Understanding the structure and function of various mechanical elements is crucial for efficient operation and maintenance. A detailed review of key elements ensures that each component performs its role within the larger system, contributing to smooth and reliable functionality.

By examining the individual sections, users can gain a clearer picture of how the system’s various elements work together. This knowledge aids in troubleshooting, repairs, and overall performance optimization, making it easier to identify and address issues as they arise.

Each component is designed with a specific function in mind, and understanding these functions helps in ensuring that all aspects of the machinery work in harmony. Regular upkeep and proper handling of these elements extend the life and effectiveness of the system as a whole.

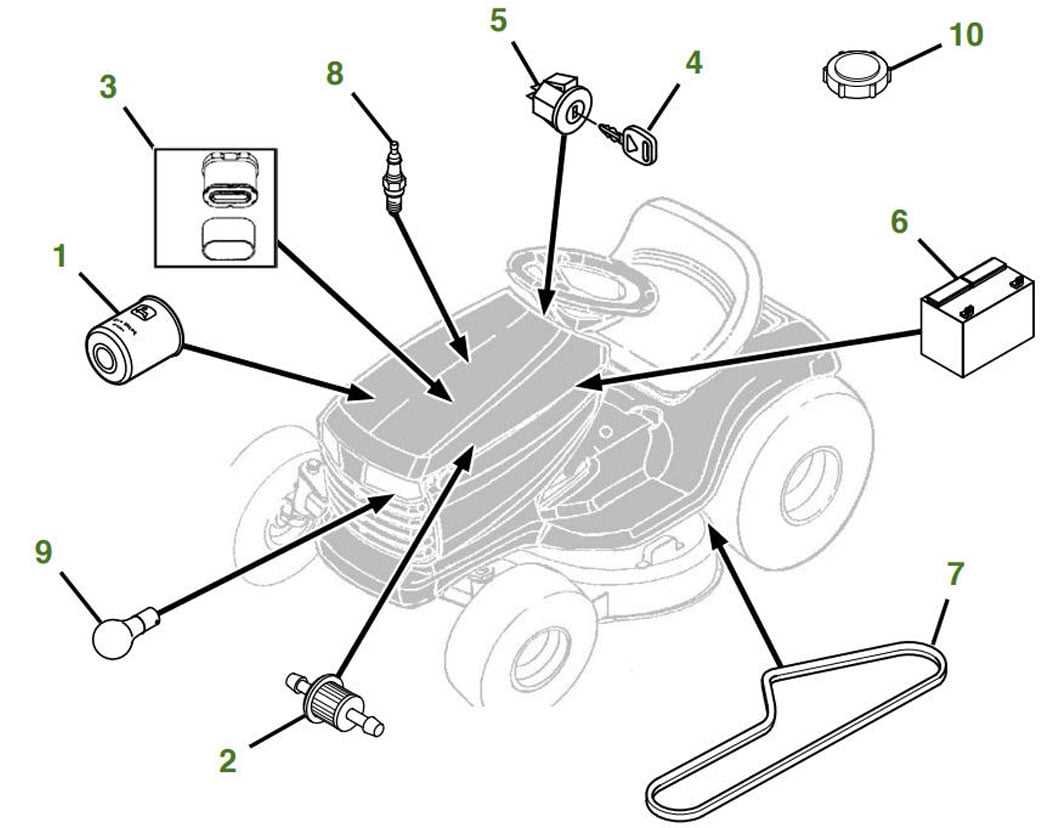

Key Components Overview

In this section, we will take a closer look at the essential elements that ensure the smooth operation of this lawn care equipment. Understanding how each part functions will help maintain optimal performance and prolong the machine’s lifespan.

Engine System

The engine is the heart of the machine, providing the necessary power for all its operations. A robust motor ensures reliable operation even under challenging conditions, delivering consistent results. Regular maintenance, such as checking oil levels and replacing filters, is crucial to keep the engine in top shape.

Cutting Mechanism

The cutting mechanism plays a vital role in achieving an even and precise trim. Blades need to be sharp and well-maintained to handle different types of terrain efficiently. Additionally, ensuring the correct height settings helps achieve the desired cutting results.

- Sharp

Blade Maintenance for the X360 Mower Deck

Regular upkeep of the cutting components is essential to ensure optimal performance and longevity of your equipment. Dull or damaged blades can result in uneven cuts, reducing the efficiency of your machine. Maintaining sharpness and balance is key to achieving smooth operation and consistent results.

Sharpening the cutting edges should be done periodically to restore their effectiveness. Use a suitable sharpening tool and ensure you remove any nicks or rough edges. After sharpening, it’s important to balance the blades to prevent vibrations during use, which can wear out other parts.

In addition, inspect for damage

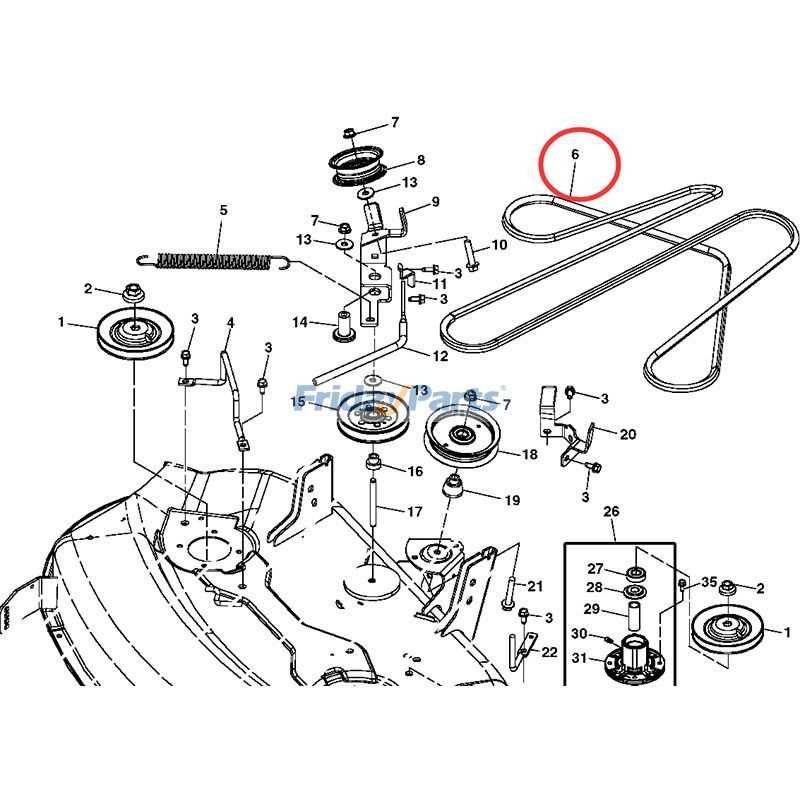

Belt System Layout in the Mower

The arrangement of the belt system plays a crucial role in ensuring smooth and efficient operation of the cutting mechanism. Proper alignment and tensioning of the components guarantee optimal performance, minimizing wear and tear on the equipment. This section provides an overview of how the belt-driven system is structured and functions in the equipment.

Main Components of the Belt System

The belt system consists of several key elements that work together to transmit power effectively. These include pulleys, tensioners, and the belt itself, each with its specific purpose. The pulleys guide the belt, maintaining its path, while the tensioners adjust the tightness of the belt to ensure continuous operation without slippage.

Power Transmission Process

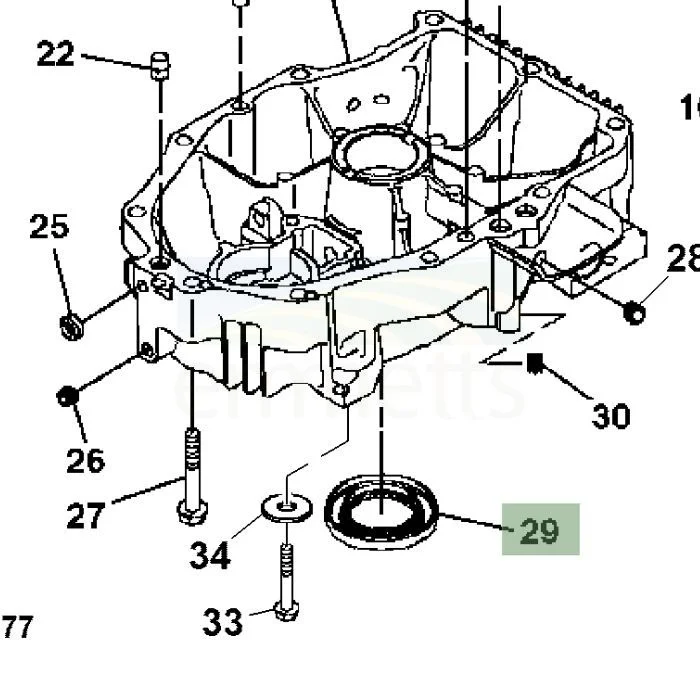

Spindle Assembly Breakdown and Care

The spindle assembly plays a crucial role in ensuring the efficient operation of a cutting system. Regular maintenance and understanding its components can significantly improve the longevity of the machine. This section focuses on the breakdown of the assembly and best practices for keeping it in optimal condition.

Key Components of the Spindle Assembly

The spindle assembly consists of several interconnected elements, each vital for smooth performance. Understanding these parts and their functions is essential for proper care.

Component Function Importance of the Idler Pulley in the Deck

The idler pulley plays a crucial role in the operation of the belt system. It ensures that the belt maintains the correct tension, allowing the machinery to function efficiently. Without a properly working pulley, the belt may slip or become misaligned, leading to potential issues in performance.

How the Idler Pulley Affects Performance

- Tension regulation: The idler pulley helps keep the belt tight, ensuring smooth movement.

- Prevention of wear: By maintaining the correct tension, it reduces wear on the belt, extending its lifespan.

- Alignment

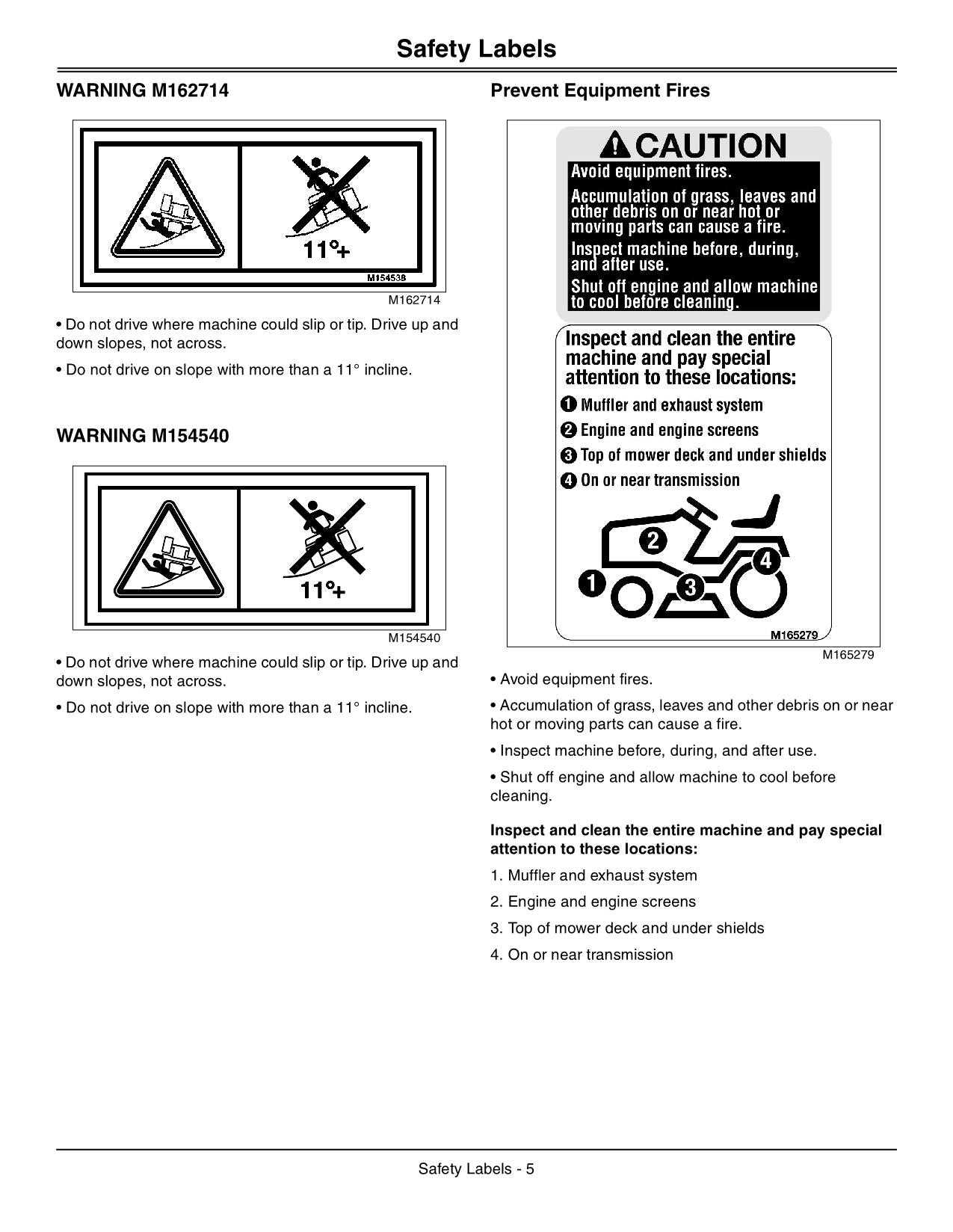

Adjusting the X360 Mower Deck Height

Properly configuring the height of the cutting mechanism is crucial for optimal performance and health of your lawn. Adjustments can influence the quality of the cut and the overall appearance of the landscape. Ensuring that the height is set according to your specific needs will enhance the efficiency of your equipment.

Here are the steps to effectively modify the height of the cutting unit:

- Prepare the Equipment: Before making any adjustments, ensure the machine is on a flat surface and the engine is turned off.

- Identify the Adjustment Mechanism: Locate the height adjustment lever or knob, typically found near the operator’s seat.

- Set the Desired Height: Move the adjustment lever or turn the knob to your preferred cutting height. Most models offer multiple height settings.

- Check the Consistency: After adjusting, it’s important to verify that all points of the cutting unit are set to the same height. Measure from the ground to the cutting edge at various points.

- Test the Setup: Start the machine and conduct a test run in a small area to ensure that the height adjustment is functioning as intended.

Regular maintenance of the cutting height not only improves the cutting efficiency but also promotes a healthier lawn by preventing scalping and uneven growth.

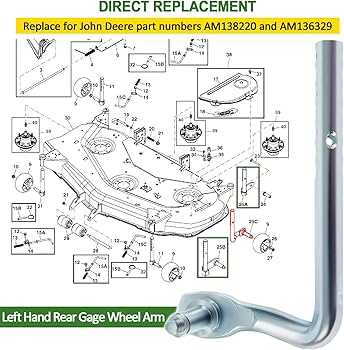

Deck Wheels: Purpose and Alignment Tips

The wheels on a cutting implement play a crucial role in ensuring effective operation and optimal results. These components are designed to support the structure while facilitating smooth movement across various terrains. Proper alignment is essential for achieving even cutting performance and extending the lifespan of the equipment.

Purpose: The primary function of these wheels is to maintain an appropriate height above the ground, allowing for efficient grass trimming. They help in distributing the weight evenly, preventing scalping and ensuring that the blades operate at the desired level. Additionally, well-functioning wheels contribute to enhanced maneuverability, making it easier to navigate around obstacles.

Alignment Tips: To ensure optimal performance, regularly check the alignment of the wheels. Misalignment can lead to uneven cutting and increased wear on the equipment. Begin by examining the wheel height and adjusting it to the manufacturer’s specifications. Use a level to verify that the wheels are positioned correctly in relation to the cutting blades. Regular maintenance and adjustment will help maintain consistent performance and prolong the life of the implement.

Cleaning Techniques for Mower Deck Undercarriage

Maintaining the cleanliness of the undercarriage is essential for optimal performance and longevity of your equipment. Regularly removing grass clippings, dirt, and debris not only enhances functionality but also prevents rust and corrosion. Implementing effective cleaning methods can significantly improve the overall efficiency and lifespan of the machinery.

Essential Cleaning Tools

Before starting the cleaning process, gather the necessary tools to ensure a thorough job. A sturdy scraper can help dislodge stubborn residues, while a pressure washer is effective for rinsing away dirt and grime. Additionally, a soft-bristle brush can be useful for detailed cleaning in hard-to-reach areas.

Effective Cleaning Steps

Begin by disconnecting the power source to ensure safety. Use the scraper to gently remove any accumulated debris, focusing on corners and edges where buildup is most common. Follow this by rinsing the area with a pressure washer, ensuring that all loosened materials are washed away. For any remaining residues, utilize the brush to scrub the surface, followed by a final rinse. Allow the undercarriage to dry completely before reassembling or storing the equipment.

Inspecting the Discharge Chute for Wear

Regular examination of the discharge chute is essential to ensure optimal performance and longevity of the cutting equipment. This component plays a critical role in directing clippings away from the blades and preventing blockages. Identifying any signs of damage or excessive wear can help maintain efficient operation and prevent costly repairs.

Signs of Wear to Look For

During inspection, pay close attention to the following indicators that may suggest deterioration:

Indicator Description Cracks Visible splits or breaks in the chute material that can lead to further damage. Deformation Any bending or warping that affects the chute’s ability to direct clippings properly. Corrosion Rust or deterioration from exposure to moisture, which can weaken the chute structure. Accumulated Debris Build-up of grass or other materials that can obstruct the flow and increase wear. Maintenance Tips

To prolong the life of the discharge chute, consider the following maintenance practices:

- Regularly clean the chute to prevent debris build-up.

- Inspect for damage after each use, particularly in harsh conditions.

- Apply protective coatings if applicable to reduce corrosion risks.

Replacing the Mower Deck Belt Efficiently

Maintaining optimal performance of your lawn care equipment requires attention to key components. One crucial element that often demands replacement is the driving belt. Understanding the process involved can enhance your efficiency and ensure your machine operates smoothly.

To begin, gather the necessary tools, including a wrench set and replacement belt. Start by disconnecting the power source to prevent any accidents. Carefully remove the protective cover to access the belt system. It is essential to examine the old belt for signs of wear, such as cracks or fraying, which may indicate the need for immediate replacement.

Once the old belt is detached, compare it with the new one to ensure proper sizing. Installation involves threading the new belt through the designated pulleys, ensuring it sits correctly in its designated grooves. Take your time to avoid misalignment, which can lead to premature wear or malfunction.

After securing the new belt, reattach the protective cover and reconnect the power source. Finally, perform a quick test to verify that everything is functioning correctly. Regularly replacing the driving belt not only prolongs the life of your equipment but also contributes to achieving a well-manicured lawn.

How to Lubricate Deck Bearings Properly

Maintaining optimal performance of the machinery requires proper care and attention to the various components involved. One essential aspect of this maintenance is ensuring that the bearings are adequately lubricated. Proper lubrication minimizes friction, reduces wear, and extends the lifespan of the equipment.

Step-by-Step Lubrication Process

To begin the lubrication process, gather the necessary tools: a grease gun, suitable lubricant, and clean rags. First, locate the bearing fittings, which are typically found near the rotating parts. Wipe away any dirt or debris from the grease fittings to prevent contamination during lubrication. Once the area is clean, apply a small amount of lubricant to each fitting. It’s crucial not to over-lubricate, as excess grease can cause damage.

Frequency of Lubrication

The frequency of lubrication depends on usage and operating conditions. For routine maintenance, check the bearings every 25 to 50 operating hours. If the machinery is used in harsher environments, such as dusty or wet conditions, consider more frequent checks to ensure that the bearings remain in optimal condition.

Common Issues with X360 Deck and Solutions

Maintaining a lawn care machine can often lead to encountering various challenges that may affect its performance. Understanding these common complications is essential for effective troubleshooting and ensuring the longevity of the equipment.

Below are some frequently observed issues along with their potential solutions:

Issue Solution Uneven cutting height Adjust the height settings on the equipment to ensure an even cut across the lawn. Grass clumping under the unit Clean the underside of the machine regularly to prevent grass build-up that can affect performance. Noise during operation Check for loose or damaged components and tighten or replace as necessary to minimize noise. Difficulty in starting Inspect the fuel system and electrical connections; replace any faulty parts to improve reliability.