Maintaining outdoor tools in top condition often requires a thorough understanding of their inner workings. Each device is designed with precision, comprising various elements that work in harmony to ensure efficient operation. By becoming familiar with the core components, users can better address any issues that may arise over time.

The intricate assembly of such equipment includes numerous mechanical and electrical elements. Knowing how these pieces fit together is essential for anyone looking to carry out repairs or replacements effectively. This guide will explore the main elements, shedding light on their role in maintaining overall performance.

With the right knowledge, you’ll find it easier to troubleshoot any challenges that may occur during the lifespan of your equipment. Clear understanding ensures that all necessary replacements or adjustments can be performed accurately, prolonging the device’s efficiency and usability.

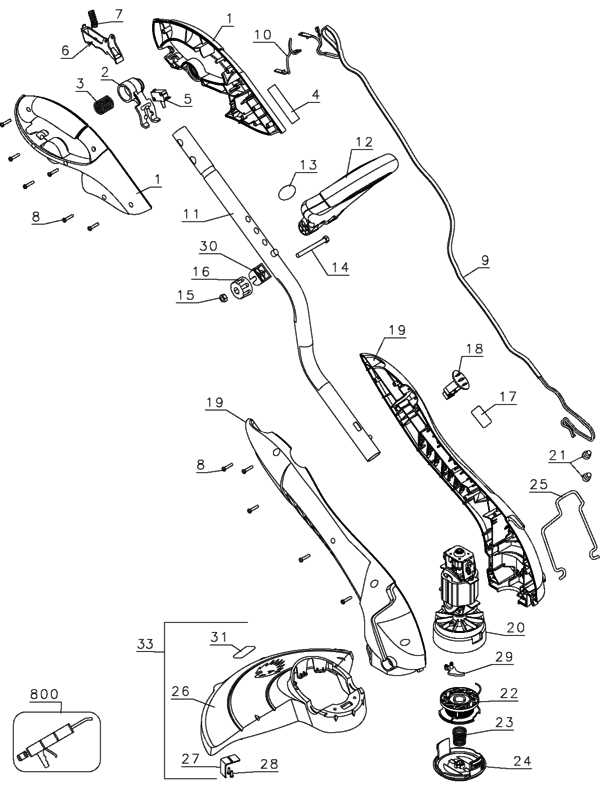

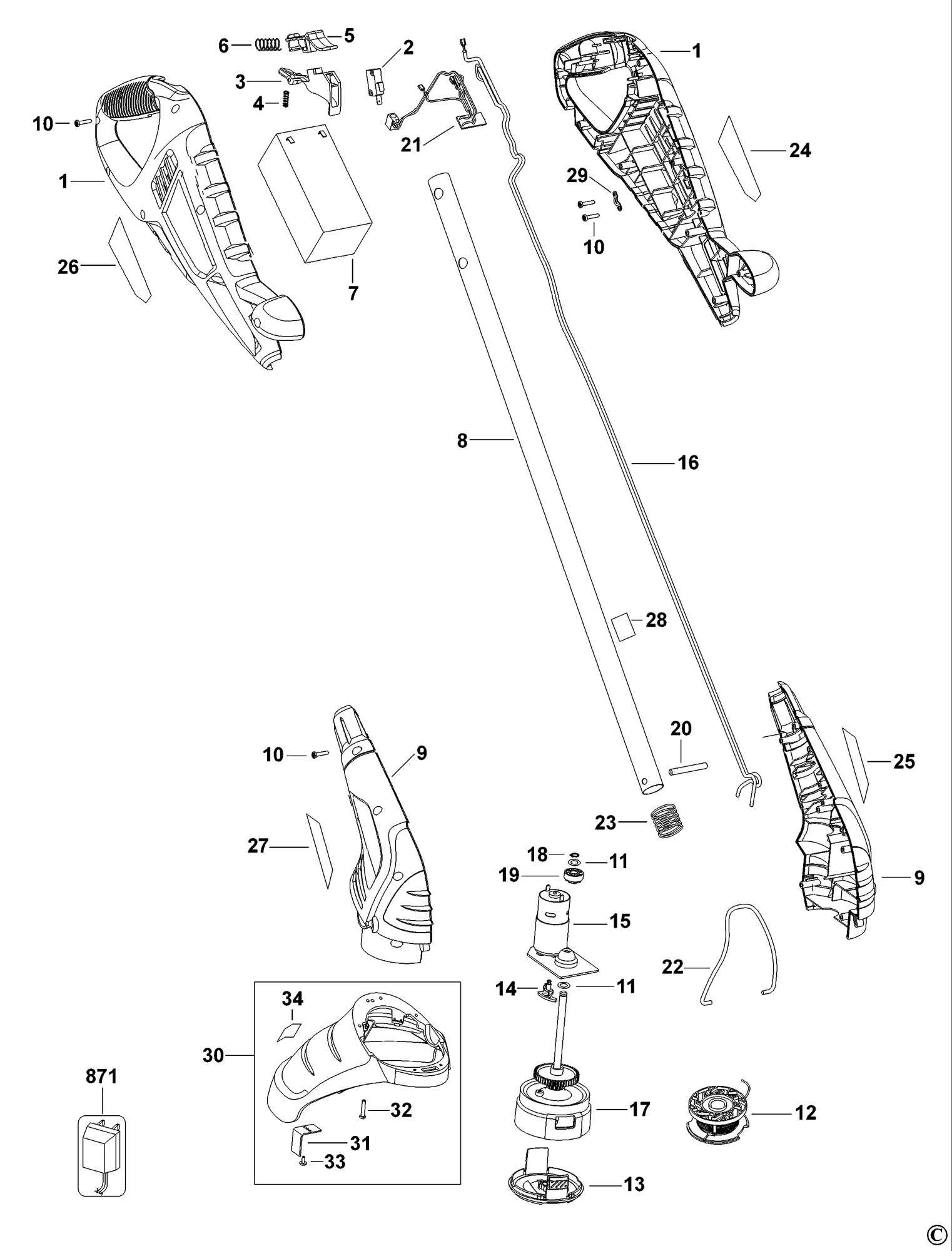

Overview of Black and Decker GH900 Components

The structure of this electric trimmer consists of several essential elements designed to ensure efficient and seamless operation. Understanding the key parts involved can help users maintain and optimize its performance over time. Each component plays a crucial role in enhancing its functionality, from the cutting mechanism to the power transmission.

Core Mechanical Elements

The core of the tool revolves around its cutting head, which is engineered for precise trimming. This part, along with the rotating spool and string, forms the heart of the system, allowing users to cut grass and weeds effectively. The ergonomic design ensures ease of use during extended periods.

Supporting Framework

The handle and the shaft are crucial for the overall balance and comfort during operation. These sections are built with adjustability in mind, enabling users to customize the length and grip for better control. The lightweight design reduces fatigue, making it ideal for various landscaping tasks.

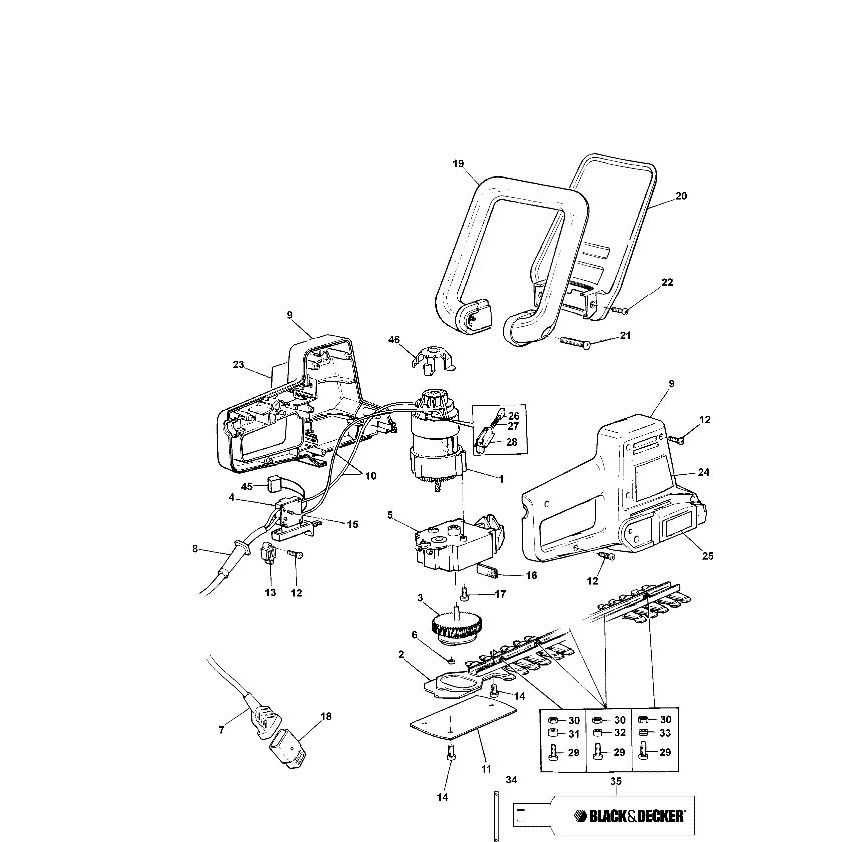

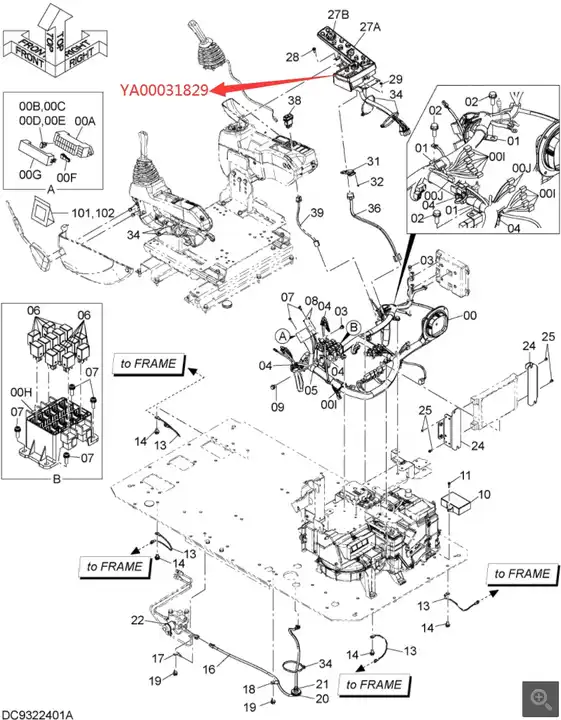

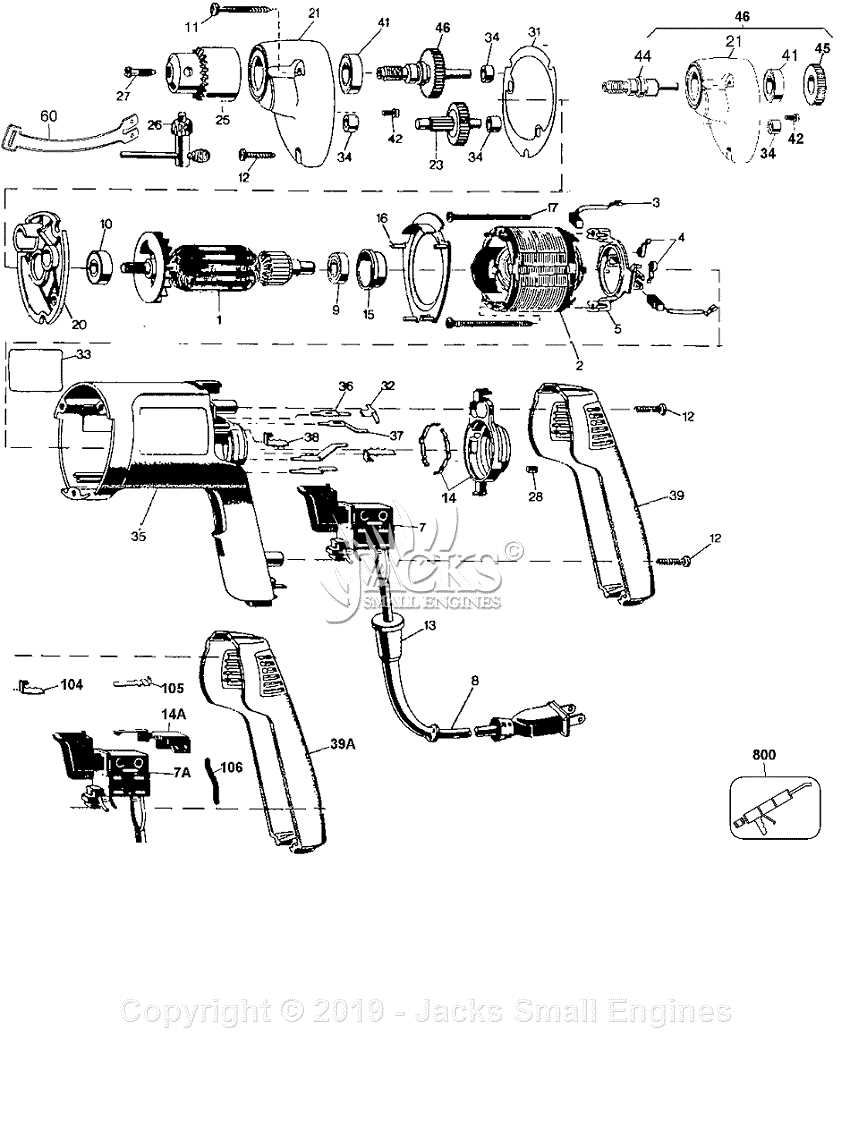

Understanding the Motor Assembly

The motor assembly is a crucial component of any electric tool, responsible for converting electrical energy into mechanical motion. It plays a significant role in driving the tool’s cutting or trimming mechanism, ensuring smooth and efficient operation. To ensure proper maintenance and repair, it’s essential to grasp how this assembly works and the individual parts that make up the system.

Below, we will explore the key elements that constitute the motor assembly:

- Electric Motor: The core of the assembly, which powers the tool by generating the necessary rotational force. This component typically requires regular checks for wear and tear.

- Drive Shaft: Connects the motor to the cutting mechanism, transmitting the motor’s energy to rotate the blade or string.

- Cooling Fan: A small fan is often attached to the motor to prevent overheating during extended use, promoting durability.

- Motor Housing: Protects the internal motor from debris and external elements, ensuring longevity and consistent performance.

By understanding how these components interact, users can better maintain their tools and troubleshoot potential issues, ensuring long-term functionality and safety.

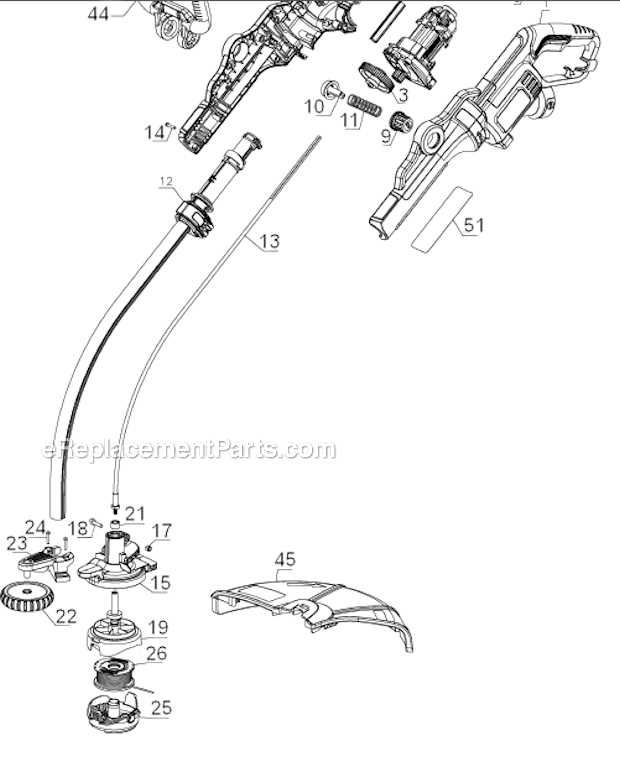

Function of the Trimmer Line Mechanism

The trimming line system plays a crucial role in maintaining the efficiency of garden tools designed for cutting grass and weeds. It ensures that the device can handle different types of vegetation with precision and speed, providing a clean cut and reliable performance during operation.

- Automatic Line Feeding: The line mechanism is designed to automatically adjust the length of the cutting thread, ensuring it remains at an optimal length for trimming. This feature prevents manual adjustments and interruptions during use.

- Line Replacement Process: When the line wears down or breaks, the spool system makes it easy to replace or reload new thread. This quick exchange process minimizes downtime and allows the user to continue working without delays.

- Efficient Cutting Action: The rotation of the line creates centrifugal force, which enhances the sharpness and efficiency of the cut. This allows the tool to handle tough weeds and thick grass effectively.

These elements together form a reliable and smooth-operating cutting system, ensuring durability and high performance across different tasks in the garden.

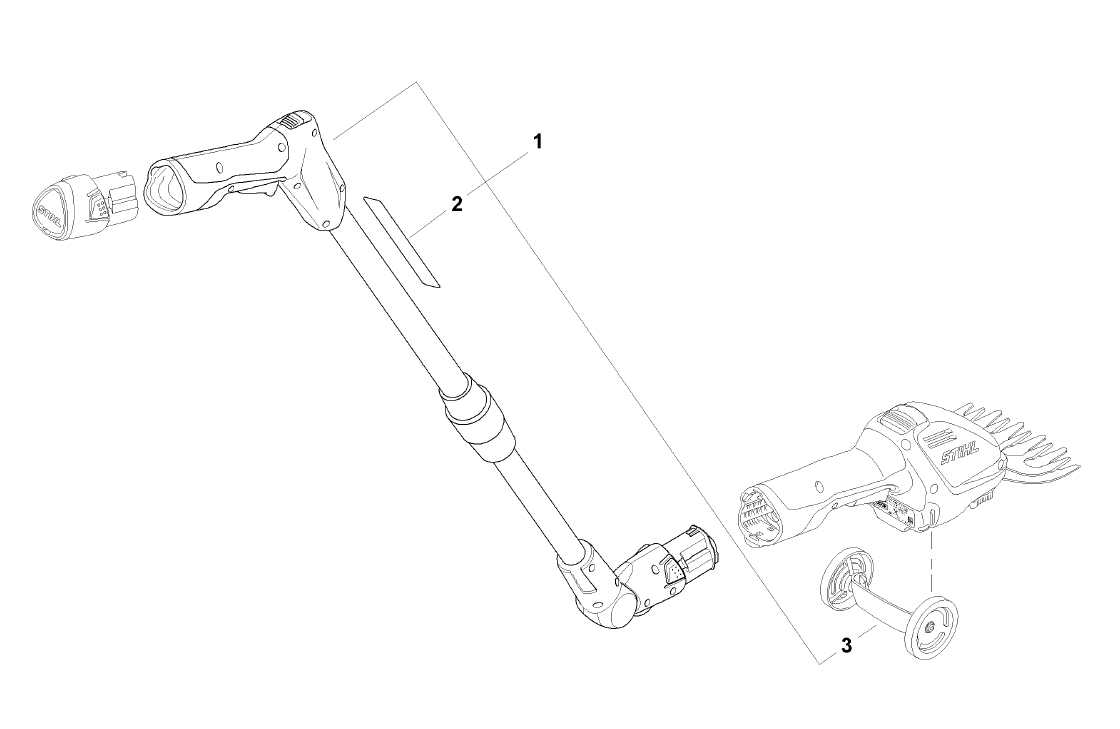

Exploring the Shaft and Handle Structure

The design of the shaft and handle is essential for ensuring stability and ease of use in any trimming tool. These elements are crafted to provide comfort and control during operation, making tasks more efficient and less physically demanding. Understanding their construction helps users operate the equipment with confidence, while maximizing performance.

Key Features of the Shaft

The shaft plays a crucial role in maintaining the balance and reach of the tool. It is constructed to be durable yet lightweight, ensuring easy maneuverability without compromising on strength. The length of the shaft is typically adjustable, allowing users to customize it according to their height or specific task requirements.

- Adjustable length for user comfort

- Lightweight but sturdy material

- Enhanced balance for prolonged use

Handle Ergonomics and Grip

Proper ergonomics in the handle design ensure a secure grip, reducing strain on the hands and wrists. The handle is often fitted with a soft, non-slip surface to prevent slipping, even during longer sessions of use. Additionally, the angle and placement of the handle are designed to provide optimal control, especially when trimming in hard-to-reach areas.

- Soft, anti-slip grip for comfort

- Strategic placement for better control

- Designed to reduce fatigue during extended use

Guard and Shield Protection Details

Effective safety mechanisms are essential for ensuring both functionality and user protection. The protective guard and shield are designed to offer a reliable barrier between the user and the operational components, reducing the risk of accidental contact during operation. These features enhance overall safety while maintaining optimal performance during use.

Durability of the Shield

The shield is crafted from high-resistance materials that can withstand regular wear and tear. This ensures that the barrier remains intact even after prolonged use, providing a long-lasting layer of protection. Its robust design helps to minimize exposure to debris and hazardous elements, contributing to a safer working environment.

Easy Maintenance and Installation

The guard is engineered for straightforward installation, allowing users to attach or detach it with minimal effort. Regular maintenance, such as cleaning and inspection, ensures the shield’s continued effectiveness. By keeping the guard in optimal condition, users can rely on consistent protection throughout the tool’s lifespan.

Role of the Power Cord Connection

The connection of the power cord plays a crucial role in ensuring the efficient operation of electric tools and appliances. This component is essential for delivering electrical energy from the outlet to the device, enabling it to function properly. A reliable connection guarantees safety and optimal performance, making it an integral part of any electrical equipment.

Several factors highlight the importance of the power cord connection:

- Safety: A well-constructed connection minimizes the risk of electrical hazards, such as short circuits or shocks.

- Performance: A strong link ensures consistent power flow, allowing the tool to operate at its best.

- Durability: High-quality connections reduce wear and tear, extending the lifespan of the device.

- Compatibility: Proper connections ensure that the tool can be used with various power sources without issues.

In summary, the connection of the power cord is vital for the safe and efficient operation of electric devices. Understanding its significance helps users maintain their tools and ensure long-lasting functionality.

Handle Grip and Comfort Features

The significance of a well-designed grip in power tools cannot be overstated. It serves not only as a point of contact between the user and the equipment but also plays a vital role in ensuring a comfortable and efficient working experience. A thoughtfully engineered handle can significantly reduce fatigue during prolonged usage, allowing for greater precision and control.

Ergonomic Design

An ergonomic handle is essential for minimizing strain on the hands and wrists. Features such as contoured shapes and cushioned materials contribute to a natural grip that aligns with the user’s hand. This thoughtful design can enhance overall handling, making it easier to maneuver the tool during various tasks.

Non-Slip Textures

Incorporating non-slip textures into the grip surface adds another layer of safety and comfort. This feature ensures a secure hold, even in wet or slippery conditions, which is crucial for maintaining control while operating the tool. Enhanced grip stability allows users to focus on their tasks without worrying about accidental slips.

Blade Housing and Mounting

The structure responsible for holding and securing the cutting element plays a critical role in ensuring both stability and precision during operation. This section explores the essential components that contribute to the proper positioning and function of the blade system.

- Mounting Bracket: A sturdy framework that supports the blade assembly, ensuring it remains securely fastened during use.

- Fastening Mechanism: Various bolts, screws, or clamps used to attach the blade housing to the main body, preventing any unwanted movement.

- Housing Cover: A protective shield designed to enclose the blade, offering protection from debris and external damage while operating.

These elements collectively ensure smooth operation and long-term durability of the cutting system,

Replacement Tips for the Line Spool

Maintaining the efficiency of your equipment requires timely replacement of certain components. One essential part that wears down over time is the line spool. Knowing when and how to replace it ensures smooth operation and helps avoid any potential issues during use.

Signs That It’s Time to Replace the Spool

- Frequent line breakages during operation

- Visible thinning or uneven wear on the spool

- Difficulty in advancing the line properly

Steps for Replacing the Line Spool

- Turn off the device and unplug it to ensure safety.

- Remove the cover by following the manufacturer’s instructions.

- Take out the worn spool and clean the area to remove any debris.

- Insert the new spool, ensuring it is properly aligned with the feed system.

- Reattach the cover securely and test the line advancement before use.

Regularly checking

Maintaining the GH900 for Longevity

To ensure your trimmer remains in optimal working condition for many years, regular maintenance is key. Proper upkeep helps prevent wear and tear, while also improving performance and extending the overall lifespan of your device. Consistent care can help you avoid costly repairs and ensure efficient operation season after season.

Start by cleaning the equipment after each use, removing any grass, dirt, or debris that may accumulate. This not only keeps the tool functioning smoothly but also prevents blockages that could damage internal components. Additionally, inspect critical parts periodically, checking for any signs of wear or damage. Replacing worn components as needed ensures the unit continues to function as intended.

Lastly, proper storage during the off-season is crucial. Keep the tool in a dry, sheltered area, away from moisture and extreme temperatures. This prevents rust and deterioration, maintaining the equipment’s efficiency for future use. With these simple steps, you can significantly extend the life of your trimmer and ensure it serves you reliably for years to come.

Common Issues with Trimmer Components

Trimmers are essential tools for maintaining a neat and tidy garden. However, over time, certain elements of the machine can experience wear and tear, leading to decreased performance. Recognizing the common problems that arise with these elements can help users keep their equipment running smoothly.

One frequent issue is line feed malfunction, where the cutting string may not advance properly during use. This can be caused by a variety of factors, including incorrect installation of the spool or debris clogging the feeding mechanism. Another problem often encountered is motor overheating, which typically occurs when the device is used for extended periods without proper maintenance. Lastly, worn-out cutting heads can reduce the effectiveness of the trimming process, requiring timely replacements to ensure optimal performance.

Upgrading Parts for Improved Performance

Enhancing the efficiency of your equipment often involves replacing or upgrading key components. By selecting more durable and efficient elements, you can extend the lifespan of your machine, reduce the need for frequent maintenance, and improve its overall functionality.

Why Upgrade Components?

Over time, the original parts of any device can wear out or fail to meet increasing performance demands. Upgrading certain elements with newer or more robust options can boost efficiency and ensure smoother operation. This not only enhances the machine’s reliability but also optimizes energy use.

Recommended Component Replacements

- Motor Upgrades: Consider upgrading to a more powerful motor that can handle tougher tasks with ease, ensuring longer operational hours without overheating.

- Improved Cutting Line: Using a higher quality or thicker cutting line can result in cleaner cuts and more efficient trimming, especially in dense vegetation.

- Handle Enhancements: Upgrading to ergonomic handles can reduce user fatigue and improve control during extended use.

- Advanced Guard System: Installing a more effective guard system can offer