When working with a specific type of power tool, it’s essential to have a clear understanding of its internal structure and the roles each element plays. This knowledge can enhance efficiency and ensure proper maintenance, allowing users to maximize the tool’s performance over time. By familiarizing oneself with the various elements, one can easily troubleshoot issues and carry out repairs when necessary.

A comprehensive overview of the various components reveals how they interact and function together. Each section contributes to the overall effectiveness of the equipment, from the motor to the housing. Gaining insight into these features helps users appreciate the engineering behind the tool and empowers them to make informed decisions regarding its use and upkeep.

In exploring the configuration of this specific equipment, users can gain valuable insights that lead to better handling and extended longevity. Understanding the relationship between different elements aids in identifying potential areas for improvement and enhances the overall user experience. With this foundational knowledge, operators can confidently engage with their tools, ensuring they operate smoothly and efficiently.

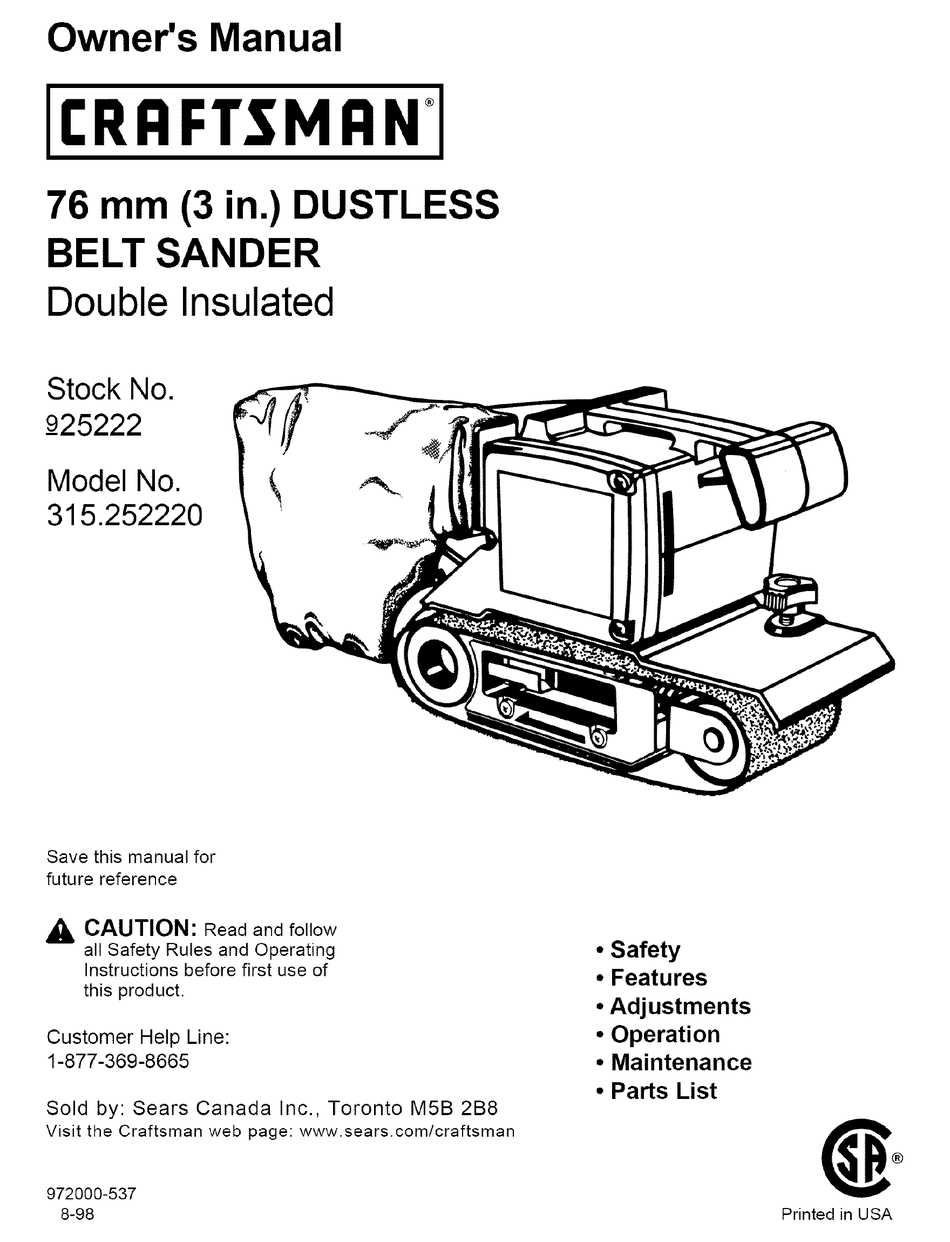

Overview of Craftsman Belt Sanders

This section provides a comprehensive insight into a specific type of power tool widely used for smoothing and shaping various surfaces. These tools are essential for both professional woodworkers and DIY enthusiasts, offering versatility and efficiency in their operations. Understanding the features and functionalities of this equipment can enhance the overall crafting experience.

Key Features

Among the standout characteristics of this equipment are its robust motor, adjustable speed settings, and ergonomic design. The powerful motor ensures that users can handle tough materials with ease, while variable speed options allow for precise control during different sanding tasks. The thoughtful design prioritizes user comfort, making extended use less taxing on the hands and arms.

Applications

This type of tool is widely utilized in various applications, including woodworking, metalworking, and home improvement projects. Whether refining edges, removing paint, or preparing surfaces for finishing, it proves invaluable in achieving smooth results. Its adaptability makes it a popular choice for many crafting endeavors.

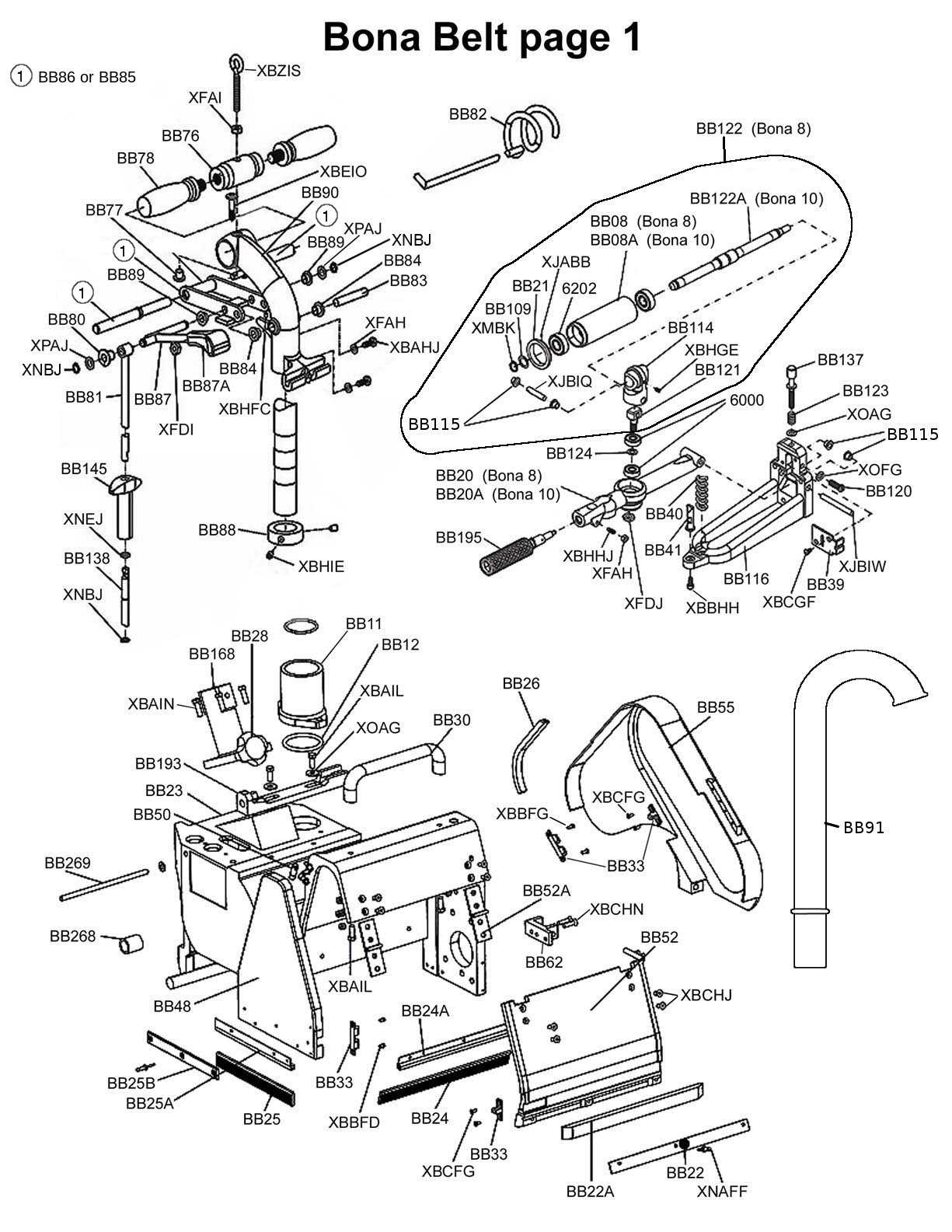

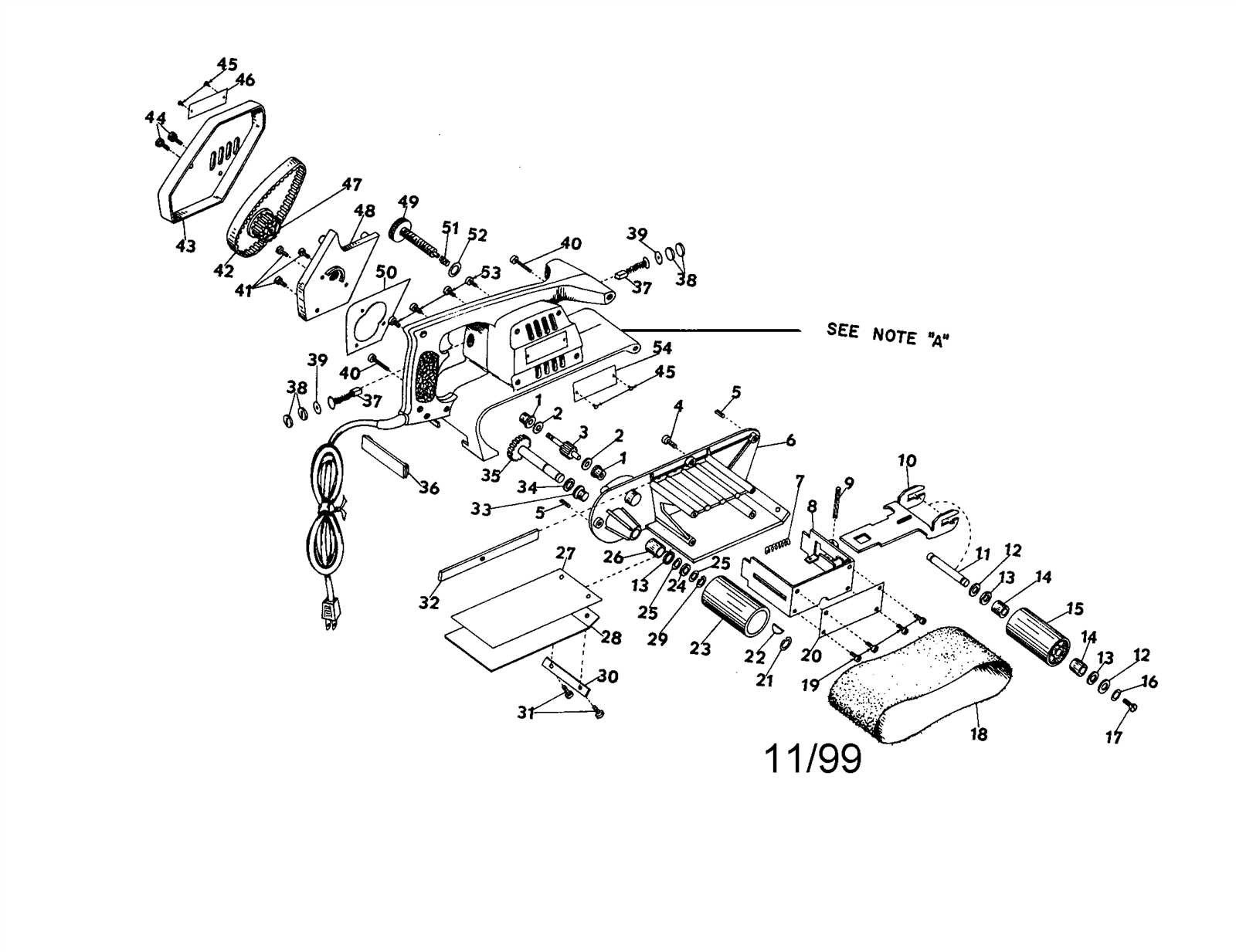

Identifying Key Parts and Functions

This section aims to provide a comprehensive overview of the essential components found in a specific type of woodworking tool, highlighting their roles and significance in ensuring optimal performance.

Motor: The heart of the equipment, the motor drives the entire system, providing the necessary power to operate efficiently. Its performance directly influences the tool’s effectiveness in material removal.

Housing: This protective casing encases the internal mechanisms, shielding them from dust and debris. It also contributes to the overall stability and ergonomic design of the apparatus.

Platform: Serving as the support structure, the platform allows for the secure placement of workpieces. It ensures that materials remain steady during operation, which is crucial for achieving precise finishes.

Grain Control Mechanism: This feature enables users to adjust the texture and finish of the surface being worked on. It provides versatility, allowing for different applications based on the desired outcome.

Dust Collection System: An integral part of maintaining a clean workspace, this system captures debris generated during operation. It enhances visibility and promotes a healthier environment by minimizing airborne particles.

Importance of Proper Maintenance

Regular upkeep of power tools is crucial for ensuring their longevity and efficiency. Neglecting maintenance can lead to decreased performance, potential damage, and safety hazards. By adhering to a routine care schedule, users can maximize the functionality of their equipment and avoid costly repairs.

Maintaining tools involves several key practices that should be followed diligently. These practices not only enhance performance but also ensure safe operation.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Cleaning components | After each use | Prevents buildup and ensures optimal functionality |

| Inspecting for wear | Monthly | Identifies issues before they escalate into significant problems |

| Lubricating moving parts | Every few months | Reduces friction and enhances efficiency |

| Replacing worn components | As needed | Maintains peak performance and safety standards |

Common Issues with Belt Sanders

Using a sanding tool can lead to several common problems that may hinder its efficiency and effectiveness. Understanding these issues can help users troubleshoot and maintain their equipment, ensuring optimal performance during woodworking or other projects.

Frequent Problems Encountered

Among the typical challenges faced, improper alignment of the sanding surface often leads to uneven results. Additionally, wear and tear on the abrasive material can reduce the tool’s ability to perform effectively. Users may also experience difficulties with the motor, which can cause inconsistent speed and power output.

Troubleshooting Tips

Addressing these issues often requires a careful inspection of the equipment. Ensuring that the sanding mechanism is correctly aligned and replacing worn-out components can enhance functionality. Regular maintenance checks can prevent motor problems and prolong the life of the tool.

| Issue | Solution |

|---|---|

| Uneven sanding results | Check alignment and replace abrasive material. |

| Reduced power output | Inspect motor and electrical connections. |

| Excessive noise | Lubricate moving parts and check for wear. |

| Frequent stalling | Ensure proper voltage supply and inspect for blockages. |

How to Replace Worn Parts

Maintaining tools in optimal condition is essential for achieving efficient performance. Over time, certain components may wear out, impacting the functionality and safety of the equipment. Understanding how to effectively replace these components can enhance longevity and ensure a smooth operation.

Follow these steps to successfully replace the worn elements:

- Identify the Worn Components:

Begin by examining the tool for any signs of damage or excessive wear. Common indicators include:

- Unusual noises during operation

- Reduced performance or power

- Visible signs of wear on surfaces

- Gather Necessary Tools:

Before starting the replacement process, ensure you have the following tools ready:

- Replacement components

- Screwdrivers

- Wrenches

- Safety goggles

- Disassemble the Unit:

Carefully remove the outer casing to access the interior parts. Keep track of the screws and components as you take them out.

- Replace the Components:

Take out the worn elements and install the new ones. Make sure everything fits securely and aligns properly.

- Reassemble the Tool:

Once the new components are in place, reattach the outer casing. Double-check that all screws are tightened adequately.

- Test the Equipment:

Before putting the tool back into regular use, conduct a test run to ensure it operates smoothly and efficiently.

Regular maintenance and timely replacement of worn elements can significantly extend the life of your equipment, ensuring optimal performance for years to come.

Tools Required for Repairs

When undertaking maintenance or fixing a malfunctioning power tool, having the right equipment is essential for a successful outcome. Proper tools not only facilitate the repair process but also ensure safety and efficiency.

Essential Hand Tools

- Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are necessary for removing and replacing screws.

- Wrenches: Adjustable and socket wrenches help in loosening or tightening nuts and bolts.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wires or small parts.

Power Tools for Efficiency

- Drill: A power drill is helpful for creating holes or driving screws quickly and efficiently.

- Multimeter: This tool is essential for testing electrical components and ensuring proper functionality.

- Vacuum: Keeping the workspace clean by removing dust and debris contributes to safer repair work.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, ensuring personal safety and the proper functioning of tools is paramount. Adhering to safety guidelines minimizes the risk of accidents and enhances the efficiency of the repair process.

Prior to beginning any repair work, it is essential to disconnect the equipment from its power source. This simple step can prevent unintentional activation, which could lead to severe injuries. Additionally, wearing appropriate protective gear such as goggles, gloves, and masks can safeguard against flying debris and harmful particles.

Furthermore, maintaining a clean and organized workspace is crucial. A cluttered area can lead to trips and falls, increasing the likelihood of mishaps. Ensure that tools are stored properly and that any spilled substances are cleaned promptly. Familiarizing oneself with the equipment’s operation manual can also provide valuable insights into safe practices during repairs.

Lastly, it is advisable to work with a partner whenever possible. Having someone nearby can offer assistance in case of emergencies, ensuring a quicker response to potential hazards.

Where to Find Replacement Parts

Locating suitable components for your tool can enhance its performance and prolong its lifespan. Whether you are looking for specific accessories or general replacements, understanding the best sources for these items is essential.

Online Retailers

Numerous online platforms specialize in offering a wide range of tools and their accompanying components. Websites such as e-commerce giants and specialized tool retailers provide convenient search options to find what you need quickly. Be sure to compare prices and check customer reviews to ensure quality and reliability.

Local Hardware Stores

Your neighborhood hardware store may carry a selection of essential components. Staff members are often knowledgeable and can assist in locating the correct items or suggesting alternatives. Additionally, they may be able to place special orders if certain components are not readily available on the shelf.

Assembly Instructions for Belt Sanders

This section provides a comprehensive guide for the assembly of sanding machines, focusing on the essential components and their configuration. Proper assembly ensures optimal performance and longevity of the tool.

Begin by gathering all necessary components, including the motor housing, sanding drum, and support structures. Ensure that each piece is clean and free from debris to facilitate a smooth assembly process.

Next, secure the motor housing in a stable position. Attach the sanding drum to the motor shaft, ensuring a snug fit to prevent any slippage during operation. Follow this by installing the necessary supports that will stabilize the entire unit, paying attention to alignment for balanced functionality.

Once all primary components are connected, double-check the tightness of screws and fittings. It’s crucial to ensure that everything is securely fastened to avoid any operational issues during use.

Finally, review the assembly to confirm that all parts are correctly installed. Make any adjustments as needed, and your machine should be ready for efficient sanding tasks.

Troubleshooting Common Problems

When working with power tools, encountering issues is not uncommon. Understanding how to identify and resolve these challenges can enhance your experience and ensure efficiency. This section provides insights into frequent complications that users may face and offers practical solutions to address them.

| Problem | Possible Cause | Solution |

|---|---|---|

| Tool won’t start | Power supply issue | Check the power cord and outlet. Ensure the device is plugged in and the outlet is functioning. |

| Excessive noise during operation | Worn components | Inspect bearings and other moving parts. Replace any damaged or worn-out parts as needed. |

| Poor performance | Improper alignment | Ensure all components are properly aligned and secure. Adjust as necessary to restore optimal function. |

| Overheating | Clogged airflow | Clean air vents and ensure there is adequate ventilation during use to prevent overheating. |