Understanding the intricacies of lawn care machinery can significantly enhance maintenance and efficiency. This section aims to provide a comprehensive look at the essential components that contribute to optimal performance. A well-structured assembly ensures longevity and reliability, making it crucial for users to grasp the specifics of each element involved.

By examining the various constituents and their arrangements, one can identify potential issues and streamline repairs. A detailed examination of these elements not only facilitates better understanding but also empowers owners to make informed decisions regarding upkeep and replacements.

Whether you are a novice or an experienced enthusiast, delving into the specifics of your equipment’s assembly will yield valuable insights. This ultimate guide serves as a resource for enhancing your knowledge and ensuring your machine operates at peak efficiency.

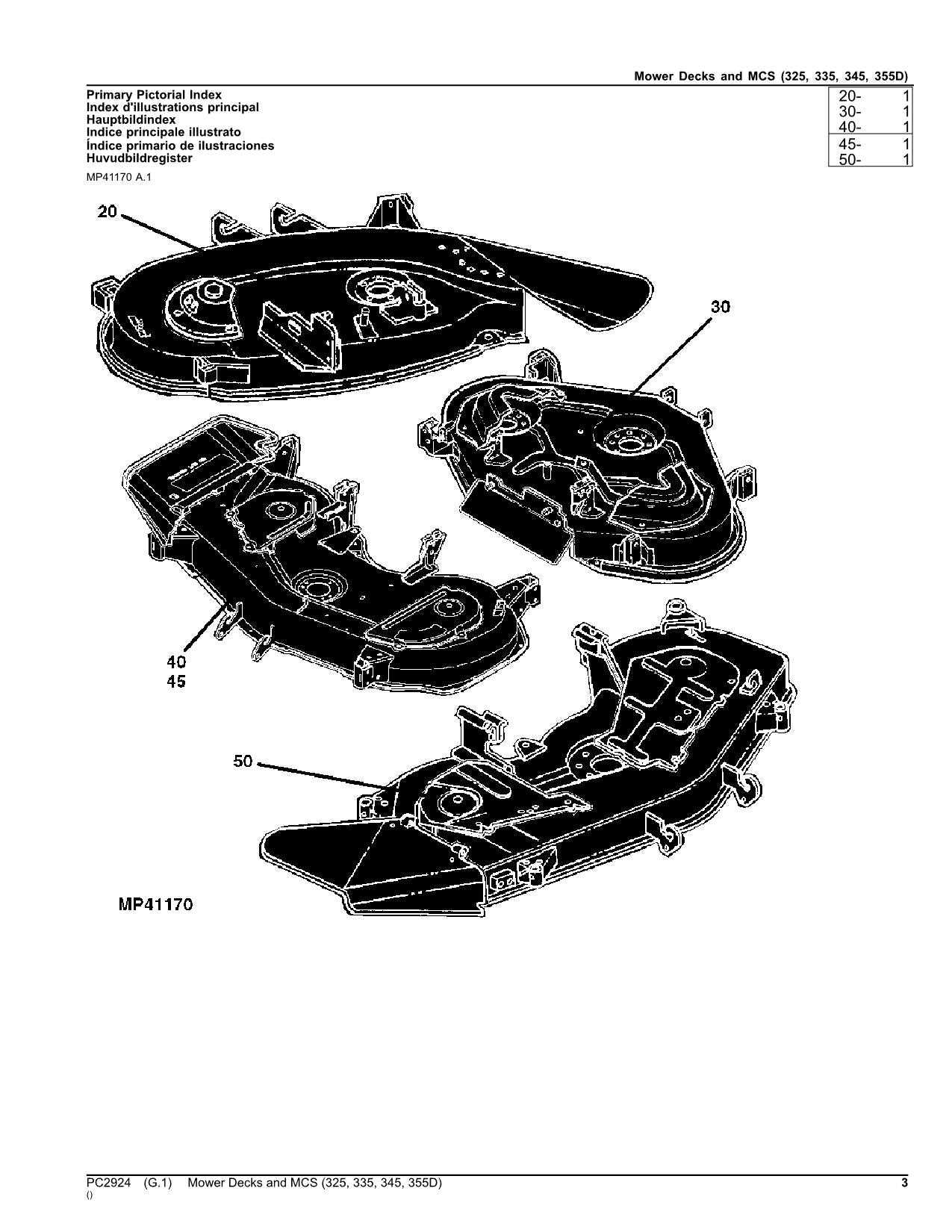

Understanding John Deere Mower Decks

When it comes to maintaining a pristine landscape, the significance of cutting apparatus cannot be overstated. These essential tools ensure even and efficient trimming, which contributes to the overall health and appearance of your greenery. Grasping the intricacies of these cutting systems enhances your ability to care for your outdoor spaces effectively.

Components play a vital role in the performance of these machines. Each element, from the rotating blades to the structural framework, is engineered for optimal functionality. Understanding how these components interact allows users to diagnose issues and perform necessary maintenance with confidence.

Moreover, accessories and additional features can greatly enhance the user experience. From mulching attachments to side discharge options, knowing what is available and how it complements the core system can lead to better results and increased satisfaction.

In summary, familiarizing oneself with these essential tools empowers users to make informed decisions regarding maintenance, upgrades, and overall operation, ensuring a beautifully maintained landscape year-round.

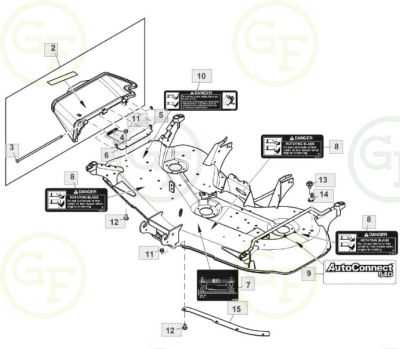

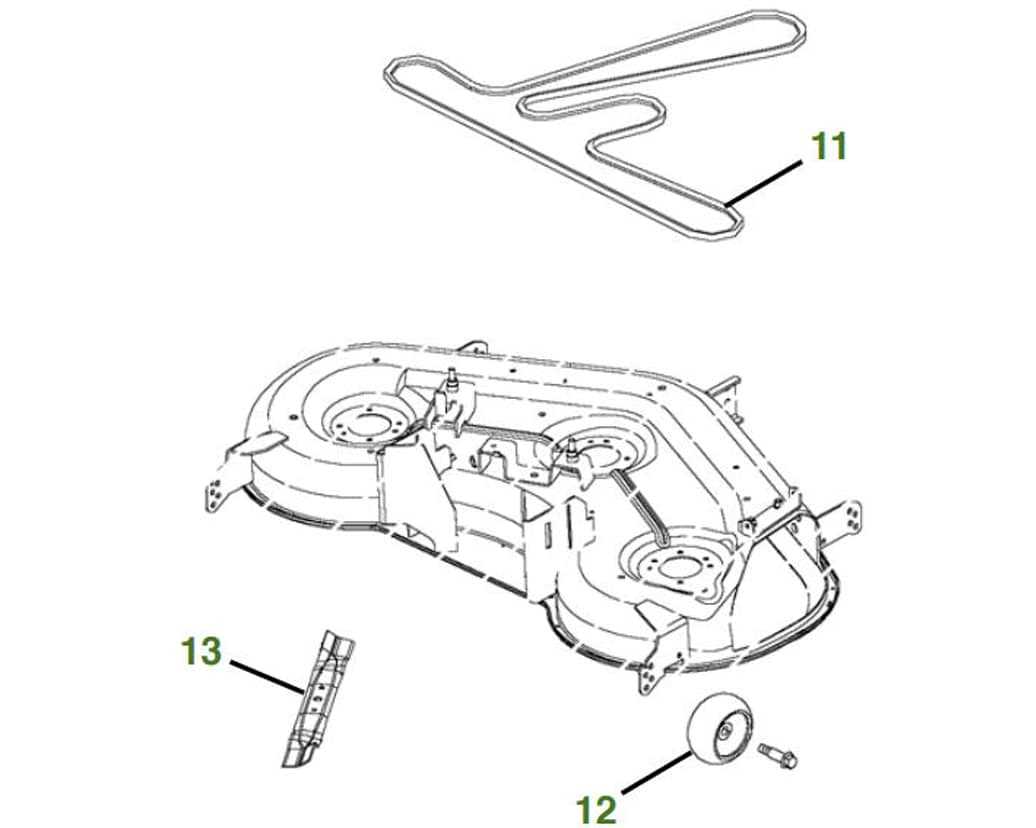

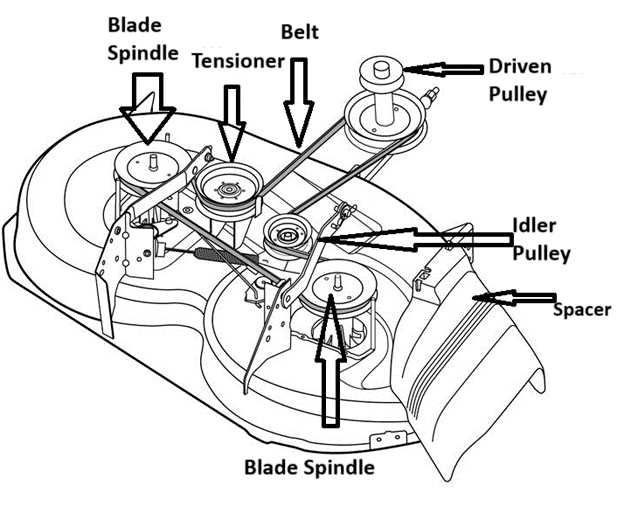

Components of a 54-Inch Mower Deck

Understanding the essential elements that contribute to the functionality of a cutting mechanism is vital for effective maintenance and performance. Each component plays a significant role in achieving an optimal result during operation.

- Blades: Sharp and durable, these are critical for achieving a clean cut.

- Spindle Assembly: Supports the blades and allows for smooth rotation.

- Housing: Encloses the internal components, providing protection and stability.

- Wheels: Facilitate movement and help in adjusting the cutting height.

- Drive Belt: Transfers power from the engine to the blades.

Each of these parts must be well-maintained to ensure the ultimate efficiency of the entire system.

Importance of Proper Maintenance

- Improved Performance: Regular maintenance helps maintain optimal functionality, allowing for better results during use.

- Increased Longevity: Consistent care can significantly extend the lifespan of your equipment, maximizing your investment.

- Cost Savings: Preventative measures can reduce the likelihood of major repairs, ultimately saving money over time.

- Safety Assurance: Well-maintained machinery is less likely to malfunction, reducing the risk of accidents during operation.

- Environmental Impact: Proper upkeep can lead to more efficient fuel usage, contributing to a lower environmental footprint.

In summary, the significance of routine care cannot be overstated. Establishing a maintenance routine ensures not only the performance and reliability of your equipment but also promotes safety and sustainability in your operations.

How to Identify Replacement Parts

Recognizing suitable components for your equipment can enhance performance and longevity. A systematic approach will ensure you choose the right elements that match your machine’s specifications.

Examine the Manual

Start by consulting the user manual, as it contains vital information about the specifications and compatible elements. Look for sections detailing maintenance and recommended replacements.

Utilize Online Resources

Online platforms offer extensive catalogs and visuals that help in pinpointing the exact items needed. Take advantage of these resources to delve into details and compare the necessary features before making your selection.

Common Issues with Mower Decks

When it comes to maintaining cutting equipment, several frequent challenges can arise that affect performance and efficiency. Understanding these issues can help ensure smoother operation and extend the lifespan of your machinery.

Uneven Cutting

One of the most prevalent problems is uneven cutting, which can result from dull blades or improper height adjustments. Regular sharpening of the blades and checking the height settings can significantly improve cutting quality.

Clogging and Debris Buildup

Another common issue is clogging due to grass clippings and debris accumulation. This can hinder functionality and lead to overheating. Regular cleaning after use and inspecting for blockages are essential practices to maintain optimal performance.

Tools Needed for Repairs

Having the right equipment is essential for effective maintenance and troubleshooting of your outdoor equipment. Proper tools not only streamline the repair process but also ensure that tasks are completed safely and efficiently.

- Wrenches and Sockets

- Screwdrivers (Flathead and Phillips)

- Pliers (Regular and Needle-Nose)

- Torque Wrench

- Utility Knife

Additionally, some specific tools might enhance your ability to delve deeper into complex repairs:

- Multi-Meter for Electrical Diagnostics

- Grease Gun for Lubrication

- Oil Filter Wrench

- Replacement Blades

- Safety Gear (Gloves and Goggles)

Investing in these essential tools can significantly improve your repair experience and lead to ultimate performance of your machinery.

Step-by-Step Repair Guide

This section provides a comprehensive approach to maintaining and fixing your lawn care equipment. By following these organized steps, you can ensure optimal performance and longevity.

| Step | Description |

|---|---|

| 1 | Gather all necessary tools and replacement components before starting the repair. |

| 2 | Disconnect the power source to prevent any accidents during the process. |

| 3 | Inspect the unit for any visible signs of damage or wear that need attention. |

| 4 | Carefully remove any parts that require replacement, using appropriate techniques. |

| 5 | Install the new components, ensuring they fit securely and align properly. |

| 6 | Reconnect the power source and test the equipment to verify successful repair. |

Where to Find Diagrams Online

Finding detailed illustrations online can significantly enhance your understanding of machinery and its components. Numerous resources are available that offer comprehensive visuals to aid in repair and maintenance tasks. Whether you are a seasoned technician or a novice, accessing these resources can prove invaluable.

Manufacturer Websites: Often, the official sites of equipment manufacturers provide a wealth of information, including manuals and detailed visuals. They ensure that the diagrams are accurate and up to date.

Online Forums: Communities dedicated to specific equipment often share user-generated content, including helpful diagrams. Engaging with these forums can lead you to rare resources that are not readily available elsewhere.

Parts Retailers: Websites that specialize in selling components often include diagrams for reference. These can help you identify specific items you may need for repairs.

Educational Resources: Various educational platforms and online libraries offer access to technical documents, including detailed illustrations that can help in understanding complex machinery.

By utilizing these resources, you can effectively navigate the world of machinery repair and ensure that you have the information needed for successful maintenance.

OEM vs. Aftermarket Parts Explained

When considering replacements for equipment components, understanding the differences between original and alternative options is crucial. Each category has its advantages and disadvantages, impacting performance, longevity, and cost. Navigating this landscape requires careful evaluation to ensure optimal functionality.

OEM items are produced by the original manufacturer, ensuring compatibility and adherence to specific standards. These components often come with warranties and are designed to work seamlessly with the equipment. However, they typically carry a higher price tag.

On the other hand, aftermarket options are made by third-party companies. They may offer a broader range of prices and could provide similar or improved performance. Nevertheless, quality can vary significantly, and not all alternatives guarantee the same level of reliability. Therefore, thorough research is essential when considering these options.

Understanding Deck Height Adjustment

Achieving the perfect cut requires an understanding of how to effectively modify the cutting height of your equipment. Proper adjustment not only enhances the aesthetics of your lawn but also promotes healthy grass growth by ensuring that blades are cut to an optimal length. This section explores the principles and methods behind height adjustments, providing essential insights for maintaining your equipment and achieving a pristine finish.

Importance of Height Adjustment

Adjusting the cutting height is crucial for several reasons:

- Grass Health: Maintaining the appropriate height helps grass develop deeper roots and resist drought and pests.

- Uniform Appearance: Consistent height leads to a more aesthetically pleasing lawn.

- Equipment Longevity: Proper adjustments reduce strain on the machinery, extending its lifespan.

Methods of Adjustment

There are various methods to adjust the cutting height effectively:

- Manual Adjustment: Most equipment comes with a lever or knob for easy manual height changes.

- Precision Measurement: Use a ruler or gauge to set the height accurately, ensuring a consistent cut.

- Regular Calibration: Periodically check the settings to ensure they remain accurate over time.

Understanding how to adjust cutting heights is vital for achieving the best results in lawn care, ensuring a healthy and beautiful landscape.

Tips for Optimizing Cutting Performance

Achieving an exceptional cut requires attention to various factors that influence the efficiency and quality of the task. Proper maintenance, the right techniques, and environmental considerations all play a significant role in ensuring optimal results. Below are essential strategies to enhance your cutting performance effectively.

Regular Maintenance

Routine upkeep is crucial for ensuring that your equipment operates at peak efficiency. Sharpening the blades regularly will significantly improve the quality of the cut, reducing stress on the machine and promoting a healthier lawn. Additionally, checking and replacing worn-out components will prevent complications during operation. Cleaning the underside of the unit after each use will also help maintain performance by preventing grass buildup that can affect cutting precision.

Cutting Techniques

Employing the right cutting techniques can lead to superior results. Adjusting the cutting height based on grass type and weather conditions ensures that the lawn receives the appropriate trim without damaging the grass. Moreover, mowing in different patterns can enhance the appearance of the yard and promote even growth. Finally, avoiding cutting wet grass will minimize clumping and ensure a cleaner finish.

Safety Precautions During Maintenance

Ensuring safety during maintenance tasks is essential for protecting yourself and your equipment. Adhering to proper protocols minimizes risks and promotes a secure working environment. Before beginning any maintenance work, it is crucial to follow established guidelines to prevent accidents and injuries.

- Always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear.

- Ensure the machine is powered down and disconnected from any power sources before starting repairs.

- Keep the workspace clean and free of debris to avoid slips and falls.

Additionally, it is important to be aware of potential hazards specific to the machinery you are working with.

- Familiarize yourself with the owner’s manual for specific safety recommendations.

- Use tools that are in good condition and appropriate for the task at hand.

- Never work alone; have a buddy system in place for assistance and support.

By taking these precautions seriously, you can effectively reduce the risk of injury and ensure a smooth maintenance process.

Cost Analysis of Replacement Parts

Understanding the financial implications of acquiring new components is essential for maintaining equipment efficiency. This analysis focuses on evaluating expenses associated with replacement items, helping users make informed decisions.

Factors influencing the cost include:

- Quality of materials

- Brand reputation

- Market demand

- Retailer pricing strategies

When considering replacements, users should evaluate:

- Initial cost versus longevity

- Compatibility with existing machinery

- Warranty and support services

Ultimately, a well-informed choice can lead to better performance and reduced long-term expenses.