When maintaining a lawn care machine, comprehending its various elements is crucial for optimal performance. Each section plays a significant role in ensuring smooth operation and efficiency during use. This knowledge not only helps in identifying issues but also aids in performing necessary repairs or replacements.

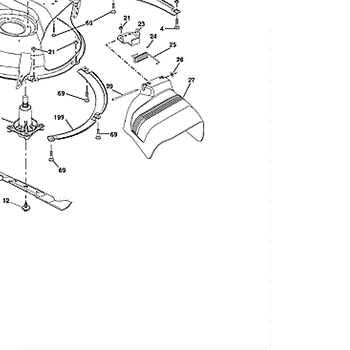

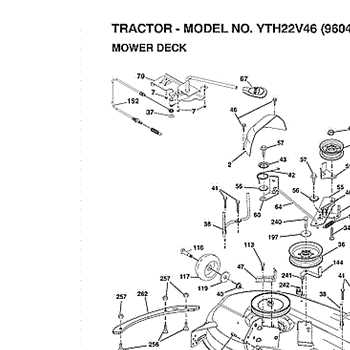

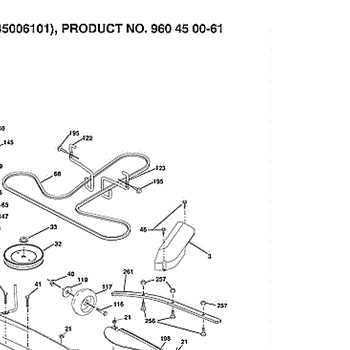

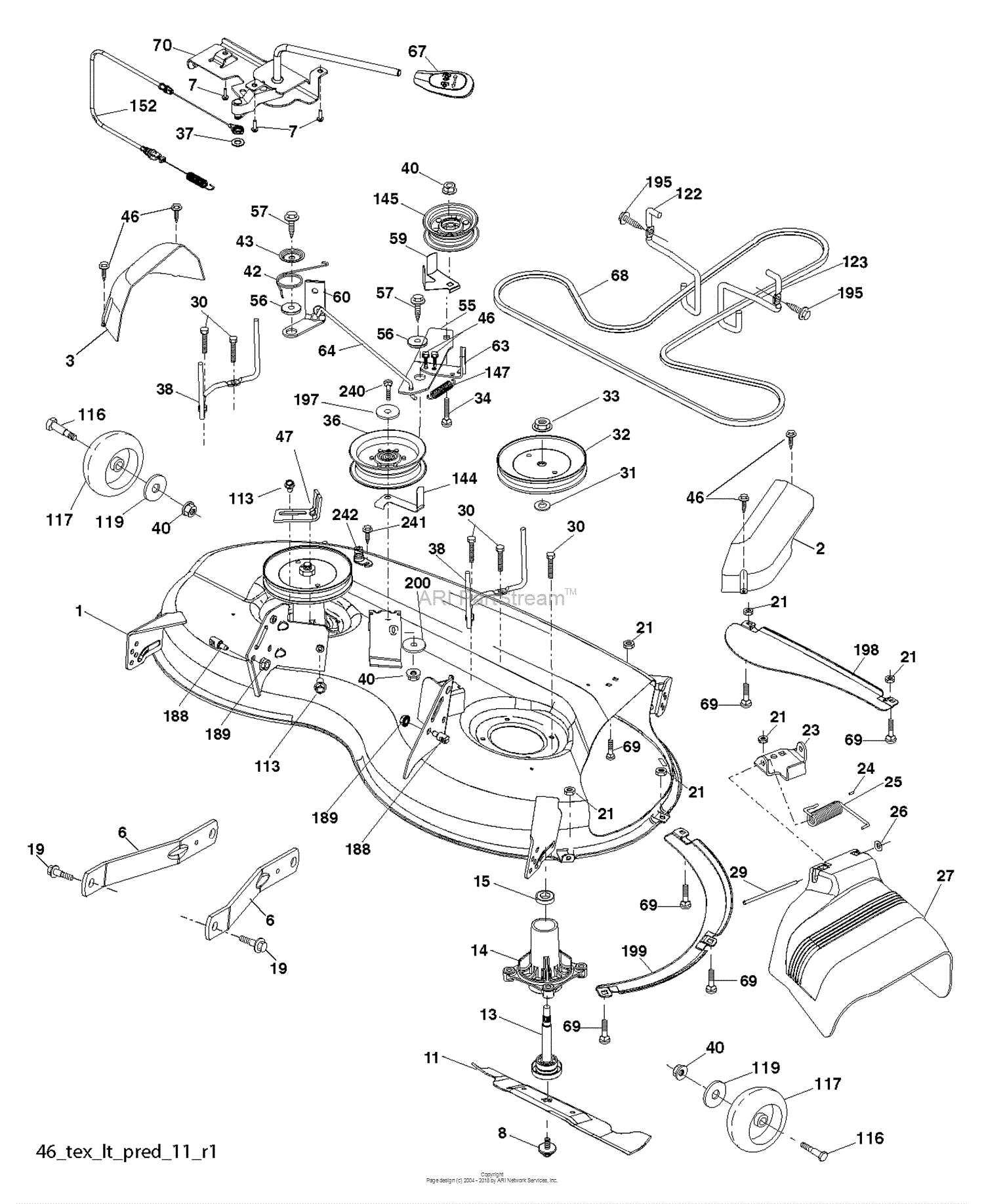

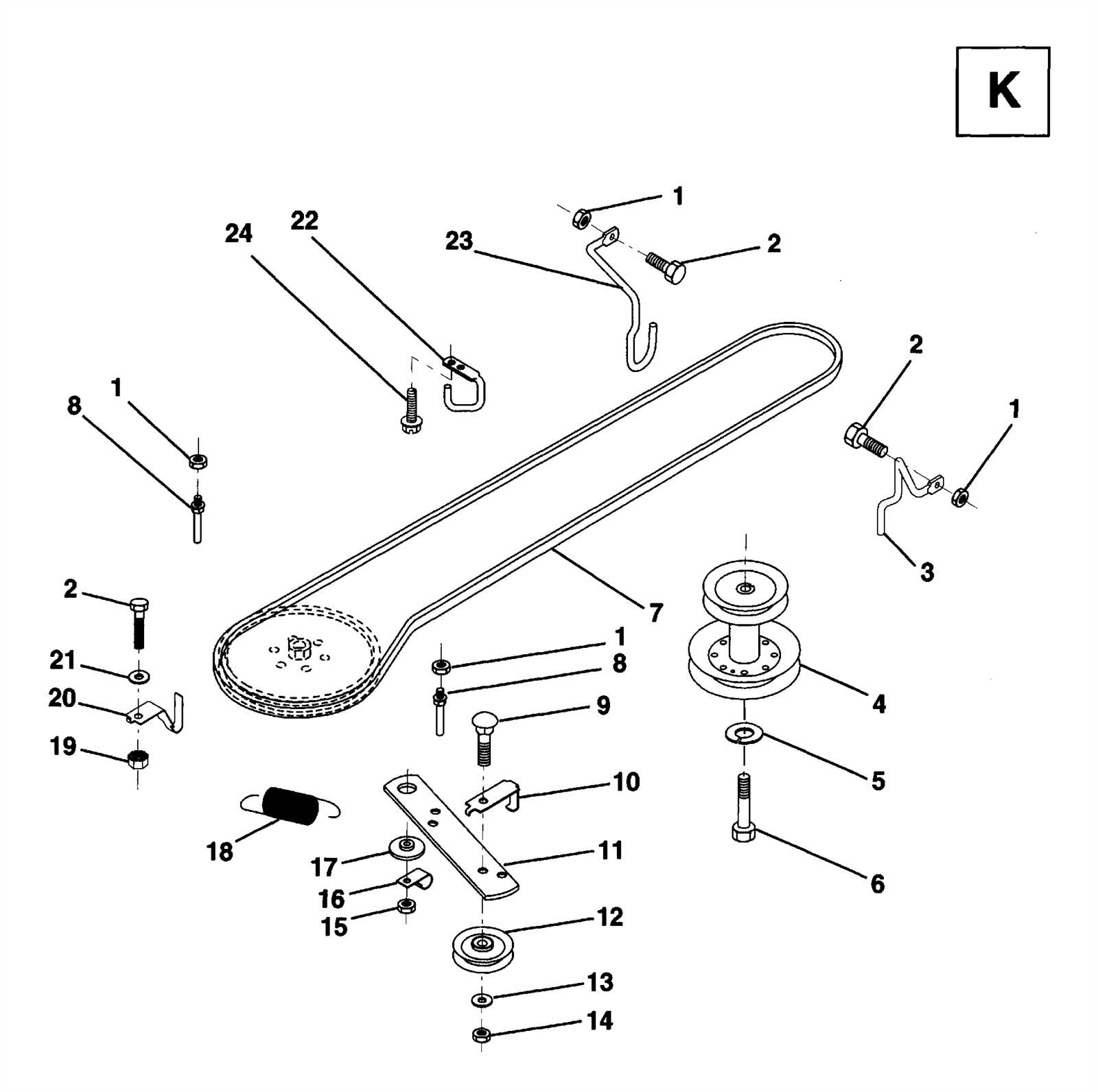

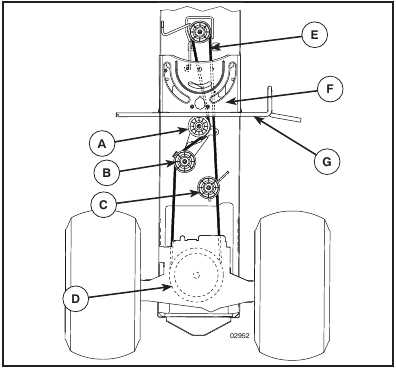

Visual aids can significantly enhance your understanding of these components. By examining a detailed representation, you can pinpoint each part’s location and function, making it easier to manage maintenance tasks effectively. Such resources are invaluable for both seasoned users and newcomers alike.

Whether you’re troubleshooting a problem or upgrading your equipment, delving into the intricacies of each component is the ultimate key to achieving longevity and reliability in your machine. With the right insights, you can ensure that your investment serves you well for years to come.

Understanding the Husqvarna YTH22V46 Deck

This section explores the essential components of a popular lawn care machine, focusing on the cutting mechanism and its functionality. By examining the various elements involved, users can gain insights into maintenance, performance, and overall effectiveness in achieving a well-manicured lawn.

Key Components and Their Functions

The cutting assembly is comprised of multiple critical elements that work in harmony. These include blades, spindles, and pulleys, each serving a unique purpose. The blades are designed to deliver a precise cut, while spindles provide the necessary rotation. Pulleys, in turn, facilitate the transfer of power from the engine to the cutting components, ensuring optimal performance.

Maintenance Tips for Longevity

Regular upkeep is vital for sustaining the efficiency of these crucial elements. Inspecting blades for dullness, checking spindles for wear, and clearing debris from the assembly can prevent issues. Additionally, ensuring proper lubrication and alignment will contribute to a longer lifespan and enhanced functionality, making the task of lawn care more manageable and effective.

Key Components of the Deck

Understanding the essential elements that contribute to the performance and functionality of lawn mowing equipment is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal cutting efficiency, stability, and durability.

Cutting Blades

The cutting blades are arguably the most critical elements, as they directly influence the quality of the lawn finish. These sharp, rotating implements are designed to slice through grass with precision, ensuring an even cut. Regular inspection and sharpening are necessary to maintain their effectiveness.

Spindle Assembly

The spindle assembly serves as the support structure for the blades, providing the necessary rotation. Its robustness is essential for preventing vibrations and ensuring smooth operation. Proper lubrication and timely replacement of worn parts can enhance its longevity and performance.

Importance of Regular Maintenance

Routine care and upkeep of your machinery are essential for ensuring optimal performance and longevity. Neglecting regular maintenance can lead to various issues that may compromise efficiency and increase repair costs. By prioritizing maintenance, you can identify potential problems early, prolong the lifespan of your equipment, and enhance its overall reliability.

Consistent inspection and servicing not only help maintain functionality but also contribute to safety. Well-maintained equipment operates more smoothly, reducing the risk of accidents and malfunctions. Additionally, keeping your machinery in top condition can improve its resale value, making it a wise investment in the long run.

Engaging in regular maintenance routines fosters a proactive approach to care. This can include cleaning, lubricating moving parts, and replacing worn components. By adopting this mindset, operators can ensure that their equipment remains in excellent working order, ultimately leading to better performance and satisfaction.

Identifying Common Issues

Understanding typical problems can enhance the longevity and performance of your machinery. Recognizing symptoms early allows for timely interventions and maintenance, preventing further damage and ensuring smooth operation.

One prevalent issue involves uneven cutting. This can be caused by dull blades or misalignment, leading to an inconsistent appearance of your lawn. Regular inspection of the blades is essential to address this.

Another frequent concern is the accumulation of debris. Grass clippings and dirt can obstruct the mechanisms, impacting efficiency. Routine cleaning of the undercarriage is crucial to maintain optimal functionality.

Lastly, vibrations during operation may indicate loose components or wear. Checking bolts and fasteners for tightness can mitigate this problem and enhance safety.

How to Access the Deck Parts

Gaining entry to the essential components of your mower is a crucial step for maintenance and repairs. By understanding the basic structure and fastenings, you can efficiently remove the covering and reach the interior mechanisms without hassle.

First, ensure that the machine is turned off and disconnected from any power source. This is vital for your safety. Next, locate the securing bolts and any clips that hold the protective casing in place. Using the appropriate tools, carefully unscrew or detach these elements to prevent damage.

Once the outer shell is removed, inspect the internal framework for wear or debris. Regular checks will help maintain functionality and extend the lifespan of your equipment.

Replacement Options for Worn Parts

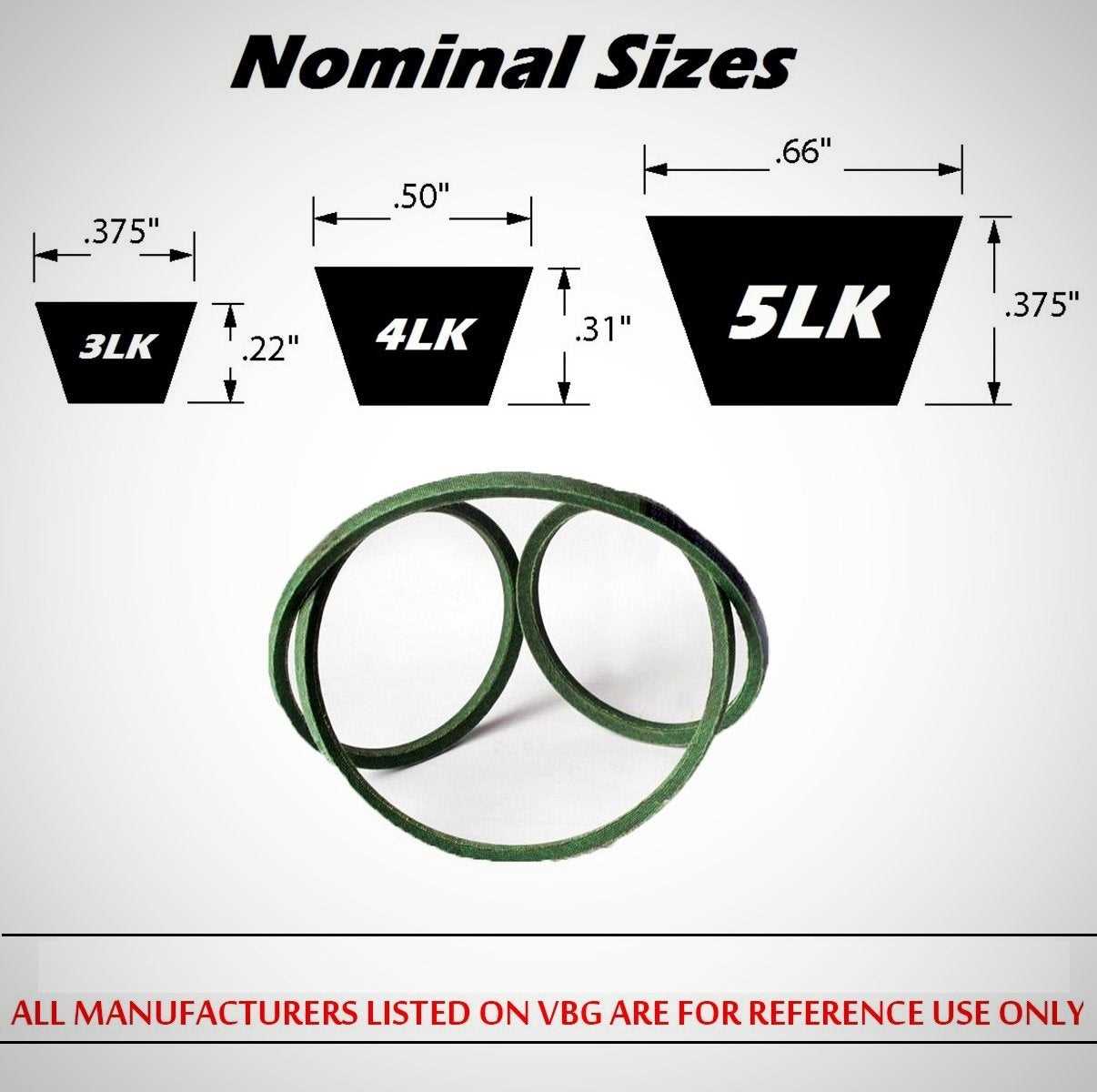

Maintaining the performance of your outdoor equipment is essential, and replacing damaged or worn components is a crucial part of that process. Selecting the right alternatives can enhance efficiency, prolong lifespan, and ensure smooth operation. Understanding the various options available for replacement can help you make informed decisions that benefit both your machinery and your budget.

Aftermarket Solutions

Aftermarket components often present a cost-effective alternative to original equipment options. These parts are produced by third-party manufacturers and can vary in quality and price. When considering aftermarket options, it’s important to research the reputation of the supplier and read customer reviews to ensure you’re choosing a reliable product.

OEM Alternatives

Original equipment manufacturer replacements guarantee compatibility and quality. While they might come at a higher price point, investing in OEM components can provide peace of mind, as these are specifically designed for your machinery. Look for authorized dealers to ensure you’re receiving genuine items that meet the manufacturer’s specifications.

In conclusion, assessing your needs and budget will guide you in selecting the best replacement options. Whether opting for aftermarket solutions or sticking with OEM products, ensuring quality and compatibility is key to maintaining optimal performance.

Utilizing the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. This tool allows users to identify each element within the machinery, ensuring that replacements and repairs can be executed with precision.

Comprehending the layout enhances the ability to locate specific items quickly, streamlining the repair process. Additionally, it facilitates troubleshooting by highlighting potential issues and their corresponding solutions.

By referencing the schematic, individuals can efficiently gather necessary supplies and execute repairs without unnecessary delays. This ultimately leads to improved performance and longevity of the equipment.

Tools Required for Repairs

When undertaking maintenance or repairs on outdoor machinery, having the right tools is essential for efficiency and precision. A well-equipped toolkit not only simplifies the process but also enhances safety and effectiveness during the task.

- Wrenches: Various sizes to fit different bolts.

- Screwdrivers: Both flathead and Phillips for diverse screws.

- Pliers: Useful for gripping and twisting components.

- Socket Set: Ideal for quickly loosening or tightening nuts.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

Additionally, specialty tools may be necessary depending on the specific repairs. Always refer to the user manual for guidance on required instruments.

Step-by-Step Repair Guide

This guide aims to provide a clear and concise process for troubleshooting and fixing common issues associated with lawn care equipment. By following these steps, you can restore functionality and extend the lifespan of your machine, ensuring a smooth mowing experience.

Tools Required

Before starting the repair, gather the following tools:

| Tool | Purpose |

|---|---|

| Screwdriver | For removing and tightening screws |

| Wrench | To loosen or tighten bolts |

| Pliers | To grip and pull components |

| Socket Set | For various sizes of nuts and bolts |

Repair Steps

Follow these steps for an effective repair:

- Ensure the equipment is powered off and disconnected from any power source.

- Identify the specific issue by inspecting the machine thoroughly.

- Remove any damaged components carefully.

- Replace with new or refurbished parts as needed.

- Reassemble the equipment, ensuring all components are secured properly.

- Test the machine to confirm it operates correctly.

Comparing Aftermarket vs. Original Parts

When considering replacements for machinery components, two primary categories emerge: those made by the original manufacturer and those produced by third parties. Each option presents its own set of advantages and drawbacks that can influence performance, longevity, and cost-effectiveness.

Quality and Performance

Original components are typically engineered to meet specific standards, ensuring compatibility and reliability. In contrast, aftermarket alternatives can vary widely in quality, with some offering enhanced performance while others may compromise on durability.

Cost Considerations

Pricing is a significant factor. Aftermarket options often provide a more budget-friendly choice, appealing to those looking to save money. However, it’s essential to weigh the initial savings against potential long-term expenses related to replacement and maintenance.

| Aspect | Original Parts | Aftermarket Options |

|---|---|---|

| Quality | High and consistent | Varies widely |

| Cost | Generally higher | Usually lower |

| Availability | Limited to manufacturer | Widely available |

| Warranty | Often included | Varies by manufacturer |

Safety Tips When Working on the Deck

When engaging in maintenance or repairs on outdoor machinery, prioritizing safety is essential. Proper precautions can prevent accidents and ensure a smooth process. Understanding the necessary steps can make all the difference in protecting both the individual and the equipment.

1. Wear Appropriate Personal Protective Equipment (PPE): Always use gloves, safety glasses, and sturdy footwear. These items protect against sharp edges, flying debris, and potential falls.

2. Disconnect Power Sources: Before beginning any work, ensure that all power supplies are turned off or disconnected. This includes removing the battery or unplugging electrical components to avoid accidental starts.

3. Secure the Area: Keep the workspace clear of obstacles and clutter. Make sure that bystanders, especially children and pets, are at a safe distance while maintenance is underway.

4. Use Proper Tools: Employ the right tools for the job. Using inappropriate or makeshift tools can lead to accidents or damage. Always inspect tools for any defects before use.

5. Follow Manufacturer Instructions: Consult the user manual for specific guidance regarding maintenance and repairs. Adhering to recommended procedures helps prevent mistakes and enhances safety.

6. Work in a Well-Lit Environment: Adequate lighting is crucial for visibility. A well-lit area minimizes the risk of accidents and helps ensure precision while working.

7. Stay Focused: Avoid distractions while performing tasks. Concentration is key to maintaining safety and efficiency during any repair or maintenance work.

By following these guidelines, individuals can create a safer environment when working on outdoor machinery, minimizing risks and enhancing their overall experience.

Seasonal Maintenance Checklist

Regular upkeep is essential for optimal performance and longevity of your outdoor equipment. Following a seasonal maintenance checklist ensures that your machinery operates efficiently and remains in excellent condition throughout the year.

- Inspect and clean the air filter to enhance airflow and engine performance.

- Sharpen or replace the blades to achieve a clean cut and prevent damage to the lawn.

- Change the oil and replace the oil filter to maintain engine health.

- Check and tighten any loose bolts or screws to ensure structural integrity.

- Examine the belts for wear and tear, replacing them if necessary.

- Clean the fuel system to prevent clogs and ensure proper fuel delivery.

- Inspect tires for proper inflation and tread wear, adjusting as needed.

- Test the battery and clean terminals to ensure reliable starts.

Regularly reviewing this checklist can help you delve into each component’s condition, ultimately prolonging the life of your equipment.

Resources for Further Assistance

When seeking help with your outdoor equipment, it’s essential to explore various avenues for support. Numerous resources can provide guidance, troubleshooting tips, and replacement information to ensure your machine operates optimally.

Online Forums and Communities

Engaging with online forums dedicated to lawn care and maintenance can be incredibly beneficial. Members often share experiences, solutions, and recommendations that can help you tackle specific issues.

Manufacturer Support and Documentation

Consulting the official support channels of the manufacturer can offer access to manuals, FAQs, and customer service. These resources are designed to provide the most accurate and reliable information for your equipment needs.