The maintenance and repair of a specific cutting unit are essential for optimal performance in lawn care. Familiarity with the intricate components of this equipment can significantly enhance its longevity and efficiency. By examining the individual elements, users can identify issues and streamline the replacement process, ensuring their machinery operates smoothly.

Each component plays a vital role in the functionality of the cutting apparatus, contributing to the overall cutting experience. A detailed exploration of these elements offers insights into their arrangement and interaction, making it easier for operators to troubleshoot and manage their equipment effectively. Whether for casual users or professional landscapers, understanding these components is crucial for successful maintenance.

In this section, we will delve into a comprehensive overview of the various elements that constitute a 42-inch cutting unit. By analyzing the structure and relationship between these components, users will gain the knowledge necessary to maintain their equipment properly, resulting in improved performance and extended service life.

Understanding John Deere Mower Decks

When it comes to maintaining a beautiful lawn, the right equipment can make all the difference. Among the various components that contribute to effective lawn care, the cutting assembly plays a pivotal role. This section explores the intricacies of these essential components, highlighting their functionality, design, and the significance of proper maintenance.

Key Features of Cutting Assemblies

The cutting assembly is engineered for efficiency and precision. It consists of multiple rotating blades designed to provide a clean and even cut, enhancing the overall health and appearance of the grass. Understanding how these assemblies work and their individual components is crucial for optimal performance and longevity.

Maintenance and Care

Regular maintenance ensures that the cutting assembly operates smoothly and effectively. This includes routine inspections, blade sharpening, and timely replacements of worn-out components. Familiarity with the various elements involved can aid in identifying issues before they escalate, ultimately saving time and resources.

| Component | Description | Function |

|---|---|---|

| Blade | Metal cutting tool | Trims grass to desired height |

| Spindle | Rotating shaft | Supports and drives the blade |

| Housing | Protective enclosure | Holds components in place |

| Lift Mechanism | Adjustable system | Raises and lowers the assembly |

Key Components of Mower Decks

Understanding the essential elements of cutting equipment is crucial for maintaining optimal performance and ensuring effective lawn care. Each component plays a vital role in the overall functionality, contributing to a well-manicured appearance and efficient operation.

The following table outlines the primary components typically found in such equipment, highlighting their functions and significance:

| Component | Description |

|---|---|

| Blades | Sharpened tools that slice through grass, creating a clean cut. |

| Spindle Assembly | Holds the blades in place and allows them to rotate efficiently. |

| Housing | Encases the cutting mechanism, providing protection and stability. |

| Belt | Transfers power from the engine to the blades, enabling movement. |

| Wheels | Facilitate mobility, allowing the apparatus to traverse various terrains. |

By familiarizing oneself with these key elements, users can better understand the mechanics of their equipment, leading to enhanced maintenance practices and improved cutting efficiency.

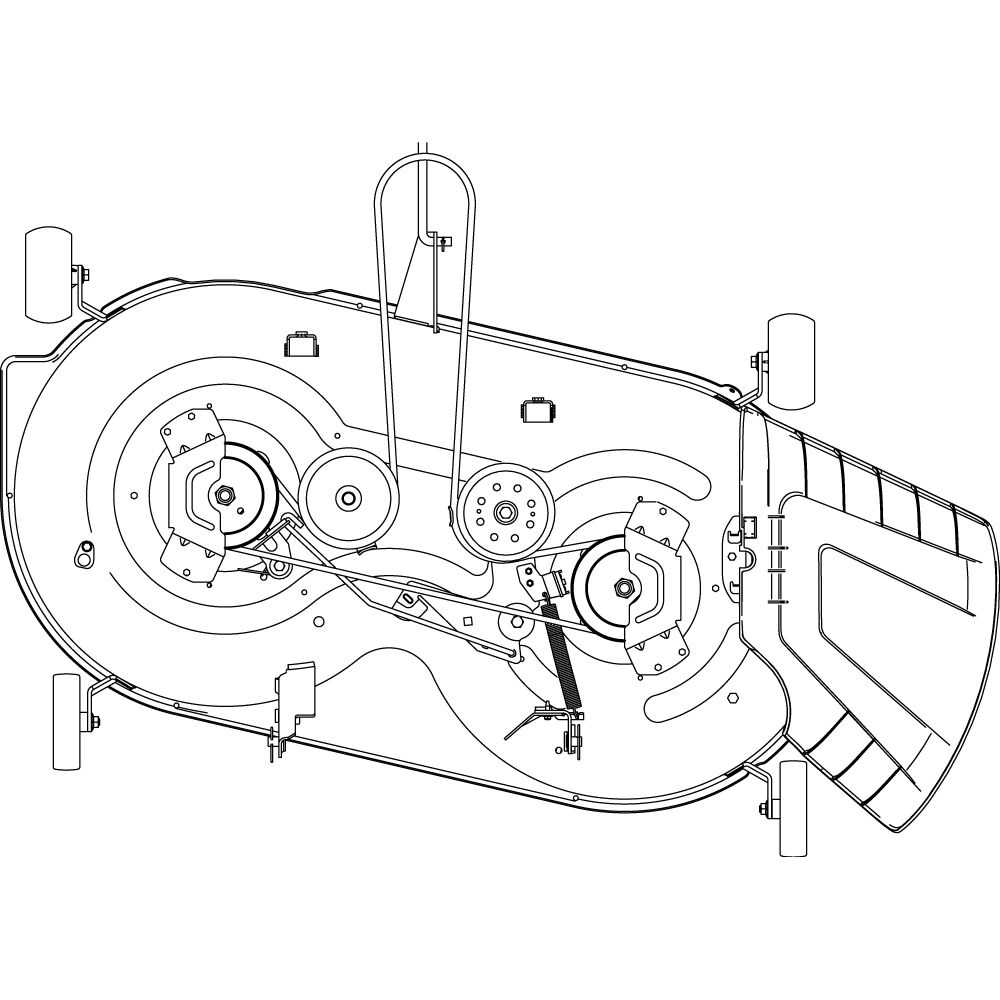

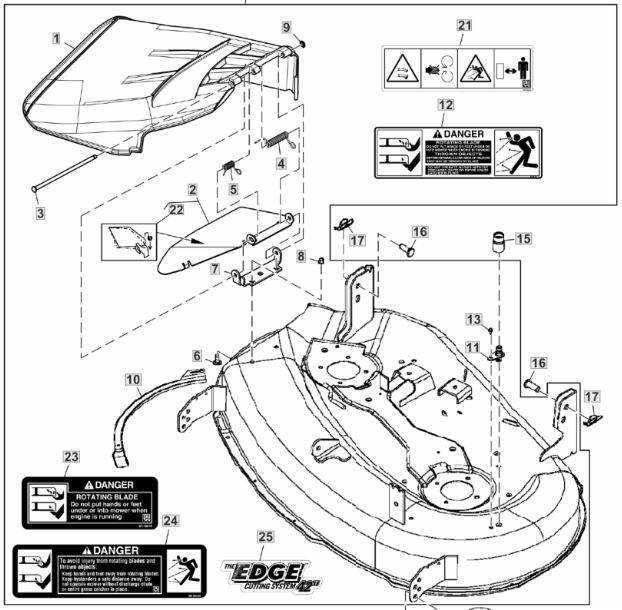

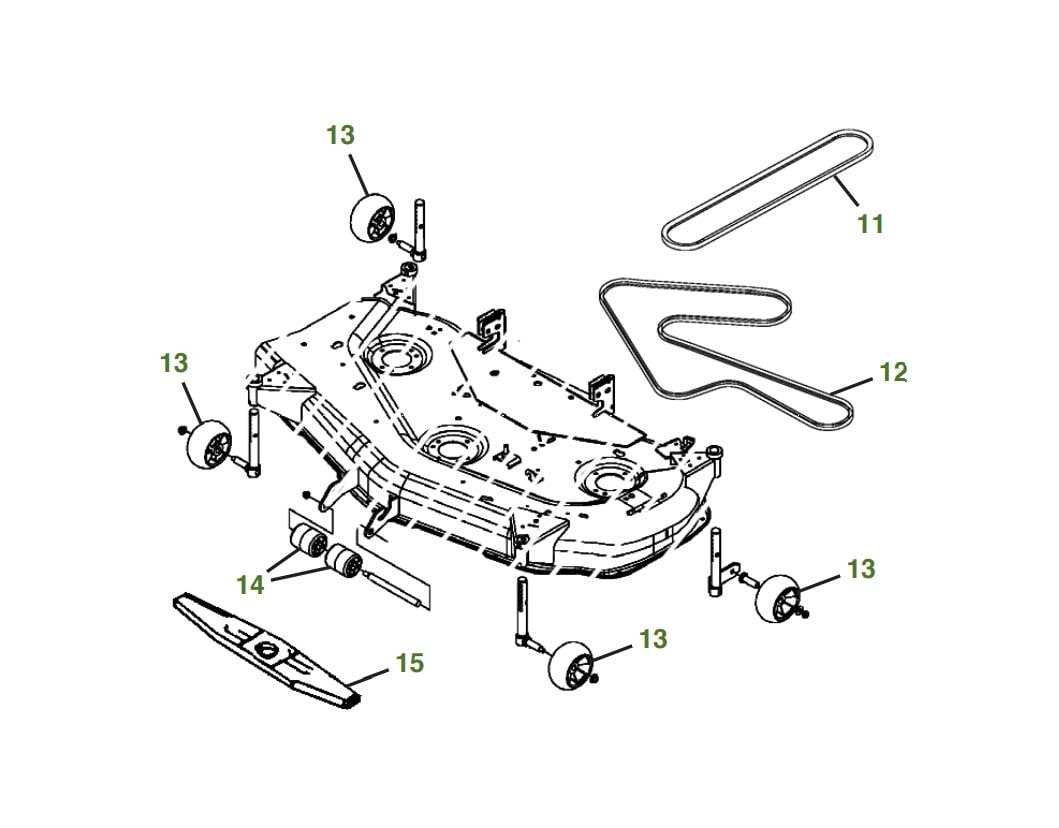

Identifying Parts in the Diagram

Understanding the various components depicted in the schematic is crucial for effective maintenance and repair. Each element serves a specific function, and recognizing them can greatly enhance your ability to troubleshoot and ensure optimal performance of your equipment. This section will guide you through the key features, enabling you to make informed decisions regarding repairs and upgrades.

Common Elements

Among the most frequently encountered components are the blades, housing, and drive mechanisms. Familiarizing yourself with these fundamental sections will provide a solid foundation for deeper exploration into the specifics of each item. Take note of their arrangement and interconnections, as this knowledge is vital for efficient operation.

Detailed Examination

A closer inspection of the visual representation reveals smaller components such as belts, pulleys, and adjustment levers. Identifying these finer details can significantly affect the performance and longevity of your machine. Ensuring that each part is in good condition and properly aligned is essential for preventing mechanical failures and ensuring a smooth operation.

How to Replace Mower Parts

Maintaining your equipment is essential for optimal performance. Over time, components may wear out or become damaged, necessitating replacement. Knowing the correct procedures can help ensure the longevity of your machinery and enhance its efficiency.

Gather Necessary Tools and Materials

Before starting the replacement process, collect all required tools and materials:

- Wrench set

- Screwdriver

- Replacement components

- Protective gloves

- Safety goggles

Steps for Replacing Components

- Ensure the equipment is turned off and disconnected from any power source.

- Identify the specific component that needs to be replaced.

- Use the appropriate tools to remove any fasteners or connections holding the component in place.

- Carefully detach the old component, ensuring not to damage surrounding areas.

- Install the new component by reversing the removal process, securing it firmly with the fasteners.

- Reconnect any electrical or mechanical links, if applicable.

- Perform a quick inspection to ensure everything is in order before testing the equipment.

Following these steps will help ensure a smooth replacement process, keeping your machinery in excellent working condition.

Maintenance Tips for Mower Decks

Proper care and upkeep are essential for ensuring the longevity and efficiency of your cutting equipment. Regular maintenance not only enhances performance but also minimizes the risk of breakdowns, ultimately saving time and money. Here are some important strategies to keep your machinery in top condition.

- Regular Cleaning: Remove grass clippings, dirt, and debris after each use. A clean surface prevents rust and maintains optimal performance.

- Inspect Blades: Check the sharpness of the cutting edges regularly. Dull blades can damage the grass and require more power to operate. Sharpen or replace blades as necessary.

- Check for Damage: Look for any signs of wear or damage, including cracks or bends. Addressing these issues early can prevent more extensive repairs later on.

- Lubricate Moving Parts: Apply appropriate lubricants to pivot points and other moving components to ensure smooth operation and reduce friction.

- Adjust Height Settings: Make sure the height settings are properly adjusted for your specific mowing conditions. This will promote healthy grass growth and improve cut quality.

- Inspect Belts and Cables: Regularly examine drive belts and cables for signs of wear or fraying. Replacing them promptly can prevent unexpected failures during operation.

- Store Properly: When not in use, store your equipment in a dry, sheltered location. Cover it to protect from dust and moisture.

By following these maintenance tips, you can ensure your cutting machinery remains efficient and reliable throughout its lifespan. Regular attention to these details will enhance performance and provide a cleaner, healthier lawn.

Common Issues with Mower Decks

The equipment designed for cutting grass can encounter various problems that hinder its performance. Understanding these challenges is essential for maintaining efficiency and ensuring longevity. By addressing common malfunctions, users can improve their experience and avoid costly repairs.

| Issue | Description | Possible Solutions |

|---|---|---|

| Uneven Cutting | This problem can occur when the cutting mechanism is not level or when the blades are dull. | Check the leveling of the assembly and sharpen or replace the blades as necessary. |

| Excessive Vibration | Excessive movement may indicate that components are loose or damaged, leading to an uncomfortable experience. | Tighten all bolts and inspect for any signs of wear or damage that need replacement. |

| Clogging | Grass build-up can restrict flow, affecting cutting efficiency and performance. | Regularly clean the area after use and consider adjusting the cutting height if clogging persists. |

| Noise Issues | Unusual sounds may signal mechanical problems or debris caught in the cutting assembly. | Inspect the mechanism for any foreign objects and ensure all components are functioning correctly. |

Finding Replacement Parts Online

Locating suitable components for outdoor machinery can be a straightforward process if you know where to look. With the abundance of resources available on the internet, enthusiasts and professionals alike can easily find the necessary items to maintain or restore their equipment. This guide will help you navigate the digital landscape to efficiently procure the right replacements.

Start by identifying the specific model of your machine. This information is crucial when searching for components, as it ensures compatibility and functionality. Once you have the model details, consider exploring various online retailers, including official manufacturers’ websites and third-party suppliers. Many platforms offer comprehensive catalogs, allowing you to browse through an extensive selection of items tailored to your needs.

Additionally, utilizing online forums and communities dedicated to outdoor equipment can provide valuable insights. Members often share their experiences with different suppliers and can recommend reliable sources for purchasing components. Don’t hesitate to reach out for advice; the collective knowledge within these groups can be a significant asset.

| Source Type | Examples |

|---|---|

| Manufacturer’s Website | Official Brand Site |

| Online Retailers | Amazon, eBay |

| Specialized Suppliers | Outdoor Equipment Stores |

| Community Forums | Reddit, Enthusiast Groups |

Before finalizing your purchase, compare prices and check for reviews to ensure you are making a wise investment. By following these steps, you can successfully find the components you need to keep your outdoor machinery running smoothly.

Tools Needed for Mower Repairs

When it comes to maintaining and fixing your landscaping equipment, having the right tools is essential. Proper tools not only make the job easier but also ensure that repairs are conducted efficiently and effectively. Below is a list of necessary instruments and equipment that will help you tackle common maintenance tasks.

- Wrenches: Adjustable and socket wrenches are crucial for loosening and tightening bolts and nuts.

- Screwdrivers: A set of flathead and Phillips screwdrivers is vital for removing and securing various components.

- Socket Set: This assortment helps in dealing with fasteners of different sizes, making it easier to work on assemblies.

- Pliers: Needle-nose and regular pliers are useful for gripping, twisting, and cutting wires.

- Jack Stands: Essential for safely lifting the equipment to access the underside during repairs.

In addition to the basic tools, consider including the following items in your toolkit:

- Torque Wrench: To ensure bolts are tightened to the manufacturer’s specifications.

- Fuel Stabilizer: Important for maintaining fuel quality during periods of non-use.

- Cleaning Supplies: Brushes, rags, and cleaning agents are necessary for removing dirt and debris from parts.

- Protective Gear: Safety goggles and gloves are important for protecting yourself during repairs.

- Service Manual: A comprehensive guide provides detailed instructions for specific models, making repairs more manageable.

Equipping yourself with these tools will not only prepare you for common repairs but also enhance the longevity and performance of your landscaping equipment.

Benefits of Regular Maintenance

Consistent upkeep of outdoor equipment is essential for optimal performance and longevity. Neglecting routine care can lead to decreased efficiency, higher operational costs, and premature equipment failure. By prioritizing regular service, users can ensure their machinery remains in excellent working condition.

Here are some key advantages of performing routine maintenance:

- Enhanced Performance: Regular check-ups help keep equipment running smoothly, ensuring it operates at peak efficiency.

- Extended Lifespan: Maintenance minimizes wear and tear, which can significantly prolong the lifespan of machinery.

- Cost Savings: Preventative care can help avoid costly repairs and replacements, ultimately saving money in the long run.

- Safety Assurance: Regular inspections reduce the risk of accidents and injuries caused by malfunctioning equipment.

- Environmental Responsibility: Well-maintained machines operate more efficiently, resulting in reduced emissions and environmental impact.

Investing time in regular maintenance is a proactive approach that yields substantial benefits, ensuring that equipment remains reliable and effective throughout its operational life.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on equipment is crucial for both personal well-being and the longevity of the machinery. Taking the necessary precautions can help prevent accidents and injuries, allowing for a more efficient repair process. Adhering to established safety protocols fosters a secure working environment, ultimately benefiting the repairer and the equipment alike.

First and foremost, always disconnect the power source before beginning any repair. This simple step can prevent accidental startups that may lead to serious injuries. Additionally, using the appropriate protective gear, such as gloves, goggles, and sturdy footwear, is essential to shield against potential hazards.

Furthermore, maintaining a clean and organized workspace is vital. Clutter can lead to slips, trips, and falls, increasing the risk of injury. Ensure all tools are in good condition and readily accessible, as this will minimize distractions and allow for a focused approach to the task at hand.

Lastly, familiarize yourself with the equipment’s manual and any safety guidelines provided by the manufacturer. Understanding the specific risks associated with the machinery will enable you to take informed precautions, enhancing your overall safety during repairs.