| Transmission |

Transfers power from the engine to the wheels, allowing for control over speed

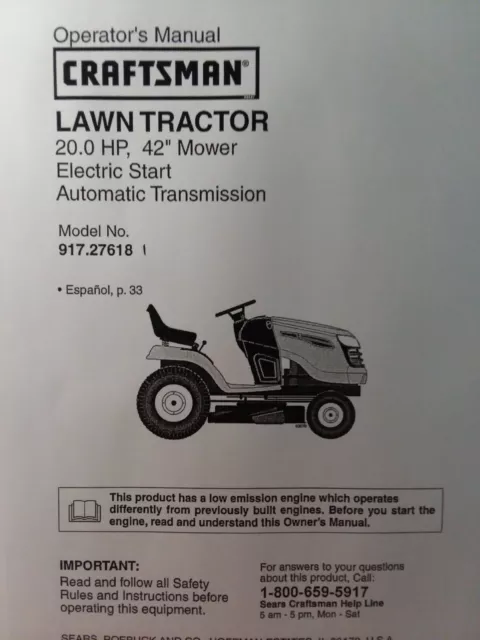

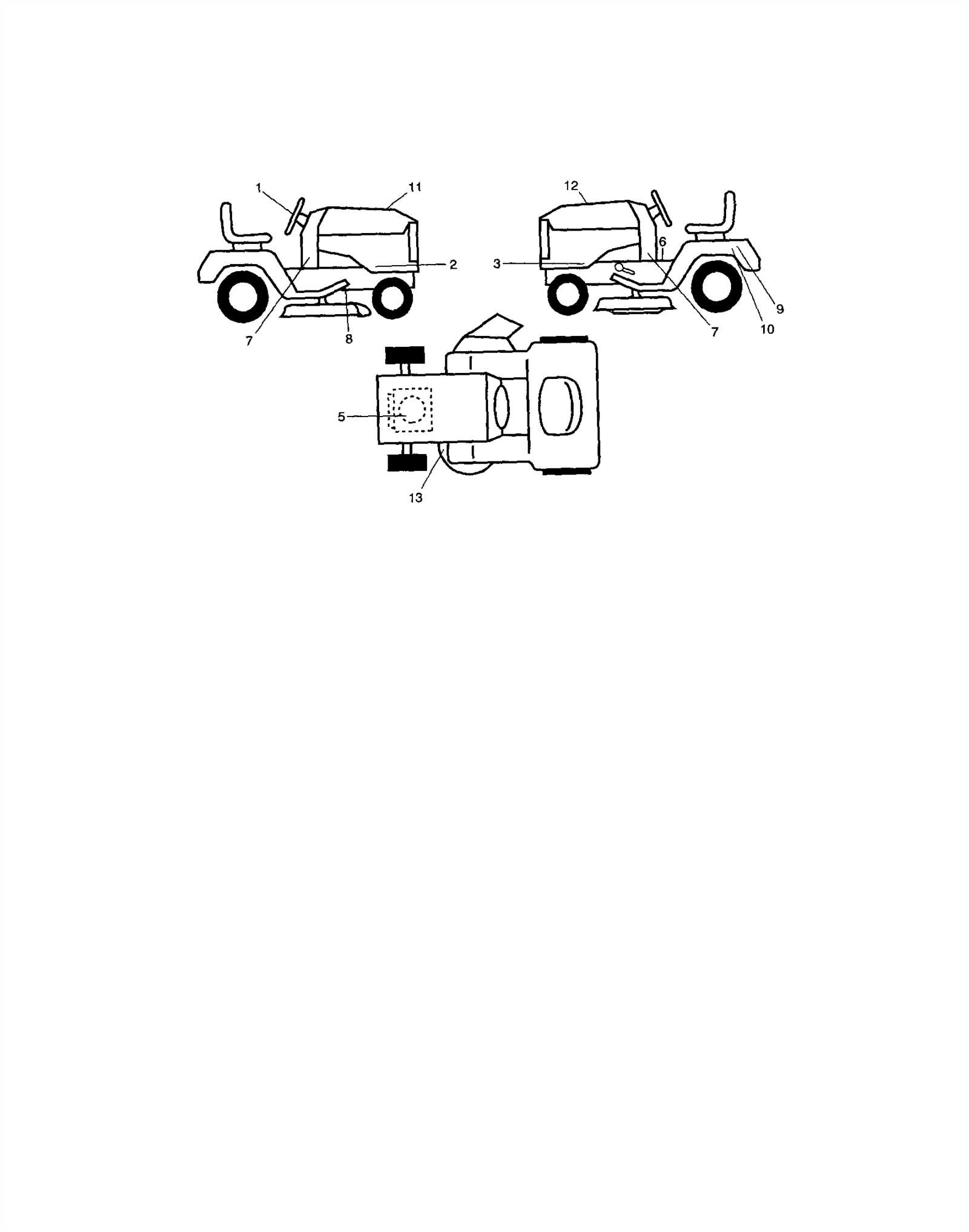

Identifying Key Components

Understanding the critical elements of the equipment is essential for proper operation and maintenance. By recognizing each part’s function and how it interacts with the overall system, you ensure both efficiency and safety in performance. This section will guide you through the primary components, helping you become more familiar with their roles and importance.

Main Structural Elements

The framework is built around several core structural elements that support the device. These include the base, frame, and mounting components, which provide stability and secure attachment of other crucial elements. The frame is engineered to handle significant stress while maintaining durability over time.

Operational Components

Key operational elements ensure the machinery runs smoothly. These include the motor, which powers the system, and various controls that manage speed, direction, and performance. Understanding how these mechanisms work together allows for efficient troubleshooting and optimization.

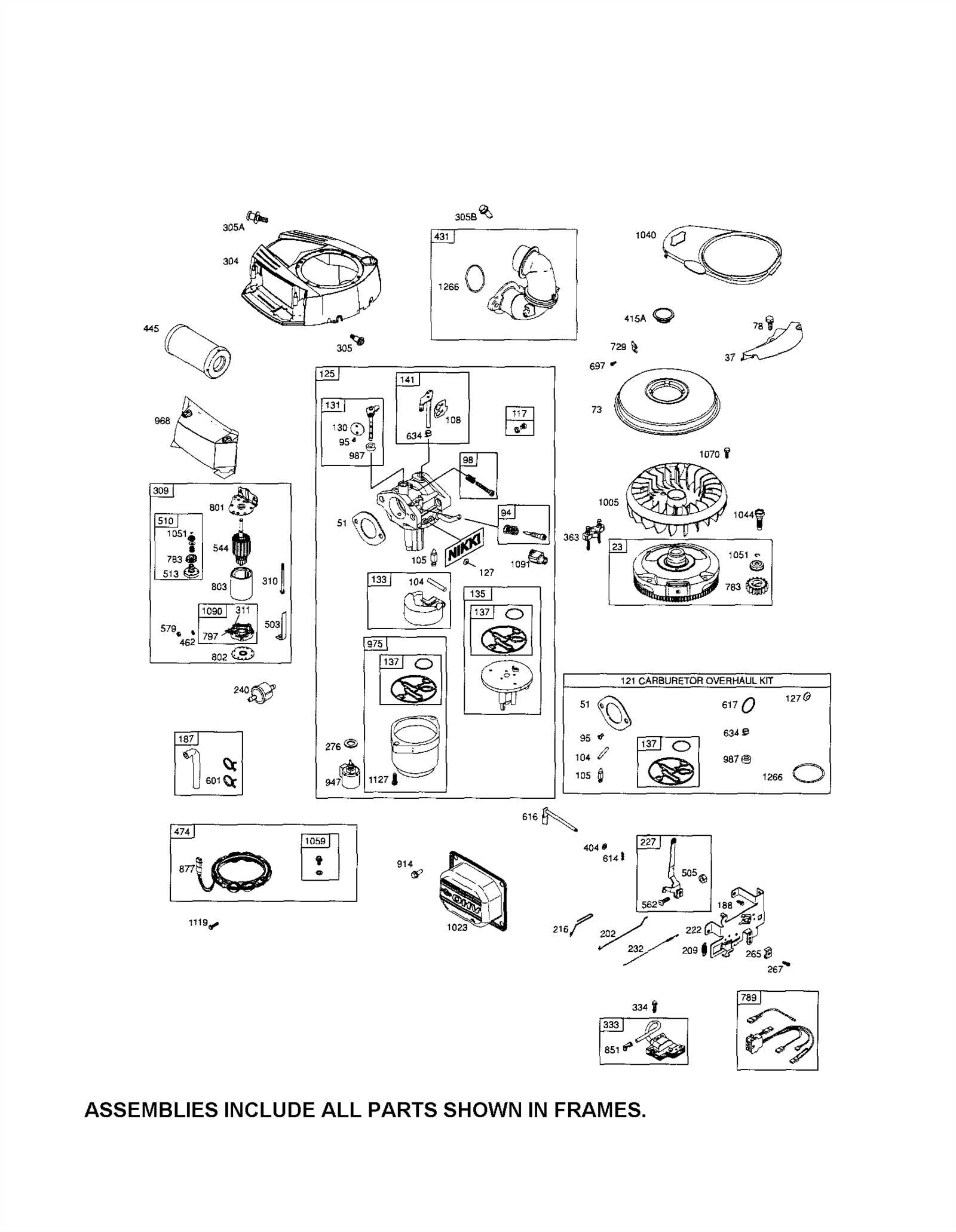

Understanding Functionality of Parts

To maintain smooth operation and prevent unexpected issues, it is essential to comprehend the role and interaction of individual elements within a machine. Each component plays a specific role, contributing to the overall performance. By recognizing how these elements work together, you can effectively troubleshoot and ensure longer durability.

Main Components and Their Roles

- Engine: Converts fuel into mechanical power, providing the energy required for operation.

- Transmission: Transfers power from the motor to the wheels, adjusting speed and torque.

- Blades: Responsible for cutting or processing materials, often requiring regular maintenance.

Essential Connections and Systems

- Drive system: Ensures the transmission of energy, connecting the engine with the drivetrain.

- Steering mechanism: Provides control over movement, allowing precision in navigation.

- Braking system: Guarantees safety by enabling quick stops and speed adjustments.

Understanding these crucial elements and their interrelations will enable efficient maintenance and timely repairs, preventing breakdowns and extending the operational life of the equipment.

Common Issues with LT2000 Components

Frequent malfunctions in riding equipment often occur due to wear or improper maintenance. Identifying these can help prevent more serious damage and extend the machine’s overall lifespan.

| Issue |

Description |

Possible Solution |

| Belt Slipping |

The drive belt may become loose, causing ineffective power transmission. |

Tighten or replace the belt to restore optimal performance. |

| Steering Difficulties |

Stiff or unresponsive steering can result from worn bearings or improper alignment. |

Inspect and lubricate the steering components, or replace faulty parts. |

| Engine Overheating |

Excess heat may arise due to clogged air filters or low oil levels. |

Regularly clean filters and ensure proper oil levels to maintain efficient cooling. |

Replacement Options for Damaged Parts

When certain elements of your equipment become worn out or malfunction, finding suitable substitutes is essential to maintaining functionality. Identifying compatible components can prolong the life of the machine, ensuring smooth performance and avoiding further issues. Exploring various replacement options allows you to keep the system in optimal working condition without unnecessary delays.

Alternative Solutions

There are several ways to source new components. You may opt for original manufacturer replacements, which guarantee a perfect fit, or consider compatible alternatives that offer similar quality at a lower cost. In some cases, used or refurbished items can be viable choices, especially if they have been properly inspected and tested.

Comparison of Replacement Choices

| Option |

Advantages |

Disadvantages |

| OEM Replacements |

Guaranteed compatibility, high quality |

Higher cost |

| Aftermarket Components |

Cost-effective, often widely available |

Potential for lower quality or fit |

Used or Ref

Maintenance Tips for Longevity

Regular upkeep of equipment ensures that it operates smoothly and extends its service life. Proper care minimizes wear and tear, leading to fewer repairs and better performance over time.

Cleaning and Lubrication

- Keep all moving components free of dirt and debris to avoid blockages.

- Lubricate essential parts periodically to prevent friction-related damage.

- Ensure that all connections are dry and clean, especially after exposure to moisture.

Inspection and Adjustment

- Examine the machine regularly for loose fasteners and secure them as needed.

- Check for signs of wear or damage, and replace any compromised elements immediately.

- Make necessary adjustments to settings to maintain optimal performance and safety.

Where to Find Genuine Parts

For ensuring the longevity and performance of your equipment, sourcing authentic components is crucial. These original pieces are designed specifically for your machine, guaranteeing compatibility and optimal functionality. Finding trusted suppliers is key to maintaining quality and avoiding unreliable alternatives.

Authorized Retailers and Websites

The most reliable way to obtain original replacements is through certified dealers or official online platforms. These outlets provide genuine products, often with warranties and customer support. Avoid generic sellers, as they may offer imitations that could compromise the efficiency of your device.

Repair Shops and Service Centers

Another dependable source for obtaining authentic components is through professional repair shops or service centers. These facilities often have direct access to original suppliers and can recommend the exact replacements needed. Consulting with them can also help in the proper installation of the new components, ensuring your equipment remains in top shape.

DIY Repairs for Common Problems

Maintaining equipment can extend its life significantly and prevent costly breakdowns. Regular troubleshooting allows you to identify issues early and fix them with simple home solutions. Understanding common malfunctions and knowing how to address them ensures your tools remain in optimal condition.

| Problem |

Solution |

| Engine won’t start |

Check the fuel level, inspect spark plugs, and ensure the ignition switch is functioning properly. Clean or replace plugs as needed. |

| Uneven cutting |

Ensure the cutting blades are sharp and aligned correctly. Tighten or adjust the blade height for an even cut. |

| Excessive vibration |

Inspect the equipment for loose components or unbalanced wheels. Tighten bolts and ensure everything is properly secured. |

| Slow operation |

Lubricate the moving parts and check for blockages that could be restricting movement. Cleaning and regular maintenance can improve performance. |

Comparative Analysis of Alternatives

When evaluating mechanical devices from different manufacturers, it is essential to consider various factors such as durability, performance, and maintenance needs. The availability of replacement elements, ease of repair, and overall cost efficiency are key aspects that can influence the choice of one model over another.

| Alternative |

Durability |

Performance |

Maintenance |

Cost Efficiency |

| Model A |

High |

Excellent |

Low |

Moderate |

| Model B |

Moderate |

Good |

Moderate |

High |

| Model C |

Low |

Average |

High |

Low |

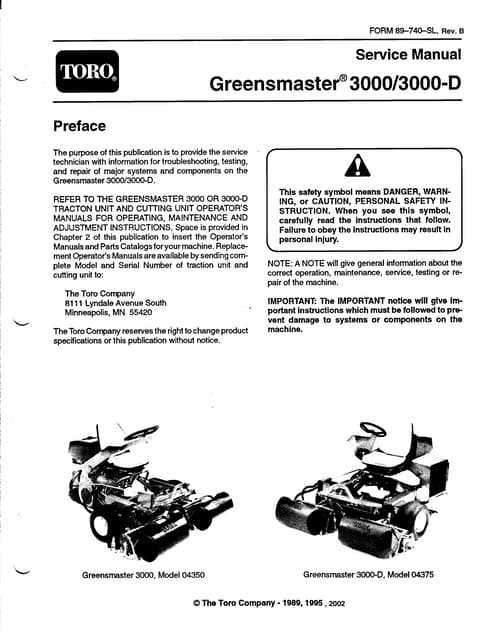

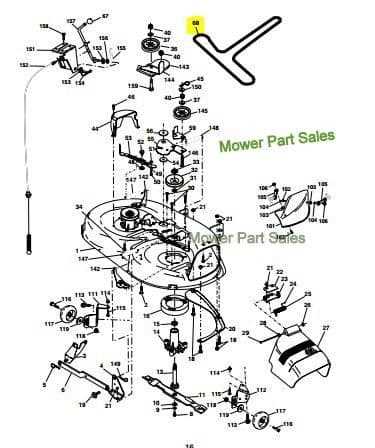

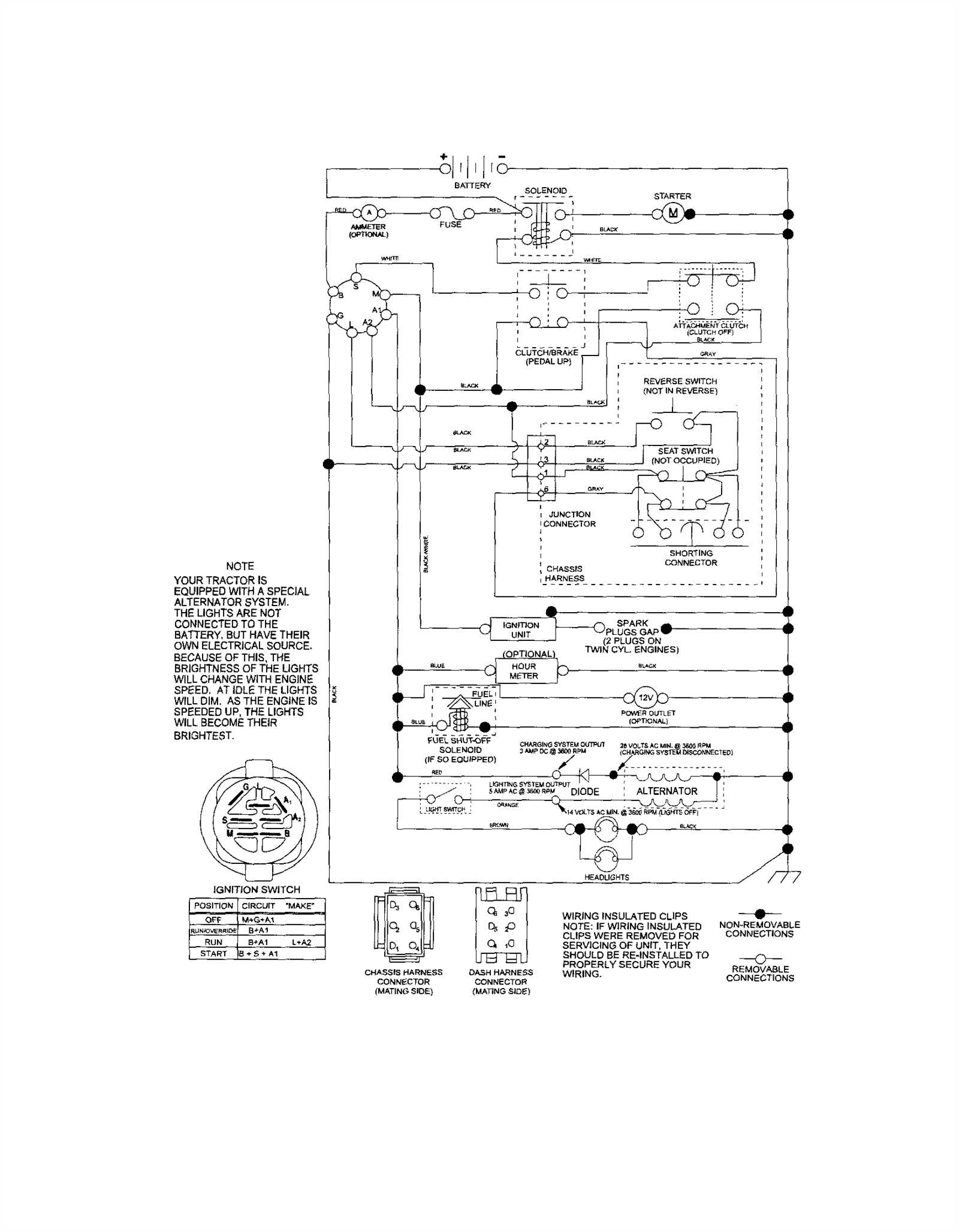

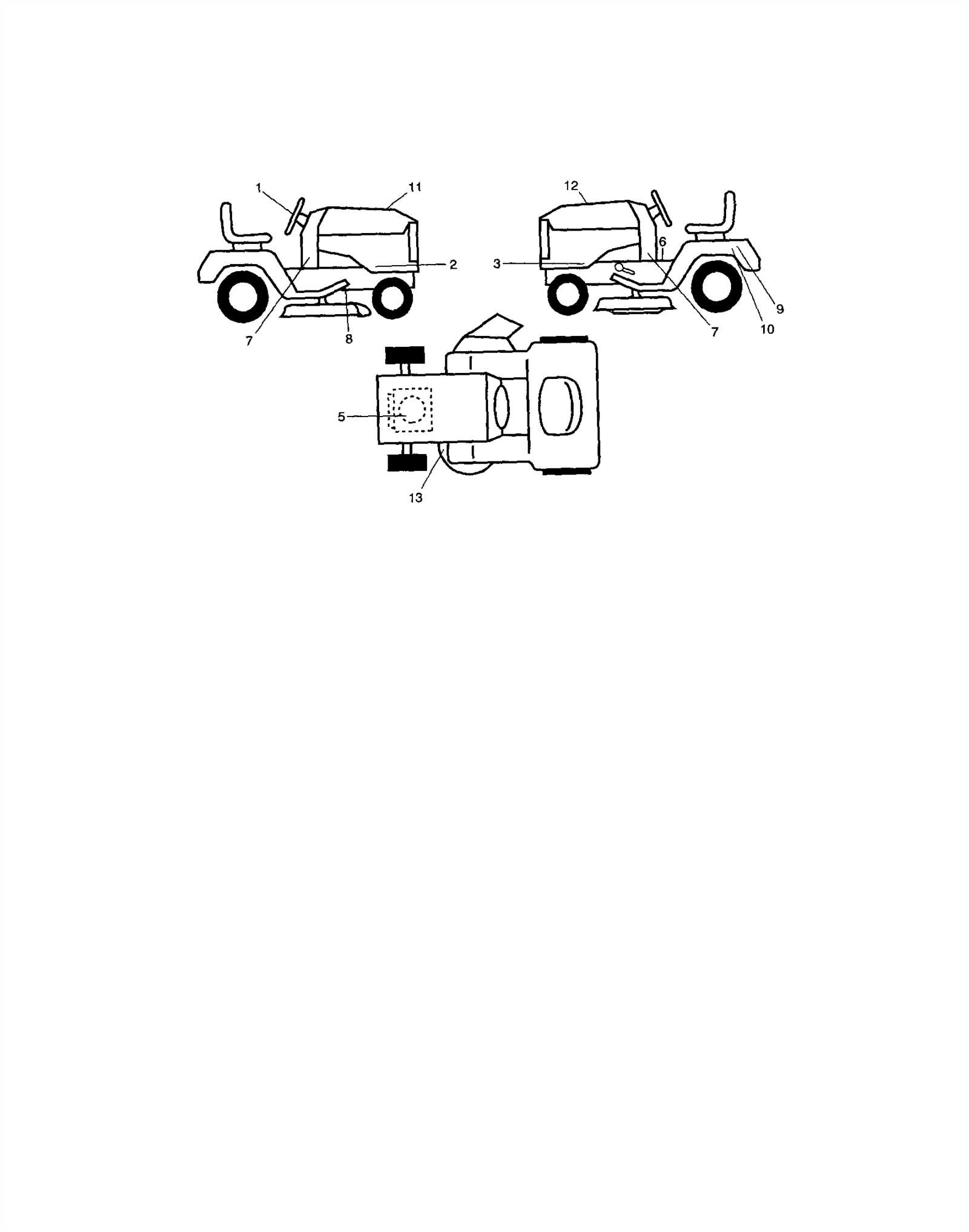

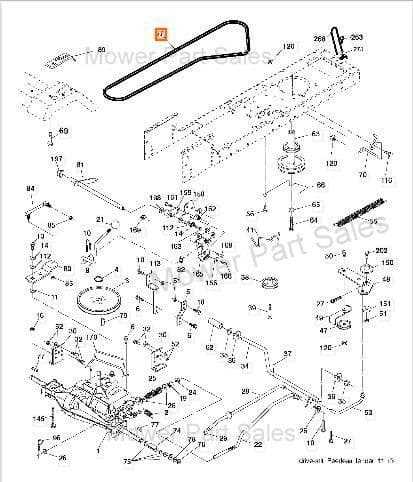

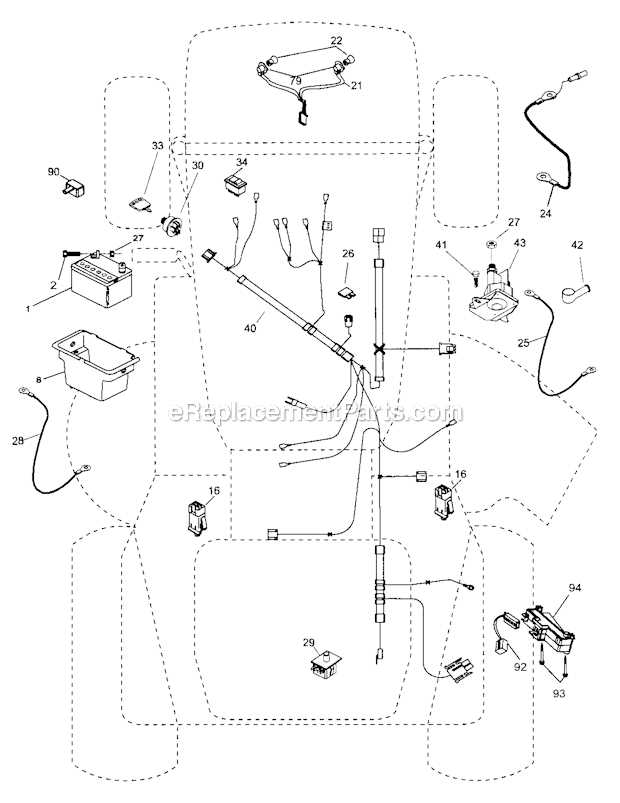

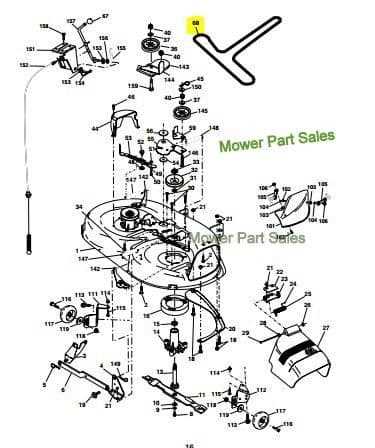

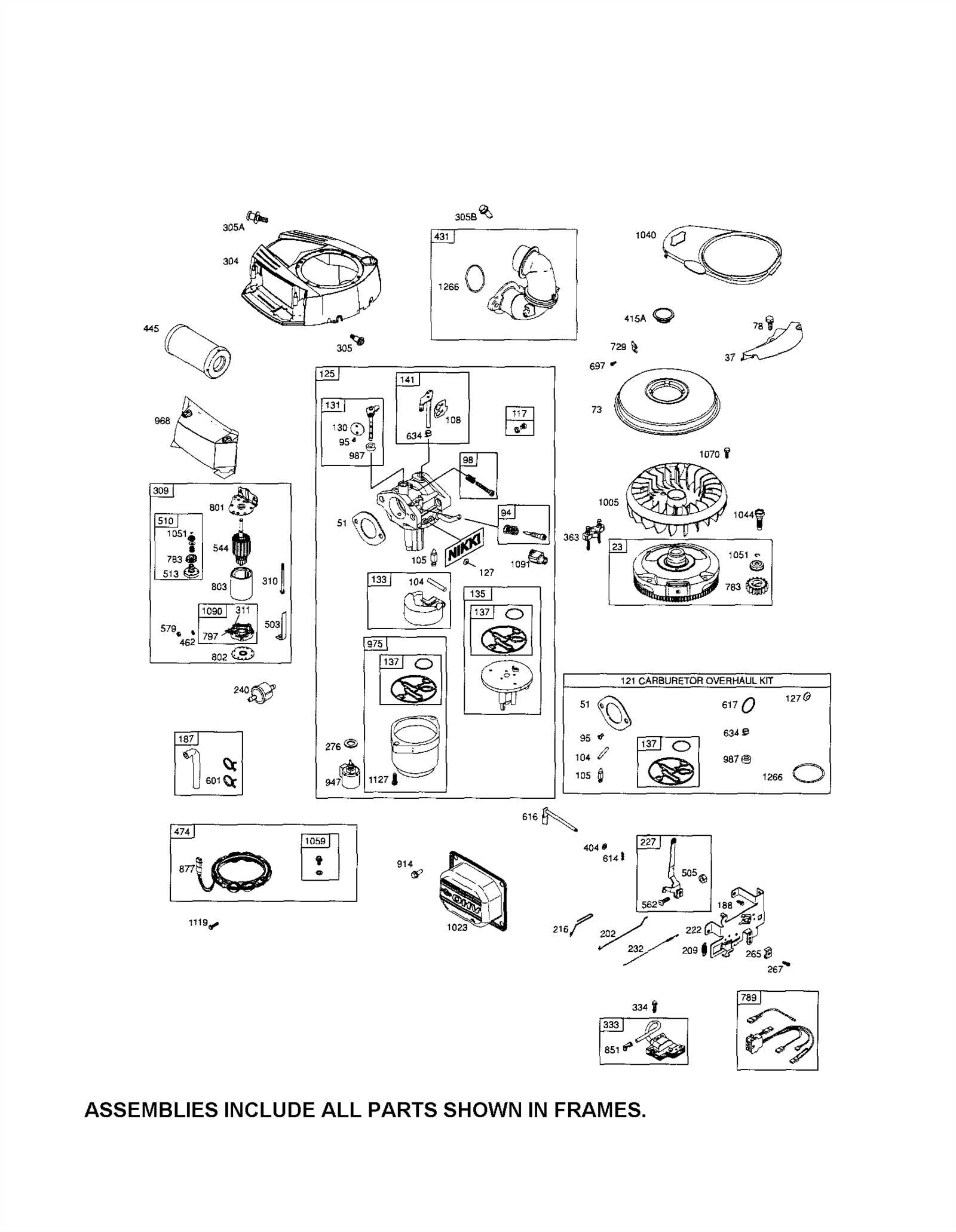

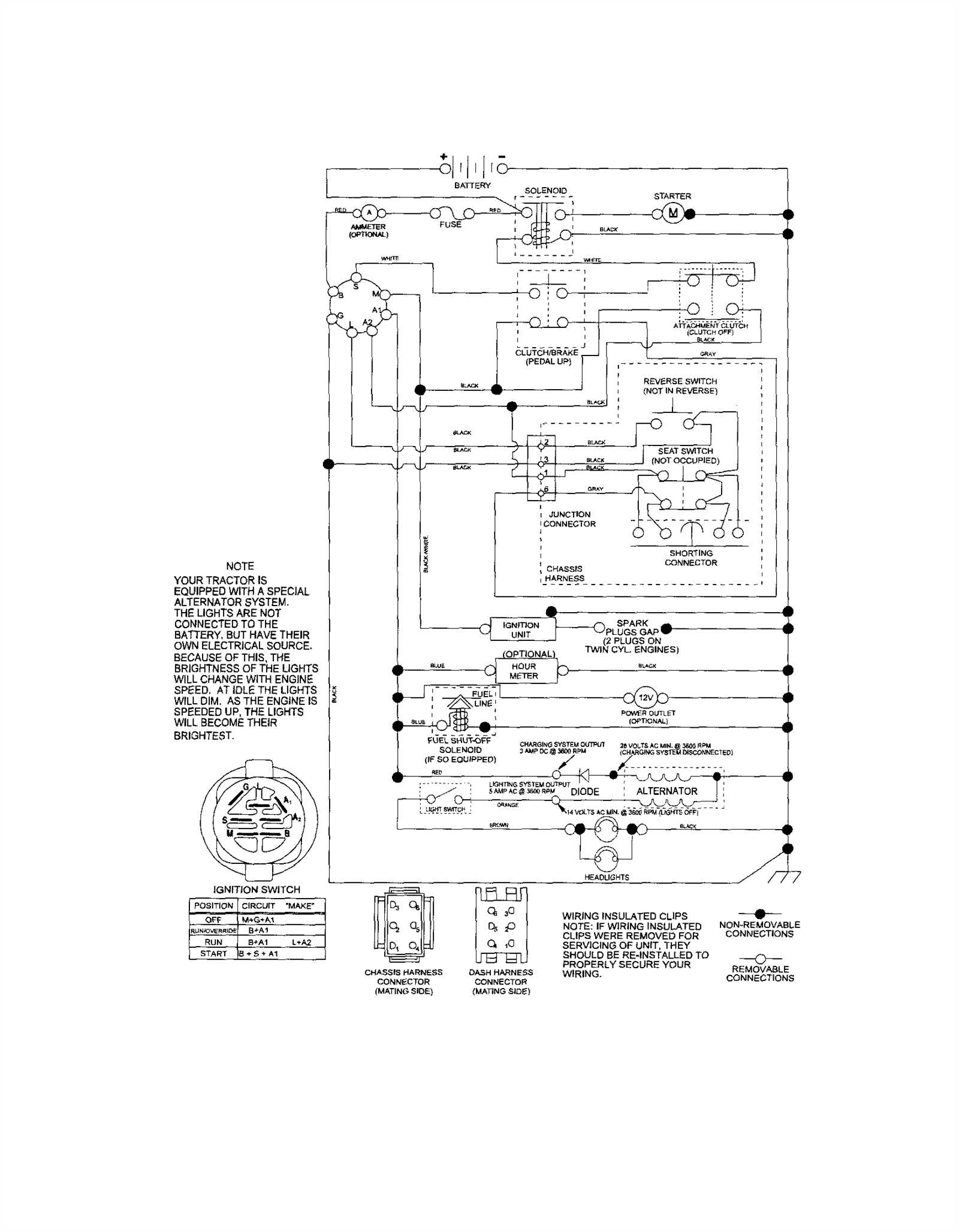

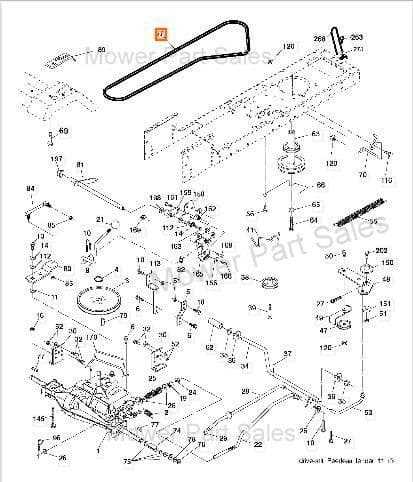

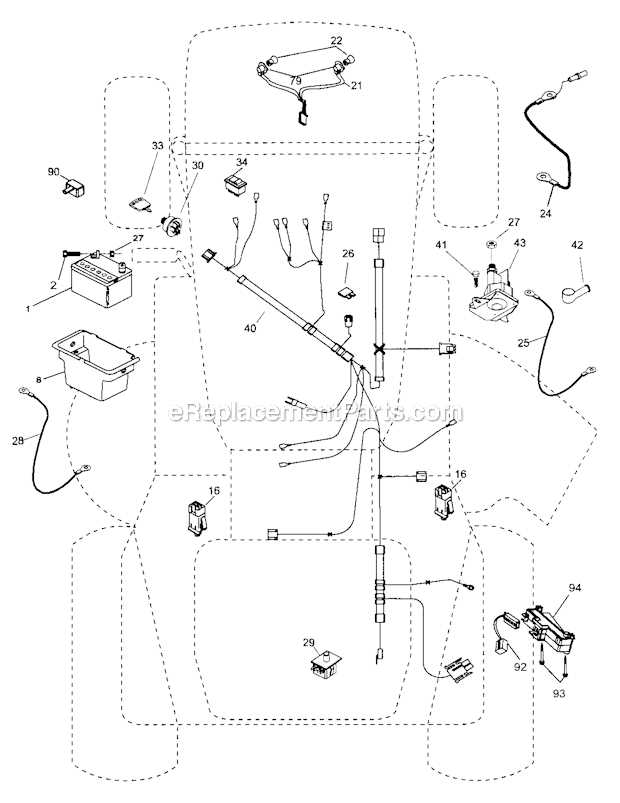

Visual Guide to Assembly

This section provides an overview of the assembly process, illustrating the essential components and their interconnections. By following these visual cues, users can achieve a seamless construction experience.

Key Components

- Base Structure

- Support Frames

- Connecting Rods

- Operational Mechanisms

- Fasteners

Assembly Steps

- Begin with the base structure, ensuring it is placed on a stable surface.

- Attach the support frames to the base, aligning them properly.

- Connect the rods, securing them with appropriate fasteners.

- Integrate the operational mechanisms, making sure they function smoothly.

- Perform a final check to ensure all components are securely assembled.

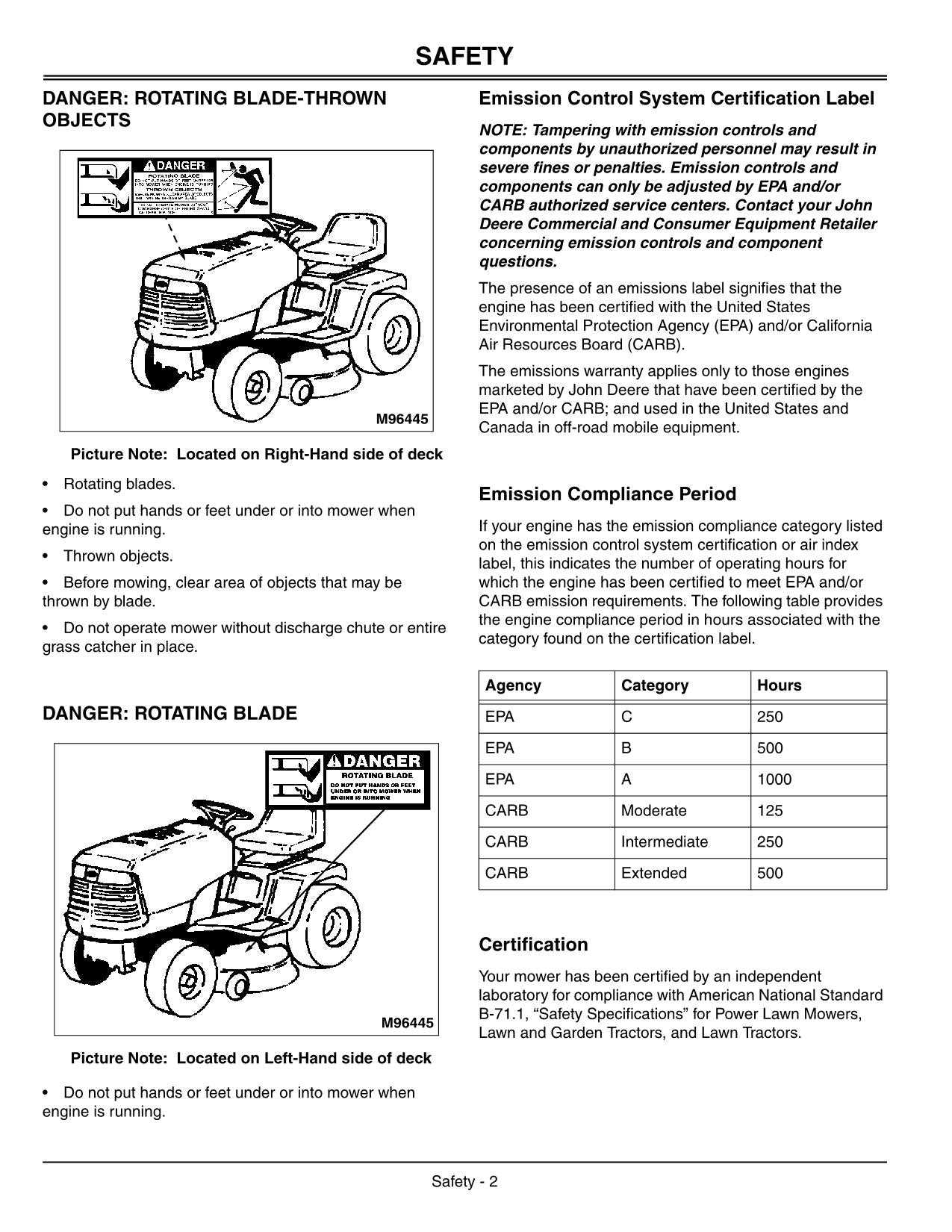

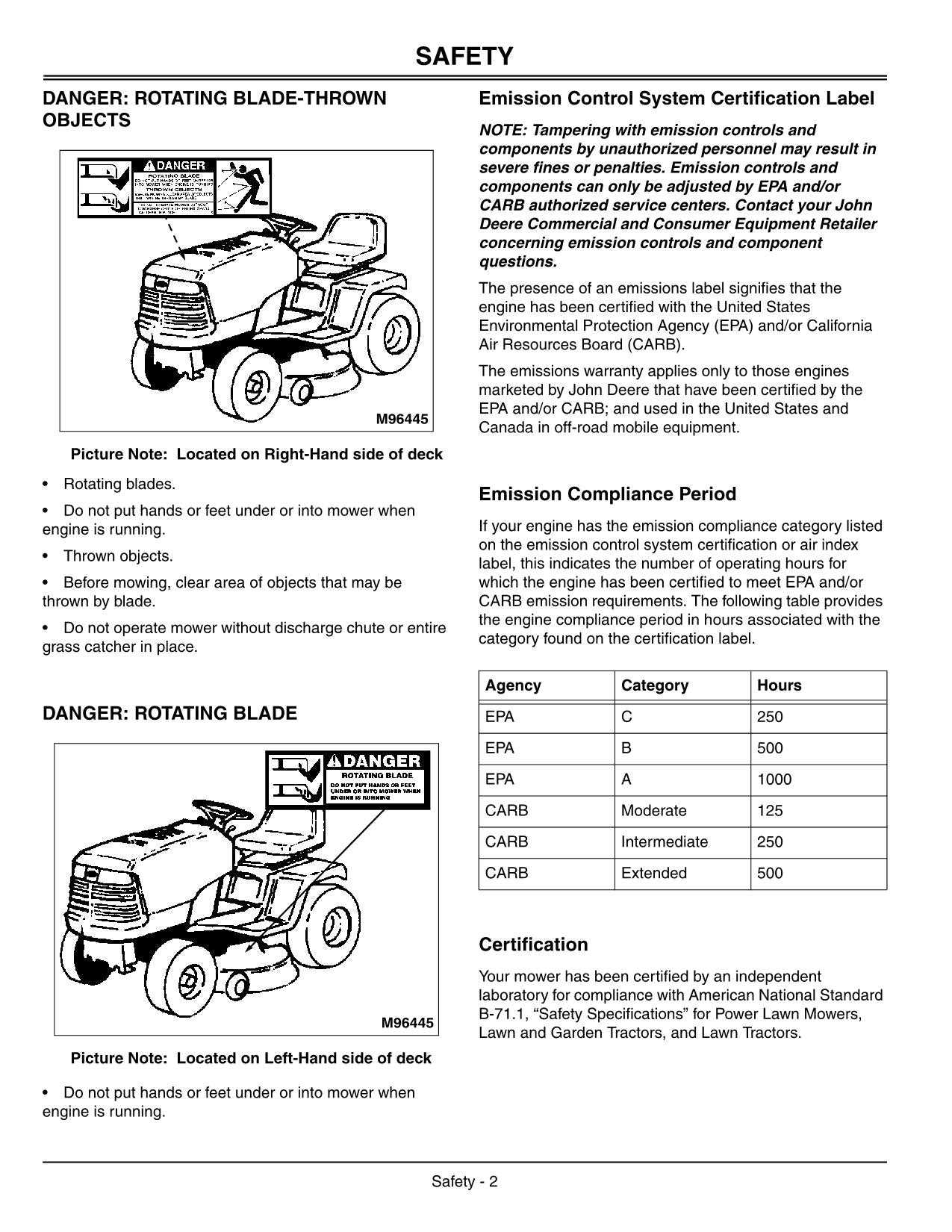

Safety Precautions When Handling Components

Ensuring safety while managing equipment elements is crucial for preventing injuries and accidents. Proper techniques and awareness can significantly reduce risks during maintenance or assembly tasks.

General Guidelines

- Always wear appropriate protective gear, such as gloves and goggles.

- Maintain a clean and organized workspace to minimize hazards.

- Be aware of your surroundings and avoid distractions while working.

- Follow the manufacturer’s recommendations for handling and installation.

Specific Safety Measures

- Inspect all components for damage before use.

- Utilize tools that are suitable for the task to prevent accidents.

- Ensure that all equipment is powered off and disconnected when making adjustments.

Frequently Asked Questions about LT2000

This section addresses common inquiries regarding the specific model, providing clarity on its features, maintenance, and operational guidelines.

General Inquiries

Many users seek information about the basic functionalities and best practices for utilizing the equipment effectively. Understanding these aspects can enhance performance and prolong lifespan.

Maintenance and Troubleshooting

Regular upkeep is essential for optimal performance. Below are some common issues and solutions:

| Issue |

Solution |

| Difficulty starting |

Check fuel levels and battery connections. |

| Uneven operation |

Inspect for blockages and ensure all components are securely attached. |

| Excessive noise |

Examine for loose parts or worn-out components. |

|

|