When maintaining your outdoor space, understanding the essential components of your lawn care machinery is crucial. Each piece plays a key role in ensuring the equipment operates efficiently and effectively. Whether you are repairing, upgrading, or simply looking to enhance your equipment’s performance, knowing how the individual parts interact is essential for successful lawn maintenance.

Comprehending the layout and function of these mechanical elements allows users to perform troubleshooting and maintenance tasks with greater ease. By understanding the placement and connection of various components, users can better assess their equipment’s condition, identify wear and tear, and make informed decisions when it comes to replacements or adjustments.

The interaction between different parts not only affects performance but also contributes to the longevity of the machinery. A well-maintained machine not only works more efficiently but also reduces the risk of costly breakdowns. In this guide, we explore the key components involved in keeping your outdoor equipment in top condition.

Essential Components of the 62C Mower Deck

The cutting system of a lawn care machine is made up of several key elements that work together to ensure precise and efficient grass trimming. These components are crucial for the overall performance, durability, and reliability of the equipment. Understanding the function of each part is essential for maintenance and optimal use.

Blades are one of the most important elements, responsible for slicing through the grass to achieve an even cut. The sharpness and durability of the blades determine the quality of the finish. Regular maintenance and occasional sharpening are necessary to maintain their performance.

Spindles serve as the rotating base for the blades. They are equipped with bearings to minimize friction and ensure smooth operation. Over time, spindles may wear out and require lubrication or replacement to keep the cutting process efficient.

Belts transfer power from the engine to the rotating blades. These components are essential for synchronizing the movement of the cutting blades, and regular inspection is needed to detect any signs of wear or damage that could lead to malfunction.

Another critical part is the housing, which surrounds and protects the rotating components. It shields the blades from debris and ensures that grass clippings are directed properly for efficient collection or dispersal.

Understanding the Blade Assembly and Mechanisms

The cutting system of a garden machine is crucial for achieving clean and efficient results. Central to this system are the blades and the mechanisms that allow them to rotate at high speeds. These components work together to ensure a precise and uniform cut across various terrains. Understanding how these parts interact is key to maintaining optimal performance and extending the life of the equipment.

The blade assembly typically consists of several key elements, including the blades themselves, the spindle that drives them, and the pulleys that transfer power from the engine. These elements are engineered to work together seamlessly, providing the necessary torque to rotate the blades with sufficient force. The blades, which are usually made from durable steel, are designed to stay sharp while cutting through grass, weeds, and other vegetation effectively.

The rotation of the blades is controlled through a series of belts and pulleys, which are connected to the engine. These mechanisms ensure that the blades spin smoothly and with the required speed. Proper alignment of the pulleys and tension of the belts are essential for avoiding undue strain on the engine and preventing wear on the blades. Regular maintenance of these components helps to keep the cutting system running efficiently and minimizes the risk of damage during operation.

Key Features of the Deck Belt System

The belt system plays a crucial role in transferring power from the engine to various components that facilitate cutting. It ensures smooth operation and efficient performance, contributing to the overall effectiveness of the equipment. Understanding its key features helps in maintaining the longevity and optimal functionality of the system.

One of the most important aspects of this system is its durability. The belts are designed to withstand high tension and resist wear, ensuring consistent power delivery over time. Additionally, the system includes tension mechanisms that help maintain proper alignment and minimize the risk of slippage, which could affect performance.

Another significant feature is the ease of maintenance. The belt system is designed for straightforward access, allowing quick inspections and replacements. This reduces downtime and keeps the machine ready for operation. Furthermore, the design minimizes friction and heat build-up, prolonging the lifespan of the belts and other related components.

How the Spindle Assembly Operates

The spindle assembly is a critical component in the functioning of the cutting system, responsible for supporting and driving the blades. This assembly allows the blades to rotate efficiently, ensuring a clean and even cut. Its design ensures smooth operation, even under heavy loads, by maintaining stability and reducing friction between the moving parts.

Key Components of the Spindle Assembly

At the core of the spindle assembly are the spindle shaft, bearings, and the housing. The shaft is powered by the engine, which transmits rotational energy through a belt or other mechanisms. The bearings, housed within the spindle, reduce friction and support the spinning action. This setup allows the blades to rotate at high speeds with precision, cutting grass effectively while minimizing wear and tear on the components.

How Power is Transferred

Power transfer to the spindle assembly is typically done through a pulley system connected to the engine. When the engine runs, it generates torque, which is then transferred via the belt to the spindle. This rotational force is what causes the blades to spin, making the system capable of cutting grass or other vegetation efficiently. Proper alignment and tension in the belt are essential to ensure optimal performance of the spindle assembly.

Examining the Mounting System

The mounting system of a lawn care equipment’s cutting mechanism is crucial for ensuring stability and efficient operation. It connects the primary unit to the chassis, allowing the cutting mechanism to function seamlessly with the rest of the machine. Understanding how this system works helps in proper maintenance and ensures the longevity of the equipment.

The mounting framework consists of various brackets, bolts, and pivot points that allow the cutting unit to stay securely in place while accommodating movement. Proper alignment of these components is essential for smooth operation and minimizing wear. Misalignment can lead to uneven cutting and unnecessary strain on the engine.

Durability of the mounting system is influenced by factors such as material strength, design, and the regularity of maintenance. Over time, components can loosen or wear out, which can affect the performance of the entire machine. Keeping an eye on these elements ensures that the equipment continues to operate efficiently, with minimal risk of malfunction.

Detailed Look at the Pulley Configuration

The system of pulleys plays a critical role in the operation of any cutting apparatus. Each component in this setup ensures the efficient transfer of mechanical energy, allowing the blades to spin with the necessary force. Understanding how these pulleys interact with each other is key to maintaining optimal performance and ensuring the longevity of the entire system.

Function of the Main Pulley

The main pulley serves as the central hub of the configuration, directing power from the engine to the other components. Its precise placement and alignment are essential for smooth operation. When functioning correctly, it ensures that the connected elements receive a consistent amount of torque, translating to efficient cutting action.

Additional Pulleys and Belts

Other pulleys in the configuration help manage the distribution of energy across the system. These smaller pulleys and the associated belts play a crucial role in adjusting the speed and direction of movement. Their wear and tear must be monitored regularly, as even minor issues can lead to significant reductions in performance.

Maintenance Tips for the Grass Bagger

Proper care and regular maintenance of the grass collector are essential for ensuring optimal performance. Keeping this component in good working condition helps avoid clogging, improves efficiency, and extends its lifespan. Here are some key tips to keep in mind to maintain the grass bagger in peak condition.

Regular Cleaning

After each use, thoroughly clean the grass collector to prevent build-up of grass clippings and debris. This helps maintain airflow and prevents blockages that can reduce the efficiency of collection.

Inspect for Wear and Tear

Check the bagger regularly for any signs of damage, such as holes, tears, or worn-out straps. If you notice any issues, repair or replace parts immediately to avoid further complications during use.

| Part | Maintenance Task | Frequency |

|---|---|---|

| Grass Bag | Check for tears and clean after each use | After every use |

| Hoses | Clear clogs and inspect for cracks | Every 10 uses |

| Mounting Brackets | Tighten screws and bolts to ensure secure attachment | Every season |

Replacing the Mower Deck Wheels Efficiently

Maintaining the wheels of your equipment is crucial for smooth operation and optimal performance. Over time, these wheels can wear out, leading to uneven cuts and potential damage to the surrounding components. Replacing them can be a simple task, but performing it efficiently ensures that your equipment continues to function at its best without unnecessary downtime.

Step-by-Step Guide for Wheel Replacement

First, ensure that the equipment is powered off and securely parked on a flat surface. The next step is to carefully lift the assembly to access the wheels. With the right tools, removing the old wheels becomes straightforward. Make sure to clean the area before installing the new wheels to prevent dirt and debris from affecting performance.

Choosing the Right Replacement

Selecting the proper replacement wheels is key to achieving the desired performance. Look for wheels with durable materials that match the specifications of your equipment. High-quality wheels can significantly extend the life of your system and reduce the frequency of future maintenance.

Finally, secure the new wheels tightly and ensure that they rotate freely. This will help maintain stability and efficiency in operation.

Identifying Deck Lift and Adjustment Parts

Understanding the components responsible for raising and adjusting the cutting system is essential for efficient maintenance and operation. These elements allow for the alteration of the cutting height and the smooth raising or lowering of the assembly, ensuring optimal performance on different terrains. Proper identification of these components helps in troubleshooting, replacing worn-out elements, and enhancing the overall functionality of the machine.

The lifting mechanism typically includes a lever or pedal that controls the vertical movement, while adjustment features may involve spindles and linkages that facilitate fine-tuning of the height settings. Recognizing these components will aid in proper alignment and ensure that the equipment remains in peak working condition for longer periods.

How the Anti-Scalp Wheels Function

Anti-scalp wheels play a critical role in preventing damage to the grass during the cutting process. These components are designed to ensure that the cutting blade does not come into direct contact with the ground, reducing the risk of scalping, which can leave unsightly patches in the lawn. By maintaining the proper distance between the blade and the surface, these wheels help deliver a smoother and more even cut.

Purpose and Importance

The primary function of these wheels is to protect the turf from being cut too low. When the blades lower to the ground, these wheels keep them elevated just enough to avoid damaging the grass roots, which can lead to brown or bald spots. By distributing the weight more evenly and acting as a buffer, they ensure a more uniform mowing experience.

How They Work

- Mounted on the sides or front of the cutting unit, these wheels adjust to the terrain’s contours.

- They act as a safeguard, lifting the blades slightly when encountering uneven ground.

- In rough or uneven areas, the wheels maintain the proper height, preventing the blades from scalping the grass.

- These wheels are often adjustable, allowing operators to set them according to their specific cutting needs and the landscape.

Common Issues and Troubleshooting the Deck

Maintaining the cutting system of your machine is essential to ensure optimal performance. Over time, several issues can arise, affecting the quality of operation. These problems often relate to the blades, alignment, or wear and tear of key components. Identifying the root cause of these issues can help restore functionality and extend the lifespan of the equipment.

Uneven Cutting is one of the most frequent problems, often caused by blades that are dull, misaligned, or damaged. Inspecting and sharpening the blades, as well as ensuring proper leveling of the cutting mechanism, can resolve this issue. Additionally, debris buildup can obstruct the blades, leading to inconsistent results.

Excessive Vibration can be a sign of blade imbalance or loose components. Ensure that all parts are tightly secured and check for any damaged or worn-out parts that may need replacement. A thorough inspection of the bearings and spindle should also be conducted to prevent further damage.

Difficulty in Engagement of the cutting system may be due to worn-out belts or faulty pulleys. Regular inspection and proper tension adjustment of the belts can prevent this issue. Replacing any worn or frayed components will help restore smooth operation.

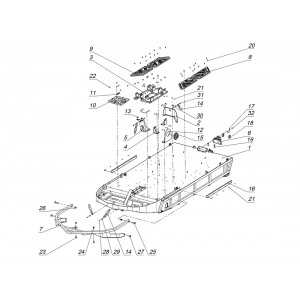

Visual Guide to the 62C Deck Diagram

This section provides a comprehensive visual reference to the components and layout of the cutting system. Understanding the arrangement and function of each element is essential for efficient maintenance and optimal performance. With a clear breakdown of the key features, this guide will help you navigate the assembly without confusion.

Assembly Overview: The system is designed for ease of use and effective operation, with each component playing a critical role in ensuring smooth operation. By reviewing the individual sections, you can better understand how each part interacts and contributes to the overall function.

Key Components: Begin by identifying the central unit, which serves as the heart of the setup. Surrounding it, you’ll find various attachments that contribute to both stability and maneuverability. Pay special attention to the smaller elements that provide fine adjustments and help maintain balance during use.