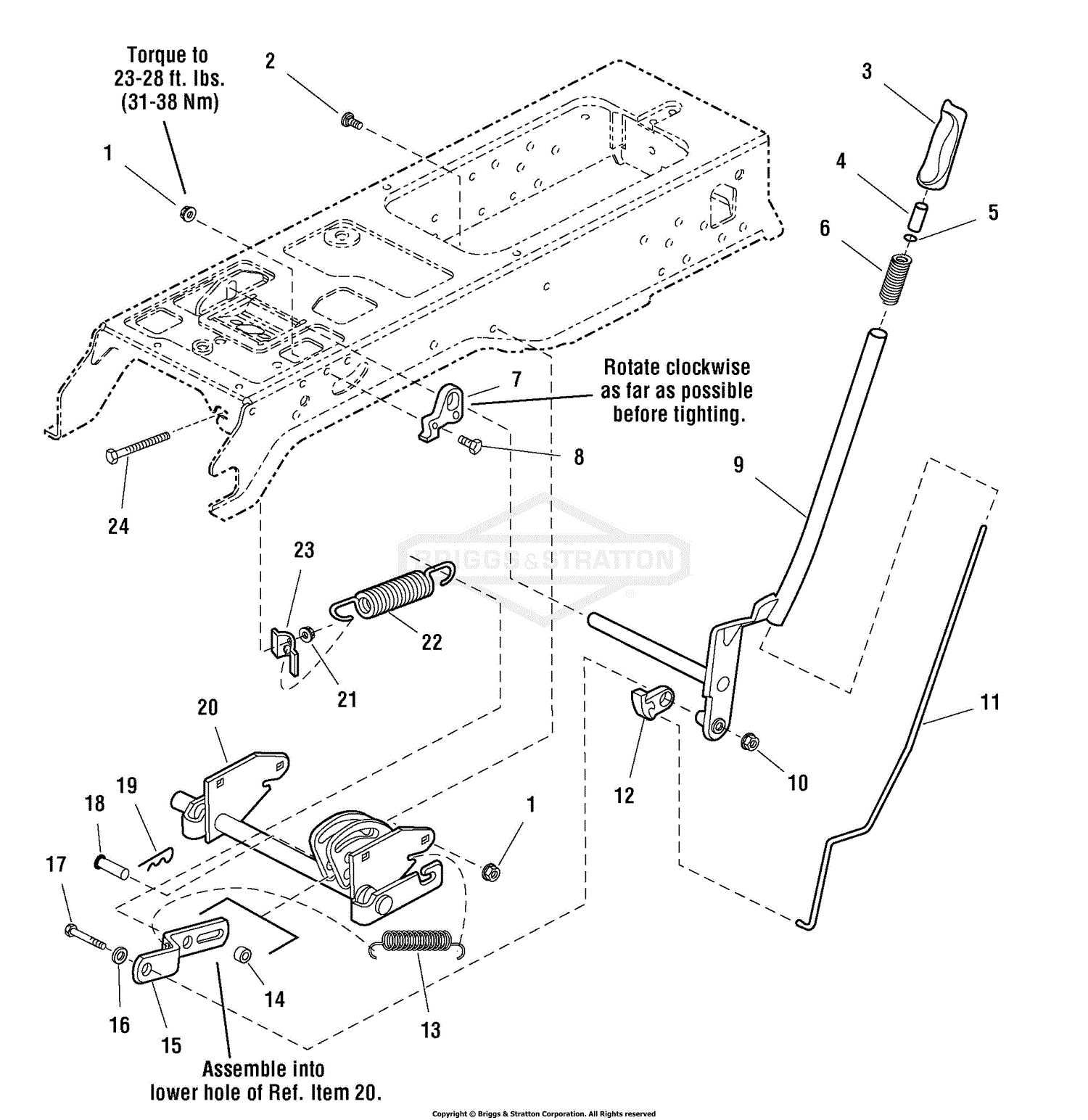

Adjusting the Deck Height Properly

Ensuring the correct height for cutting equipment is crucial for achieving optimal results and maintaining the health of your lawn. Proper adjustments not only enhance performance but also contribute to the longevity of the machinery. This section will guide you through the essential steps and considerations for setting the cutting height effectively.

Understanding the Importance of Height Adjustment

Correct height settings influence several factors:

- Grass Health: Cutting at the right level promotes healthy growth and reduces stress on the grass.

- Clippings Management: Proper height helps in managing clippings effectively, preventing buildup and promoting even distribution.

- Equipment Longevity: Maintaining the ideal height reduces wear and tear on the blades and other components.

Steps for Adjusting Cutting Height

Follow these guidelines to ensure accurate height adjustments:

- Check Manufacturer Recommendations: Refer to the user manual for suggested height settings based on grass type and conditions.

- Position the Equipment: Ensure that the equipment is on a flat, level surface before making adjustments.

- Adjust the Height: Utilize the adjustment lever or mechanism to set the desired height. Make small increments for precision.

- Test the Height: Conduct a test cut in a small area to assess the effectiveness of the adjustment.

- Fine-tune as Necessary: If the results are not satisfactory, make further adjustments until the desired height is achieved.

By following these steps, you will ensure that your cutting equipment operates efficiently, leading to a healthier and more aesthetically pleasing lawn. Regular checks and adjustments are key to maintaining peak performance throughout the mowing season.

Finding Compatible Parts for Craftsman Decks

Identifying suitable components for lawn care equipment can significantly enhance performance and longevity. Ensuring that every piece fits well and operates seamlessly is essential for maintaining efficiency. This section provides guidance on locating the right replacements to keep your machine running smoothly.

When searching for compatible elements, consider the following strategies:

- Consult the Manual: Always refer to the owner’s guide for specific recommendations regarding compatible components. It often contains valuable information on part numbers and compatibility.

- Use Manufacturer’s Resources: Check the manufacturer’s website or contact customer support for official resources that list compatible options. This can save time and prevent mistakes.

- Explore Online Marketplaces: Websites like eBay or Amazon offer a vast selection. Use filters and search tools to narrow down your choices based on compatibility.

- Join Online Forums: Engaging with communities dedicated to lawn care equipment can provide insights from experienced users. They often share tips on compatible components and their performance.

Furthermore, it’s crucial to compare specifications before making a purchase:

- Check Dimensions: Ensure that the measurements of the replacement parts match those of the original.

- Review Material Quality: Opt for components made from durable materials to enhance lifespan and functionality.

- Examine User Reviews: Reading feedback from other customers can help gauge the reliability and effectiveness of a particular option.

By following these guidelines, you can successfully identify and procure the right elements for your lawn equipment, ensuring optimal operation and maintenance.

Tools Required for Mower Deck Repair

Repairing a lawn cutting machine requires a specific set of instruments to ensure a smooth and efficient process. Having the right tools at your disposal not only facilitates the repair but also enhances the quality of the work performed. Below is a comprehensive list of essential tools that will aid in performing repairs effectively.

Essential Tools

- Wrenches: A variety of socket and open-end wrenches will help in loosening and tightening bolts and nuts.

- Ratchet Set: A ratchet set allows for quick adjustments and is invaluable for reaching tight spaces.

- Screwdrivers: A selection of Phillips and flat-head screwdrivers is crucial for removing screws and fasteners.

- Plier Set: Pliers can assist in gripping, twisting, and cutting various components.

- Torque Wrench: This tool is essential for applying a specific amount of torque to fasteners, ensuring proper assembly.

- Utility Knife: Useful for cutting various materials or packaging when working on components.

- Measuring Tape: Accurate measurements are key when aligning or adjusting parts during repairs.

Safety Equipment

- Safety Glasses: Protect your eyes from debris and flying particles.

- Gloves: Wear gloves to prevent injuries from sharp edges and hot surfaces.

- Ear Protection: Use earplugs or earmuffs when working with loud machinery.

Equipping yourself with these tools will not only make the repair process more efficient but also ensure safety and precision throughout the job. Being prepared is the first step towards a successful maintenance task.