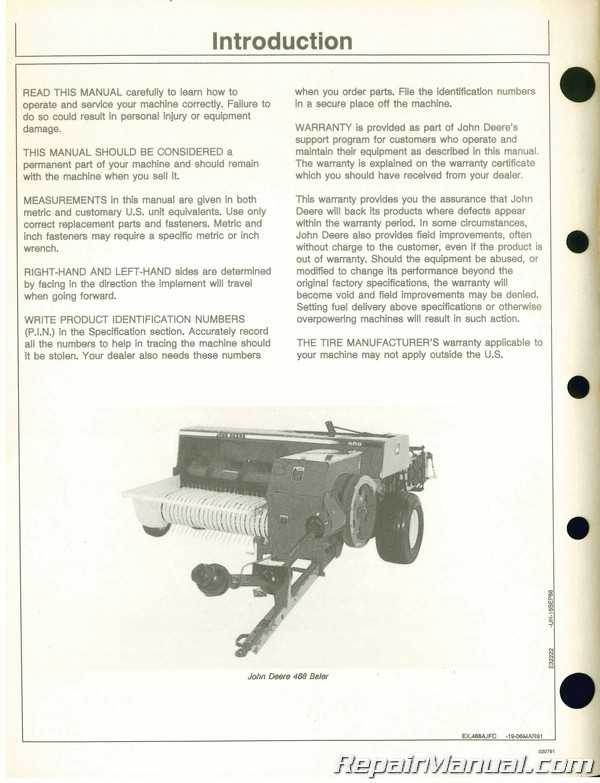

The world of agricultural machinery is vast, and understanding the various elements that keep these machines running efficiently is crucial. Every piece of equipment is made up of multiple interconnected components, each playing a vital role in the overall operation. When these elements are well-maintained and understood, the efficiency and longevity of the machinery are significantly enhanced.

In this section, we will explore the structure and functionality of a key agricultural machine. Focusing on its internal and external mechanisms, you will gain insights into how each part contributes to the smooth operation of the equipment. By understanding the role of these elements, you will be better equipped to maintain and troubleshoot the machinery as needed.

Additionally, recognizing the importance of regular inspection and timely replacement of essential parts ensures that the machine performs at its best in the field. Through careful analysis of its structure, you will see how individual components come together to form a cohesive and reliable system.

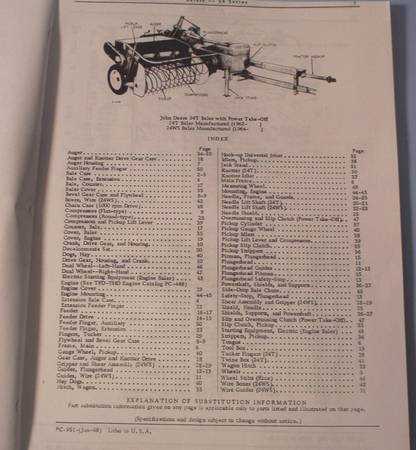

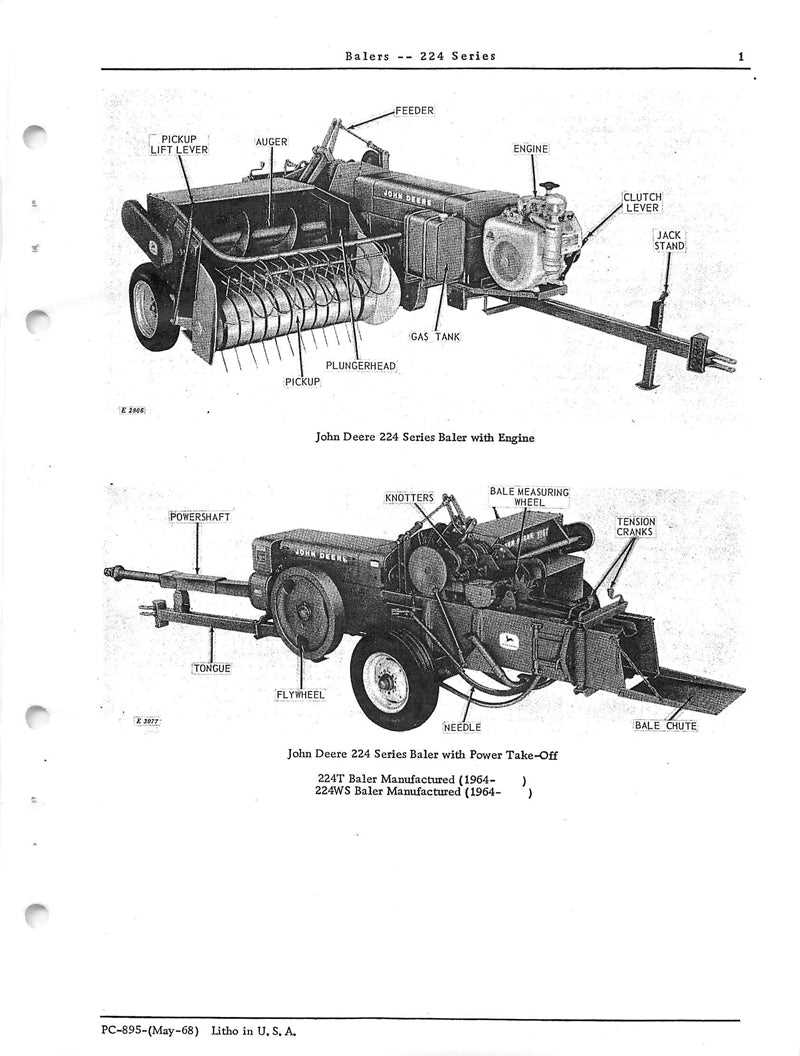

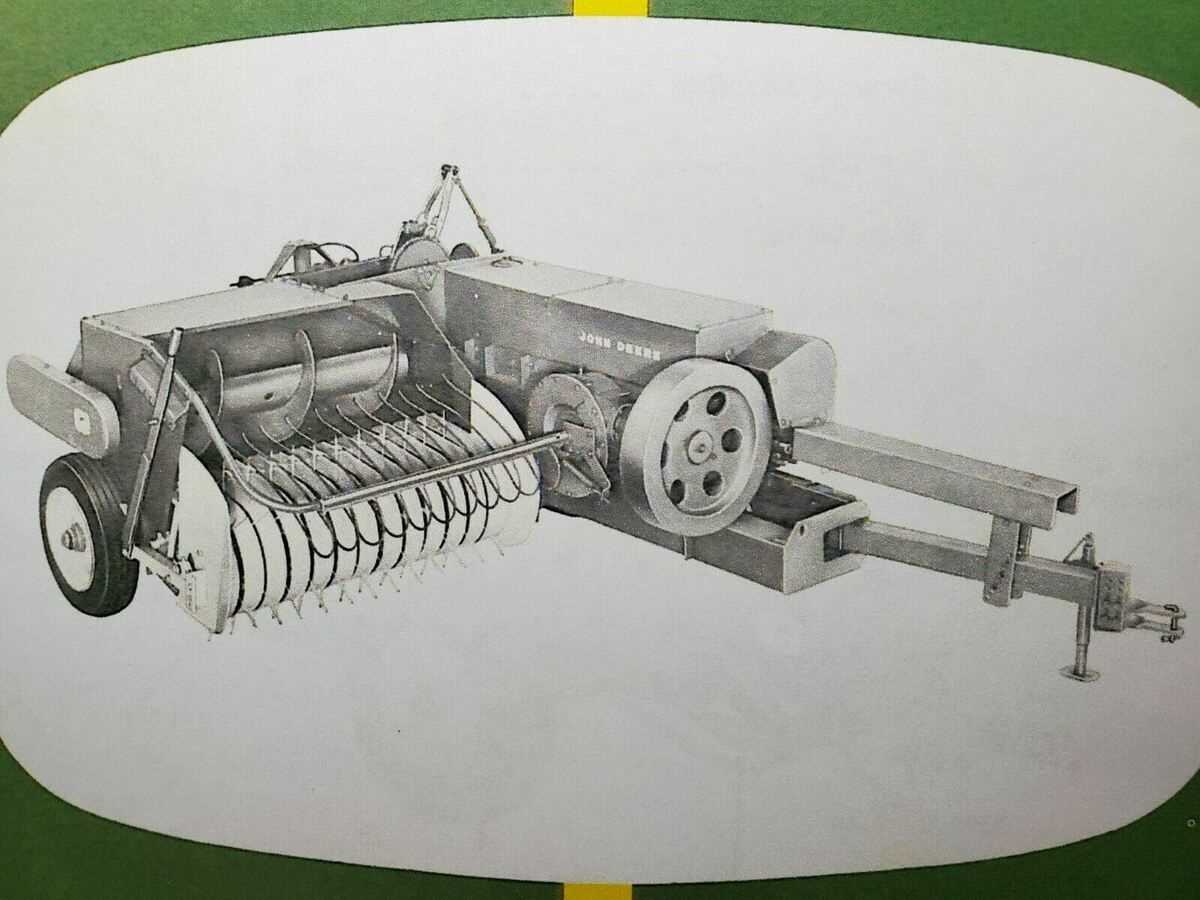

Understanding the John Deere 24T Baler Mechanism

The operation of agricultural machinery relies on a precise system of moving components that work together to achieve efficient and reliable functionality. To fully grasp how this machine functions, it’s important to explore the mechanics that contribute to its overall performance. Each part plays a role in ensuring the process runs smoothly, from gathering material to forming it into a final product, making the system a key aspect of farm equipment.

Key Functions of the Compression Mechanism

One of the most vital parts of the machine is its compression mechanism, which is responsible for shaping and binding the material. This section of the system involves a series of actions that compact the material into a manageable form. Understanding the steps in this process helps to maintain optimal efficiency and troubleshoot potential issues that may arise during operation.

How the Feeding System Works

The feeding system plays a crucial role in guiding material through the machine. This component ensures that raw material is consistently delivered to the next stage of processing. With proper maintenance, the feeding system guarantees continuous and even flow, reducing downtime and improving productivity during use.

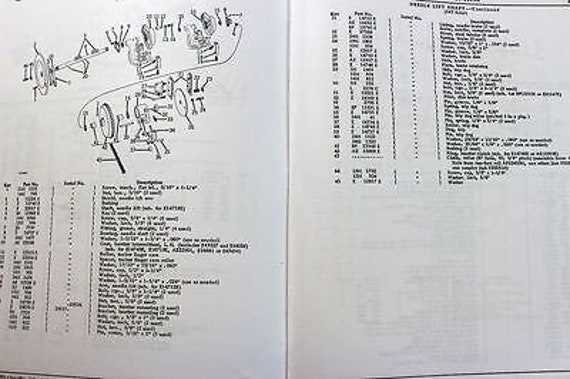

Key Components of the 24T Baler

The functionality of the machine relies on several vital elements that work together to ensure smooth operation. Understanding these essential parts helps in maintaining efficiency and longevity of the equipment.

Main Mechanisms

At the core of the equipment’s functionality are the primary mechanical systems, which handle the gathering, compressing, and tying processes. These components are engineered to handle heavy loads and continuous operation, ensuring reliability under various conditions.

- Pickup Mechanism: This part is responsible for collecting material from the ground, guiding it into the next stage of the process.

- Compression Chamber: In this section, the material is compacted into manageable bundles, ready for further handling.

- Knotting System: This crucial feature ties the compacted bundles, securing them for transport and storage.

Additional Features

Supporting the primary mechanisms are several secondary systems that enhance performance and efficiency. These ensure smooth transitions between stages

How the Pickup Mechanism Works

The pickup system is designed to collect loose materials from the ground and feed them into the machinery for further processing. Its role is crucial in ensuring efficient gathering of the crop without leaving residue behind. The mechanism is built to work smoothly, adapting to different terrains and materials.

The process involves several components working in unison to lift and transfer the material. Below is a detailed explanation of how the system operates:

- Tines: These are flexible prongs that sweep the material off the ground and move it towards the feeding system.

- Cam Track: This part guides the tines, ensuring they follow a specific path for optimized pickup and release of material.

- Augers: Positioned on either side of the system, these spiral components funnel the material inward, ensuring it is evenly distributed for the next phase.

- Feeding Chamber: The material is directed into this section, where it gets compressed and prepared for further handling.

The efficiency of this system lies in its synchronized movement, ensuring that the crop is picked up effectively

Exploring the Knotter System Functionality

The knotter mechanism is a crucial component of many agricultural machines, responsible for ensuring that materials are securely fastened during operation. This system plays a vital role in enhancing the overall efficiency of the equipment by handling the tying process with precision. Understanding how this intricate system works can help operators maintain smoother and more reliable performance in the field.

Knotter functionality revolves around its ability to manage the binding process efficiently. It operates by creating tight, durable knots that hold materials together as the machine processes them. Critical elements within the knotter are designed to work in perfect synchronization, ensuring that each step of the tying process is completed flawlessly. This reduces potential downtime caused by incomplete or loose ties.

The seamless interaction between the various mechanical components of the knotter system allows for consistent performance, even in demanding working conditions. Regular maintenance and a good understanding of how this system functions are essential for keeping the equipment operating at its best, ensuring reliable and high

Understanding the Bale Ejector Operation

The bale ejector is a crucial component designed to ensure smooth and efficient removal of bundles after they are formed. This mechanism works in sync with the rest of the equipment to guarantee consistent output, minimizing any disruptions during the process. A clear understanding of how it operates helps in maintaining productivity and preventing potential jams or delays.

Main Function of the Ejector

The primary role of the ejector is to release the finished bundles from the chamber, pushing them onto the ground or into a storage unit. It uses synchronized movements to keep the workflow uninterrupted, working seamlessly with the overall machinery. Proper alignment and timing are essential for optimal performance, ensuring each bundle is handled without issue.

Key Elements for Smooth Operation

Several components contribute to the effective function of the ejector. These include levers, springs, and hydraulic systems that work together to apply

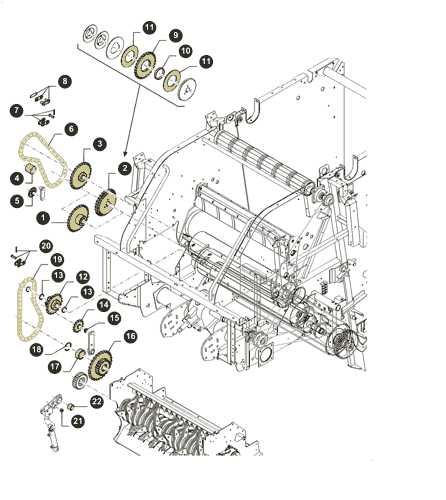

Drive Chains and Their Importance

Drive chains play a crucial role in the functioning of various agricultural machinery, ensuring efficient power transmission from the engine to different components. Their design and durability significantly affect the overall performance and reliability of the equipment. Proper maintenance and understanding of these chains are essential for maximizing operational efficiency and minimizing downtime.

The effectiveness of drive chains is determined by their ability to transfer torque smoothly and withstand heavy loads. High-quality chains are designed to endure the rigors of demanding tasks, while their construction materials contribute to longevity and resistance to wear. Regular inspection and timely replacement are vital in preventing unexpected failures that could lead to costly repairs and operational delays.

Moreover, the alignment and tension of the drive chains are critical for optimal performance. Incorrect tension can lead to slippage or excessive wear, reducing the machine’s efficiency. By maintaining the proper specifications, operators can ensure that their equipment runs smoothly, ultimately enhancing productivity and extending the lifespan of the machinery.

Role of the Plunger in Baling

The plunger serves a vital function in the process of compacting and forming material into dense units. This mechanism operates by pushing the feedstock into a predetermined shape, ensuring that the resulting bundle is tightly compressed. A well-functioning plunger enhances efficiency and consistency in the production of these compacted units.

In this context, the mechanism contributes significantly to the overall performance of the equipment. Its design allows for effective material movement, promoting optimal flow and minimizing blockages. As the plunger cycles, it applies considerable force, which is crucial for achieving the desired density and shape.

Furthermore, the reliability of the plunger impacts the longevity of the machinery. Regular maintenance and timely replacement of worn components can prevent breakdowns and extend operational life. Properly functioning plungers also reduce the likelihood of material damage, thus ensuring the integrity of the final product.

In conclusion, the plunger’s role is essential in maintaining efficiency, product quality, and machine durability within the baling process. Understanding its importance can lead to improved operational practices and better results in the field.

Twine and Its Proper Installation

The role of binding material in agricultural machinery is essential for ensuring that harvested materials are securely held together. Proper handling and installation of this material can greatly affect the overall efficiency of the equipment. Understanding the nuances of installation is crucial for optimal performance and durability.

When installing binding material, consider the following steps to ensure proper setup:

- Choose the Right Material: Select a binding option that is suitable for the specific type of crop being processed.

- Preparation: Before installation, inspect the equipment for any wear or damage that may affect functionality.

- Threading: Carefully thread the binding material through the designated guides, ensuring there are no twists or kinks.

- Tension Adjustment: Set the appropriate tension to ensure that the material is snug but not overly tight, which can cause breakage.

- Testing: Run a few trial cycles to confirm that the material feeds correctly and adjusts as necessary.

Maintaining binding materials in optimal condition and ensuring correct installation will significantly enhance the effectiveness and longevity of the machinery. Regular checks and adjustments are recommended to prevent issues during operation.

Common Issues with the Feeder Mechanism

The feeder mechanism is a crucial component in ensuring efficient operation during the collection and processing of materials. However, various challenges can arise, affecting performance and productivity. Understanding these common issues can help operators implement timely solutions and maintain optimal functionality.

Clogging Problems

One of the frequent concerns involves clogging within the feeder system. This can occur when debris, twigs, or other materials accumulate, hindering the smooth flow of items. Regular maintenance and inspection are essential to prevent blockages and ensure the continuous operation of the mechanism.

Inconsistent Feeding Speed

Another prevalent issue is the inconsistency in the feeding speed, which may lead to uneven processing. Variations can result from worn-out components or misalignment. Adjusting the tension and ensuring all parts are correctly positioned can help mitigate this issue and enhance overall efficiency.

Maintaining the Flywheel and Clutch

The proper upkeep of the flywheel and clutch is essential for ensuring optimal performance and longevity of agricultural machinery. Regular maintenance not only enhances efficiency but also prevents potential breakdowns, which can lead to costly repairs and downtime. Understanding the key components and their functions is vital for effective maintenance.

Periodic inspection and adjustment of the flywheel and clutch mechanisms contribute significantly to the smooth operation of equipment. These components are subject to wear and tear due to friction and operational stress. Thus, it is crucial to monitor their condition and address any issues promptly.

| Maintenance Task | Frequency | Description

Tips for Proper Baler AdjustmentsEnsuring optimal performance from your machinery involves making the right adjustments to enhance efficiency and output. This section offers valuable insights into effective modification techniques that can lead to improved functionality and reduced wear. Here are key considerations to keep in mind when making adjustments:

By following these tips, you can achieve better results and prolong the lifespan of your machinery. |

|---|