The ability to maintain and repair mechanical devices often hinges on a clear understanding of their individual elements. Identifying these elements and understanding how they interact is crucial for efficient operation and long-term durability. This section will explore the intricacies of various mechanical assemblies, offering insights into the arrangement and function of each component.

Whether you’re working with a complex system or a simpler machine, visualizing the internal structure helps in pinpointing issues and performing regular maintenance. By recognizing how different parts connect and move, you can ensure smoother operations and avoid unnecessary breakdowns.

In the following sections, we will delve deeper into the specific elements that make up these systems, highlighting their roles and providing a clear overview of their layout and connections. This knowledge will empower you to approach repairs and upgrades with greater confidence and precision.

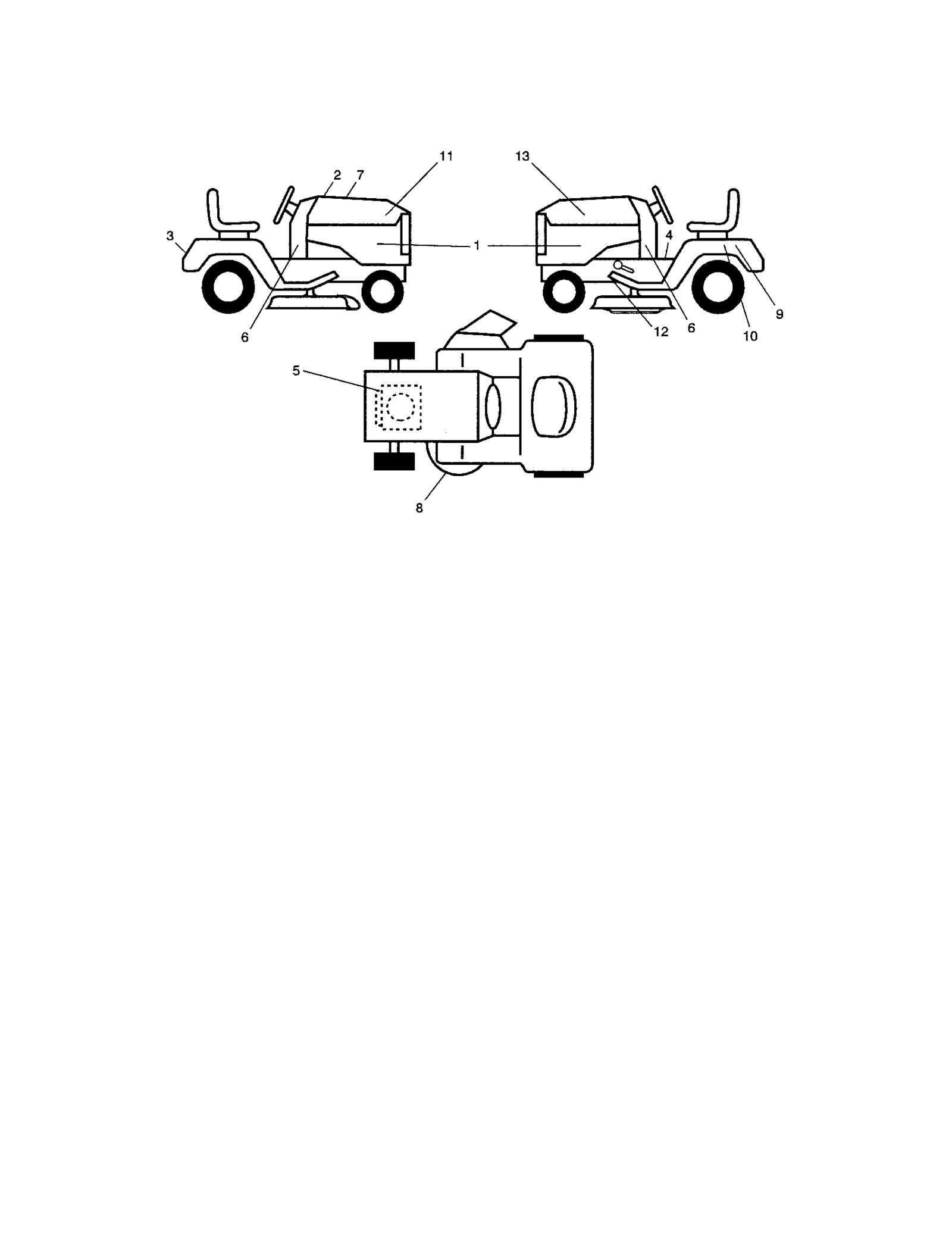

Overview of Craftsman DLS 3500 Components

Understanding the different elements that make up this machine is essential for ensuring its proper maintenance and functionality. Each part plays a significant role in the overall performance, and recognizing their functions helps in identifying potential issues and optimizing the equipment’s efficiency.

Structural framework provides the necessary support and stability, holding the entire system together. It’s designed to withstand heavy use and ensure durability under various conditions.

Engine components are the driving force behind the machine’s operation. These parts work together to deliver the power needed for optimal performance, ensuring smooth and consistent functioning during use.

Another crucial aspect is the transmission system, which controls the movement and speed. This mechanism allows for seamless adjustments while operating, contributing to a more controlled and efficient experience.

The

Key Elements of the Craftsman DLS 3500

The machinery in question consists of several essential components that work together to ensure smooth operation and reliability. These components play crucial roles in the overall functionality, contributing to its efficiency, performance, and durability. Understanding the main structural parts can help with maintenance, troubleshooting, and enhancements.

Engine and Power System

The power source is at the heart of this equipment, delivering the necessary force to operate effectively. This section includes key elements such as the motor, fuel system, and other critical mechanisms responsible for energy conversion. Proper upkeep of these elements is vital for optimal performance.

Transmission and Control Mechanism

The transmission unit connects the power system to the wheels, facilitating movement and speed control. Alongside the transmission, steering and braking mechanisms are also integral to maintaining stability and safety during use. Regular checks ensure that these systems remain responsive and reliable.

| Component | Function |

|---|---|

| Power Supply | Provides electrical energy to the system. |

| Wiring Harness | Facilitates the transmission of electricity between components. |

| Switches | Control the flow of electricity to different parts. |

| Connectors | Join various electrical elements, ensuring secure connections. |

Fuel System Components and Diagram

The fuel system plays a crucial role in ensuring the efficient operation of any engine. It is responsible for delivering the right amount of fuel to the combustion chamber, where it mixes with air for optimal ignition. Understanding the components of this system can help users diagnose issues and maintain their equipment effectively.

Typically, the fuel system consists of several key components, each serving a specific function. Below is a detailed overview of these elements, along with their arrangement.

| Component | Description |

|---|---|

| Fuel Tank | Stores the fuel needed for operation, ensuring a consistent supply. |

| Fuel Pump | Transfers fuel from the tank to the engine, maintaining adequate pressure. |

| Fuel Filter | Removes impurities from the fuel, protecting the engine components from damage. |

| Carburetor / Fuel Injector | Mixes fuel with air in the correct ratio for combustion. |

| Fuel Lines | Connect various components, allowing the fuel to flow throughout the system. |

By familiarizing oneself with these components, operators can better understand the intricacies of the fuel system and ensure their machinery runs smoothly.

Deck and Blade Mechanism Explained

The cutting apparatus and its supporting framework are essential components of any lawn maintenance tool. Understanding how these elements interact can significantly enhance the performance and longevity of the equipment. This section delves into the functionality and design of the cutting deck and blade system.

The deck serves as the foundation that houses the cutting mechanism, providing stability and guiding the tool’s operation. Its structure is designed to facilitate efficient airflow, which is crucial for achieving a clean and even cut. The arrangement of the blades within the deck plays a vital role in determining the quality of the trimming.

The blades themselves are engineered to rotate at high speeds, creating a sharp and precise cutting action. They are typically positioned in a way that maximizes their efficiency, ensuring that grass is cut uniformly. Regular maintenance, including sharpening and alignment, is necessary to keep the blades in optimal condition.

Additionally, the height adjustment feature allows users to customize the cutting depth according to their specific lawn care needs. This flexibility is vital for adapting to varying grass types and seasonal growth patterns, ensuring that the tool remains effective throughout the year.

In summary, the relationship between the deck and blade mechanism is a critical aspect of lawn care equipment, influencing both performance and user satisfaction. Proper understanding and maintenance of these components will lead to a more effective and enjoyable mowing experience.

How to Identify Common Replacement Parts

Understanding how to recognize essential components in your equipment is crucial for effective maintenance and repairs. Identifying these elements not only ensures smooth operation but also extends the lifespan of your tools. Here, we will explore practical methods to help you pinpoint the most frequently replaced items.

Begin by consulting the user manual or documentation that came with your device. These resources often include illustrations and descriptions of the various components, making it easier to locate what you need. If you do not have the manual, many manufacturers provide digital versions on their websites.

Another effective method is to refer to online forums or communities where users share their experiences and insights. These platforms can provide valuable information on which components are most likely to wear out and how to replace them efficiently.

Lastly, consider creating a table to categorize common elements and their functions. This can serve as a quick reference guide when you need to make repairs. Below is an example of how such a table might be organized:

| Component Name | Description | Common Issues |

|---|---|---|

| Motor | Powers the tool’s functions | Overheating, failure to start |

| Battery | Supplies energy for operation | Decreased runtime, swelling |

| Blade | Cutting element for various materials | Dullness, chipping |

| Switch | Controls the power flow | Non-responsiveness, intermittent function |

By employing these strategies, you can efficiently identify and manage the most frequently needed components, ensuring your equipment remains in optimal working condition.

Maintenance Tips for Craftsman DLS 3500

Regular upkeep is essential to ensure the longevity and efficiency of your equipment. Proper maintenance not only enhances performance but also prevents unexpected breakdowns. Implementing a few key practices can significantly extend the lifespan of your machine.

- Routine Cleaning: Remove dust and debris after each use to prevent buildup that can hinder operation.

- Lubrication: Apply appropriate lubricants to moving parts regularly to minimize friction and wear.

- Check Belts and Blades: Inspect belts and cutting edges for signs of wear. Replace them as needed to maintain cutting efficiency.

- Monitor Electrical Components: Periodically examine wires and connections for damage or corrosion to ensure safe operation.

- Storage Conditions: Keep the equipment in a dry, temperature-controlled environment to protect it from moisture and temperature fluctuations.

Following these practices will help keep your machinery in optimal working condition, reducing the risk of repairs and ensuring reliable performance for years to come.