Maintaining an efficient cutting apparatus is crucial for achieving a well-manicured landscape. Understanding the various elements that contribute to its optimal functionality can significantly enhance performance and longevity. This section delves into the intricate layout of components that make up a specific cutting system, providing a comprehensive overview of their roles and relationships.

Identifying the various segments of the assembly allows users to troubleshoot issues and perform necessary maintenance tasks effectively. Each segment plays a pivotal role in the overall operation, ensuring that the equipment performs at its best. By gaining insights into these components, operators can ensure their machinery remains reliable and efficient for years to come.

Additionally, recognizing the interconnectivity of these elements can aid in making informed decisions when it comes to upgrades or replacements. The information presented in this section will serve as a valuable resource for anyone looking to enhance their understanding of this cutting system and its components.

Understanding the essential elements that contribute to the functionality of a grass-cutting apparatus is crucial for optimal performance and maintenance. This section explores various components involved in the system, highlighting their roles and significance.

Key Elements of the Cutting System

Each segment plays a pivotal role in ensuring efficiency and precision during operation. Here are the primary elements:

- Blades: Critical for achieving a clean cut, these sharp implements vary in design depending on the intended purpose.

- Spindles: These rotating mechanisms support the blades and facilitate their movement.

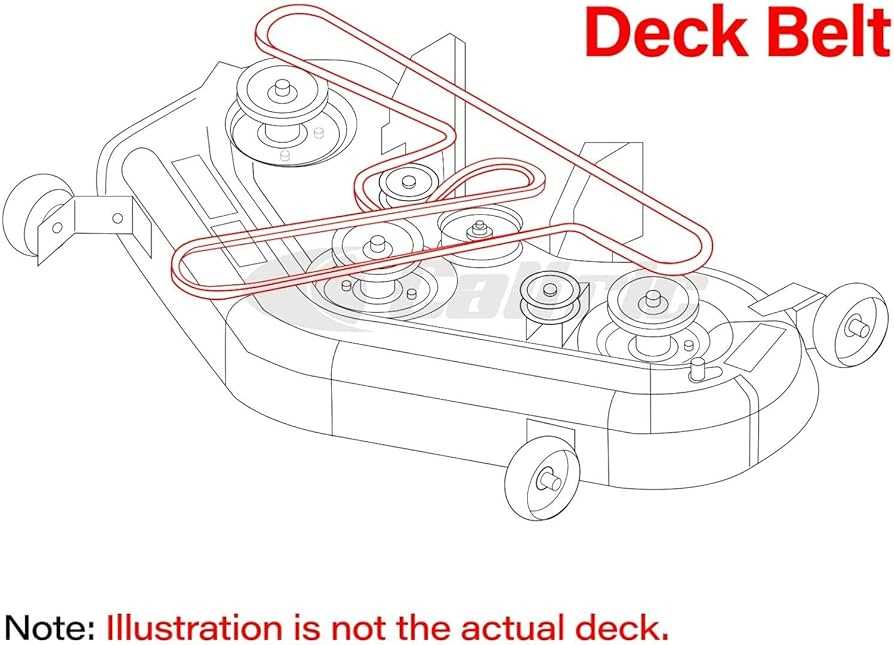

- Belts: Connecting different components, these are vital for power transmission throughout the apparatus.

- Housing: The outer casing protects internal parts and contributes to the overall structure.

Importance of Regular Maintenance

Ensuring the longevity of the cutting apparatus relies on consistent upkeep. Key maintenance tasks include:

- Regularly inspecting and sharpening the blades to enhance cutting efficiency.

- Checking and replacing worn belts to prevent unexpected breakdowns.

- Cleaning the housing to remove debris and maintain airflow.

- Lubricating moving parts to reduce friction and wear.

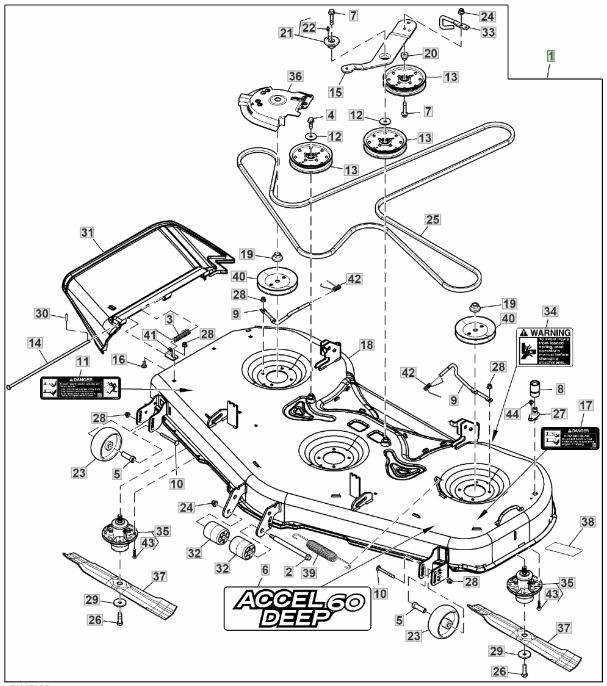

Identifying Key Parts of the Deck

Understanding the essential components of the cutting apparatus is crucial for effective maintenance and optimal performance. Familiarizing oneself with these elements not only enhances operational efficiency but also contributes to the longevity of the equipment. In this section, we will explore the primary features and their functions.

Key Components Overview

The cutting unit comprises several vital elements, each playing a specific role in the overall functionality. Among these, the rotary blades are fundamental, as they are responsible for achieving a clean and even cut. Additionally, the housing structure serves to protect the internal mechanisms while ensuring durability against wear and tear.

Supporting Structures

Other significant components include the drive system, which facilitates the movement of the cutting assembly, and the attachment points that connect the unit to the main machinery. Understanding these supporting structures is essential for troubleshooting and ensuring seamless operation during use.

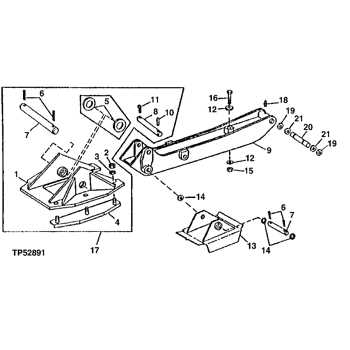

Exploring the Deck Assembly Process

The process of assembling the cutting platform involves a systematic approach to ensure functionality and efficiency. Each component plays a crucial role in achieving optimal performance. Understanding the relationships between the various elements is essential for a successful build.

First, it is important to identify the necessary components that contribute to the overall structure. These include the frame, rotating blades, and support brackets, which must be meticulously aligned during assembly. Attention to detail at this stage can prevent future issues.

Next, securing the components together requires specific fasteners and tools. Ensuring that each connection is tight and secure is vital for maintaining stability and preventing vibrations during operation. Proper torque specifications should always be followed to guarantee safety and longevity.

Finally, once the assembly is complete, it is essential to conduct a thorough inspection. This includes checking for any misalignments or loose fittings. A well-executed assembly not only enhances performance but also extends the lifespan of the equipment.

Common Issues with Mowing Equipment

Regular maintenance of grass-cutting equipment is essential for ensuring optimal performance and longevity. However, users often encounter various challenges that can affect efficiency and effectiveness. Understanding these issues can help in troubleshooting and maintaining the machinery properly.

Frequent Problems

- Uneven Cutting: One of the most common complaints is an uneven cutting height, which can lead to a patchy lawn. This can result from worn blades, improper leveling, or issues with wheel height adjustments.

- Clumping Grass: Accumulation of grass clippings can cause clumping, leading to a messy appearance. This often occurs when the blades are dull or when the cutting height is set too low.

- Noise Issues: Excessive noise during operation may indicate loose components or damaged bearings, requiring immediate attention to avoid further damage.

Maintenance Tips

- Regularly inspect and sharpen blades to ensure clean cuts.

- Check and adjust the height settings for uniform cutting.

- Clean the underside frequently to prevent grass build-up.

Maintenance Tips for Optimal Performance

To ensure the highest efficiency and longevity of your equipment, regular upkeep is essential. Adopting a proactive maintenance routine can prevent potential issues and enhance functionality. This section offers practical suggestions for maintaining your machinery effectively.

1. Regular Inspections: Frequent checks can help identify wear and tear before they escalate into major problems. Look for signs of damage, rust, or loose components. Addressing these issues promptly can save time and resources.

2. Cleanliness is Key: Keeping your equipment free of debris, grass clippings, and dirt not only improves appearance but also optimizes performance. Utilize a brush or compressed air to clean hard-to-reach areas, ensuring smooth operation.

3. Lubrication: Proper lubrication of moving parts reduces friction and wear, contributing to smoother performance. Use the recommended lubricants as specified in the manufacturer’s guidelines and apply them at regular intervals.

4. Blade Maintenance: Sharp and well-aligned blades are crucial for effective cutting. Regularly inspect and sharpen blades, replacing them if necessary. This practice enhances cutting quality and reduces strain on the machine.

5. Seasonal Preparation: Adjust your maintenance routine according to seasonal changes. Before winter, consider winterizing your equipment by draining fuel and performing thorough inspections to avoid issues during the next operational season.

By following these maintenance tips, you can ensure optimal performance and extend the lifespan of your machinery, allowing it to operate efficiently for years to come.

Replacement Parts Overview for Durability

Maintaining optimal performance in outdoor machinery relies heavily on the quality of its components. Ensuring that all necessary elements are readily available can significantly enhance the longevity and reliability of the equipment. This section aims to provide insights into essential components that contribute to sustained functionality.

Utilizing high-quality replacements is crucial for minimizing wear and tear over time. Durable alternatives are designed to withstand harsh conditions, ensuring that the machinery operates smoothly, even under demanding circumstances. Choosing parts made from robust materials will not only improve efficiency but also reduce the frequency of necessary repairs.

Furthermore, regular inspections and timely replacements of worn elements can help prevent unexpected failures, enhancing overall productivity. By investing in superior components, operators can ensure that their equipment remains in peak condition, ready to tackle any task with ease and reliability.

How to Troubleshoot Common Problems

Addressing technical issues with equipment can be daunting, especially when dealing with performance hiccups. However, by following systematic approaches, many operational issues can be diagnosed and resolved effectively. Below are steps to help you identify and fix some of the most frequent complications.

Identifying Performance Issues

If your equipment is not running as efficiently as it should, the first step is to pinpoint the root cause. Look for signs such as uneven operation, excessive noise, or unexpected changes in functionality. Regular maintenance checks can help catch potential issues early, ensuring smooth performance. Pay attention to mechanical components, as wear and tear over time can lead

Tools Needed for Mower Repair

When preparing for maintenance or fixing outdoor equipment, having the right set of tools is essential for efficiency and safety. Proper tools will not only make the process faster but also help prevent damage to both the equipment and the components you’re working with.

Below is a list of commonly required tools for handling typical repairs and adjustments:

| Tool | Purpose | |||||

|---|---|---|---|---|---|---|

| Socket Wrench Set | Ideal for removing or tightening bolts and nuts of varying sizes. | |||||

| Screwdrivers (Flathead and Phillips) | Necessary for loosening screws on

Benefits of Using Genuine PartsWhen maintaining equipment, choosing original components ensures long-term efficiency and reliability. These authentic pieces are specifically designed to work seamlessly with your machinery, offering superior performance and a longer lifespan. By investing in factory-made replacements, you can avoid potential risks associated with imitations, which may not fit or function as expected. Enhanced DurabilityOriginal parts are engineered to meet the exact specifications of the machinery, making them more durable. This means less wear and tear over time, ultimately saving you money on future repairs or replacements. Authentic components are crafted from high-quality materials that guarantee the integrity of your equipment. Improved Safety

|

| Safety Measure | Description |

|---|---|

| Disconnect Power | Always cut off any power source before beginning repairs or inspections to avoid unintended starts. |

| Wear Protective Gear |