When it comes to maintaining and optimizing your machinery, a clear understanding of its individual elements is crucial. Whether you are a novice user or an experienced technician, having a visual representation of the various components can greatly enhance your ability to troubleshoot and repair.

This guide aims to provide insight into the essential elements of a specific type of equipment, highlighting how each component contributes to its overall functionality. By exploring this intricate network of parts, you can gain a deeper appreciation for the mechanics at play.

In addition, knowing the layout of your machinery allows for more efficient repairs and upgrades, ultimately prolonging its lifespan and improving performance. Delve into this essential knowledge to ensure that your operations run smoothly and effectively.

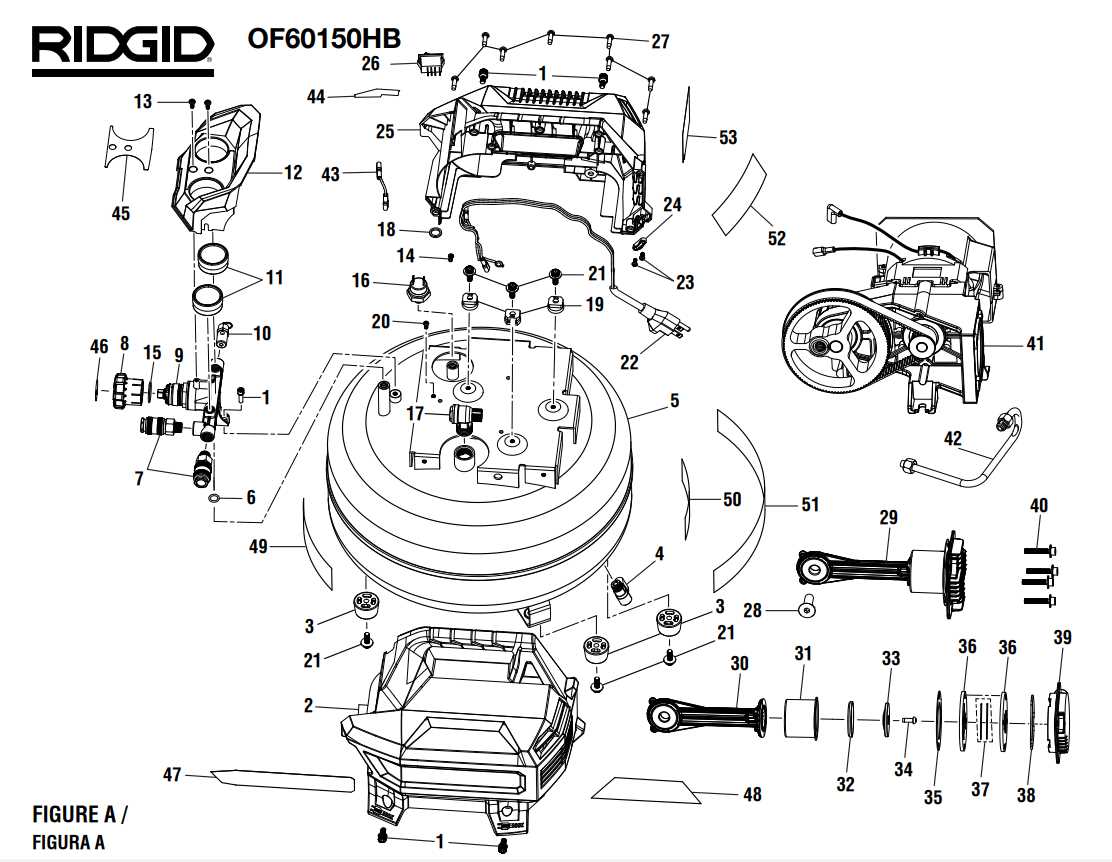

Bostitch 6 Gallon Air Compressor Overview

This powerful machine is designed for a variety of tasks, making it an essential tool for both professionals and DIY enthusiasts. With its robust construction and efficient performance, it stands out in the market for its reliability and versatility. Users can expect impressive results whether tackling simple household projects or more demanding industrial applications.

Features include a compact design that enhances portability, allowing for easy transportation from one job site to another. The efficient motor provides quick recovery times, ensuring that users can maintain workflow without unnecessary delays. Additionally, the unit operates quietly, making it suitable for environments where noise levels must be minimized.

Maintenance is straightforward, with accessible components that simplify servicing. The durable materials used in its construction contribute to longevity, providing users with a dependable option for their pneumatic needs. Overall, this equipment represents a solid investment for anyone looking to enhance their tool collection.

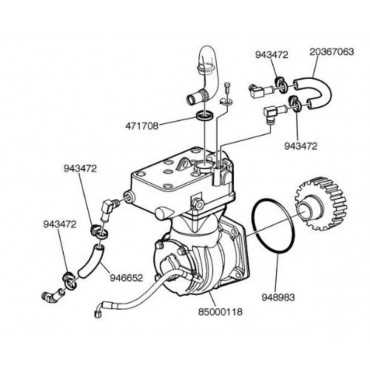

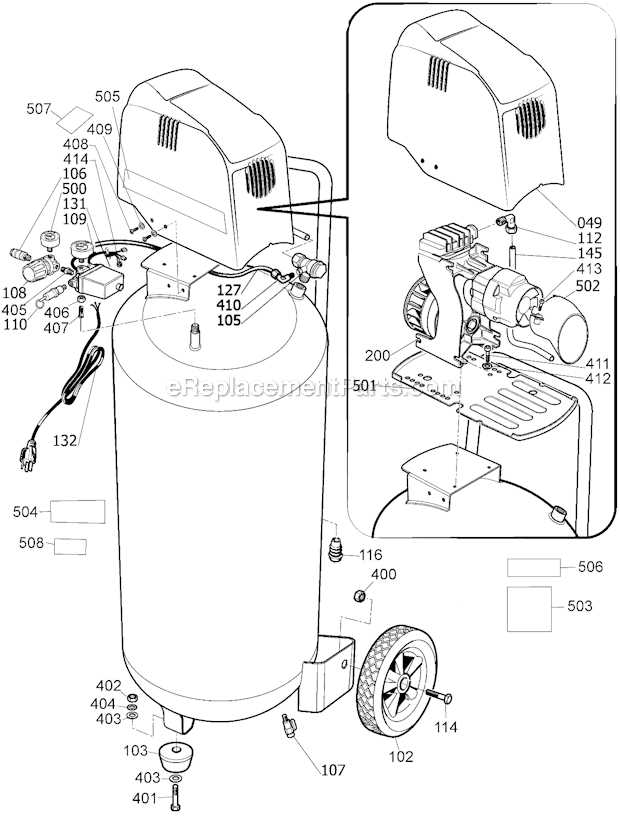

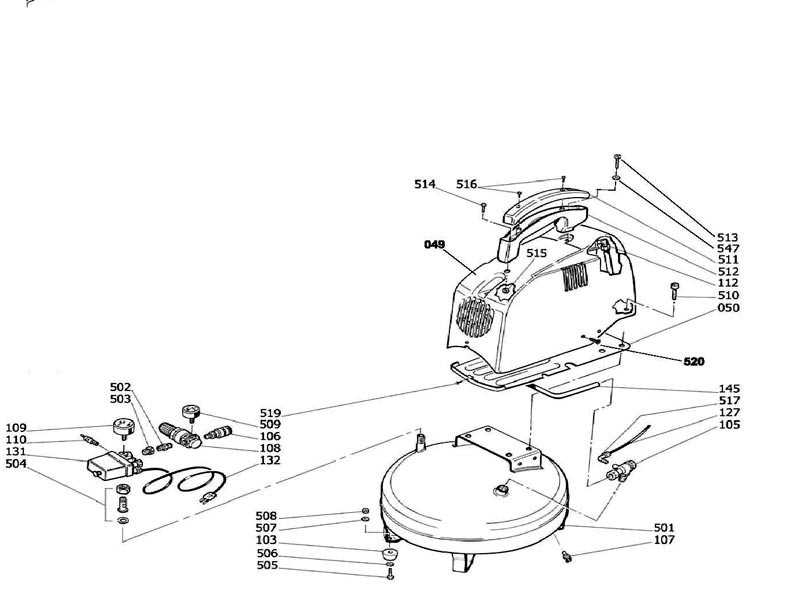

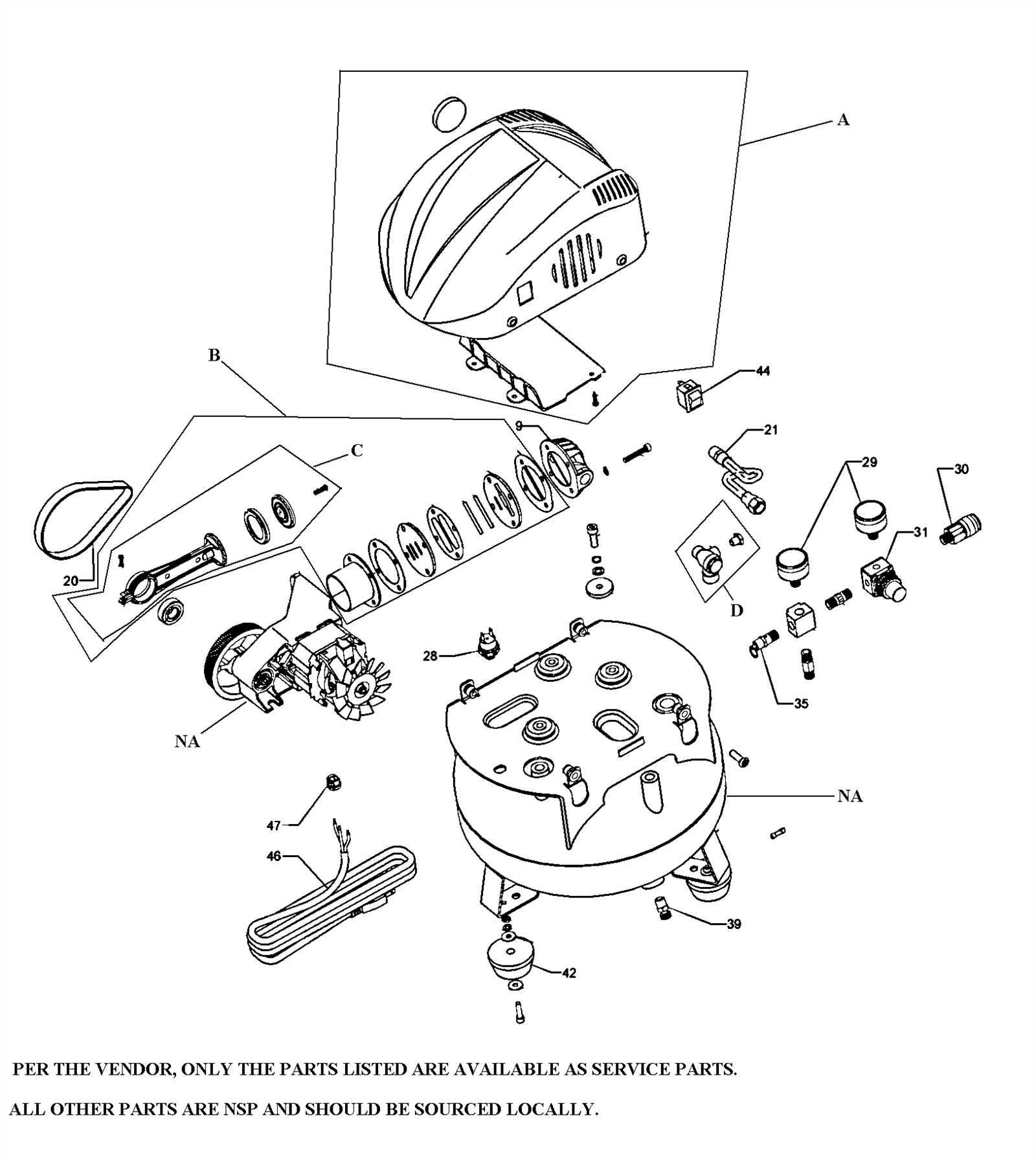

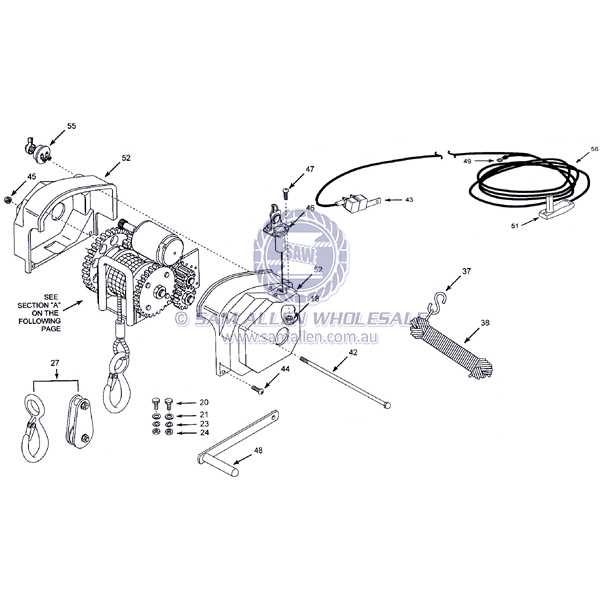

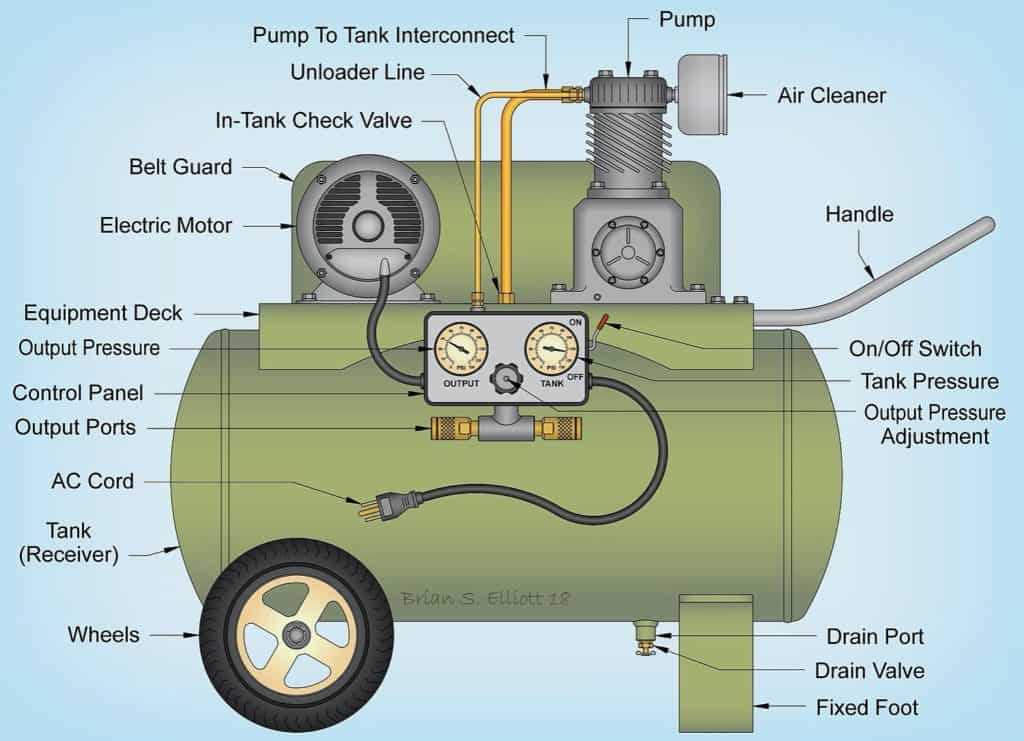

Understanding Air Compressor Diagrams

Grasping the layout of these machines is essential for effective maintenance and troubleshooting. By examining the visual representations, one can identify the various components and their functions within the system. This knowledge enhances the user’s ability to perform repairs and upgrades with confidence.

Typically, these illustrations provide a detailed view of the unit’s structure, showcasing elements such as valves, tanks, and motors. Each part is labeled clearly, allowing for easy reference and understanding. Familiarity with these visuals can ultimately lead to improved performance and longevity of the equipment.

Additionally, recognizing the arrangement of components can aid in diagnosing issues that may arise during operation. By following the schematic, users can quickly pinpoint areas that require attention, facilitating more efficient problem-solving. Overall, a solid comprehension of these layouts empowers users to maintain their machinery effectively.

Key Components of Bostitch Compressors

Understanding the essential elements of these machines is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficiency and reliability in various applications.

- Motor: The driving force that powers the entire unit, converting electrical energy into mechanical energy.

- Pump: Responsible for compressing the air and increasing its pressure, this part is vital for the machine’s functionality.

- Tank: Stores the compressed substance, providing a reserve that enables consistent output during operation.

- Regulator: Controls the pressure level, ensuring that the output meets the specific requirements of tools and equipment.

- Pressure Gauge: Displays the current pressure level, allowing users to monitor and adjust settings as needed.

- Safety Valve: Prevents over-pressurization by releasing excess pressure, ensuring safe operation.

- Hoses and Fittings: Facilitate the transfer of the compressed substance to tools, playing a key role in the overall functionality.

Each of these components is designed to work in harmony, contributing to the overall efficiency and durability of the unit. Regular maintenance and awareness of these elements can significantly enhance performance and extend the lifespan of the machine.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your equipment. Regular attention to specific components can greatly enhance performance and reliability.

- Check and clean filters frequently to prevent blockages.

- Inspect hoses for wear and replace them if necessary.

- Regularly lubricate moving parts to reduce friction.

- Monitor pressure levels to ensure they remain within recommended ranges.

- Store the unit in a dry environment to avoid rust and corrosion.

By following these practices, you can significantly improve efficiency and prolong the lifespan of your machinery.

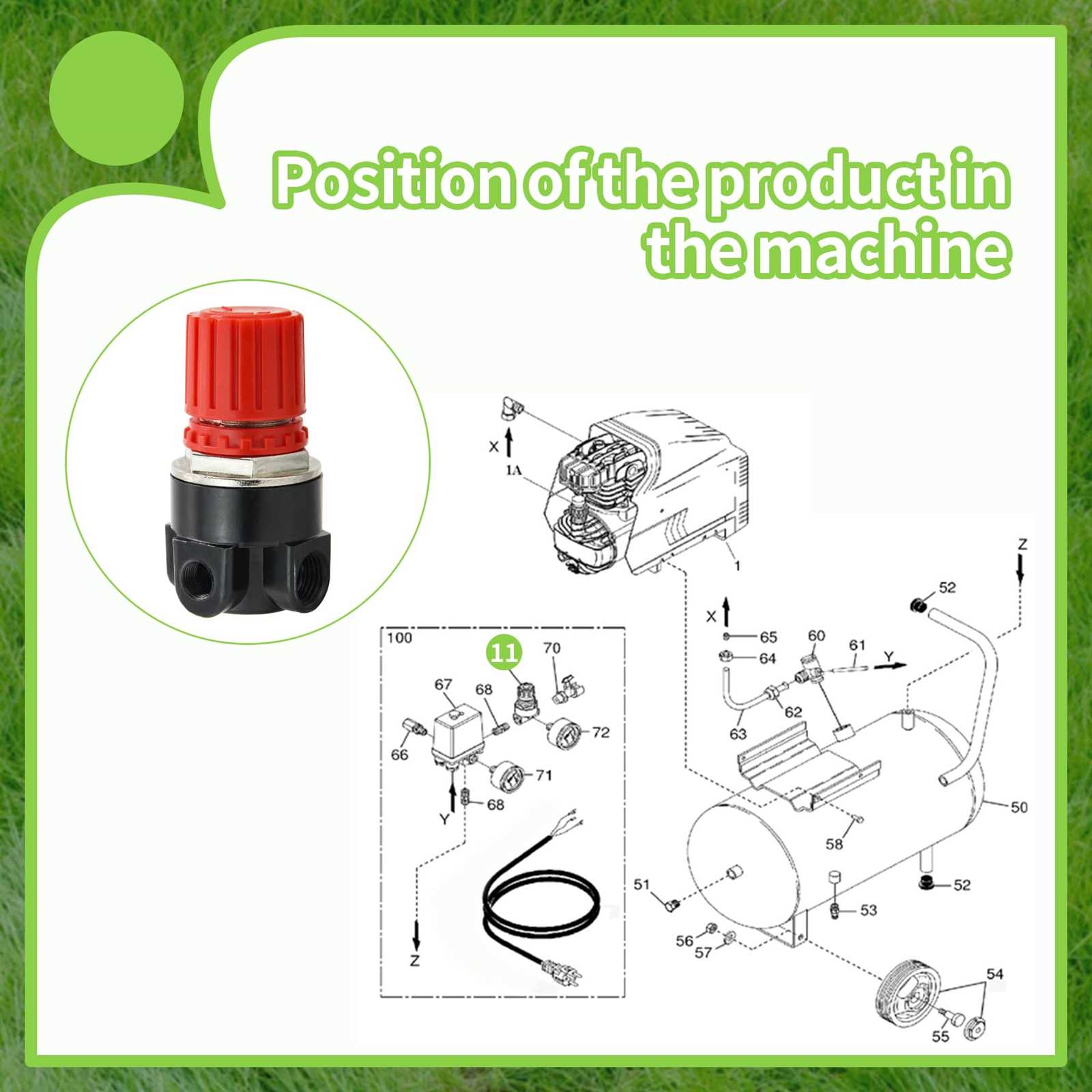

Common Replacement Parts Explained

Understanding the essential components of machinery is crucial for effective maintenance and longevity. This section highlights key elements that often require replacement over time, ensuring optimal performance and reliability.

Pressure Switch: This component regulates the system’s pressure, turning the unit on and off as needed. A malfunction can lead to inconsistent operation.

Air Filter: Essential for keeping contaminants out of the system, a clean filter is vital for efficiency. Regular checks and replacements are recommended to maintain airflow.

Safety Valve: This mechanism prevents excessive pressure build-up, ensuring safe operation. If faulty, it poses a risk, making timely replacements essential.

Hoses: Durable hoses are necessary for efficient transfer of compressed air. Over time, wear and tear can lead to leaks, requiring prompt attention.

Regulator: This part controls the output pressure of the system. A damaged regulator can affect performance, necessitating immediate replacement.

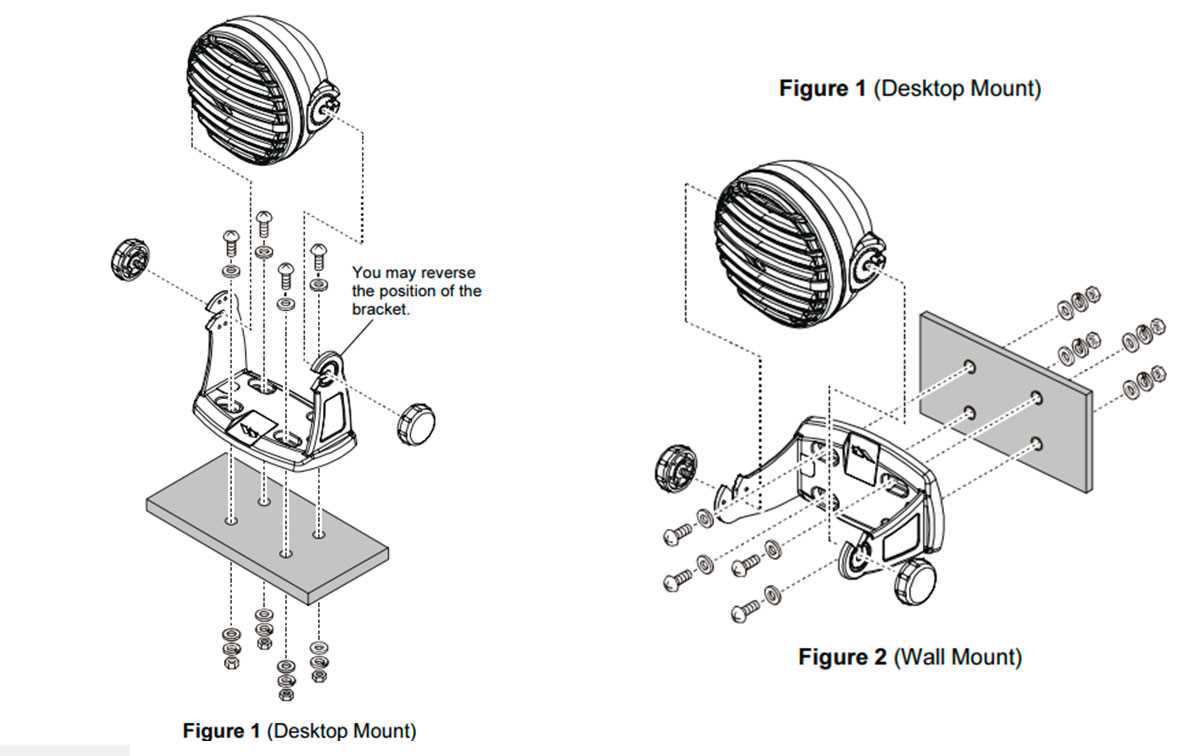

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective assembly and maintenance. These illustrations provide an organized way to identify each element, ensuring you can accurately comprehend how everything fits together.

Identifying Key Symbols

Familiarizing yourself with common symbols used in these visuals can greatly enhance your comprehension. Often, each symbol corresponds to specific functions or types of components.

Using a Reference Table

| Symbol | Description |

|---|---|

| Fastener | |

| Tool | |

| ⚙️ | Gear |

Referencing such tables while studying the illustrations can provide clarity and improve your overall understanding of the assembly process.

Troubleshooting Common Issues

Identifying and resolving typical challenges is essential for maintaining optimal functionality of your equipment. Many problems can arise due to various factors, and understanding these can significantly enhance performance and longevity.

Low Pressure Output

If the pressure seems inadequate, first check for any leaks in the hoses or fittings. Ensure that all connections are secure and inspect the seals for wear. Additionally, examine the intake filter; a clogged filter can restrict airflow and lead to diminished pressure.

Excessive Noise Levels

Unusual sounds may indicate underlying issues. Examine the mounting bolts for tightness, as loose components can create vibrations. Furthermore, inspect the motor and belts; any signs of damage or misalignment could contribute to increased noise levels. Regular maintenance is crucial for preventing these concerns.

Safety Precautions for Users

Ensuring safety while operating machinery is essential to prevent accidents and injuries. Users must adhere to specific guidelines to maintain a secure environment during usage. Awareness of potential hazards and proper handling techniques is key to a safe experience.

| Precaution | Description |

|---|---|

| Read the Manual | Familiarize yourself with the user manual to understand operational guidelines and safety measures. |

| Wear Protective Gear | Use safety goggles, gloves, and ear protection to safeguard against noise and debris. |

| Check for Damage | Inspect equipment for any signs of wear or damage before use to ensure functionality. |

| Maintain Ventilation | Operate in a well-ventilated area to avoid inhaling fumes or vapors. |

| Keep Area Clear | Maintain a tidy workspace, free from obstacles that could cause trips or falls. |

Where to Find Replacement Parts

Finding suitable components for your equipment can be a challenging task, but there are numerous resources available to assist you. Understanding where to look and how to source quality items is essential for maintaining optimal functionality.

Online Retailers

Many online platforms specialize in providing a vast selection of components. Here are some popular options:

- Dedicated hardware websites

- General e-commerce sites with extensive inventories

- Specialized stores that focus on specific brands

Local Stores

Visiting local retailers can be beneficial for immediate needs. Consider these places:

- Home improvement centers

- Automotive supply shops

- Independent tool retailers

By exploring both online and local resources, you can ensure you find the components you need for efficient repairs and maintenance.

Comparing Bostitch Models

This section focuses on the differences and similarities between various models from the brand. Understanding these distinctions can help users make informed decisions based on their specific needs and applications. Whether it’s for DIY projects or professional use, knowing the right features can enhance performance and efficiency.

| Model | Power Output | Weight | Noise Level | Max Pressure |

|---|---|---|---|---|

| Model A | 1.5 HP | 30 lbs | 70 dB | 125 PSI |

| Model B | 2.0 HP | 35 lbs | 68 dB | 150 PSI |

| Model C | 1.0 HP | 25 lbs | 75 dB | 100 PSI |

Each model offers unique advantages tailored to different tasks. Users should evaluate the specifications against their requirements to determine which option best suits their project goals.

Upgrades and Modifications Available

Exploring enhancements and adjustments can significantly elevate performance and functionality. Many enthusiasts seek to optimize their equipment for specific tasks, ensuring that they meet ultimate demands in various projects.

Upgraded Pressure Regulators: Replacing the standard regulator with a high-performance model can improve pressure consistency and response time.

Advanced Filter Systems: Implementing superior filtration can extend the life of the machinery and enhance output quality, particularly for sensitive applications.

Additional Storage Options: Integrating larger tanks or supplementary storage can provide extended operational time, minimizing interruptions during use.

Sound Dampening Modifications: Adding insulation or noise-reducing features can create a more pleasant working environment, especially in residential areas.

Performance Monitoring Tools: Incorporating digital gauges or monitoring systems allows users to track performance metrics in real-time, aiding in maintenance and efficiency improvements.

FAQs About Bostitch Compressors

This section addresses common inquiries regarding a popular brand of portable pressure tools. Understanding these machines can help users optimize their performance and maintenance practices.

Common Questions

- What should I do if my unit won’t start?

- How often should I perform maintenance on my device?

- Can I use it for multiple tasks simultaneously?

- What is the optimal pressure setting for various applications?

Maintenance and Troubleshooting

- Regularly check and replace the oil if applicable.

- Inspect the air filter and clean or replace as needed.

- Ensure all connections are secure to avoid leaks.

- Store in a dry place to prevent corrosion and damage.

For further assistance, consult the user manual or contact customer support for detailed guidance tailored to specific models.