Understanding the internal and external elements of an off-road utility vehicle is essential for maintaining optimal performance and longevity. Every detail, from the engine configuration to the smallest mechanical connection, plays a significant role in ensuring reliable operation in challenging terrains. This section will provide a detailed overview of the key assemblies and configurations that contribute to the functionality of these versatile machines.

In this guide, we will highlight the various structural aspects and mechanical systems that are critical for smooth operation. By examining the different elements, users can gain insight into how each part interacts to create a robust and dependable vehicle. Special attention will be given to the practical aspects of assembly and component maintenance to ensure the vehicle remains in top condition.

Whether you are a seasoned mechanic or simply an enthusiast, this information will serve as a comprehensive resource for understanding how these machines are built and maintained,

Key Components of the 2011 John Deere Gator 825i

The core structure of this utility vehicle is built around various critical elements that work together to ensure reliability and high performance. Understanding the main parts can help in maintaining and optimizing its functionality, ensuring a long lifespan and efficient operation on all terrains.

Engine and Transmission

The heart of the machine is its power unit, which drives performance and is responsible for smooth and responsive handling. This includes the fuel system, cooling mechanisms, and transmission setup, which allow for seamless gear transitions and consistent power output during operation.

Suspension and Chassis

The frame of the vehicle supports its entire structure and ensures durability in various working conditions. The suspension system is key to providing a stable and comfortable ride, while the chassis design enhances strength and balance

Engine and Powertrain Breakdown

The heart of any utility vehicle lies in its engine and powertrain system, responsible for delivering the necessary force and stability for various tasks. In this section, we will explore the key elements of this vital system, examining how its components work together to ensure optimal performance and durability.

Key Components of the Engine

- Cooling system – essential for maintaining appropriate engine temperatures during operation.

- Fuel system – delivers the right amount of fuel for efficient combustion and power output.

- Exhaust system – removes combustion gases to ensure smooth engine operation and efficiency.

Powertrain System Overview

The powertrain transfers energy from the engine to the wheels, making movement possible. It includes several important components that ensure power is effectively distributed

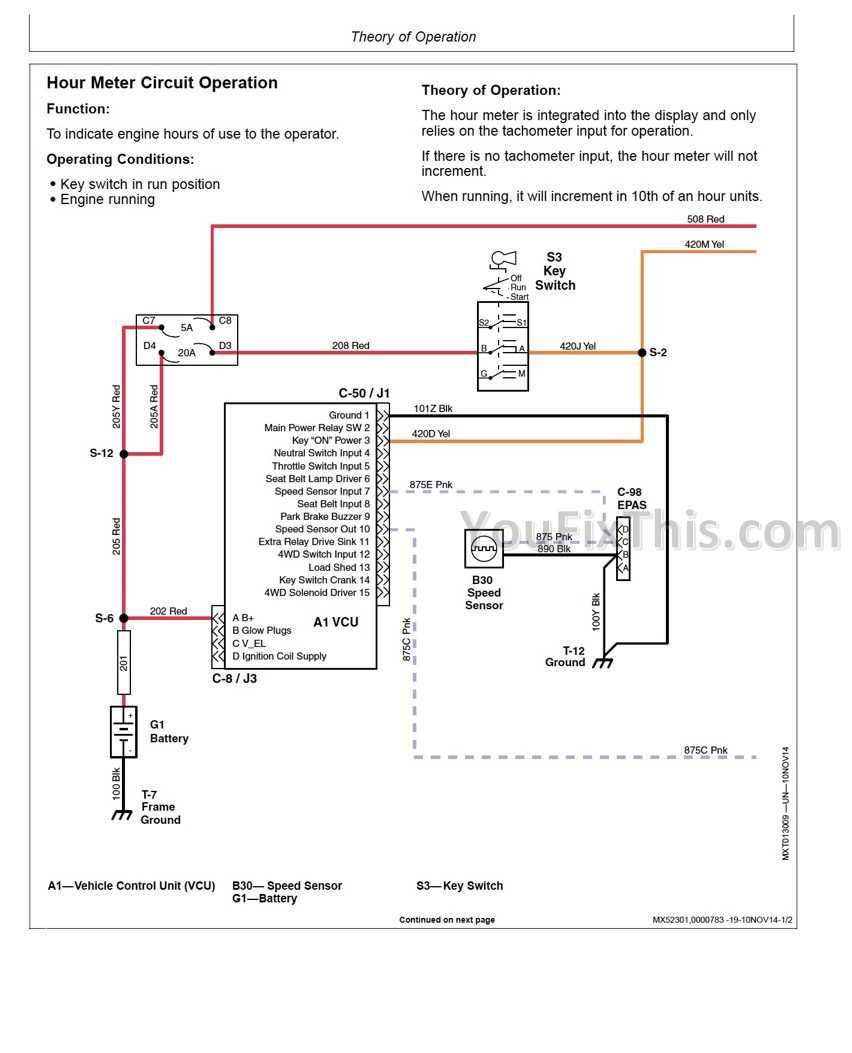

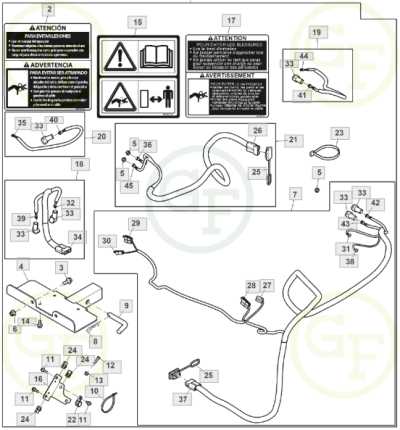

Electrical System Overview

The electrical system plays a critical role in ensuring the proper operation and functionality of the vehicle. It connects various components, providing the necessary power and control to keep essential systems running smoothly. Understanding the key elements of the electrical setup is essential for efficient maintenance and troubleshooting.

- Battery: Supplies power to all electrical components and is responsible for starting the engine.

- Wiring: Acts as the network, carrying electrical current to different parts of the vehicle, ensuring consistent functionality.

- Fuses and Relays: Protect the system from overloads and short circuits by interrupting the flow of electricity when necessary.

- Charging System: Maintains the battery’s charge while the engine is running, ensuring continuous power supply.

- Switch

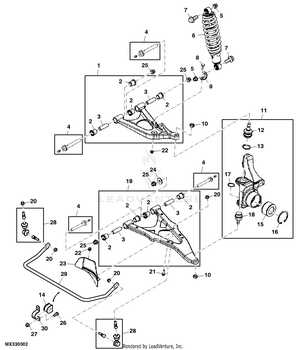

Suspension and Steering Parts Layout

The layout of the suspension and steering components plays a crucial role in ensuring smooth handling and stability. These elements work together to absorb shocks from uneven surfaces and provide precise control when navigating various terrains. A well-designed structure helps distribute forces evenly, maintaining balance and ride comfort.

Suspension system includes various elements designed to reduce the impact of rough ground. Key components in this system contribute to the vehicle’s ability to maintain traction and stability.

Steering mechanisms are equally important, as they allow for responsive control and directional changes. Each part is strategically placed to ensure accuracy in movement and reduce wear on connected components.

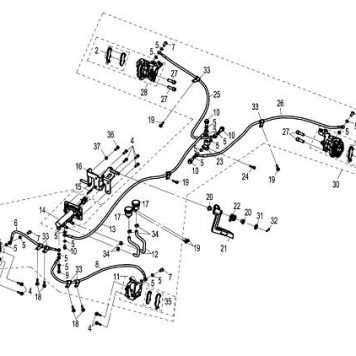

Fuel System Components

The fuel system is essential for ensuring the reliable operation of any utility vehicle, providing the necessary flow of fuel to the engine. Understanding the different elements that make up this system can help maintain efficiency and prevent potential issues over time.

Main Elements of the Fuel System

Key components involved in the fuel system include the fuel pump, injectors, and filter. These parts work together to ensure fuel is properly delivered and filtered, which is crucial for optimal engine performance. Regular inspection and maintenance of these components can prolong the life of the vehicle.

Fuel Delivery Process

The process begins with the fuel pump drawing fuel from the tank, moving it through the lines, and ensuring that it reaches the injectors. The injectors then spray the correct amount

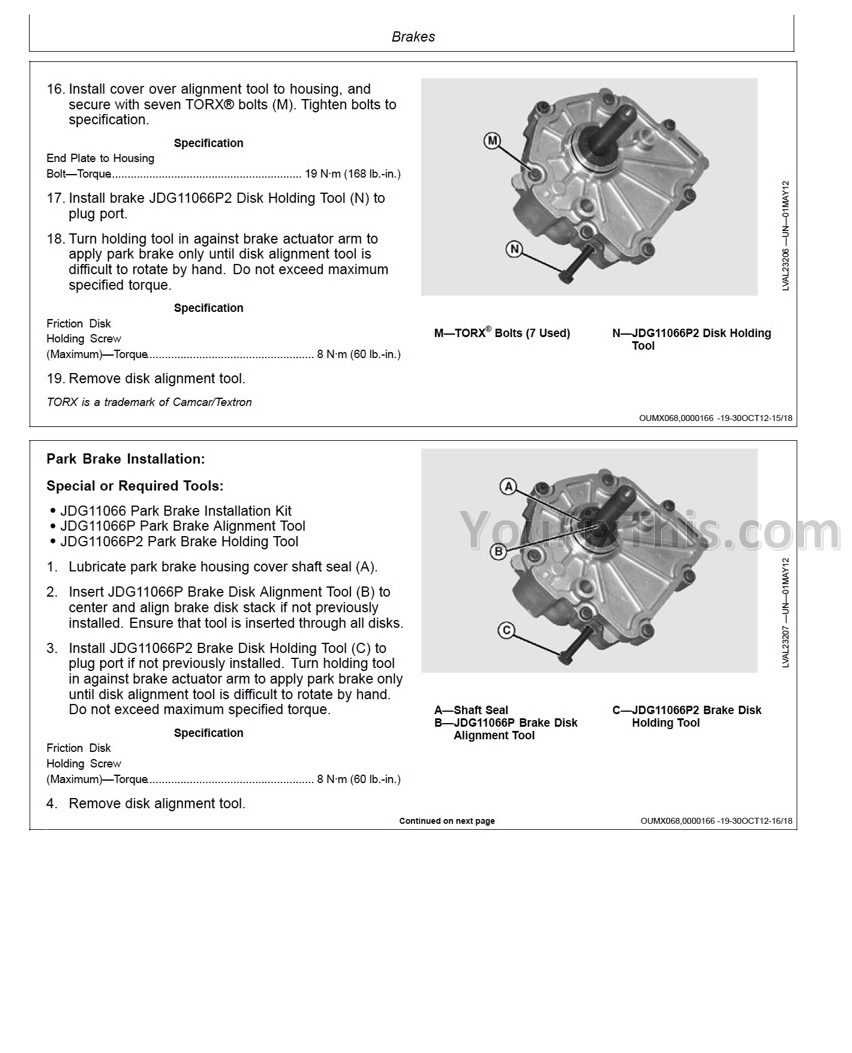

Brake System Diagram

The braking mechanism of an all-terrain vehicle is crucial for ensuring safety and control during operation. Understanding the configuration and components of the braking system can enhance maintenance and troubleshooting efforts.

Key elements of the braking system include:

- Brake Pedal: The primary control for activating the braking system.

- Brake Lines: Hoses that transport hydraulic fluid to the brake components.

- Calipers: Devices that apply pressure to the brake pads, creating friction against the rotors.

- Brake Pads: Friction materials that engage with the rotors to slow down the vehicle.

- Rotors: Disc-shaped components that the brake pads clamp onto to stop the vehicle.

- Master Cylinder: The component that generates hydraulic pressure when the brake pedal is pressed.

Regular inspection and maintenance of these components can help ensure optimal performance and longevity of the braking system. Identifying worn or damaged parts is essential for maintaining safety standards.

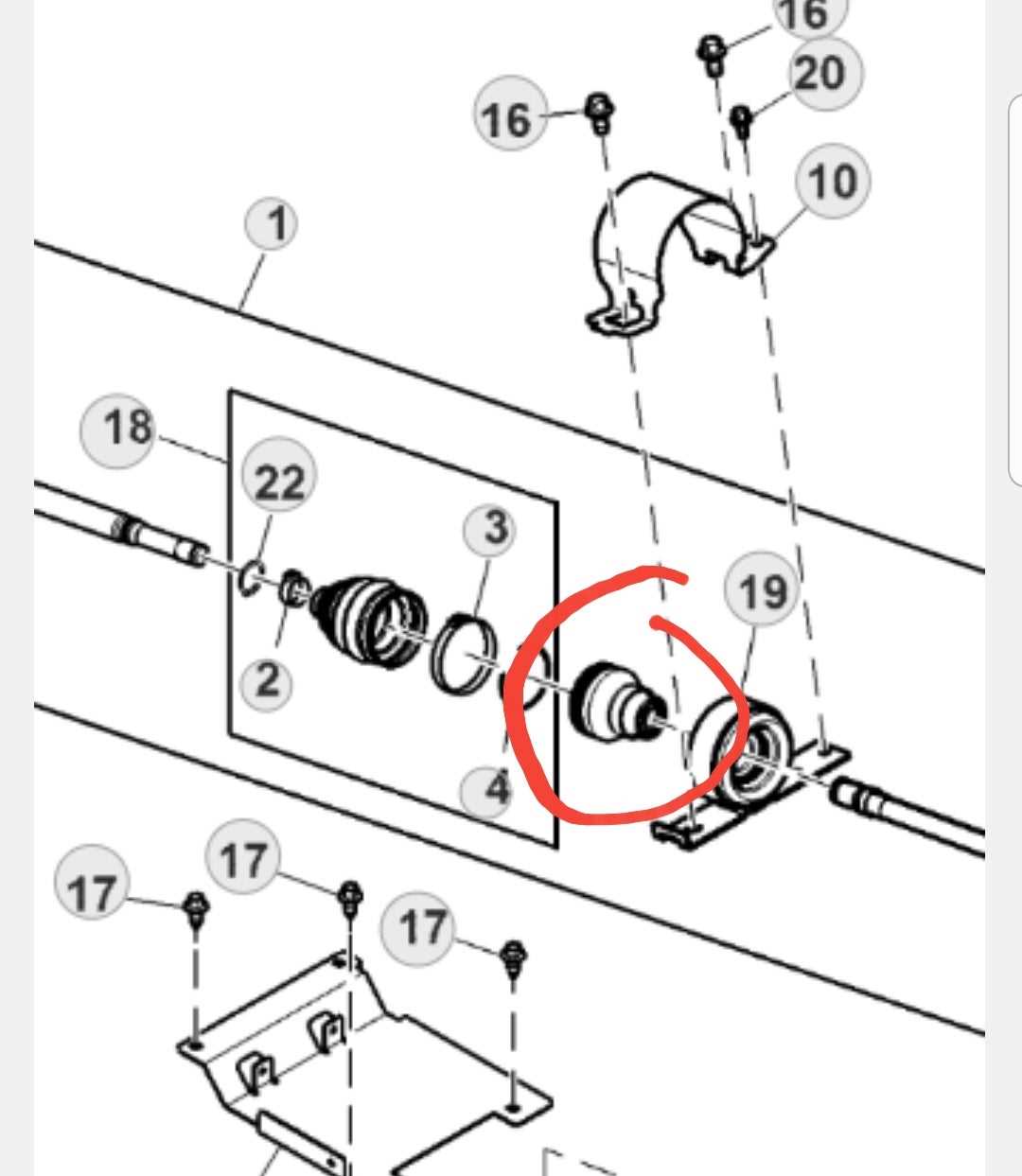

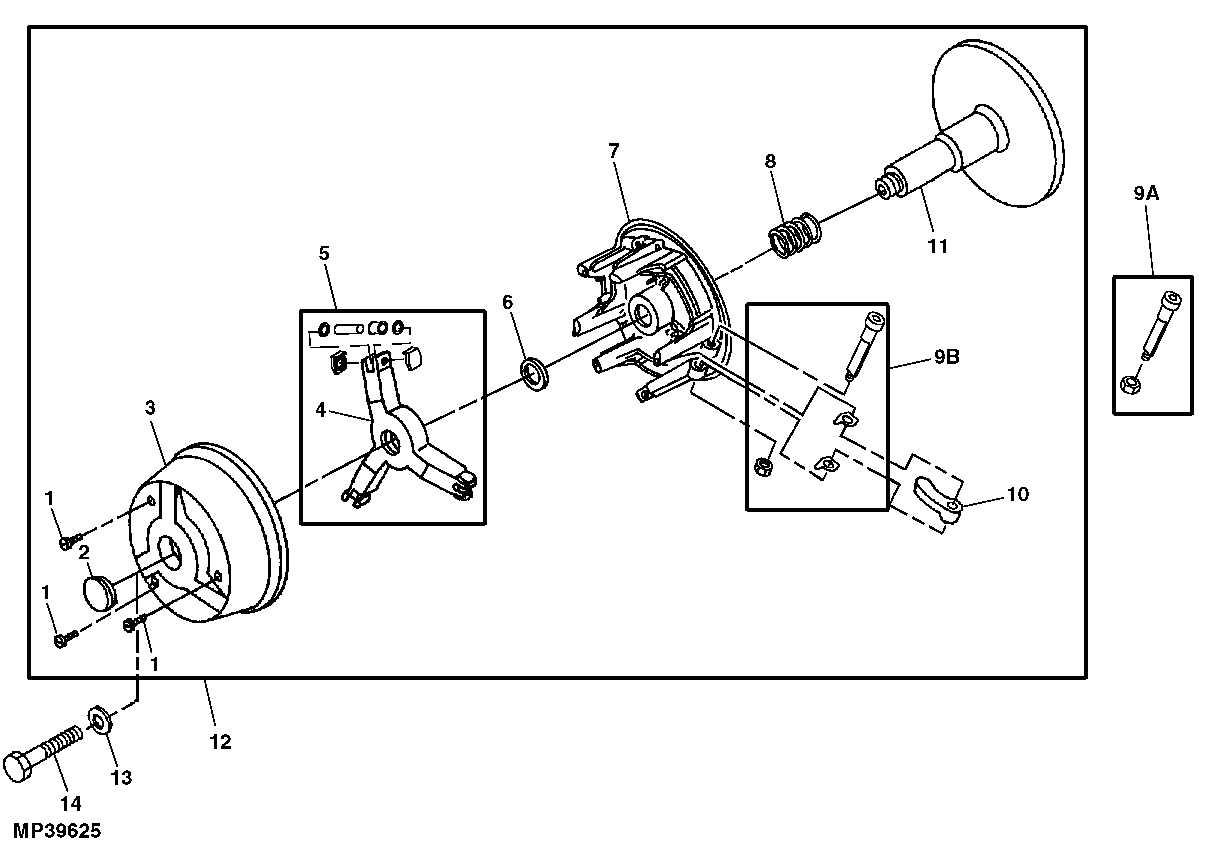

Transmission Assembly and Parts

The transmission assembly is a crucial component of any off-road utility vehicle, responsible for transferring power from the engine to the wheels. Understanding the different elements of this assembly is essential for maintaining optimal performance and ensuring longevity. Proper knowledge of each part’s function and placement can significantly enhance the efficiency of the vehicle.

Key components of the transmission assembly include the gearbox, drive shafts, and various supporting structures. The gearbox facilitates the selection of gears, allowing for smooth acceleration and deceleration. Drive shafts transmit the rotational power from the gearbox to the wheels, enabling movement across various terrains. Additionally, supporting structures, such as mounts and brackets, ensure stability and alignment within the assembly.

Regular inspection and maintenance of the transmission assembly can prevent premature wear and tear. Ensuring that all components are functioning correctly will contribute to a more reliable and efficient driving experience. It is advisable to refer to the specific specifications and guidelines for the particular model to perform accurate repairs and replacements.

Cooling System and Radiator Parts

The cooling system is essential for maintaining optimal engine performance and preventing overheating. It consists of various components that work together to regulate the temperature of the engine, ensuring it operates efficiently under varying conditions. Understanding the different elements involved in this system can help in troubleshooting and maintenance.

Key components of the cooling assembly include:

Component Description Radiator This device dissipates heat from the engine coolant, allowing it to cool before recirculating back to the engine. Water Pump Circulates coolant through the system, ensuring efficient heat transfer and maintaining consistent temperatures. Thermostat Regulates the flow of coolant based on the engine temperature, opening and closing as needed to maintain optimal conditions. Cooling Hoses Flexible tubes that transport coolant to and from the engine and radiator, vital for maintaining fluid circulation. Fan Assists in air circulation through the radiator, enhancing cooling efficiency during operation. Exhaust System and Muffler Layout

The exhaust assembly plays a crucial role in the efficient operation of the engine, ensuring the proper expulsion of combustion gases while minimizing noise. Understanding the configuration and components involved in this system can greatly enhance maintenance and performance. This section provides an overview of the essential elements that comprise the exhaust structure and muffler arrangement, facilitating smoother engine operation and compliance with emission standards.

Component Description Exhaust Header A tubular section that collects exhaust gases from the engine’s cylinders and directs them towards the muffler. Mid-Pipe A connecting pipe that channels the gases from the exhaust header to the muffler, often designed for optimal flow. Muffler A device that reduces engine noise by dissipating sound waves and modifying gas flow through a series of chambers or perforated tubes. Tailpipe The final section that expels exhaust gases into the atmosphere, often positioned to minimize backpressure. Chassis and Frame Construction

The chassis and frame serve as the foundation of any utility vehicle, providing essential support and stability during operation. A well-engineered framework ensures durability and enhances the overall performance of the vehicle, making it suitable for a variety of tasks.

Key elements of chassis and frame construction include:

- Material Selection: The choice of materials is critical, as they must balance strength and weight. Commonly used materials include high-strength steel and aluminum alloys.

- Design Efficiency: The design should maximize rigidity while minimizing weight, allowing for better handling and improved fuel efficiency.

- Modular Components: A modular approach facilitates easier repairs and upgrades, enabling users to customize their vehicles based on specific needs.

- Welding and Fabrication Techniques: Advanced welding methods contribute to the integrity of the frame, ensuring that joints can withstand heavy loads and stress.

- Corrosion Resistance: Protective coatings and treatments are essential to prevent rust and corrosion, extending the lifespan of the chassis.

In summary, the construction of the chassis and frame is a fundamental aspect that significantly impacts the vehicle’s performance, durability, and versatility in various applications.

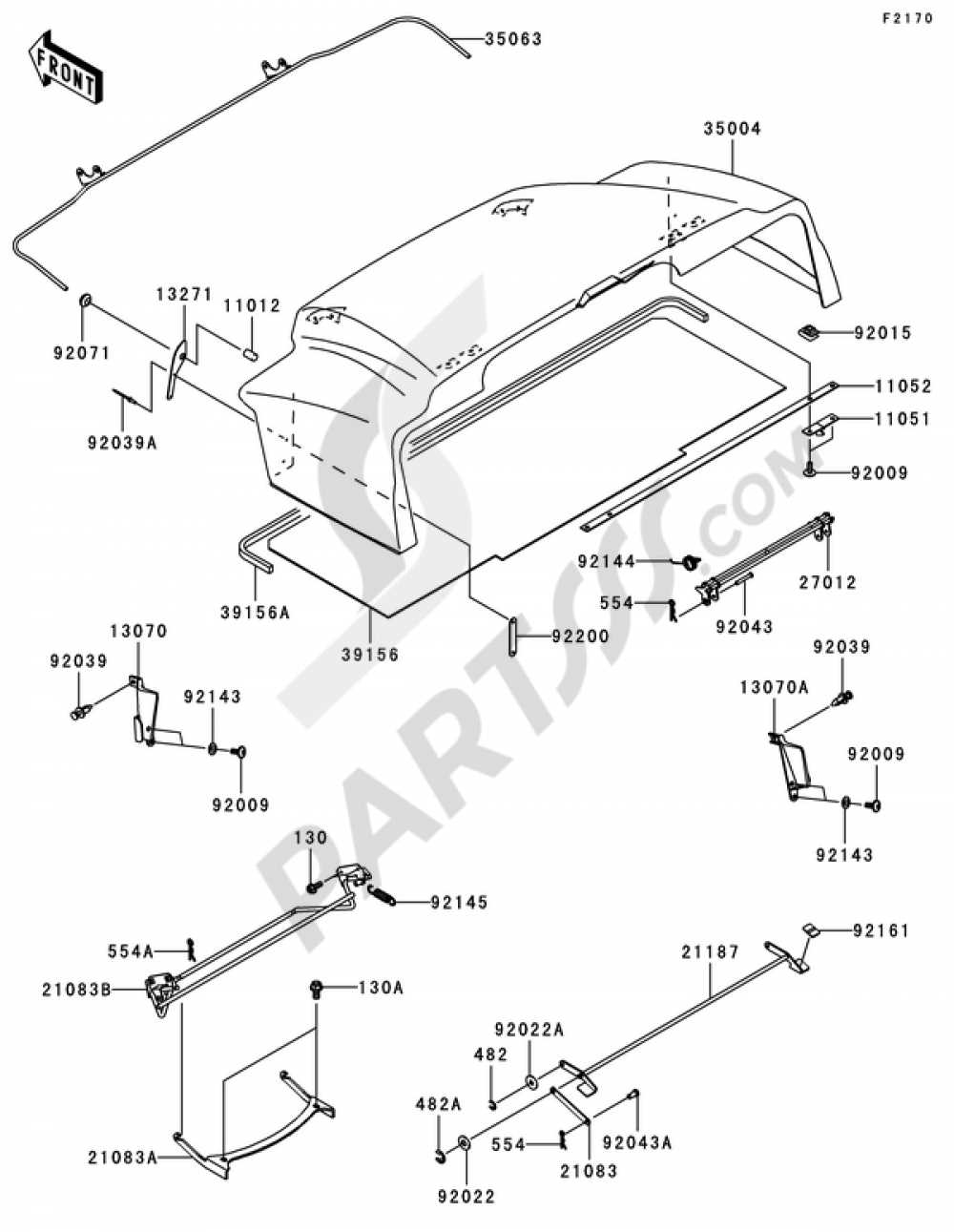

Body Panels and Accessories

The body components of utility vehicles play a crucial role in both aesthetics and functionality. These elements not only enhance the overall appearance but also provide protection and support to various internal mechanisms. Understanding the different panels and additional features available can greatly assist in customizing and maintaining the vehicle’s performance.

Panel Types: The main exterior components typically include the front and rear panels, side coverings, and fenders. Each part is designed to withstand harsh conditions while offering a streamlined look. Durability is key, as these panels must endure environmental challenges such as UV rays, moisture, and rough terrain.

Accessories: In addition to standard panels, a range of accessories can enhance both utility and style. Features like storage compartments, protective guards, and aesthetic upgrades can be added to personalize the vehicle. Investing in quality accessories can not only improve functionality but also increase the vehicle’s longevity.