Maintaining a lush, well-manicured lawn requires a reliable machine designed for efficient grass cutting. A comprehensive knowledge of its individual components is essential for optimal performance and longevity. This section delves into the various elements that make up this essential tool, providing insights into their functionality and interconnections.

Exploring the assembly reveals the importance of each part in achieving a smooth and effective operation. From the cutting mechanism to the supporting structures, every component plays a vital role in ensuring the machine operates at peak efficiency. This guide will illuminate the intricate workings of the device, helping users identify and understand its critical features.

Whether you’re a seasoned operator or new to lawn maintenance, familiarizing yourself with the intricate design will enhance your ability to troubleshoot and perform necessary upkeep. A detailed examination of the assembly will empower you to make informed decisions when it comes to repairs and replacements, ultimately leading to a more enjoyable experience in lawn care.

Understanding the D160 Mower Deck

The cutting mechanism of this popular outdoor equipment is a vital component that greatly influences its performance and efficiency. Familiarizing oneself with its structure and functionality is essential for effective maintenance and operation. This segment delves into the various elements that constitute the cutting assembly, highlighting their roles and importance in achieving a well-manicured lawn.

At the core of this assembly is the rotary cutting feature, which employs sharp blades to shear grass at a consistent height. This mechanism is supported by several crucial components that ensure smooth operation and durability. Proper knowledge of these components aids users in troubleshooting common issues and facilitates effective repairs, ultimately prolonging the lifespan of the machine.

Additionally, the arrangement and configuration of these elements contribute significantly to the overall cutting quality. Users must pay attention to the spacing and alignment, as these factors directly impact the efficiency of the grass-cutting process. Understanding how each piece interacts allows for better adjustments and optimizations, leading to improved results.

Regular inspections and maintenance routines are critical for keeping the cutting system in peak condition. By staying informed about the various components and their functions, operators can make informed decisions regarding upkeep and repairs. This knowledge fosters a greater appreciation for the equipment, ensuring that it performs at its best throughout its lifespan.

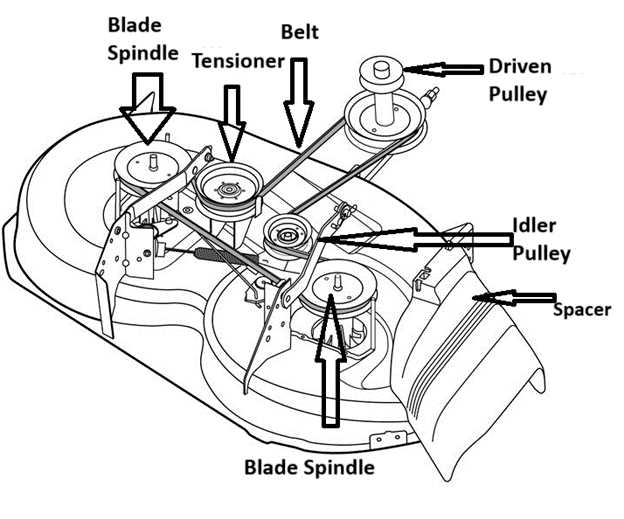

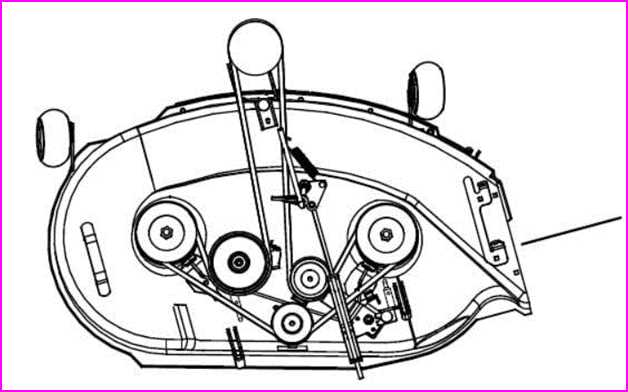

Components of the Mower Deck

The cutting system of a grass trimming machine consists of various essential elements that work together to achieve efficient grass management. Each component plays a critical role in ensuring the machine operates smoothly and effectively, contributing to the overall performance and longevity of the equipment.

Key Elements

Understanding the main components can help users maintain and troubleshoot their machines effectively. Each section is designed to fulfill specific functions, enhancing the overall efficiency of the system.

| Component Name | Description |

|---|---|

| Blade Assembly | Central unit responsible for cutting grass at various lengths, designed for sharpness and durability. |

| Spindle Housing | Protects the rotating shaft and supports the blade assembly, ensuring stability during operation. |

| Lift Mechanism | Allows users to adjust the height of the cutting unit, facilitating cutting at desired grass lengths. |

| Belts | Transmit power from the engine to the blade assembly, crucial for smooth operation and efficiency. |

| Support Frame | Provides structural integrity to the entire unit, allowing for stability and durability during use. |

Maintenance Considerations

Regular inspection and maintenance of these elements are vital for optimal performance. Keeping components clean, sharp, and properly adjusted will enhance the functionality and lifespan of the entire assembly.

Common Issues with Mower Decks

Maintaining a cutting unit is essential for achieving optimal performance and longevity. However, several common challenges can arise during usage, affecting its efficiency and overall functionality. Identifying these issues early on can save time and resources while ensuring that the equipment operates smoothly.

Uneven Cutting

One frequent problem encountered is uneven trimming, which can result from improper alignment or height settings. This inconsistency may lead to an unsightly lawn and can necessitate additional passes to achieve a uniform appearance. Regularly checking the alignment and making adjustments as needed can help mitigate this issue.

Clogging

Another prevalent concern is the buildup of grass clippings and debris, which can obstruct the cutting mechanism. This accumulation not only affects performance but can also cause damage if not addressed promptly. To prevent this, it is advisable to clean the unit after each use and ensure that the discharge area is clear.

Being aware of these typical problems and addressing them proactively can enhance the efficiency and lifespan of the equipment.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan and optimal performance of your equipment. Regular attention to various components will not only enhance functionality but also prevent costly repairs in the long run. Adopting a proactive approach to maintenance can significantly increase the reliability and efficiency of your machinery.

Here are some key practices to consider for effective maintenance:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check Oil Levels | Every use | Ensure that oil levels are within the recommended range to promote smooth operation. |

| Inspect Blades | Weekly | Examine cutting edges for wear and sharpen or replace as necessary to maintain cutting efficiency. |

| Clean Underbody | After each use | Remove debris and grass clippings to prevent rust and improve airflow. |

| Check Belts and Cables | Monthly | Inspect for signs of wear or fraying, and replace if needed to ensure proper function. |

| Battery Maintenance | Seasonally | Clean terminals and check connections to ensure reliable starting and operation. |

Implementing these practices will help maintain your equipment’s efficiency and prolong its life, leading to more enjoyable and productive use.

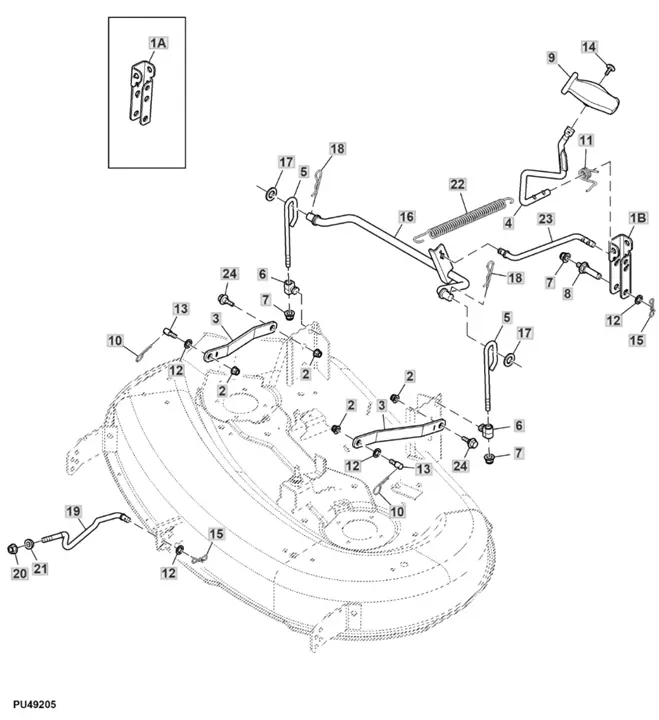

Parts Identification and Functionality

This section aims to provide an overview of various components utilized in a specific lawn maintenance machine, highlighting their significance and roles in ensuring optimal performance. Understanding these elements is essential for effective upkeep and troubleshooting, enabling users to maintain their equipment in prime condition.

Each element within this mechanism serves a unique purpose, contributing to the overall functionality. For instance, the cutting assembly is crucial for achieving precise grass trimming, while the drive system facilitates movement across different terrains. Additionally, adjustable settings allow operators to customize cutting heights, enhancing the machine’s adaptability to varying lawn conditions.

Moreover, wear components such as bearings and belts require regular inspections to prevent operational disruptions. Recognizing signs of wear can lead to timely replacements, thereby prolonging the lifespan of the equipment. Furthermore, understanding how each part interacts within the system provides valuable insights for effective troubleshooting and repair.

Replacement Parts Overview

Understanding the essential components of lawn maintenance equipment is crucial for effective operation and longevity. This section provides a comprehensive look at the various elements that may need to be replaced over time, ensuring that your machine remains in optimal working condition. Regular maintenance and timely replacements can significantly enhance performance and efficiency.

When considering component replacements, it’s important to identify the specific items that may wear out or become damaged during usage. From cutting blades to belts and pulleys, each element plays a vital role in the overall functionality of the equipment. Utilizing high-quality replacements is essential for maintaining reliability and achieving the desired results in your landscaping tasks.

Furthermore, having a well-structured overview of available components aids in planning and budgeting for maintenance. By familiarizing yourself with the various options and their respective functions, you can make informed decisions about necessary upgrades or replacements. This proactive approach can save time and resources in the long run, ensuring that your equipment performs at its best.

Tools Required for Repairs

When performing maintenance on your equipment, having the right tools at your disposal is crucial for ensuring efficient and effective repairs. This section outlines the essential instruments needed to facilitate the process, allowing for a smoother experience and minimizing potential complications during the task.

First and foremost, a set of wrenches is indispensable. These come in various sizes and types, including socket and adjustable options, enabling you to tackle different fasteners with ease. Additionally, a screwdriver set featuring both flathead and Phillips varieties is necessary for loosening or tightening screws.

Another important tool is a ratchet and socket set. This equipment simplifies the task of removing bolts and nuts, especially in tight spaces. Furthermore, a torque wrench is recommended to ensure that all fasteners are tightened to the manufacturer’s specifications, preventing future issues.

To enhance your workflow, consider having pliers on hand for gripping and twisting wires or other components. A utility knife can also be beneficial for cutting through various materials such as tape or zip ties during the repair process.

Finally, a reliable work light will aid visibility, particularly in dimly lit areas, allowing you to see intricate components clearly. By equipping yourself with these essential tools, you can approach repairs with confidence and achieve successful results.

Assembly Instructions for D160 Deck

This section provides a comprehensive guide to assembling the cutting mechanism for your equipment. Proper assembly is crucial for optimal performance and longevity. By following these instructions carefully, you can ensure that all components fit together seamlessly and function as intended.

Step 1: Begin by laying out all the necessary components on a flat surface. This will help you visualize the assembly process and ensure that you have everything required before starting.

Step 2: Identify the main frame and attach the necessary brackets. Make sure to secure them tightly using the provided fasteners. A well-attached frame will provide the structural integrity needed for the entire assembly.

Step 3: Next, position the blades. Align each blade with its corresponding mounting point and ensure they are oriented correctly. Use the specified tools to secure them firmly, paying attention to the manufacturer’s torque specifications.

Step 4: After the blades are secured, install the drive mechanism. This component connects the power source to the blades, enabling them to rotate efficiently. Check for any obstructions and ensure that all connections are tight.

Step 5: Finally, perform a thorough inspection of the assembly. Ensure that all parts are securely fastened and that there are no loose components. After confirming everything is in place, you can proceed to the testing phase to verify functionality.

By following these steps, you will successfully assemble the cutting mechanism, ensuring it operates smoothly and efficiently for your needs.

Visual Guide to Mower Parts

This section aims to provide a clear and detailed representation of the components essential for maintaining and operating a lawn care machine. Understanding these elements can enhance the performance and longevity of the equipment, ensuring efficient and reliable operation.

Essential Components

- Cutting Mechanism

- Drive System

- Chassis

- Wheel Assembly

- Grass Collector

Maintenance and Care

- Regularly inspect the cutting mechanism for wear and damage.

- Ensure the drive system is free from debris and well-lubricated.

- Check the wheel assembly for proper alignment and pressure.

- Clean the grass collector after each use to prevent clogs.

Upgrades for Improved Performance

Enhancing the efficiency and effectiveness of your outdoor equipment can significantly boost its operational capabilities. By incorporating a variety of modifications, users can achieve a more powerful and reliable experience. Whether you are seeking increased power, better handling, or enhanced durability, there are several options to consider that can elevate your machinery’s performance.

Power and Efficiency Enhancements

One of the most impactful improvements is upgrading the engine components. Implementing a high-performance air filter can enhance airflow, resulting in improved combustion and overall efficiency. Additionally, investing in a premium fuel system can optimize fuel delivery, maximizing the power output. Regular maintenance of these components is also essential for sustaining peak performance.

Durability Improvements

Upgrading certain structural elements can lead to a longer lifespan for your equipment. Utilizing reinforced materials for key parts can enhance resistance to wear and tear. Furthermore, implementing protective coatings can shield against rust and corrosion, which is crucial for longevity, especially in challenging environments. These enhancements ensure that your equipment remains reliable over time.

Where to Purchase Replacement Parts

Finding quality components for your outdoor equipment can significantly enhance its performance and longevity. Various sources provide essential items, ranging from authorized retailers to online marketplaces. Understanding where to seek these resources can simplify your maintenance process and ensure your machinery operates at its best.

Here are some reliable options for acquiring replacement items:

| Source Type | Description | Examples |

|---|---|---|

| Authorized Dealers | These outlets provide genuine components, ensuring compatibility and quality. | Local dealership, manufacturer’s website |

| Online Retailers | Many websites offer a wide range of components, often at competitive prices. | Amazon, eBay, specialized parts websites |

| Local Repair Shops | Local repair facilities may stock essential items and can assist with installation. | Small engine repair shops, garden centers |

| Aftermarket Suppliers | These suppliers provide alternatives to original components, often at lower prices. | Online aftermarket retailers, discount parts stores |

Choosing the right source for your components depends on your specific needs, budget, and preference for original versus alternative items. It is advisable to compare prices and check reviews to ensure you receive quality products.

Comparing D160 with Other Models

This section explores the differences and similarities between a specific model and its counterparts in the same category. By examining the features, performance, and overall design, users can gain insight into how this particular variant stacks up against others in the lineup.

When considering various alternatives, it’s essential to analyze key aspects such as cutting efficiency, ease of maintenance, and user comfort. Many options may offer comparable horsepower and cutting widths, yet subtle distinctions in design and engineering can significantly impact user experience and functionality.

Additionally, evaluating the attachments and compatibility with other implements can provide further context for making an informed decision. Each model may excel in certain areas, making it crucial for potential buyers to consider their specific needs and preferences when comparing their options.

Customer Experiences and Feedback

This section aims to provide insights into user interactions and impressions regarding the maintenance equipment’s operational components. By collecting and analyzing feedback from various users, we can gain valuable perspectives that highlight strengths, areas for improvement, and overall satisfaction with the product.

User Reviews Summary

Feedback from individuals who utilize this type of equipment can offer a wealth of information. Many users have shared their thoughts on performance, reliability, and ease of use, contributing to a comprehensive understanding of the product’s capabilities.

| User Rating | Comments |

|---|---|

| 5/5 | Exceptional performance; easy to maneuver and efficient. |

| 4/5 | Great build quality, but I faced minor assembly challenges. |

| 3/5 | Decent overall; however, I expected more durability. |

| 2/5 | Not satisfied with the functionality; had issues with some components. |

| 1/5 | Disappointing experience; did not meet my expectations. |

Common Themes in Feedback

Several recurring themes emerge from user comments. Many appreciate the efficiency and effectiveness of the equipment, while others express concerns about certain aspects, such as durability and ease of assembly. Addressing these issues can lead to enhancements in future iterations of the product.