In the realm of home maintenance, a reliable cleaning device can significantly enhance efficiency. Knowing the intricate layout of such a machine is essential for optimal performance and longevity. Familiarity with each element not only facilitates effective troubleshooting but also empowers users to conduct routine maintenance and repairs with confidence.

By dissecting the various sections of these cleaning units, one can uncover the vital roles that each piece plays in the overall functionality. From the motor to the filtration system, comprehending how these components interact can lead to improved upkeep and performance. This knowledge is invaluable, particularly for those who wish to extend the lifespan of their equipment or simply understand it better.

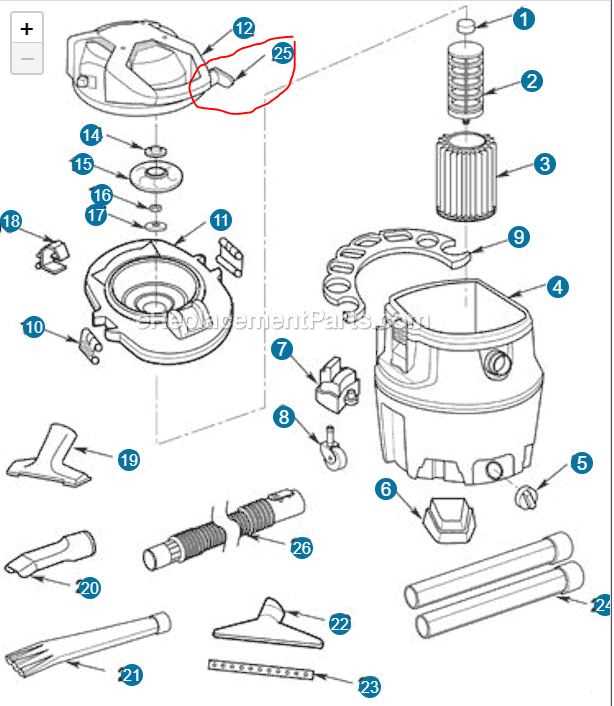

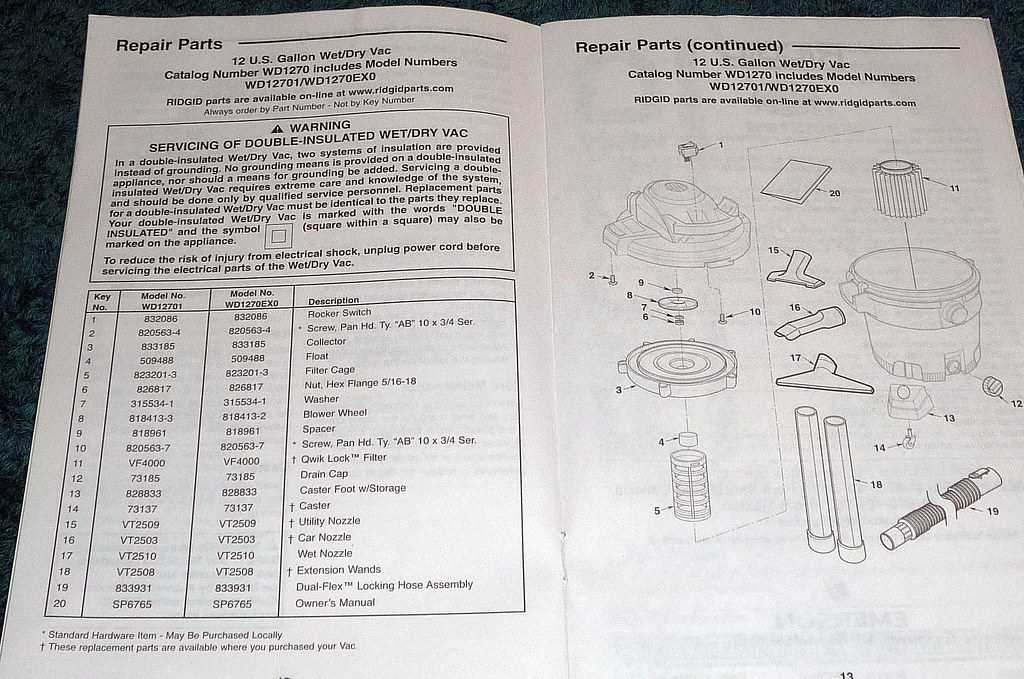

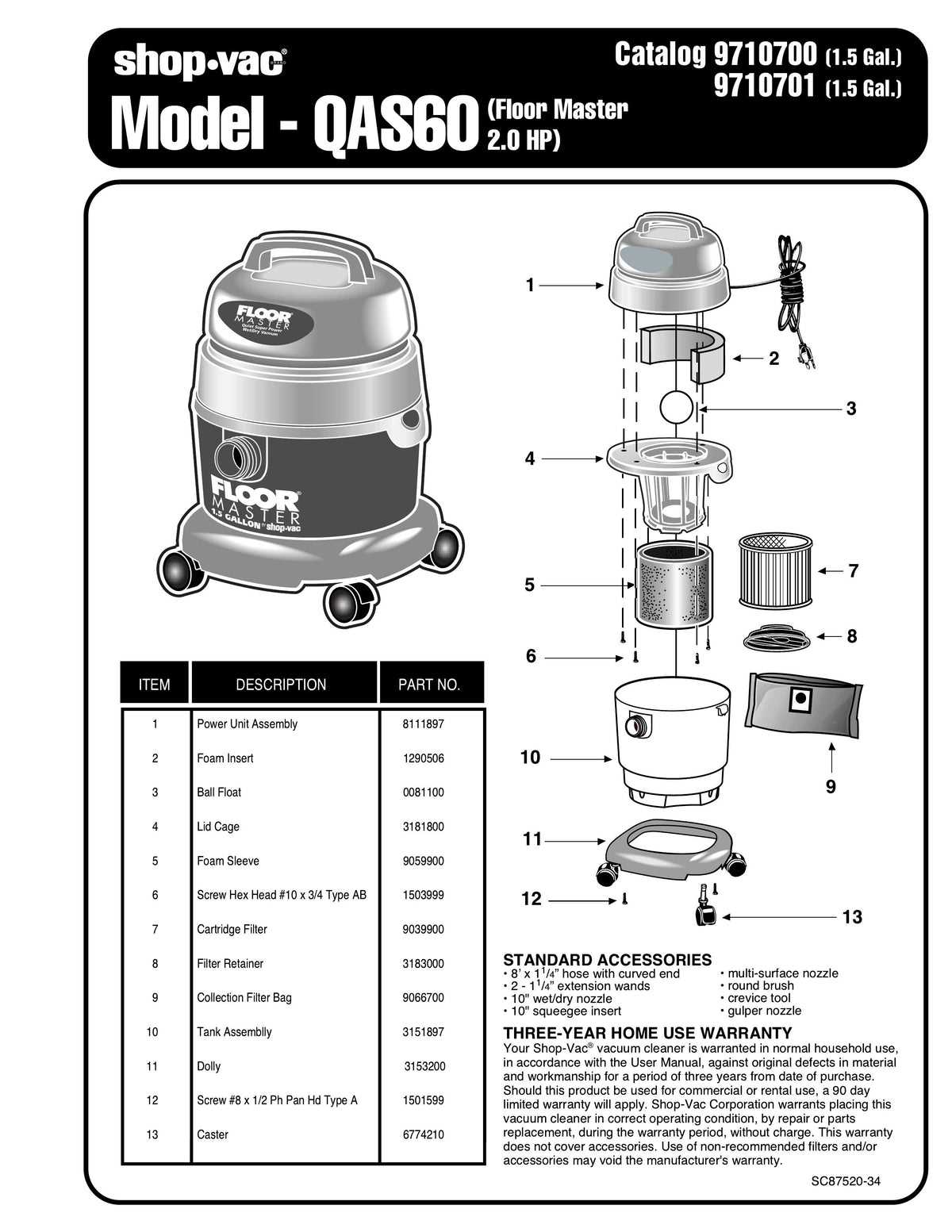

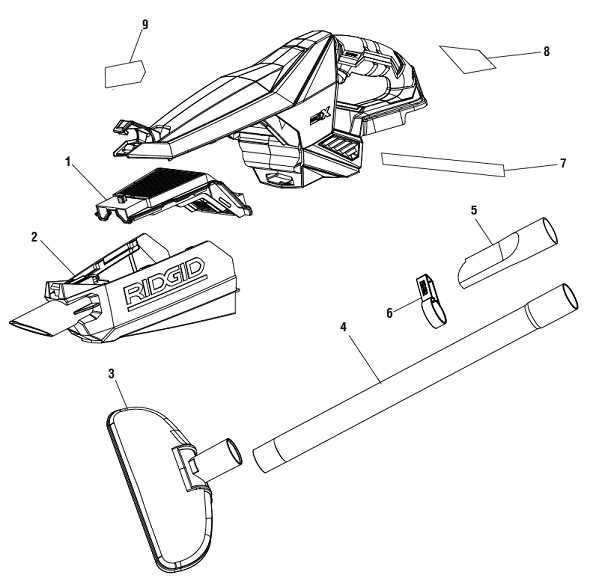

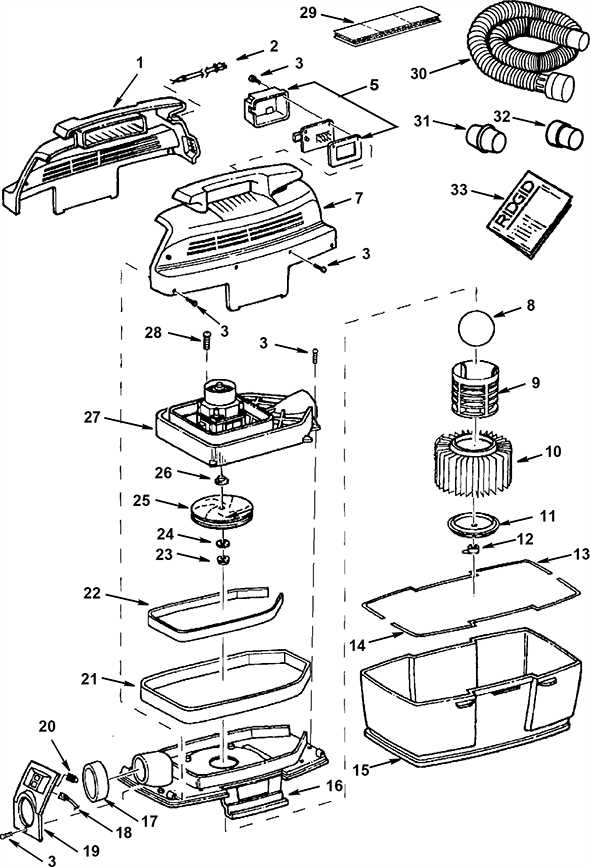

Moreover, having access to a comprehensive visual representation of the machine’s makeup can simplify the repair process. This guide serves as a practical resource, providing clarity and insight into the essential elements that contribute to a well-functioning cleaning apparatus. With this understanding, users can make informed decisions regarding replacements and upgrades, ensuring their devices remain in peak condition.

Understanding Ridgid Shop Vac Components

When exploring the inner workings of an industrial cleaning device, it’s essential to recognize the various elements that contribute to its efficiency and functionality. Each component plays a crucial role in ensuring optimal performance and durability, enhancing the overall user experience.

Key Elements of the Device

The primary sections include the motor assembly, which powers the unit, and the collection tank, where debris is stored. Additionally, filters are vital for maintaining air quality, while hoses and attachments facilitate versatile cleaning options. Understanding these components allows users to make informed decisions regarding maintenance and upgrades.

Importance of Regular Maintenance

Regular upkeep of these elements is essential for longevity. Neglecting any part can lead to diminished performance or even permanent damage. By familiarizing oneself with each component, users can effectively troubleshoot issues and extend the life of their equipment.

Importance of Knowing Parts Diagrams

Understanding the visual representation of components is crucial for effective maintenance and repair. Such illustrations not only simplify the identification of individual elements but also enhance comprehension of how they interact within the overall system. This knowledge empowers users to tackle issues confidently and ensures that repairs are carried out accurately.

Moreover, familiarizing oneself with these visuals can significantly reduce downtime and costs associated with repairs. By knowing what each part looks like and its specific function, users can easily pinpoint problems, order the right replacements, and execute fixes without unnecessary delays.

| Benefits | Details |

|---|---|

| Enhanced Understanding | Visual aids clarify the relationships between components. |

| Improved Efficiency | Quick identification of faulty parts reduces repair time. |

| Cost Savings | Accurate parts ordering minimizes unnecessary purchases. |

| Increased Confidence | Knowledge of components encourages DIY repairs. |

Common Issues with Shop Vacs

Many users encounter similar challenges when utilizing their cleaning devices, which can impact performance and efficiency. Understanding these frequent problems can help maintain optimal functionality and prolong the lifespan of the equipment.

Clogging is one of the most prevalent issues, often resulting from debris accumulation in the hoses or filters. Regular inspection and cleaning can prevent this from becoming a significant setback.

Noisy Operation may indicate loose components or mechanical wear. Addressing these issues promptly can lead to quieter performance and more effective cleaning.

Poor Suction can stem from various factors, including a full container or dirty filters. Ensuring that the device is emptied and maintained will help restore its ultimate efficiency.

Electrical Problems might arise due to faulty cords or switches. Checking for damage and ensuring proper connections is crucial for safe and reliable use.

Overheating can occur if the device is used continuously without breaks. Allowing the equipment to cool down between uses can mitigate this issue and enhance longevity.

Identifying Essential Replacement Parts

Understanding the key components of your cleaning equipment is crucial for maintaining its efficiency. Familiarizing yourself with the various elements can help you quickly address issues when they arise.

- Filters: Essential for capturing debris and maintaining airflow.

- Hoses: Important for directing suction to the intended area.

- Buckets: Collect waste and require regular inspection for damage.

- Wheels: Facilitate mobility, so check for wear and tear.

- Motors: The heart of the machine; any malfunction can hinder performance.

By recognizing these vital elements, you can ensure your equipment operates at its best, ultimately prolonging its lifespan and effectiveness.

Exploring Ridgid Shop Vac Models

This section focuses on various models of powerful cleaning devices designed for both home and professional use. Each variant offers unique features that cater to different cleaning needs and preferences.

- Compact Units: Ideal for small spaces and quick clean-ups.

- Heavy-Duty Models: Built to handle tough debris and extended use.

- Wet and Dry Options: Versatile in managing both liquid and solid waste.

- Specialized Accessories: Enhance functionality for specific tasks.

By examining these various models, users can delve into their capabilities to find the ultimate solution for their cleaning challenges.

Where to Find Parts Diagrams

Locating detailed schematics for equipment can greatly enhance maintenance and repair tasks. Various resources offer these valuable visual aids, ensuring you can easily identify components and their arrangements. Whether you are looking for manuals or digital resources, a variety of options are available to meet your needs.

Online Retailers: Many online retailers provide downloadable schematics alongside product listings. Check the product description sections for links to PDF manuals.

Manufacturer Websites: The official websites of manufacturers often have dedicated sections for support, where you can access schematics and other helpful resources.

Repair Forums: Community forums and repair blogs frequently share links to schematics. Engaging with other users can also yield additional insights and recommendations.

Local Hardware Stores: Some local stores maintain archives of manuals and schematics for various equipment. A visit or call may uncover resources not available online.

Exploring these avenues will ultimately lead you to the information you need for effective repairs.

Step-by-Step Assembly Guide

This guide provides clear instructions for assembling your cleaning device effectively. Following these steps will ensure that each component fits together seamlessly, allowing you to make the most of your equipment.

Required Components

| Component | Quantity |

|---|---|

| Main Body | 1 |

| Hose | 1 |

| Filter | 1 |

| Collection Tank | 1 |

| Power Cord | 1 |

Assembly Steps

Begin by connecting the main body to the collection tank. Align the notches carefully and push down until you hear a click, indicating a secure fit. Next, attach the filter by sliding it into the designated slot within the main unit. Ensure it is seated properly to avoid any leakage during operation.

Proceed to connect the hose; insert one end into the main body and twist to lock it in place. Finally, plug in the power cord and check for any loose connections. Once everything is securely attached, your equipment is ready for use!

Maintenance Tips for Longevity

Ensuring the extended life of your cleaning device requires regular upkeep and attention. By implementing simple yet effective maintenance practices, you can enhance performance and prevent premature wear and tear.

| Maintenance Task | Frequency | Tips |

|---|---|---|

| Clean or Replace Filters | Monthly | Check for clogs and wash reusable filters thoroughly. |

| Inspect Hoses | Every Use | Look for cracks or blockages and clear them immediately. |

| Check Seals | Every Use | Ensure all seals are intact to maintain suction efficiency. |

| Empty Collection Container | After Each Use | Prevent overflow and maintain optimal performance. |

| Lubricate Moving Parts | Quarterly | Use appropriate lubricants to reduce friction. |

How to Troubleshoot Shop Vac Problems

Addressing issues with your cleaning device can be straightforward if you follow a systematic approach. Identifying common problems and their solutions can help restore functionality and extend the lifespan of your equipment.

| Issue | Possible Cause | Solution |

|---|---|---|

| No Power | Faulty outlet or power cord | Check the outlet and inspect the cord for damage. |

| Poor Suction | Clogged hose or filter | Clear any obstructions and clean or replace the filter. |

| Unusual Noise | Loose components or debris | Tighten screws and remove any foreign objects. |

| Overheating | Blocked airflow | Ensure vents are clear and avoid prolonged use. |

Comparing Accessories for Different Models

When evaluating various models of industrial cleaning equipment, it’s essential to consider the range of compatible accessories that enhance functionality and efficiency. Each unit may come with specific attachments and tools designed to optimize performance, making it crucial to understand the distinctions and similarities among them.

Compatibility is a key factor when assessing accessories. While some tools are universally compatible across different models, others may be tailored to specific units, limiting their use. This can affect both convenience and cost-effectiveness, as users might need to invest in multiple accessories for different machines.

Another important aspect is versatility. Certain attachments can perform multiple tasks, making them valuable additions regardless of the model. For instance, a multi-surface tool can be advantageous for users who need to transition between various cleaning applications, thus providing more value for the investment.

Durability and material quality also play significant roles in accessory selection. Accessories made from robust materials tend to last longer, withstand harsh conditions, and require less frequent replacement. This longevity not only saves money over time but also ensures consistent performance.

Ultimately, by comparing the available accessories for different models, users can make informed decisions that enhance their cleaning capabilities and align with their specific needs and preferences.

Understanding Shop Vac Specifications

When selecting a vacuuming solution for various tasks, it’s essential to grasp the fundamental specifications that influence performance and efficiency. These characteristics determine how well the equipment can handle debris, liquid, and other materials across different environments, whether for home use or professional applications.

Key specifications to consider include power rating, suction capability, and tank capacity. The power rating, typically measured in watts or horsepower, indicates the motor’s strength and its ability to generate airflow. Higher ratings generally correlate with better performance, especially in demanding situations.

Suction capability is another crucial factor, as it reflects how effectively the device can lift and move particles. This metric is often represented in inches of water lift or airflow measured in cubic feet per minute (CFM). Understanding these figures helps users choose a model suited to their specific cleaning requirements.

Lastly, tank capacity affects how much debris or liquid can be collected before needing to empty. A larger tank is beneficial for extensive projects, reducing downtime. Balancing these specifications according to personal or professional needs ensures optimal functionality and satisfaction with the equipment.

DIY Repairs and Upgrades

Taking matters into your own hands can greatly enhance the functionality and lifespan of your equipment. Whether you’re looking to fix a malfunction or boost performance, understanding the inner workings can lead to successful outcomes.

Common Repairs

- Inspecting and replacing worn-out seals.

- Cleaning clogged filters to restore airflow.

- Fixing electrical issues with simple wiring adjustments.

Upgrading Components

- Swapping out standard filters for high-efficiency alternatives.

- Installing additional attachments for versatile use.

- Upgrading the power cord for improved durability.

Recommended Retailers for Replacement Parts

Finding reliable sources for essential components can significantly enhance the longevity and performance of your equipment. Numerous retailers offer a variety of options, ensuring you can locate exactly what you need with ease.

Online Retailers

- Amazon – A vast selection with customer reviews.

- eBay – Great for both new and used items.

- Walmart – Competitive prices and local availability.

- Home Depot – Reliable for hardware and accessories.

Local Stores

- Ace Hardware – Personalized service and expert advice.

- Lowe’s – A broad inventory of home improvement products.

- True Value – Community-oriented and knowledgeable staff.