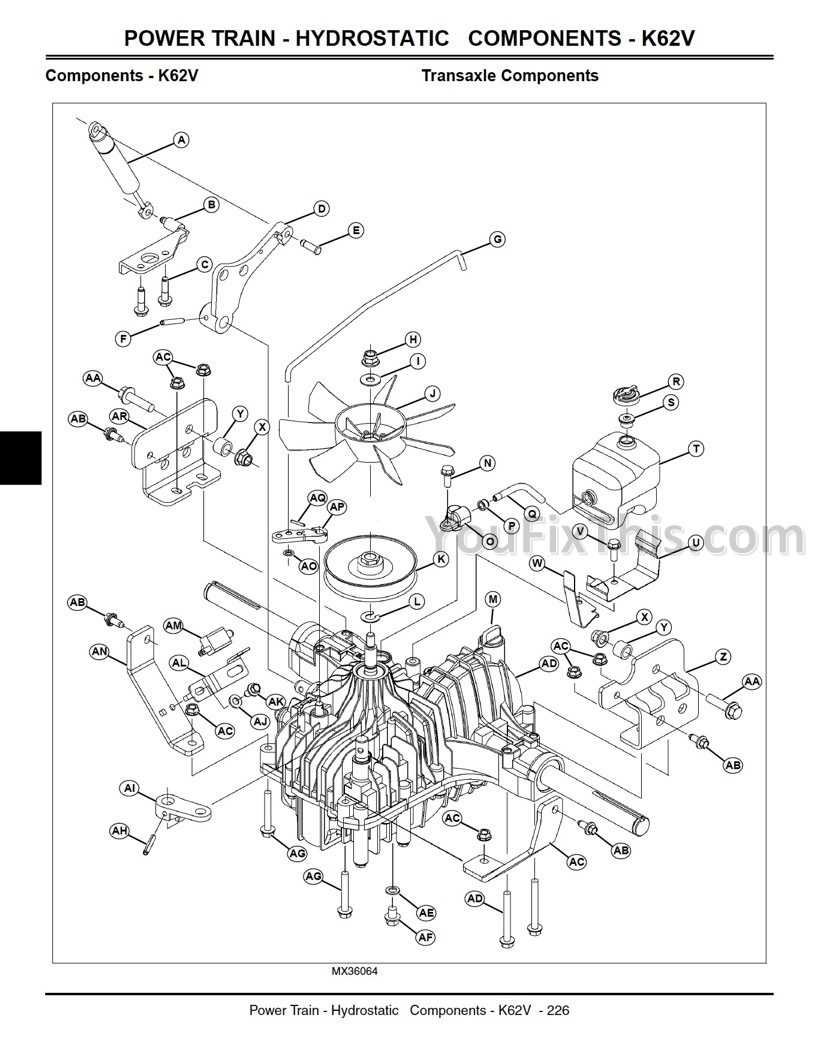

In the realm of agricultural machinery, comprehending the various components and their arrangements is crucial for effective maintenance and repair. This section delves into the intricate layout of essential elements, providing insights that can enhance the longevity and performance of your machinery.

Recognizing the significance of each individual component can empower operators and technicians alike. By familiarizing oneself with how these pieces interconnect, one can troubleshoot issues more efficiently and implement preventative measures that safeguard against future breakdowns.

Furthermore, having a clear visual reference of these components can aid in the identification of worn or damaged parts, streamlining the replacement process. This understanding not only fosters better handling of equipment but also contributes to the overall success of agricultural operations.

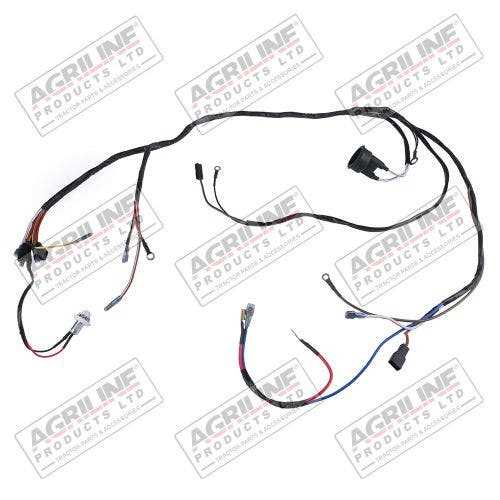

Lawn tractors are essential machines designed for efficient grass maintenance. Understanding the typical elements that make up these vehicles can enhance their operation and maintenance. Here are the key components often found in these gardening machines.

- Engine: The power source of the tractor, which drives the entire system. It is crucial for the performance and efficiency of the machine.

- Transmission: This component transfers power from the engine to the wheels, allowing for movement at various speeds.

- Deck: The cutting unit located beneath the tractor, responsible for mowing the grass. Its design can vary depending on the width and cutting height settings.

- Wheels: These provide mobility and stability, allowing the tractor to navigate different terrains smoothly.

- Steering System: A mechanism that enables the operator to control the direction of the machine with ease.

- Battery: Supplies electrical power to start the engine and power various electrical components of the tractor.

- Chassis: The structural framework that supports all other components and ensures durability during operation.

Familiarity with these vital elements can assist users in troubleshooting and performing regular maintenance, ultimately prolonging the lifespan of the equipment.

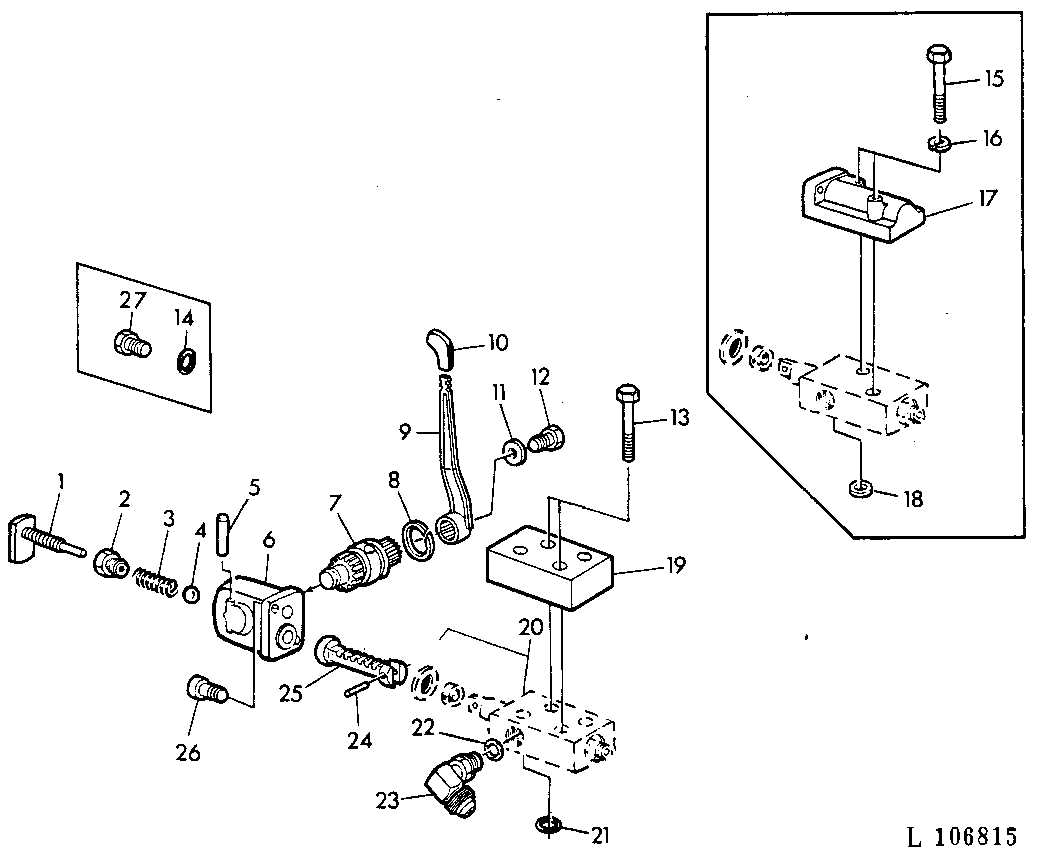

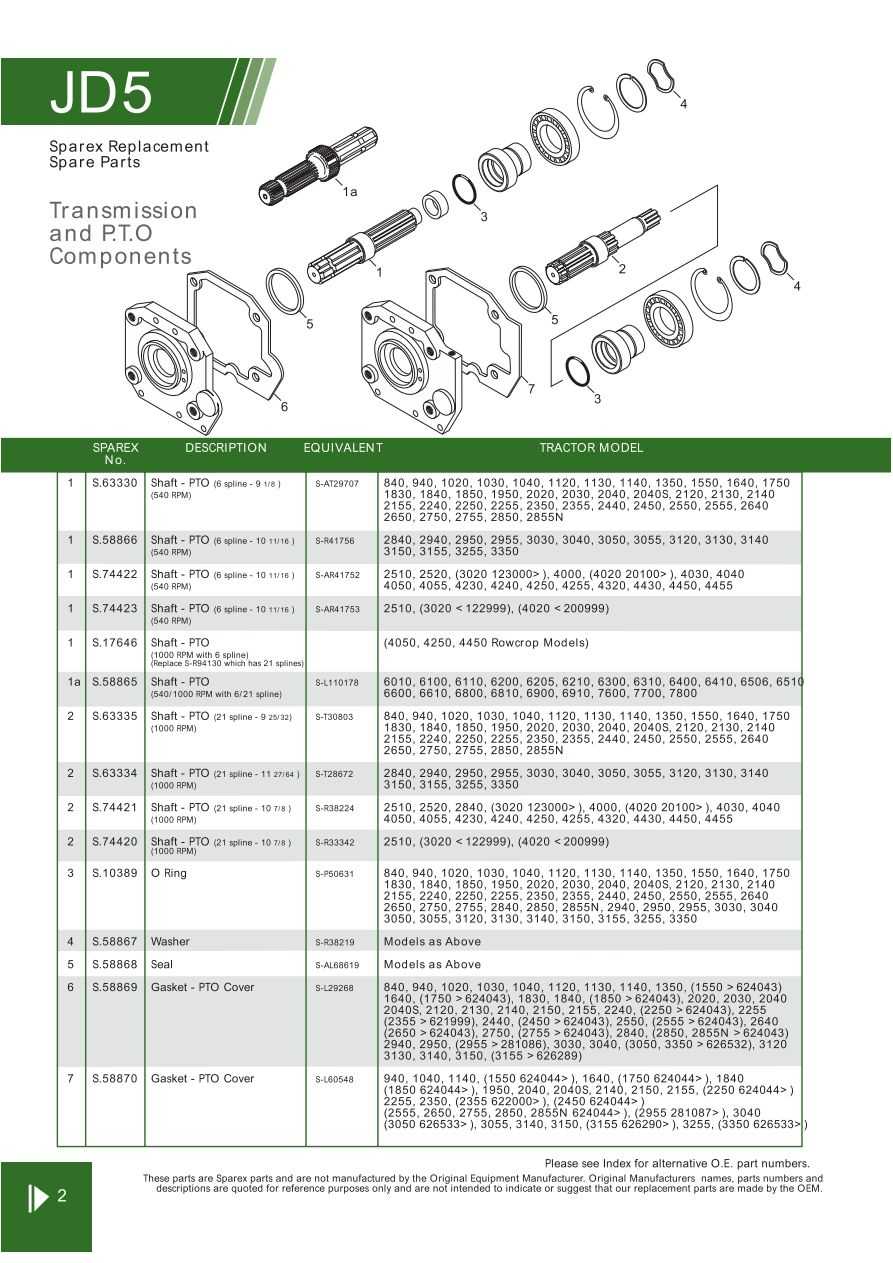

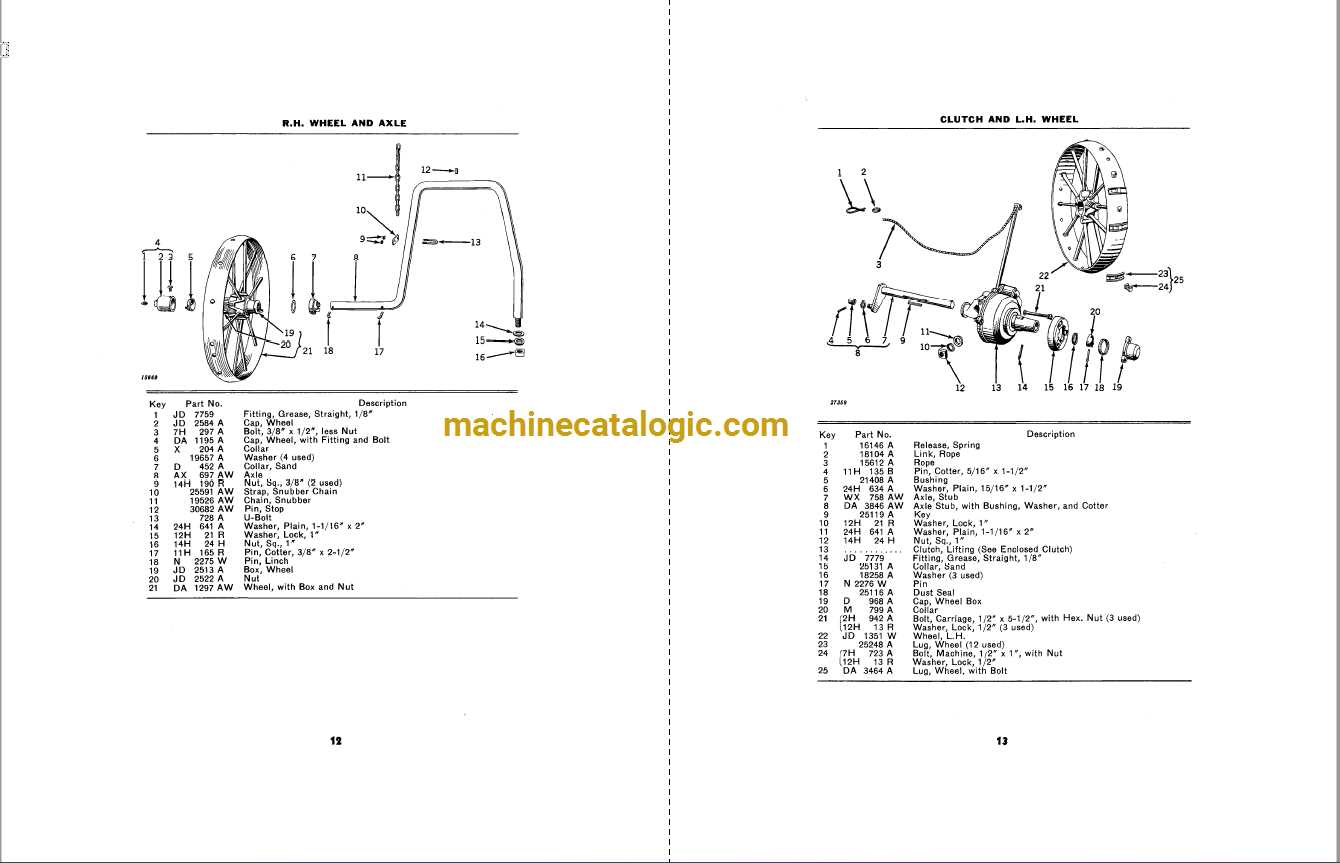

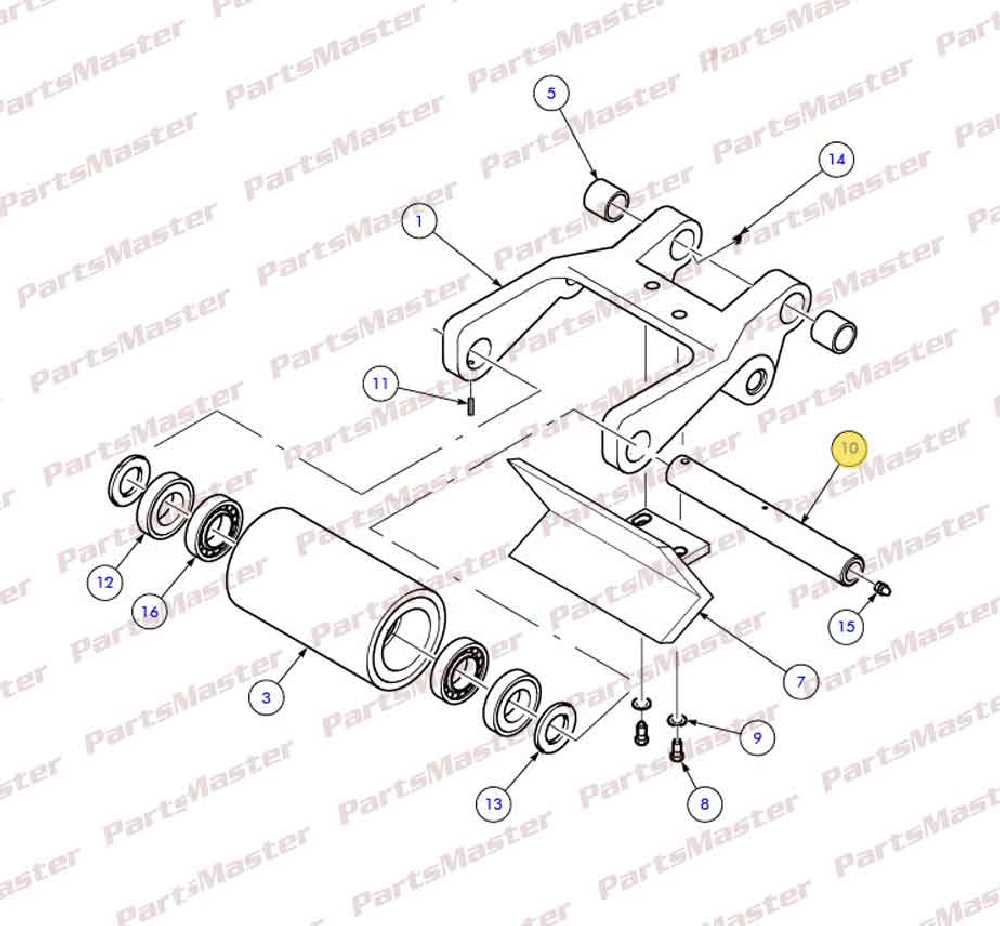

Understanding the Parts Diagram

Grasping the structure of machinery components is essential for effective maintenance and repair. A visual representation serves as a valuable tool, allowing users to identify individual elements and their relationships within the assembly. This understanding is crucial for both novice and experienced operators, facilitating informed decisions during troubleshooting or replacement procedures.

Key benefits of utilizing such illustrations include:

- Clear identification of each component

- Enhanced comprehension of assembly relationships

- Streamlined repair and maintenance processes

To effectively interpret these visuals, it is important to pay attention to:

- Labels: Each component is typically labeled for easy identification.

- Connections: Observe how parts interact and are connected to one another.

- Groupings: Some elements may be grouped, indicating they function together.

Familiarity with these aspects will improve your ability to navigate the assembly effectively, ensuring timely repairs and optimal performance.

Where to Find Replacement Parts

When it comes to maintaining your machinery, locating suitable components can be a crucial task. Fortunately, there are numerous avenues available for sourcing the necessary items to keep your equipment in optimal condition. Understanding where to search can save time and ensure that you receive quality replacements.

Online Retailers are among the most accessible resources. Numerous websites specialize in offering a wide selection of components for various models. These platforms often provide detailed descriptions and compatibility information, making it easier to identify the right items for your needs. Additionally, customer reviews can help gauge the quality of the products before making a purchase.

Local Dealers are another excellent option. Many manufacturers have authorized dealerships that carry an inventory of essential components. Visiting these locations allows you to speak with knowledgeable staff who can provide guidance and assistance in selecting the correct items. Furthermore, you may be able to order parts that are not readily available in-store.

Salvage Yards offer a more budget-friendly alternative. These establishments often have a variety of used components that are still in good working condition. While the selection may vary, it is possible to find rare or hard-to-find items at a fraction of the cost of new ones. However, ensure that any used components are thoroughly inspected before installation.

Finally, online forums and community groups dedicated to enthusiasts and professionals can be invaluable. These platforms allow users to share advice, resources, and even trade components. Engaging with fellow machinery owners can lead to recommendations for reliable sources and tips on where to find specific items.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires regular upkeep and attention to detail. Implementing a consistent maintenance routine can greatly extend the life of your equipment, enhancing its performance and reliability. Here are some essential practices to consider for optimal care.

- Regular Inspections: Frequently check key components for signs of wear or damage. Early detection can prevent more significant issues down the line.

- Cleanliness: Keep the equipment clean by removing dirt, debris, and contaminants. A clean machine operates more efficiently and is less prone to breakdowns.

- Lubrication: Ensure all moving parts are adequately lubricated to reduce friction and wear. Refer to the manufacturer’s recommendations for suitable lubricants.

- Fluid Levels: Regularly monitor and maintain appropriate fluid levels, including oil, coolant, and hydraulic fluids. Proper fluid management is crucial for optimal performance.

By following these guidelines and remaining vigilant about maintenance, you can enhance the lifespan of your machinery, ensuring it remains in top working condition for years to come.

Signs of Wear in Components

Recognizing the signs of deterioration in machinery components is crucial for maintaining optimal performance and preventing unexpected failures. Various indicators can suggest that specific parts may be experiencing excessive wear and require inspection or replacement. Being vigilant about these signs can help ensure the longevity of equipment and avoid costly repairs.

Common Indicators of Deterioration

- Unusual Noises: Listen for grinding, rattling, or clicking sounds that may indicate a malfunctioning part.

- Increased Vibrations: Noticeable shaking or vibrations during operation can signify that components are out of balance or worn.

- Leaks: Fluid leaks around seals and connections often indicate wear, necessitating prompt attention.

- Excessive Heat: Overheating of parts can result from friction caused by wear, impacting overall functionality.

Visual Signs to Monitor

- Cracks or Fractures: Inspect components for visible damage, such as cracks or chips, which can compromise structural integrity.

- Discoloration: Changes in color or surface texture can indicate overheating or material degradation.

- Wear Patterns: Check for uneven wear on contact surfaces, which may suggest misalignment or insufficient lubrication.

Repair vs. Replacement Considerations

When faced with mechanical issues, the choice between mending components and opting for new replacements is crucial. Evaluating the extent of the damage, associated costs, and long-term implications can significantly impact the performance and longevity of the machinery.

Repairing existing elements may offer immediate solutions while preserving original components. However, it might not always be feasible or cost-effective, especially for extensive damage. On the other hand, replacing parts can ensure enhanced performance and reliability, albeit at a higher initial expense.

| Consideration | Repair | Replacement |

|---|---|---|

| Cost | Generally lower, depending on the extent of the damage | Usually higher initial investment |

| Time | Often quicker, especially for minor issues | May take longer due to sourcing and installation |

| Longevity | May not last as long if not thoroughly repaired | Tends to provide a longer-lasting solution |

| Performance | Could restore functionality, but not always to original standards | Can enhance efficiency and effectiveness |

Ultimately, the decision should factor in the specific circumstances, including the machine’s age, intended use, and budget constraints. Engaging with knowledgeable professionals can aid in making an informed choice that aligns with operational needs.

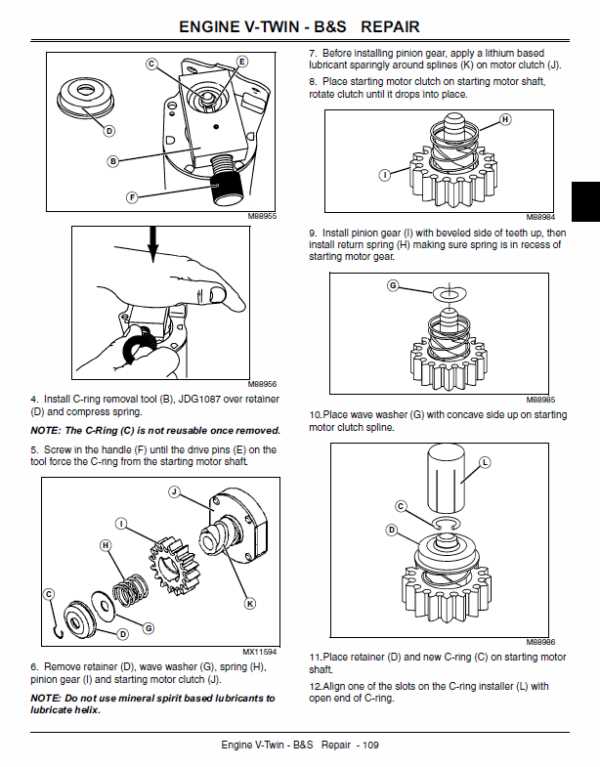

Utilizing Diagrams for DIY Repairs

Visual representations serve as invaluable tools for anyone embarking on do-it-yourself restoration projects. They offer a clear and organized way to understand the components of a system, making it easier to identify what needs to be repaired or replaced. By leveraging these visual aids, individuals can navigate complex tasks with greater confidence and efficiency.

When approaching repairs, following a structured method can enhance success rates. Here are some key steps to consider:

- Assess the Situation: Begin by evaluating the condition of the equipment. Take note of any visible issues or malfunctioning elements.

- Refer to Visual Aids: Use illustrations to pinpoint the specific areas that require attention. These images can clarify how different components interact.

- Gather Necessary Tools: Compile a list of tools required for the task. This might include wrenches, screwdrivers, or specialized equipment.

- Follow the Steps: Adhere to the sequence of actions suggested by the visual references. This approach minimizes errors and promotes safety.

- Double-Check Your Work: After completing the repair, review your actions to ensure everything is correctly assembled and functioning.

By implementing these strategies, enthusiasts can effectively utilize visual representations to streamline their repair endeavors. The combination of careful planning and the use of helpful images ultimately leads to more successful outcomes in any restoration project.

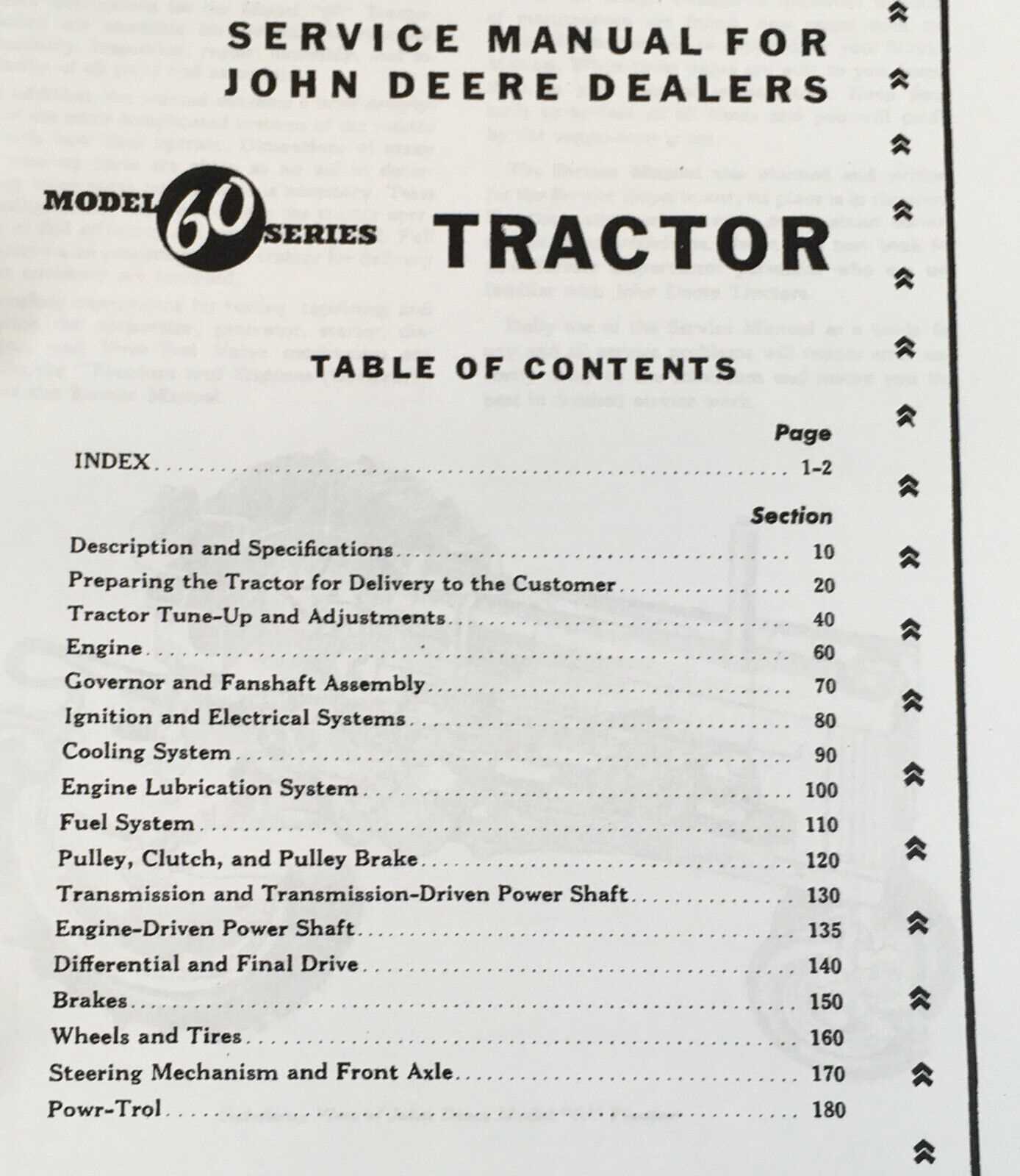

Resources for Technical Support

Accessing reliable resources for technical assistance is crucial for maintaining and troubleshooting machinery. Whether you are seeking manuals, online forums, or expert advice, having the right tools at your disposal can significantly enhance your understanding and efficiency in handling equipment issues. This section will explore various avenues to ensure you receive the support you need.

Online Communities and Forums

Engaging with online communities dedicated to machinery enthusiasts can provide valuable insights. These platforms often feature discussions on common challenges, shared experiences, and solutions from fellow users. Participating in these forums allows you to ask questions and gain perspectives from those who have encountered similar situations.

Official Manufacturer Resources

Utilizing resources provided by the manufacturer is another effective way to obtain accurate information. Official websites typically offer access to manuals, troubleshooting guides, and FAQs that can assist in addressing technical concerns. Additionally, reaching out to customer support can provide personalized assistance tailored to your specific requirements.