Maintaining the efficiency and functionality of your outdoor machinery is essential for optimal performance. Every operator should familiarize themselves with the essential elements that contribute to smooth operation. By exploring the intricate arrangements and relationships between these components, users can ensure their equipment runs flawlessly.

In this section, we will delve into the various crucial elements that make up the foundational structure of your device. Recognizing the layout and interaction of these pieces will empower you to troubleshoot effectively and execute necessary maintenance tasks. Whether you’re replacing worn parts or simply seeking to enhance your understanding, this information is the ultimate guide for any enthusiast.

By gaining insight into how each element works together, you can significantly improve your machinery’s longevity and reliability. With a solid grasp of these fundamentals, you’ll be well-equipped to tackle any challenges that arise, ensuring your equipment remains in peak condition throughout its lifespan.

Murray Lawn Mower Deck Overview

This section provides an insightful exploration into the fundamental components that contribute to the effective operation of your cutting equipment. Understanding these elements is crucial for maintaining optimal performance and longevity.

Key Components

The essential elements work in harmony to ensure a seamless experience. Each piece plays a specific role, influencing both functionality and efficiency.

| Component | Function |

|---|---|

| Chassis | Supports the overall structure and holds all parts together. |

| Blades | Responsible for the cutting action, providing a clean finish. |

| Spindles | Enable the rotation of blades, crucial for performance. |

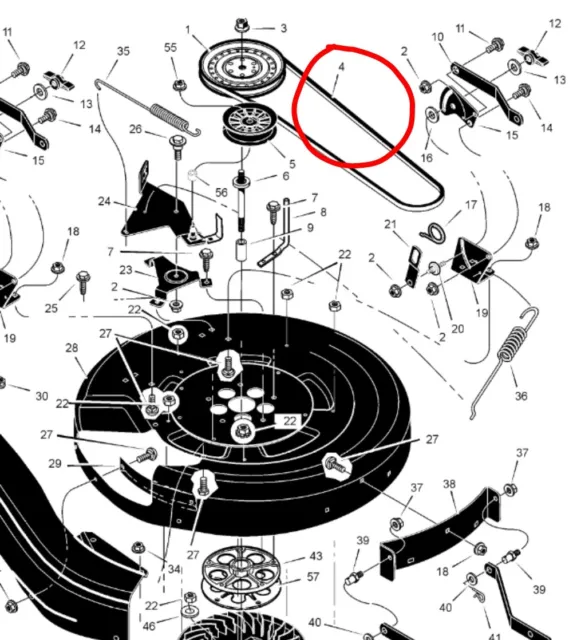

| Drive Belt | Transfers power from the engine to the blades. |

Maintenance Tips

Importance of Lawn Mower Deck

The foundational structure of any cutting apparatus plays a crucial role in its overall performance and efficiency. This component not only houses essential mechanisms but also directly influences the quality of the finished surface. Understanding its significance is vital for maintaining optimal functioning.

First and foremost, this structure ensures that the blades operate at the correct height and angle, facilitating an even cut. Additionally, it protects internal mechanisms from debris and damage, prolonging the lifespan of the entire machine.

Moreover, regular inspection and maintenance of this area can prevent costly repairs, ensuring smooth operation. In conclusion, a well-maintained foundational element is essential for achieving the best results in any grass-cutting task.

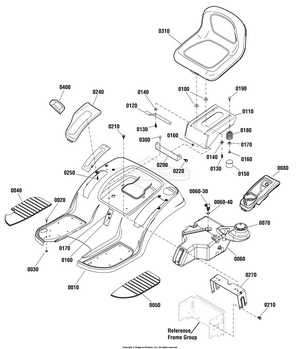

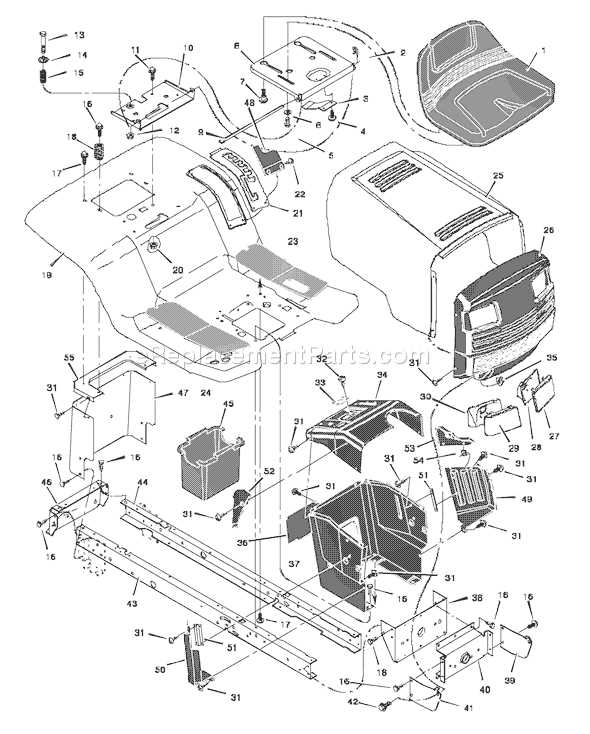

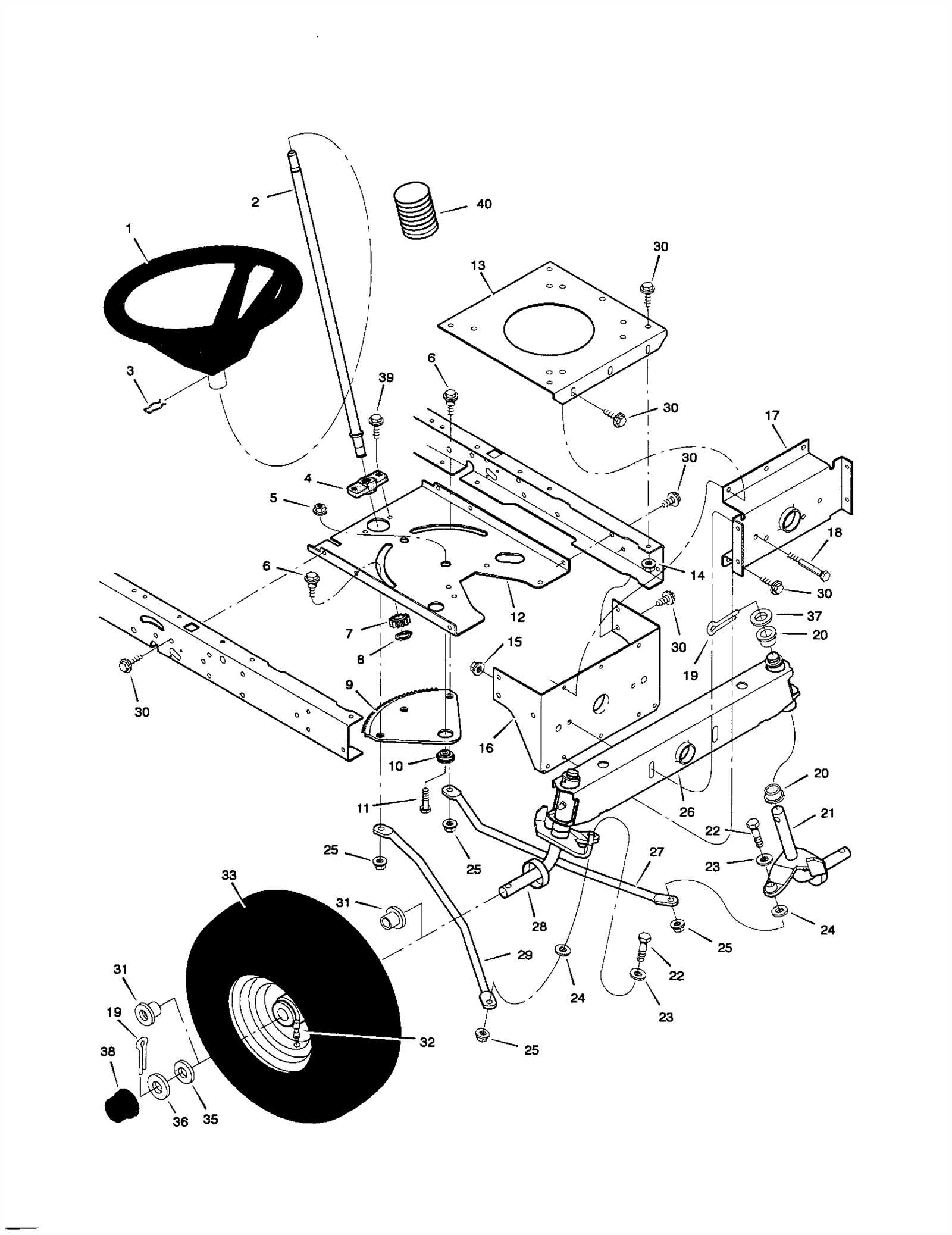

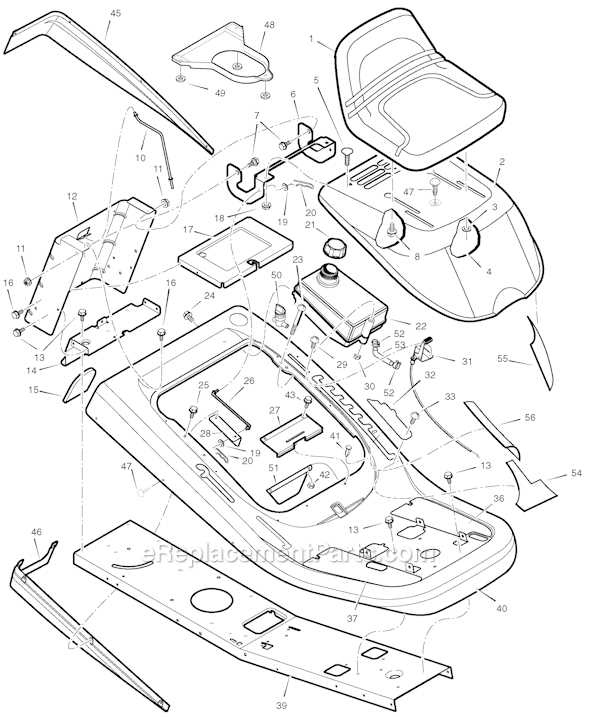

Identifying Deck Parts in Diagrams

Understanding the various components depicted in technical illustrations is essential for effective maintenance and repair. By familiarizing oneself with the layout and labeling, users can navigate these visuals more efficiently.

- Labels: Clear identifiers are crucial for recognition.

- Shapes: Different geometric representations often signify specific elements.

- Connections: Lines can indicate how components interact or attach to each other.

To effectively interpret these visuals, one should focus on:

- Recognizing common symbols.

- Understanding the scale and proportions used.

- Consulting any accompanying notes or legends for additional context.

By honing these skills, individuals can streamline their understanding of mechanical assemblies, leading to better upkeep and functionality.

Common Issues with Mower Decks

Maintaining a cutting apparatus involves understanding various challenges that can arise during operation. Over time, components may experience wear and tear, leading to decreased performance and efficiency. Identifying these common problems is essential for effective upkeep and optimal functionality.

Uneven Cutting

One prevalent issue is uneven cutting, often caused by misaligned blades or an unbalanced frame. Regular inspection and adjustment can help achieve a consistent and smooth finish on grass surfaces.

Clogging and Buildup

Another frequent concern is the accumulation of debris, which can hinder performance and cause overheating. Cleaning the apparatus regularly, especially after use, minimizes this risk and ensures a clean cutting experience.

Maintenance Tips for Deck Longevity

Ensuring the durability of your outdoor equipment requires regular care and attention. By implementing effective maintenance practices, you can significantly extend its lifespan and performance. This section outlines essential strategies to keep your apparatus in optimal condition, allowing you to enjoy its functionality for years to come.

1. Regular Cleaning: After each use, take time to remove debris and clippings that accumulate. Use a brush or a blower to keep surfaces clear, preventing rust and corrosion.

2. Lubrication: Apply appropriate lubricants to moving components regularly. This minimizes friction and wear, ensuring smooth operation and reducing the likelihood of mechanical failures.

3. Inspection: Conduct periodic checks for any signs of damage or wear. Look for cracks, loose screws, or frayed belts, and address any issues immediately to avoid further complications.

4. Proper Storage: When not in use, store your equipment in a dry, sheltered location. This protects it from the elements, which can lead to deterioration over time.

5. Seasonal Maintenance: At the beginning of each season, perform a comprehensive maintenance check. Replace any worn parts and ensure everything is functioning as intended to prepare for the upcoming usage period.

By adhering to these maintenance tips, you can ensure that your outdoor apparatus remains reliable and effective, ultimately saving you time and resources in the long run.

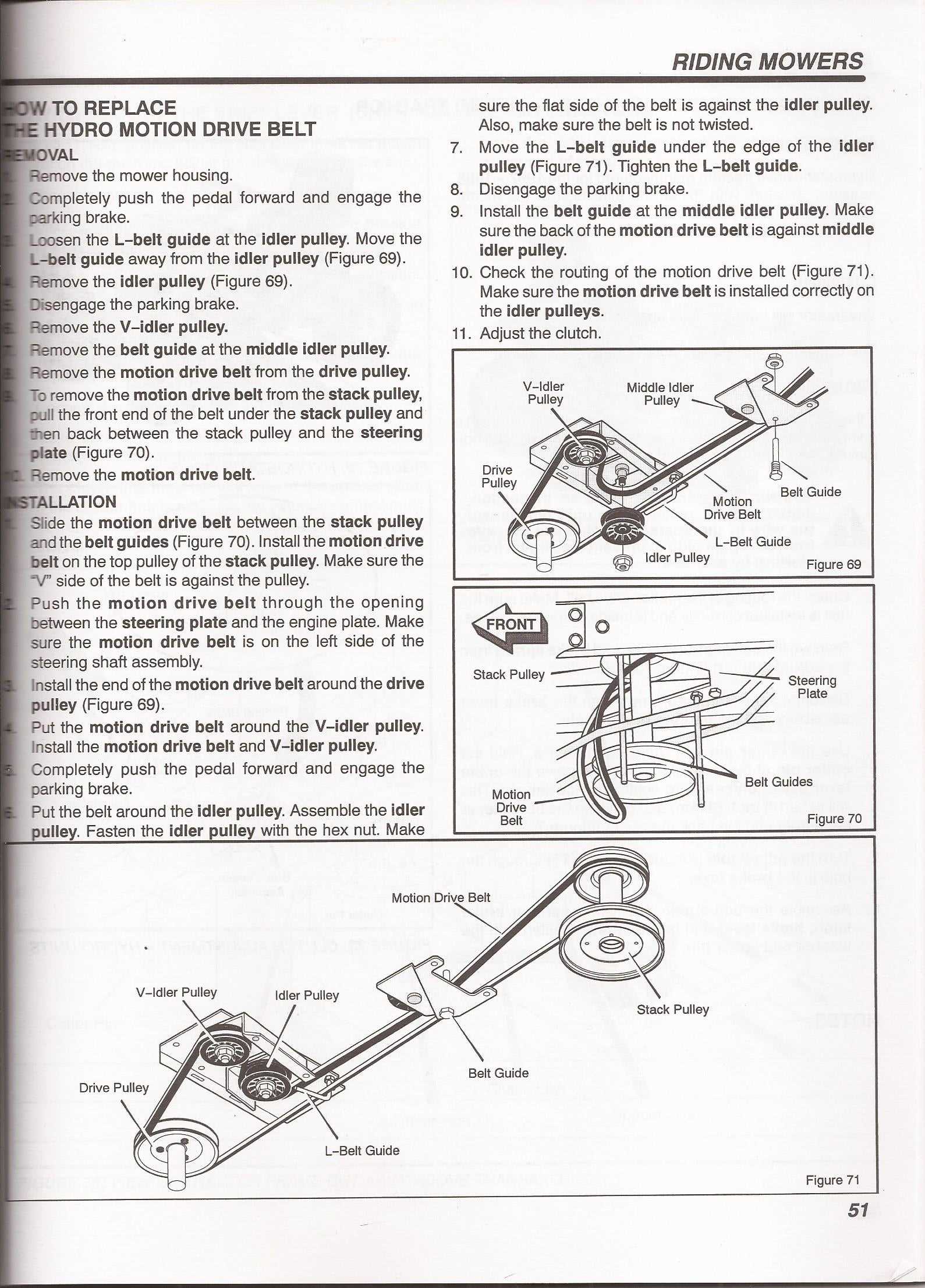

Replacing Worn-Out Deck Components

Over time, various components of your equipment can wear down, affecting performance and efficiency. Addressing these issues promptly ensures optimal functionality and prolongs the lifespan of your machinery.

Identifying Worn Components

Before proceeding with replacements, it’s essential to inspect and identify the parts that require attention. Look for signs of damage such as cracks, excessive rust, or unusual wear patterns that indicate a need for replacement.

Replacement Procedure

Once you’ve determined which components need to be swapped out, follow these general steps to ensure a smooth process:

| Step | Action |

|---|---|

| 1 | Gather necessary tools and new components. |

| 2 | Disconnect power sources and remove the old parts carefully. |

| 3 | Install the new components, ensuring proper alignment and secure fittings. |

| 4 | Reconnect power sources and perform a test run to confirm functionality. |

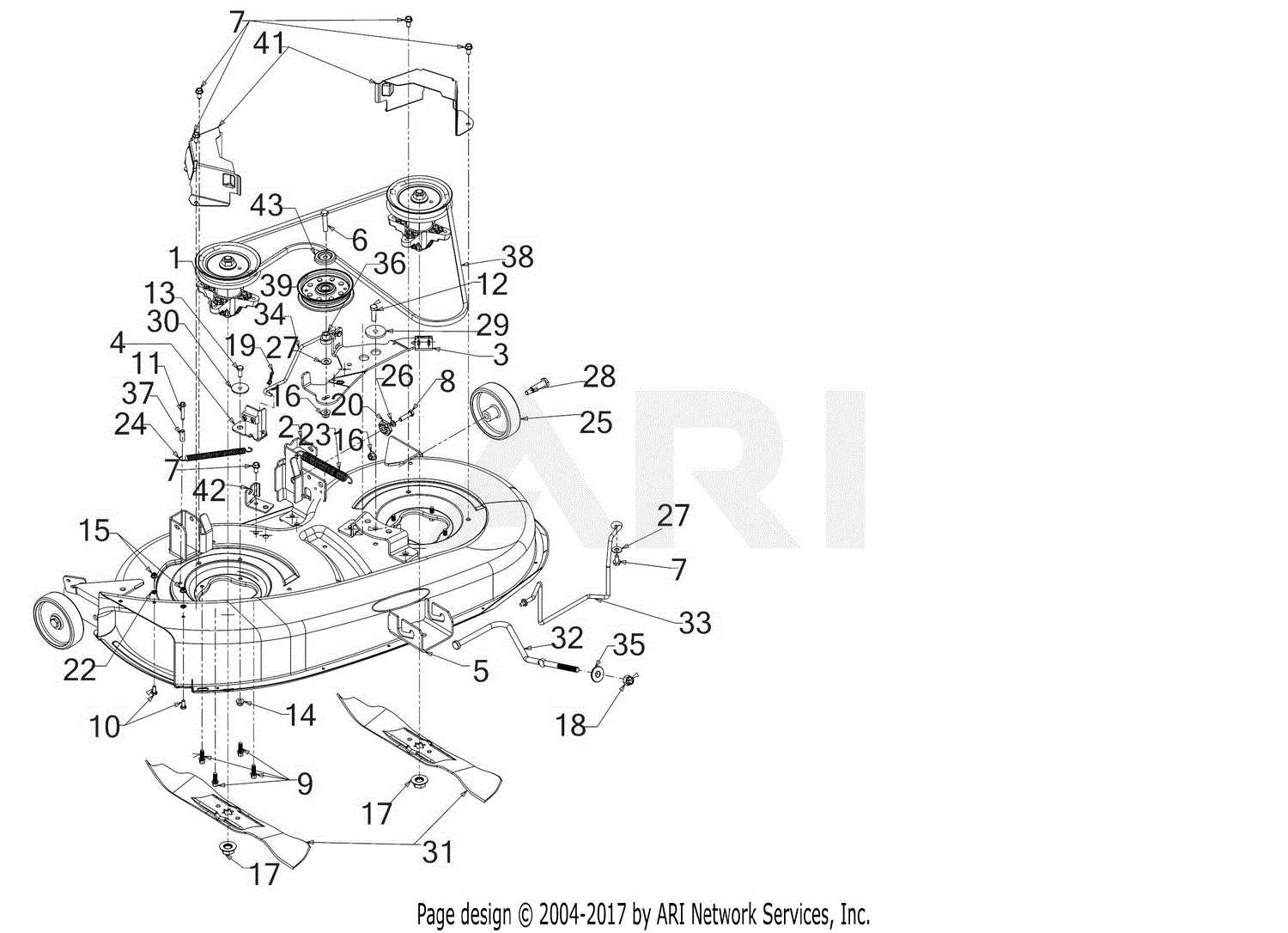

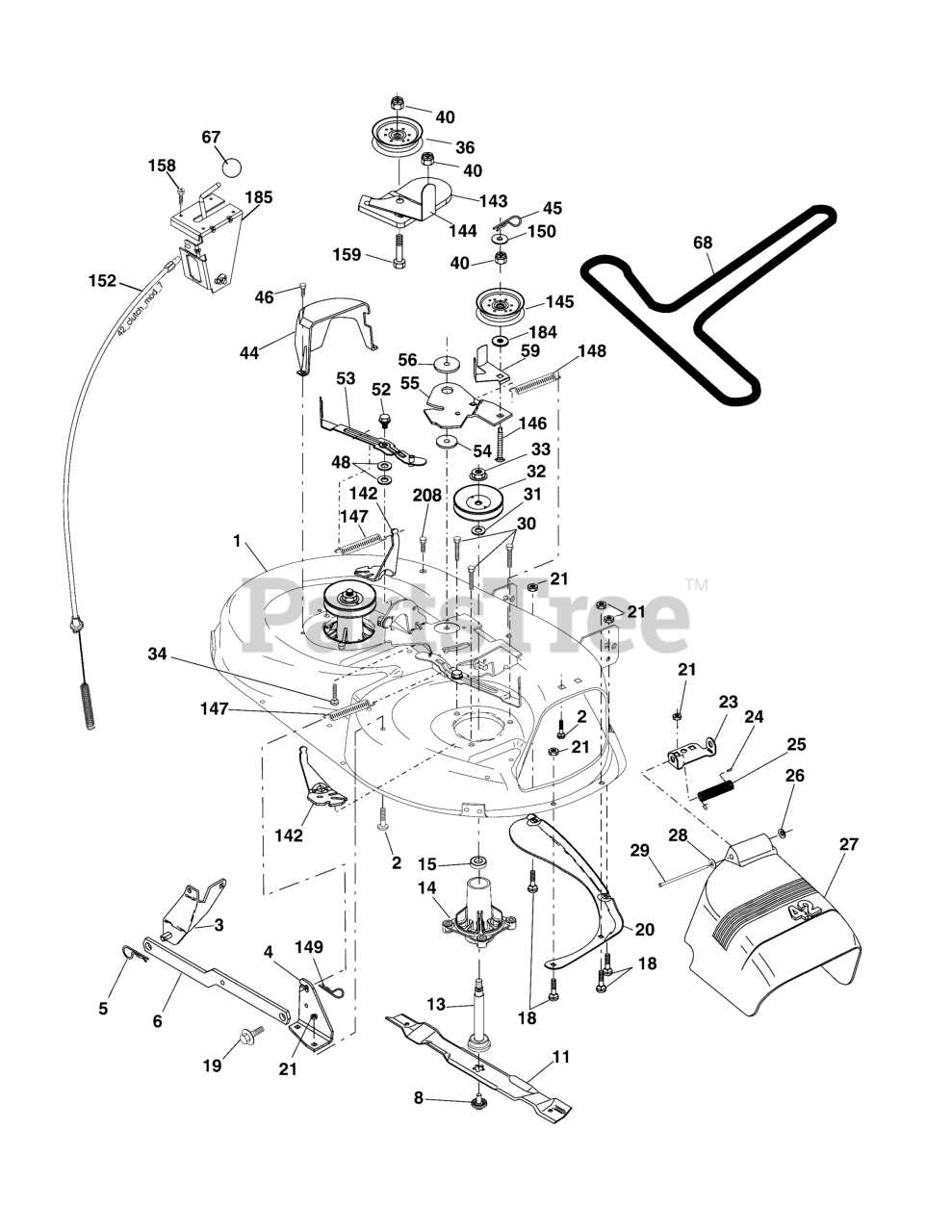

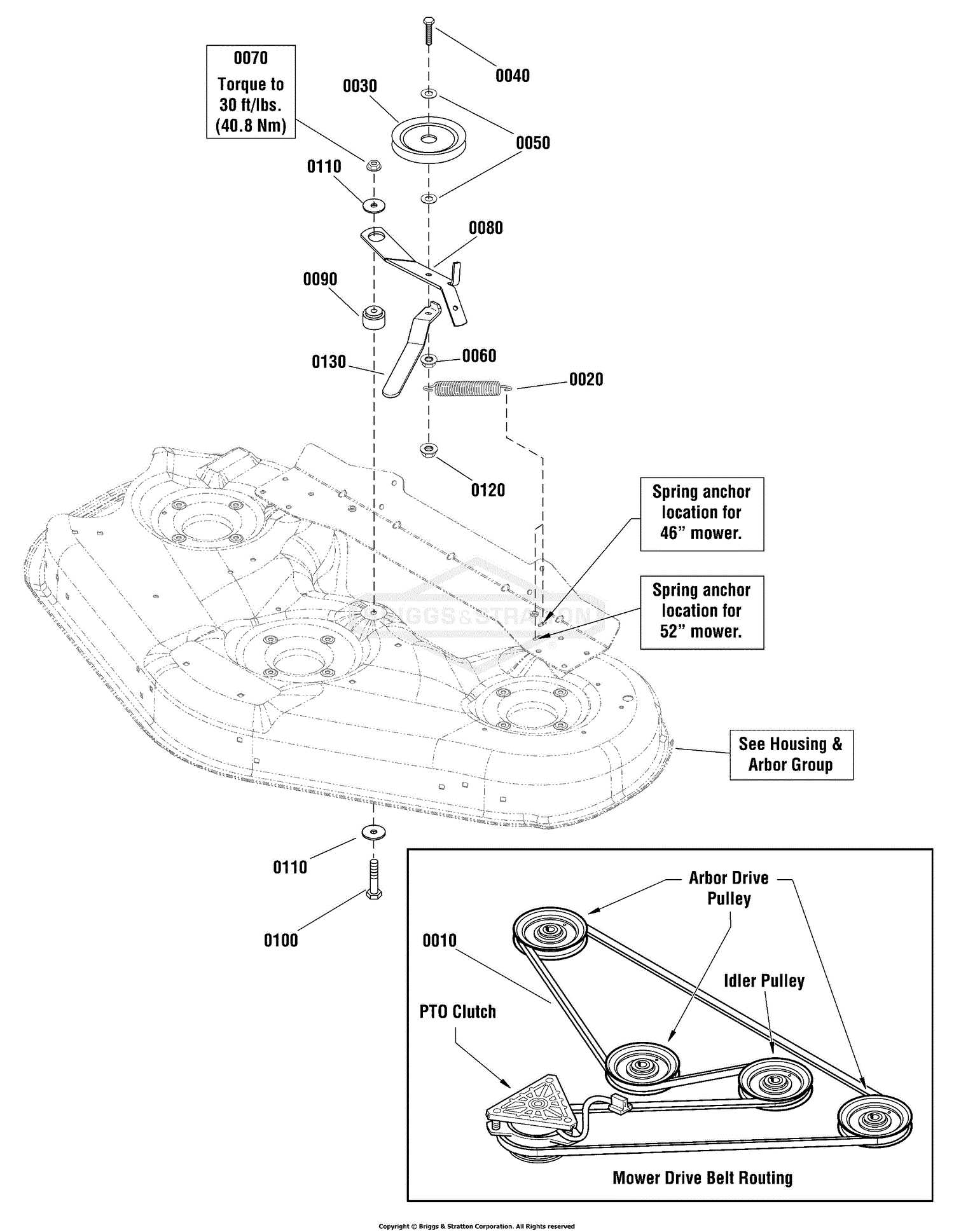

Understanding Deck Assembly Process

The process of assembling the cutting mechanism of a garden tool involves several key components that work in harmony to achieve efficient performance. Each element plays a critical role, contributing to the overall functionality and reliability of the equipment. Gaining a clear understanding of how these components fit together can greatly enhance maintenance and repair efforts.

Key Components and Their Functions

Each segment of the assembly serves a specific purpose. The rotating blades, for instance, are designed to provide a precise cut, while the housing ensures protection and stability during operation. Additionally, the attachment points and adjustment mechanisms allow for customization according to the user’s preferences and the terrain type.

Steps for Assembly

To effectively piece together the cutting unit, start by organizing all necessary components. Follow a systematic approach: first, secure the base structure, then attach the blades, ensuring they are positioned correctly. Finally, connect any additional features, such as height adjusters, to complete the setup. This methodical assembly not only improves performance but also prolongs the lifespan of the equipment.

Tools Needed for Deck Repairs

Proper maintenance of outdoor equipment requires specific tools to ensure effective repairs and longevity. Having the right instruments at hand simplifies the process, making it efficient and straightforward.

Essential Tools

- Socket Set

- Wrench Set

- Philips and Flathead Screwdrivers

- Pliers

- Hammer

- Utility Knife

Safety Gear

- Gloves

- Safety Glasses

- Ear Protection

Equipping yourself with these items will ensure that you are ready to tackle any maintenance challenges effectively.

Safety Precautions During Maintenance

Ensuring safety during upkeep is essential to prevent accidents and injuries. Proper precautions create a secure environment for both the operator and those nearby.

Essential Guidelines

- Always disconnect the power source before starting any maintenance tasks.

- Wear appropriate personal protective equipment, such as gloves and goggles.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Keep tools organized and within reach to minimize distractions.

Handling Equipment Safely

- Ensure that all components are securely fastened before operation.

- Regularly inspect for wear and tear to avoid malfunctions.

- Follow the manufacturer’s instructions meticulously for repairs and replacements.

Where to Find Replacement Parts

Finding components for your outdoor equipment can be a straightforward process if you know where to look. Numerous sources provide an extensive range of alternatives, ensuring you can maintain the performance of your machinery.

Online Retailers: Many websites specialize in equipment supplies, offering convenient browsing and home delivery options. These platforms often feature detailed catalogs, making it easy to locate the specific items you need.

Local Dealers: Visiting nearby retailers can provide immediate access to essential components. The advantage of this approach is the ability to consult with knowledgeable staff who can assist in selecting the right pieces.

Manufacturer Websites: Official sites often have sections dedicated to replacement components, complete with diagrams and part numbers. This ensures you find the correct fit for your model.

Forums and Community Groups: Engaging with fellow enthusiasts can lead to valuable insights and recommendations for reliable sources. Many communities share tips on where to find hard-to-locate items.

Ultimately, exploring these avenues will help you successfully procure the necessary components for your equipment.

How to Interpret Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations serve as guides, showcasing the various elements and their interconnections. By mastering how to read these visuals, one can streamline the repair process and ensure all necessary items are addressed.

Key Elements to Look For

- Labels: Identify the names or codes associated with each part, which are essential for ordering replacements.

- Numbering: Often, parts are numbered sequentially, helping to establish their order or relationship to one another.

- Connection Points: Look for indications of how components are linked, whether through bolts, screws, or other fasteners.

- View Angles: Diagrams may present multiple perspectives, giving insight into complex assemblies.

Steps to Follow

- Begin by identifying the overall layout of the illustration, noting how components are organized.

- Refer to any accompanying legend or key that explains symbols or color codes used in the representation.

- Cross-reference the identified components with any available lists to ensure completeness.

- When replacing items, use the visual as a reference to guide your assembly or disassembly.

By following these guidelines, anyone can effectively utilize visual schematics for their repair needs, ensuring a smoother and more efficient process.

Comparing Different Deck Models

Understanding the various designs available for cutting equipment can significantly influence performance and user experience. Each configuration offers unique features tailored to specific needs, from cutting width to material durability, which ultimately affects efficiency and maintenance.

Design Features

Different configurations boast distinctive attributes that cater to a range of tasks. For instance, some models emphasize a wider cutting area, while others prioritize maneuverability in tight spaces. Choosing the right design depends largely on the intended application and user preferences.

Material and Durability

Material quality plays a crucial role in longevity and performance. Some variants utilize robust metals, ensuring they withstand rigorous use, while others may offer lighter constructions for enhanced mobility. Evaluating the balance between strength and weight can lead to the ultimate choice for optimal functionality.

Resources for Further Learning

Expanding your knowledge on maintenance and repair can greatly enhance your skills and confidence. Here are various materials and platforms that can provide valuable insights and guidance.

Online Resources

Utilizing the internet can open up a wealth of information. Consider exploring forums, instructional videos, and articles dedicated to equipment upkeep.

Books and Manuals

Many books and technical manuals offer in-depth knowledge and are excellent references for understanding mechanisms and troubleshooting techniques.

| Type | Resource | Link |

|---|---|---|

| Online Forum | Gardening Community | Visit |

| Video Tutorial | YouTube Mechanics Channel | Watch |

| Book | Maintenance Guide | Find on Amazon |