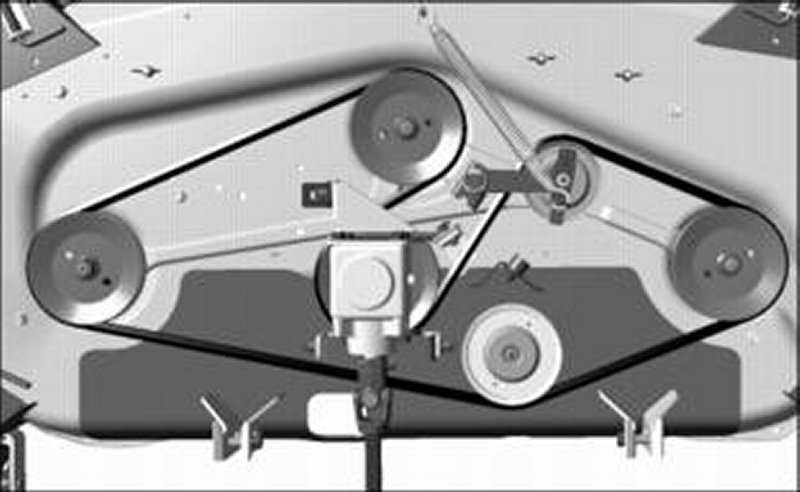

In the realm of lawn maintenance, having a thorough grasp of the various elements that make up cutting machinery is essential for effective operation and upkeep. A well-designed system ensures optimal performance, enabling the user to achieve the desired results with minimal effort. Familiarity with these components not only aids in troubleshooting but also empowers individuals to make informed decisions regarding repairs and replacements.

The intricate layout of the machinery showcases how different segments interact to produce efficient cutting capabilities. Recognizing each element’s role enhances one’s ability to identify potential issues and implement appropriate solutions. Furthermore, understanding the relationship between these components contributes to a smoother maintenance routine, ensuring longevity and reliability in the equipment.

When equipped with knowledge about the specific elements involved, users can confidently navigate repairs or upgrades. This expertise transforms what might seem like a daunting task into a manageable process. Ultimately, comprehending the structure and function of the various components fosters a sense of ownership and satisfaction in lawn care practices.

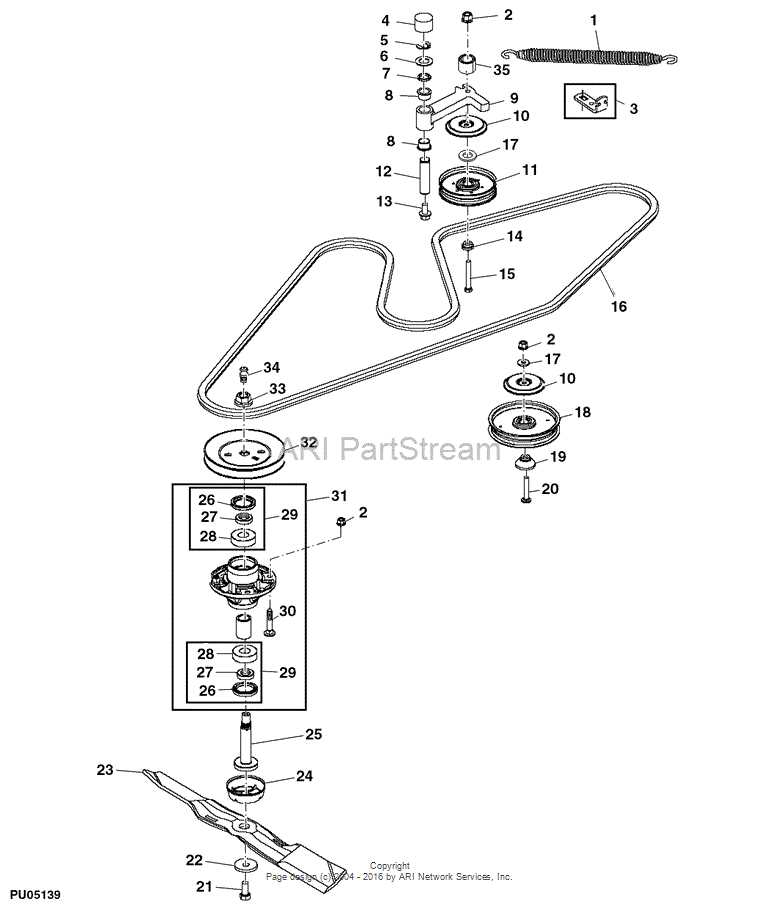

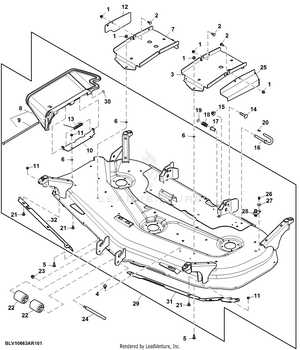

Grasping the layout of a cutting apparatus is essential for effective maintenance and repairs. By familiarizing oneself with the schematic representation, users can easily identify individual components and their respective functions, facilitating efficient troubleshooting and part replacement.

This visual guide typically includes various sections that illustrate key elements of the machinery, offering clarity on assembly and disassembly processes. Here are some benefits of consulting such a schematic:

- Identification: Quickly locate each component and its specific role within the system.

- Maintenance: Understand which parts require regular upkeep and monitoring.

- Troubleshooting: Efficiently diagnose issues by tracing back through the layout.

- Replacement: Determine the exact pieces needed for repairs, minimizing downtime.

Overall, becoming acquainted with the visual representation not only enhances operational efficiency but also empowers users to undertake repairs with confidence.

Common Issues with Mower Decks

The functioning of grass-cutting machinery can be affected by various challenges that users may encounter. Understanding these common problems can lead to better maintenance and a more efficient operation.

1. Uneven Cutting: One frequent issue is uneven grass trimming, which can result from dull blades or improper height settings. Regular blade sharpening and adjustment of the cutting height are essential for achieving a uniform finish.

2. Clogging: Another common problem is the accumulation of grass clippings and debris. This can hinder performance and lead to overheating. Regular cleaning after use can prevent clogs and maintain optimal airflow.

3. Vibration: Excessive vibrations during operation may indicate loose components or misalignment. Checking and tightening bolts and screws can resolve this issue, ensuring a smoother performance.

4. Rust and Corrosion: Exposure to moisture can cause rust, which weakens metal components. Applying protective coatings and storing the equipment in a dry place can help mitigate this issue.

5. Belt Wear: The wear and tear of belts is another common concern that can affect the efficiency of the machinery. Regular inspection and timely replacement can help avoid breakdowns during use.

Replacement Parts for 62C Model

When it comes to maintaining your lawn care equipment, having access to quality components is essential. These elements play a crucial role in ensuring the longevity and efficiency of your machine. Understanding the various options available for replacements can help you make informed decisions for upkeep.

Identifying the appropriate components can significantly enhance performance. Whether you require new blades, belts, or spindles, it is important to choose high-quality alternatives that align with your equipment’s specifications. Utilizing compatible replacements not only improves functionality but also ensures that your device operates at its best.

Moreover, sourcing these items from reputable suppliers guarantees authenticity and reliability. This attention to detail is crucial for achieving optimal results in your lawn maintenance tasks. Investing in suitable components ultimately leads to a smoother operation and a well-maintained outdoor space.

Maintenance Tips for Mower Deck

Regular upkeep is essential for ensuring optimal performance and longevity of your lawn care equipment. By following a few simple practices, you can enhance efficiency and prevent potential issues. Proper maintenance not only saves time but also reduces the need for costly repairs.

Cleaning Procedures

Keeping the surface free of grass clippings, dirt, and debris is crucial. A clean environment allows the equipment to function smoothly. Use a brush or a hose to remove accumulated materials after each use. This helps in preventing corrosion and ensures better cutting efficiency.

Regular Inspections

Frequent checks for wear and tear can help identify issues before they become serious. Inspect blades for sharpness, and look for any signs of damage. Timely replacements and adjustments can greatly extend the life of your equipment.

| Maintenance Task | Frequency |

|---|---|

| Clean the surface | After each use |

| Inspect blades | Monthly |

| Sharpen blades | Every 20 hours of use |

| Check belts and cables | Seasonally |

How to Identify Worn Parts

Identifying components that have experienced significant wear is essential for maintaining optimal performance of your equipment. Regular inspections help ensure that everything operates smoothly and efficiently, preventing potential breakdowns and costly repairs.

Visual Inspection: Start by closely examining the exterior of each element. Look for signs of damage such as cracks, rust, or unusual wear patterns. Any visible irregularities can indicate that the part may need to be replaced.

Operational Performance: Pay attention to how the machinery functions during use. Unusual noises, vibrations, or decreased efficiency can signal that certain components are no longer performing at their best. If you notice any of these issues, it may be time to investigate further.

Measurement: For precise identification, utilize measuring tools to assess the dimensions of critical parts. Comparing these measurements against the manufacturer’s specifications can reveal whether a component has worn down beyond acceptable limits.

Consult Documentation: Reference the user manual or service guides for specific recommendations regarding maintenance intervals and signs of wear. These resources provide valuable insights that can help you make informed decisions about replacement and repairs.

Benefits of Original Equipment Parts

Using authentic components for machinery can significantly enhance performance and longevity. These specialized items are designed to meet the original specifications, ensuring that the equipment operates smoothly and efficiently. Below are some key advantages of opting for original parts.

- Quality Assurance: Authentic components are manufactured to rigorous standards, guaranteeing reliability and durability.

- Optimal Fit: These parts are specifically designed for compatibility with the equipment, reducing the risk of malfunction.

- Improved Performance: Original parts help maintain the intended functionality, allowing machinery to operate at peak efficiency.

- Warranty Protection: Utilizing genuine components often helps preserve the warranty of the machinery, providing peace of mind.

- Better Resale Value: Equipment that has been maintained with original parts tends to retain its value more effectively over time.

Choosing authentic components ensures that the machinery remains in optimal condition, ultimately leading to cost savings and enhanced productivity.

Compatibility with Other Models

Understanding the compatibility of specific components with various machines can enhance the performance and efficiency of your equipment. Many parts are designed to fit multiple models, providing flexibility and options for users looking to optimize their tools.

When considering replacement components or enhancements, it is essential to identify which models can accommodate these parts. This not only streamlines maintenance but also expands the functionality of your machinery.

| Model Series | Compatible Parts | Notes |

|---|---|---|

| Series 100 | Various components | Check specific requirements for fitment. |

| Series 200 | Multiple options available | Ideal for users seeking enhanced features. |

| Series 300 | Standard parts | Compatibility confirmed for standard configurations. |

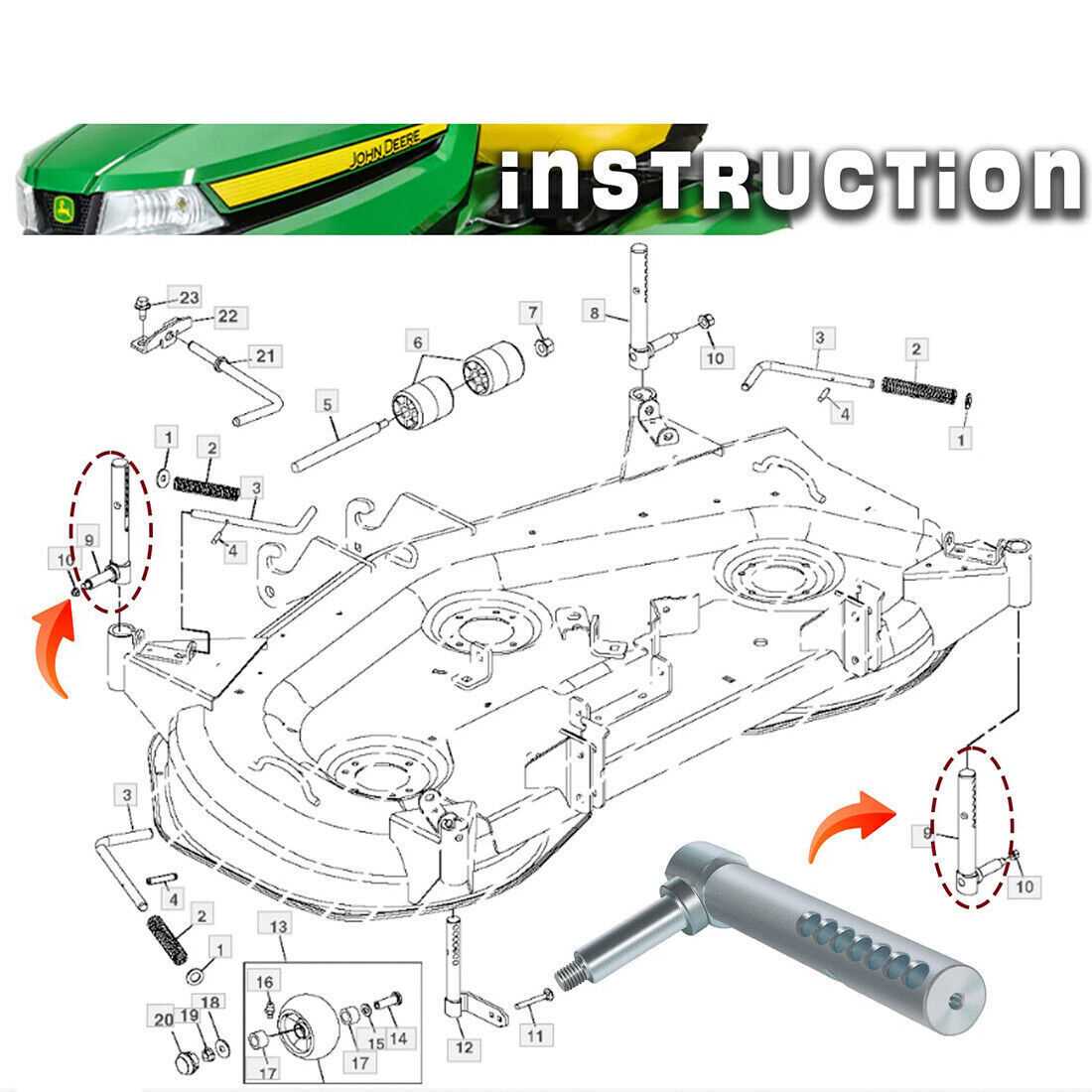

Tools Needed for Repairs

When performing maintenance and fixing outdoor machinery, having the right tools is essential for effective and efficient work. A well-equipped toolkit ensures that you can tackle various tasks with confidence and precision.

For general repairs, you will typically require a combination of hand tools such as wrenches, screwdrivers, and pliers. Additionally, socket sets and ratchets are invaluable for loosening and tightening fasteners in tight spaces.

In some cases, specialty tools like blade sharpeners and alignment tools may be necessary to ensure that all components function correctly. Investing in quality equipment can save time and prevent frustration during repair sessions.

Always remember to wear appropriate safety gear, including gloves and goggles, to protect yourself while working with tools. Proper preparation and the right instruments will lead to successful maintenance outcomes.

Step-by-Step Repair Instructions

This section provides a comprehensive guide for conducting repairs on your equipment. Following these instructions carefully will ensure a smooth process, enabling you to restore functionality efficiently. Each step is outlined to facilitate understanding and execution.

Begin by gathering all necessary tools and materials before starting the repair. This preparation helps streamline the process and reduces interruptions. Make sure to have a clean workspace to keep track of all components easily.

Next, refer to the relevant manual or visual references to identify the specific areas that need attention. Carefully inspect for any signs of wear, damage, or misalignment. Document any issues you encounter, as this information will be useful during the repair process.

Proceed with disassembly by following the designated steps, ensuring that you keep track of each component’s location. Use appropriate tools to avoid damaging any parts. Organizing screws and small items can prevent confusion during reassembly.

Once you have access to the necessary sections, clean all surfaces thoroughly to remove debris and residue. Inspect parts for any signs of wear or potential failure. Replace any components as needed based on your assessment.

After completing the necessary repairs and replacements, reassemble the equipment in the reverse order of disassembly. Ensure that each component is securely fastened and correctly aligned to prevent future issues.

Finally, perform a thorough test to confirm that everything is functioning properly. Regular maintenance checks can help identify potential problems early, prolonging the life of your equipment.

Where to Purchase Replacement Parts

Finding suitable components for your lawn maintenance equipment is crucial for ensuring its longevity and efficiency. Various options are available for acquiring these essential items, whether through local retailers, specialized stores, or online platforms. Understanding where to look can help streamline the replacement process and minimize downtime.

Local Retailers and Dealers

One of the most straightforward methods to source necessary items is by visiting local retailers or authorized dealers. These establishments often carry a selection of items and can provide expert advice on compatibility and installation. Additionally, purchasing locally allows for immediate access to components without the wait associated with online orders.

Online Marketplaces

For those seeking convenience, online marketplaces present a vast array of options. Numerous websites specialize in outdoor equipment and can provide detailed information about available items. Comparing prices and reading customer reviews can help you make informed decisions before finalizing your purchase.

| Source Type | Benefits |

|---|---|

| Local Retailers | Immediate access and expert advice |

| Authorized Dealers | Guaranteed compatibility and quality assurance |

| Online Marketplaces | Wider selection and price comparisons |