Understanding the intricate assembly of a lawn maintenance tool is essential for effective operation and maintenance. This section provides insights into the various elements that contribute to the functionality and efficiency of this equipment. By familiarizing yourself with the individual components, you can enhance your knowledge and ensure the longevity of your machine.

Visual aids play a crucial role in comprehending the layout and interconnection of these elements. A detailed representation will facilitate a clearer understanding of how each segment interacts within the system. This knowledge empowers users to diagnose issues, perform repairs, and conduct routine upkeep more effectively.

Whether you are a novice or an experienced user, having access to a comprehensive overview of the machine’s assembly can greatly improve your operational skills. Armed with this information, you can navigate maintenance tasks with confidence, ensuring your equipment remains in optimal condition for years to come.

Understanding John Deere Z445 Components

This section explores the essential elements that make up a popular outdoor equipment model. Each component plays a vital role in the overall functionality, ensuring efficient operation and maintenance. By examining these elements, users can gain a deeper appreciation for how they work together to enhance performance and longevity.

Main Elements Overview

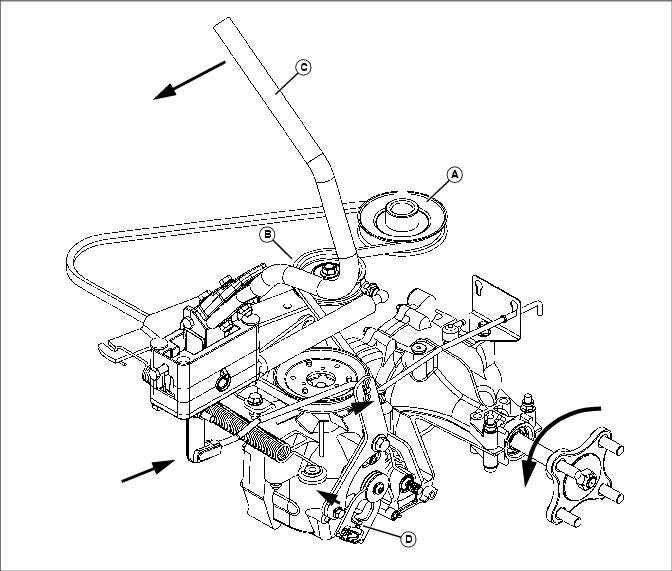

The key components consist of various mechanical and structural elements that contribute to the effectiveness of the machine. These include the drive system, which powers movement, and the cutting apparatus, responsible for achieving precise trimming results. Additionally, support structures and control mechanisms are integral to user experience and operational ease.

Understanding the functionality of each component is crucial for effective maintenance and repair. Regular inspections and timely replacements of worn-out parts can significantly extend the lifespan of the equipment. Familiarity with the individual elements not only aids in troubleshooting but also empowers users to perform basic servicing tasks confidently.

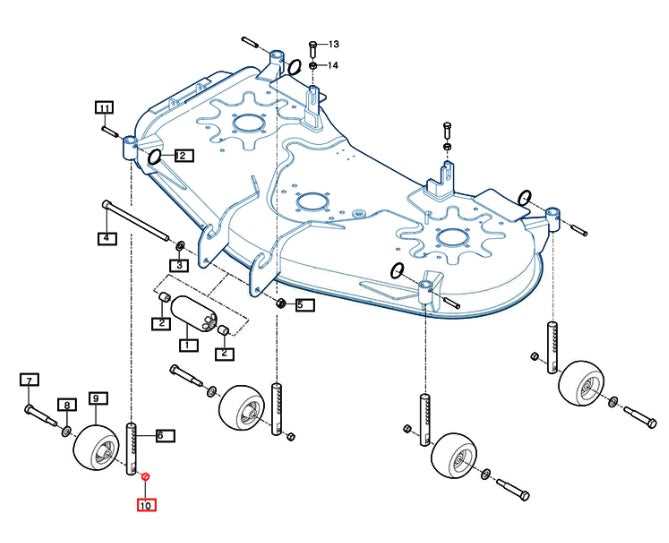

Overview of Mower Deck Assembly

The assembly of cutting apparatuses plays a vital role in the functionality and efficiency of lawn maintenance equipment. Understanding the various components and their arrangement is crucial for effective operation and maintenance. This section provides a comprehensive look at the structural elements and their interconnections, ensuring users can optimize their experience with their lawn care machines.

The following table outlines the key components involved in the assembly of the cutting apparatus, detailing their functions and significance.

| Component | Function | Importance |

|---|---|---|

| Housing | Encloses and protects internal components | Provides structural integrity and safety |

| Blades | Cut grass and other vegetation | Essential for achieving a clean cut |

| Spindle | Holds the blades and allows rotation | Critical for blade movement and efficiency |

| Lift Mechanism | Adjusts the height of the cutting apparatus | Enables customization for different terrains |

| Drive System | Transfers power from the engine to the blades | Vital for operational performance |

Key Parts of Z445 Mower Deck

This section outlines the essential components of the cutting assembly, providing insights into their functions and significance in ensuring efficient operation. Understanding these crucial elements can enhance maintenance and troubleshooting efforts, ultimately leading to improved performance.

Major Components

- Cutter Blades: The primary instruments for grass cutting, designed to provide a clean and even finish.

- Spindles: These are responsible for supporting and rotating the blades, ensuring they operate smoothly.

- Belts: These transfer power from the engine to the cutting mechanism, playing a vital role in the operation.

- Chassis: The structural framework that holds all elements together, providing stability during use.

- Deck Shell: The protective casing that houses the blades and other components, helping to direct clippings and debris.

Additional Elements

- Lift Mechanism: Allows the user to raise and lower the cutting assembly for varying grass heights.

- Washout Port: Facilitates cleaning the underside, promoting maintenance and longevity.

- Anti-Scalp Wheels: Prevents scalping the turf by keeping the cutting assembly at the correct height over uneven terrain.

Functionality of Each Component

This section delves into the roles and operations of various elements within the cutting apparatus. Understanding how each part interacts with others can enhance maintenance and troubleshooting efforts, ensuring optimal performance during usage.

The primary element is the blade assembly, responsible for the actual cutting action. Its sharp edges are designed to slice through grass with precision, promoting an even finish. Additionally, the rotation speed of the blades contributes to efficiency and effectiveness.

Next is the drive mechanism, which transmits power from the engine to the blade assembly. This component ensures that the blades operate smoothly and consistently, adapting to various grass types and terrains.

The housing structure plays a crucial role in protecting internal components while also aiding in the aerodynamics of the entire system. Its design helps direct clippings away from the cutting area, preventing clogging and promoting a cleaner cut.

Furthermore, the adjustment system allows users to modify the cutting height, providing flexibility based on individual preferences and grass conditions. This feature is essential for maintaining lawn health and appearance.

Lastly, the support framework contributes to the overall stability of the apparatus during operation. It ensures that all components remain aligned, reducing wear and extending the lifespan of the equipment.

Maintenance Tips for Optimal Performance

To ensure peak efficiency and longevity of your equipment, regular upkeep is essential. Implementing a consistent maintenance routine not only enhances functionality but also prevents unexpected breakdowns. By paying attention to specific areas, you can guarantee that your machinery operates smoothly throughout its lifespan.

Routine Inspections

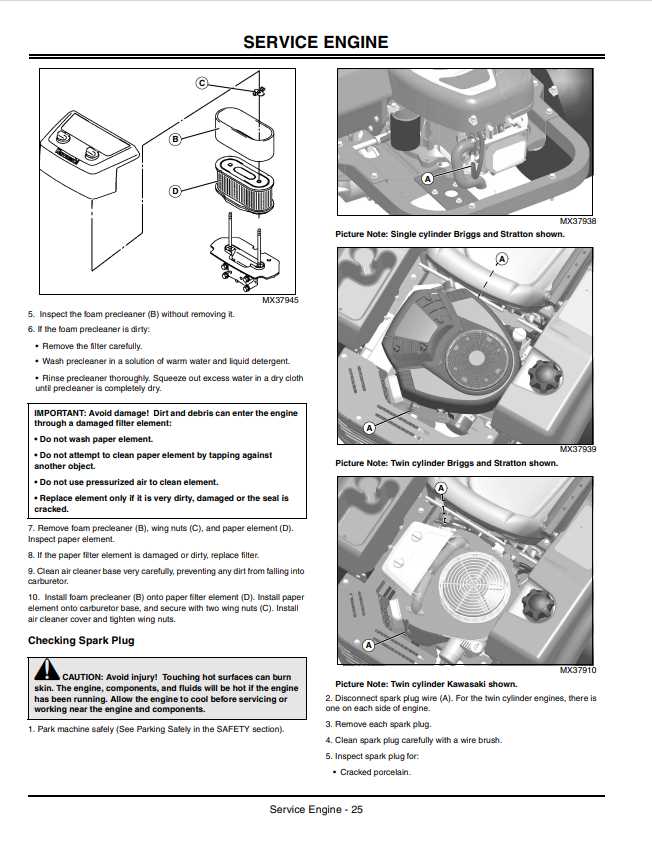

Conducting frequent checks on your equipment helps identify wear and tear early. Look for any signs of rust, loose components, or leaks. Additionally, ensure that all moving parts are adequately lubricated. This proactive approach minimizes the risk of major repairs and maintains optimal performance levels.

Cleaning and Debris Removal

Regularly removing debris and grass clippings from critical areas is crucial. Accumulated materials can impede function and lead to overheating or other issues. Use a soft brush or cloth to clean surfaces after each use, paying special attention to ventilation areas. This practice not only extends the life of your machine but also enhances its efficiency during operation.

Common Issues and Troubleshooting Steps

Maintaining optimal performance in lawn care equipment can be challenging due to various factors that may arise during operation. Users may encounter specific malfunctions or inefficiencies that can impede functionality. Understanding these common concerns and their respective solutions can significantly enhance the longevity and efficiency of the machinery.

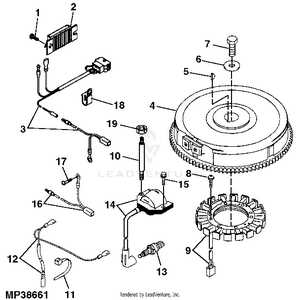

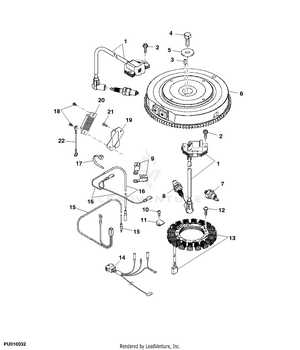

Engine Starting Problems

One of the most frequent challenges faced is the inability to start the engine. This issue can stem from several factors, including a depleted battery, faulty ignition system, or blocked fuel lines. To troubleshoot, first check the battery charge and connections. If the battery is in good condition, inspect the ignition components and ensure that fuel is reaching the engine. Cleaning or replacing filters can also be beneficial in restoring functionality.

Cutting Quality Issues

Another prevalent issue relates to subpar cutting performance. Uneven grass length or poor quality cuts may indicate dull blades or improper height settings. To address this, inspect the blades for wear and sharpen or replace them as necessary. Additionally, adjusting the cutting height according to the type of grass being maintained can result in a more uniform appearance and healthier lawn.

Parts Replacement Procedures Explained

Understanding the process of replacing components is essential for maintaining equipment efficiency and longevity. This section provides a clear overview of the necessary steps involved in the replacement of various elements within a specific model, ensuring optimal performance and reliability.

1. Identifying the Component: The first step involves accurately identifying the component that requires replacement. Consult the manual or reference guide to ensure you have the correct specifications and details regarding the part in question.

2. Gathering Tools and Materials: Before proceeding, gather all necessary tools and materials needed for the replacement process. This may include wrenches, screwdrivers, replacement components, and safety gear.

3. Disassembly: Carefully disassemble the existing component. Follow the reverse order of assembly as outlined in the manual, ensuring that each piece is removed without causing damage to surrounding elements.

4. Installing the New Component: Once the old component is removed, install the new part in its designated location. Ensure it is properly aligned and securely fastened according to the manufacturer’s guidelines.

5. Testing the Equipment: After installation, conduct a thorough test of the equipment to confirm that the new component functions correctly. Listen for unusual sounds and observe the operation to ensure everything is working smoothly.

6. Final Inspection: Perform a final inspection to ensure all tools have been removed and that the area is clean. Document the replacement in your maintenance records for future reference.

Tools Required for Repairs

Proper maintenance and repair of equipment are essential for optimal performance. Having the right tools at your disposal can make the process more efficient and effective. Below is a list of essential instruments needed for servicing various components.

- Wrench Set: A variety of sizes is necessary for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips screwdrivers will be required to remove and install screws.

- Socket Set: This set will allow for quick removal and installation of fasteners.

- Pliers: Useful for gripping, bending, and cutting wires or small components.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Utility Knife: Handy for cutting various materials such as tape, rope, or plastic.

- Grease Gun: Essential for lubricating moving parts to reduce wear and tear.

Additionally, having safety gear, such as gloves and goggles, is recommended to protect against injuries during the repair process.

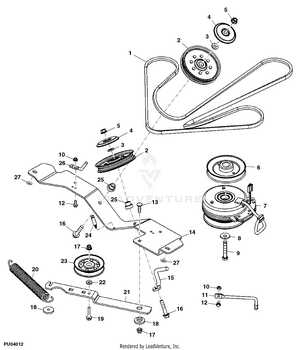

Illustrative Parts Diagram Analysis

This section delves into a comprehensive examination of a visual representation of components. Such illustrations serve as essential tools for understanding the configuration and relationship between various elements. They provide clarity and insight, making it easier to identify individual components and their functions.

When analyzing a visual representation, consider the following key aspects:

- Component Identification: Each element is labeled, allowing for quick recognition of its role within the overall structure.

- Connection Points: Arrows or lines often indicate how different parts interact, showing the assembly or disassembly process.

- Functional Groups: Elements may be categorized into groups based on their function, facilitating a better understanding of how they work together.

- Maintenance Indicators: Some illustrations highlight areas that require regular upkeep, guiding users on where to focus their attention.

By utilizing these diagrams, operators can effectively troubleshoot issues, perform maintenance, and ensure optimal functionality. A detailed analysis empowers users to navigate complexities and enhances their overall experience with the equipment.

Purchasing Quality Replacement Parts

When it comes to maintaining outdoor machinery, sourcing high-quality components is essential for ensuring longevity and optimal performance. Selecting the right substitutes not only improves functionality but also prevents potential issues in the future. It is crucial to understand the various options available and to make informed choices that align with your specific needs.

Identifying Trusted Suppliers

Finding reputable vendors is a vital step in the procurement process. Look for suppliers that specialize in outdoor equipment and have positive reviews from customers. Established companies often provide warranties and customer support, which can enhance your purchasing experience. Additionally, ensure that the seller offers genuine or OEM alternatives to guarantee compatibility and reliability.

Comparing Options and Prices

Once you have identified potential suppliers, it is important to compare different products and their pricing. Take the time to assess various offerings to find the best fit for your equipment. Reading customer reviews and expert opinions can also provide valuable insights into the performance and durability of the components you are considering.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance offers numerous advantages that can enhance the longevity and efficiency of the equipment. Genuine items are specifically designed to meet the original specifications, ensuring compatibility and optimal performance. This commitment to quality results in improved reliability and reduced chances of malfunction, which can be crucial for seamless operation.

Quality Assurance

Authentic components undergo rigorous testing and quality control to guarantee their durability and performance. By choosing these items, users can trust that they are investing in high-grade materials that will withstand wear and tear, thereby minimizing the need for frequent replacements and repairs.

Cost-Effectiveness

While authentic components may come at a slightly higher initial cost, they often prove to be more economical in the long run. Their reliability leads to fewer breakdowns and maintenance issues, ultimately saving time and money on repairs. Additionally, genuine parts often come with warranties, providing further peace of mind for users.

Safety Precautions During Repairs

Ensuring personal safety is the top priority when performing any maintenance or mechanical adjustments. Awareness of potential hazards and adherence to essential protective measures can significantly reduce the risk of injury during technical work.

Personal Protective Equipment

Before starting any repair, it is vital to equip yourself with the appropriate gear. Wearing protective gloves, safety goggles, and sturdy footwear can prevent injuries from sharp components or unexpected incidents. A well-fitted helmet and ear protection are recommended for operations involving loud equipment.

Proper Tool Handling

Using the correct tools for the job ensures both safety and efficiency. Ensure that all tools are in good condition before use, avoiding damaged or worn-out items. Incorrect usage