Exploring the intricacies of mechanical systems in classic motorbikes offers a fascinating glimpse into the design and engineering behind these timeless machines. For those who appreciate the unique charm of vintage two-wheelers, gaining a comprehensive understanding of how each element fits together can be invaluable, especially when it comes to restoring or maintaining these iconic models.

Whether you’re working on a restoration project or simply trying to keep an old favorite running smoothly, having a clear view of the mechanical layout can make all the difference. Visual guides that break down the individual elements of the machine provide essential insights into the positioning and interaction of various components. This understanding not only aids in identifying the right replacements but also ensures proper installation for optimal performance.

By examining the structure in detail, enthusiasts can more easily navigate the intricacies of these classic models, ensuring that even the smallest elements receive the attention they deserve. Such visual references are particularly useful for tackling complex maintenance tasks, allowing you to approach each repair with confidence and precision.

Honda CT90 Parts Diagram

The illustration serves as a visual guide, helping users understand the arrangement and connection of various components. It provides a clear overview of how each element is positioned and how they interact within the mechanical structure. By studying the visual representation, one can easily identify key elements, making maintenance or repairs more efficient.

Exploring the visual details allows for a deeper understanding of how individual elements function together. Whether replacing an item or troubleshooting an issue, the visual guide ensures that every step is performed accurately, minimizing potential errors.

Having a comprehensive visual reference streamlines the process of locating specific items, ensuring a smoother experience when performing adjustments or upgrades. It offers clarity and supports enthusiasts in keeping everything in optimal condition.

Engine Component Breakdown

The inner workings of an engine involve various interconnected elements that ensure smooth operation and optimal performance. Understanding the structure and function of these components helps in recognizing potential issues and maintaining the engine’s efficiency.

Core Mechanical Elements

The engine is built around essential mechanical parts that interact to generate motion. These elements work together in a synchronized manner, each playing a critical role in converting energy into power, keeping the entire system running efficiently.

Supportive Systems

Besides the core mechanisms, there are auxiliary systems designed to enhance performance and durability. These include cooling, lubrication, and ignition systems, which ensure the engine runs smoothly under different conditions, preventing overheating and wear.

Electrical System Overview

The electrical system in a motorized two-wheeler plays a crucial role in ensuring reliable operation and overall safety. It powers various components, enabling functions such as lighting, ignition, and charging. Understanding the key elements and connections within this system is essential for effective maintenance and troubleshooting.

Main Components of the System

- Battery: Acts as the main source of power, supplying electricity when the engine is not running or at low speeds.

- Ignition Coil: Converts low-voltage power from the battery to high-voltage energy for the spark plug, facilitating combustion.

- Alternator: Generates electricity while the engine is running, keeping the battery charged and supplying power to other components.

- Regulator/Rectifier: Ensures the voltage stays within safe levels and converts alternating current (AC) from the alternator to direct current (DC).

Common Electrical Issues and Solutions

- Weak or Dead Battery: Frequent causes include insufficient charging, excessive electrical load, or an aging battery. Regular checks and timely replacement are recommended.

- Dim or Flickering Lights: Could indicate a faulty alternator, poor connections, or issues with the voltage regulator. Inspect wiring and components for signs of wear

Frame and Body Parts

The structure and exterior components play a crucial role in the overall design and functionality of the two-wheeler. These elements not only provide support and protection but also contribute to the aesthetic appeal and stability. Understanding the different components involved in the frame and exterior design helps in ensuring proper maintenance and efficient use.

Main Structure

The core frame forms the foundation, supporting various mechanical and electrical systems while maintaining balance. It is built to withstand different forces encountered during rides and offers a base for attaching other elements. Regular inspection and upkeep of this main structure are essential for maintaining stability and safety.

Protective Panels and Covers

Exterior panels and protective covers are designed to shield internal mechanisms from debris and environmental factors. These covers not only serve a protective function but also add to the visual style, enhancing the overall appearance. Ensuring these components are securely attached and in good condition can prevent wear and tear on underlying systems.

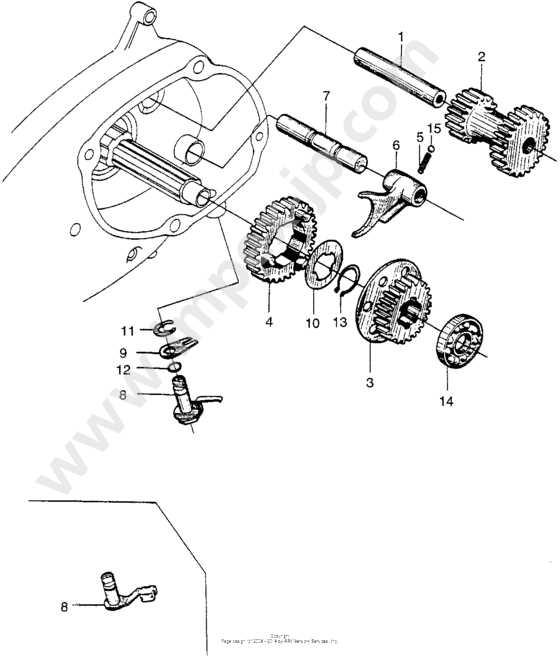

Transmission Diagram Explained

The transmission system is a crucial component that allows for seamless shifting between gears, ensuring efficient power delivery and smooth driving. Understanding how the system functions can help in diagnosing potential issues and performing maintenance more effectively. The illustration offers a visual breakdown of the components, helping to grasp their roles and connections.

Main Components Overview

The transmission consists of several key elements that work together to transfer power from the engine to the wheels. Below is a breakdown of these components and their functions:

- Gears: Different-sized gears allow for changes in speed and torque, helping the engine operate within optimal ranges for various driving conditions.

- Clutch Assembly: This system disconnects the engine from the transmission to allow for gear changes. It consists of plates, springs, and a release mechanism.

- Shift Forks: These components move the gears along the transmission shaft, engaging the correct gear for the desired speed.

- Output Shaft: Transfers the rotational force from the gears to the drive system, powering the wheels.

Common Issues and Maintenance Tips

To keep the transmission system functioning smoothly, regular checks and maintenance are essential. Here are some tips:

- Inspect the clutch for wear and replace it if slipping occurs.

- Ensure gear

Fuel System Components

The fuel system plays a crucial role in the operation of any engine, ensuring the proper delivery of fuel to achieve optimal performance. Understanding the various elements that constitute this system is essential for maintaining efficiency and reliability. Each component works in harmony to facilitate the seamless flow of fuel from the tank to the engine, ensuring that the vehicle runs smoothly.

Key Elements of the Fuel System

At the heart of the fuel system lies the fuel tank, where the liquid fuel is stored until needed. From the tank, fuel is drawn through a series of lines and filters designed to eliminate impurities, thereby protecting the engine from potential damage. The fuel pump, an integral component, creates the necessary pressure to transport the fuel efficiently. Additionally, the carburetor or fuel injector regulates the fuel-air mixture, optimizing combustion for improved performance.

Maintenance Considerations

Regular maintenance of the fuel system is vital for ensuring longevity and efficiency. This includes checking for leaks, replacing filters, and ensuring that all connections are secure. Keeping the fuel system clean helps prevent clogging and ensures a steady flow of fuel, which is essential for peak performance. By taking proactive measures, one can avoid more significant issues down the line, thus enhancing the overall longevity of the vehicle.

Suspension and Fork Assembly

The system responsible for absorbing shocks and ensuring a smooth ride consists of various components that work in harmony. Proper functionality of this assembly is crucial for stability and control, contributing significantly to the overall performance of the vehicle. Understanding the structure and operation of these elements can enhance the riding experience and ensure longevity.

Components of the Assembly

This assembly includes a range of parts designed to support the weight of the vehicle while providing cushioning during movement. Key elements encompass the forks, springs, and dampers, each playing a vital role in managing impact and enhancing comfort. The interaction between these components is essential for optimal handling and responsiveness on diverse terrains.

Maintenance Considerations

Regular inspection and maintenance of the assembly are paramount to avoid potential issues. Ensuring that the springs are properly tensioned and the dampers are functioning effectively can prevent premature wear and enhance safety. It is advisable to consult a professional for detailed evaluations and replacements when necessary to maintain peak performance.

Brake System Parts Identification

The braking mechanism is crucial for ensuring safety and control while navigating various terrains. Understanding the components involved in this system is essential for effective maintenance and repair. This section delves into the key elements that make up the braking assembly, highlighting their functions and significance.

Brake Lever: This component serves as the primary interface for the rider, enabling the application of braking force with ease. It is typically mounted on the handlebars for quick access.

Brake Cable: This flexible conduit connects the lever to the brake assembly, transmitting the force applied at the lever to engage the braking mechanism.

Brake Shoes: These are the friction elements that press against the drum to create stopping power. Their material composition can significantly affect performance and longevity.

Drum: The circular housing that encases the brake shoes, facilitating the interaction that slows down or halts the movement of the vehicle.

Spring: This component ensures that the brake shoes return to their original position once the braking force is released, maintaining proper function and responsiveness.

By familiarizing oneself with these elements, individuals can more effectively troubleshoot issues and perform necessary upkeep, leading to enhanced safety and performance.

Exhaust System Configuration

The exhaust system plays a crucial role in ensuring optimal performance and efficiency of a vehicle. It facilitates the expulsion of gases produced during combustion, contributing to both the functionality and sound of the machine. A well-designed exhaust layout not only aids in reducing emissions but also enhances the overall experience of the ride.

Key Components of the Exhaust System

At the heart of the exhaust configuration are several integral elements. The exhaust manifold collects gases from the engine cylinders and directs them into the subsequent sections. Following this, the catalytic converter serves to reduce harmful emissions by converting them into less harmful substances. Finally, the muffler plays a significant role in managing sound levels, ensuring a pleasant auditory experience while minimizing noise pollution.

Importance of Proper Configuration

Ensuring that each part of the exhaust system is correctly configured is essential for maintaining peak performance. Misalignments or blockages can lead to increased back pressure, which adversely affects engine efficiency and longevity. Regular inspections and timely replacements of worn-out components are vital to keep the exhaust system functioning optimally, thus supporting the overall health of the vehicle.

Wheels and Tires Details

The components responsible for movement play a crucial role in any vehicle’s performance. Understanding the specifications and maintenance of these elements can enhance both safety and efficiency. Proper selection and care are essential for optimal functionality on various terrains.

When it comes to the wheels, several factors should be considered:

- Diameter: The size of the wheels directly influences the overall handling and speed.

- Material: Different materials, such as alloy or steel, affect weight and durability.

- Design: Various styles not only impact aesthetics but also performance characteristics.

Similarly, the choice of tires significantly impacts the driving experience:

- Tread Pattern: The design of the tire surface affects traction and handling in diverse conditions.

- Rubber Compound: The composition of the tire affects grip, wear resistance, and performance.

- Inflation Pressure: Maintaining the correct pressure ensures safety and efficiency.

Regular inspections and maintenance of these components are vital. Ensuring proper alignment, balancing, and periodic replacements can lead to a smoother ride and enhanced longevity. Whether traversing urban streets or rugged trails, the condition of these elements determines overall driving satisfaction.

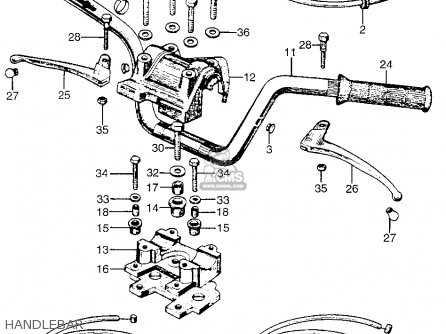

Handlebars and Control Layout

The handlebars and their associated controls play a crucial role in the overall functionality and rider experience of a motorcycle. They provide essential leverage for steering and house various switches and instruments that enhance the rider’s ability to navigate and operate the vehicle effectively. Understanding the layout and arrangement of these components is vital for both maintenance and ergonomic comfort.

Component Function Throttle Grip Controls engine power by regulating airflow. Brake Lever Engages the front braking system for deceleration. Clutch Lever Disengages the engine from the transmission for gear shifting. Turn Signal Switch Activates indicators for lane changes and turns. Horn Button Emits sound for alerting other road users. Headlight Switch Controls the front lighting system for visibility. Speedometer Displays current speed and can include odometer functions. Air Intake and Filter Placement

Effective airflow is crucial for optimal engine performance, influencing both power output and efficiency. The design and positioning of the intake system, along with the filter, play significant roles in maintaining clean airflow while preventing contaminants from entering the combustion chamber. Understanding the layout and function of these components ensures proper maintenance and enhances overall functionality.

In many vehicles, the air intake is strategically located to maximize airflow while minimizing the risk of dust and debris infiltration. The placement of the filter is equally important, as it acts as the first line of defense against harmful particles that could adversely affect engine longevity. Regular inspection and replacement of the filter are essential to sustaining performance.

Component Function Maintenance Tips Air Intake Duct Channels outside air into the engine Inspect for cracks or blockages regularly Air Filter Traps dirt and debris from entering the engine Replace every 12,000 miles or as needed Filter Housing Encloses the air filter, providing structural support Check for leaks or wear and tear