In the realm of heavy machinery, a thorough comprehension of the internal structure and organization is crucial for efficient operation and maintenance. Knowing how each component interacts within the machine can significantly enhance performance and prolong its lifespan. This section aims to provide insights into the intricate arrangement of elements that make up a specific model.

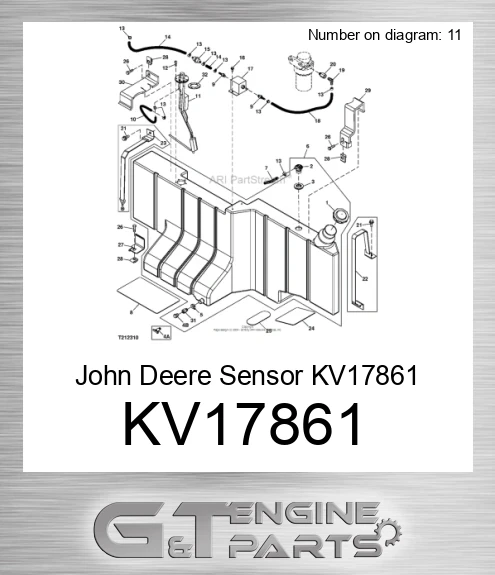

Detailed illustrations serve as valuable resources for technicians and operators alike. They not only help in identifying individual components but also facilitate troubleshooting and repair processes. A well-structured layout allows for easier access to essential features, ultimately leading to more effective management of equipment.

By exploring these layouts, users can gain a better understanding of their machinery, ensuring that all parts function harmoniously. This knowledge empowers operators to address issues swiftly and confidently, minimizing downtime and maximizing productivity in various tasks.

Understanding John Deere 250 Skid Steer

This section delves into the essential aspects of a versatile compact machine designed for various tasks in construction and landscaping. Known for its reliability and efficiency, this equipment serves as a crucial asset for operators seeking to enhance productivity on job sites. A comprehensive understanding of its components and functionality can significantly improve maintenance and operational capabilities.

Key Features and Benefits

Among its many attributes, the compact loader is celebrated for its maneuverability and robust performance. Equipped with a powerful engine, it provides ample lifting capacity, making it suitable for a range of applications, from digging to lifting heavy materials. The user-friendly controls further enhance its appeal, allowing operators to navigate tight spaces with ease.

Maintenance Considerations

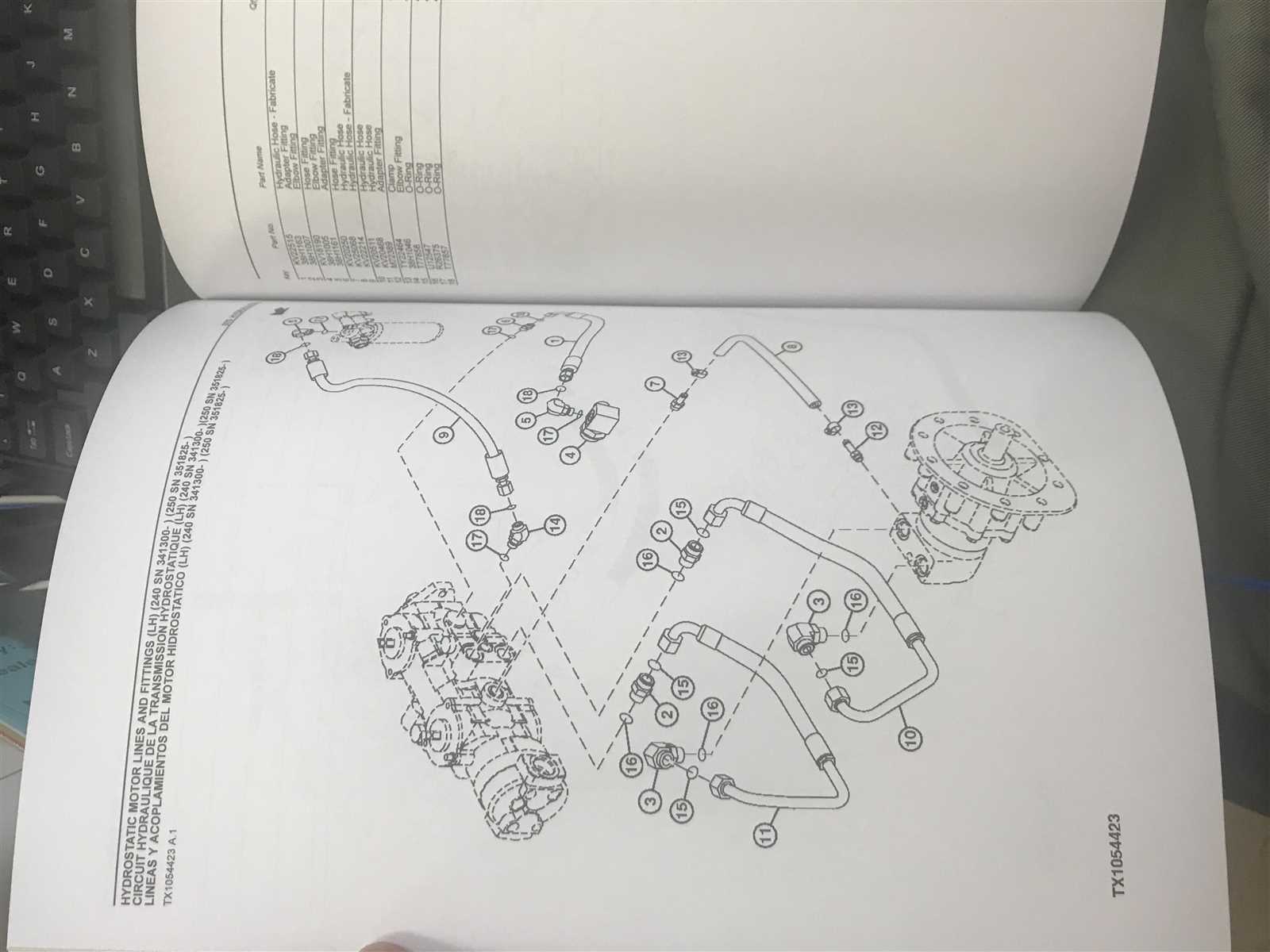

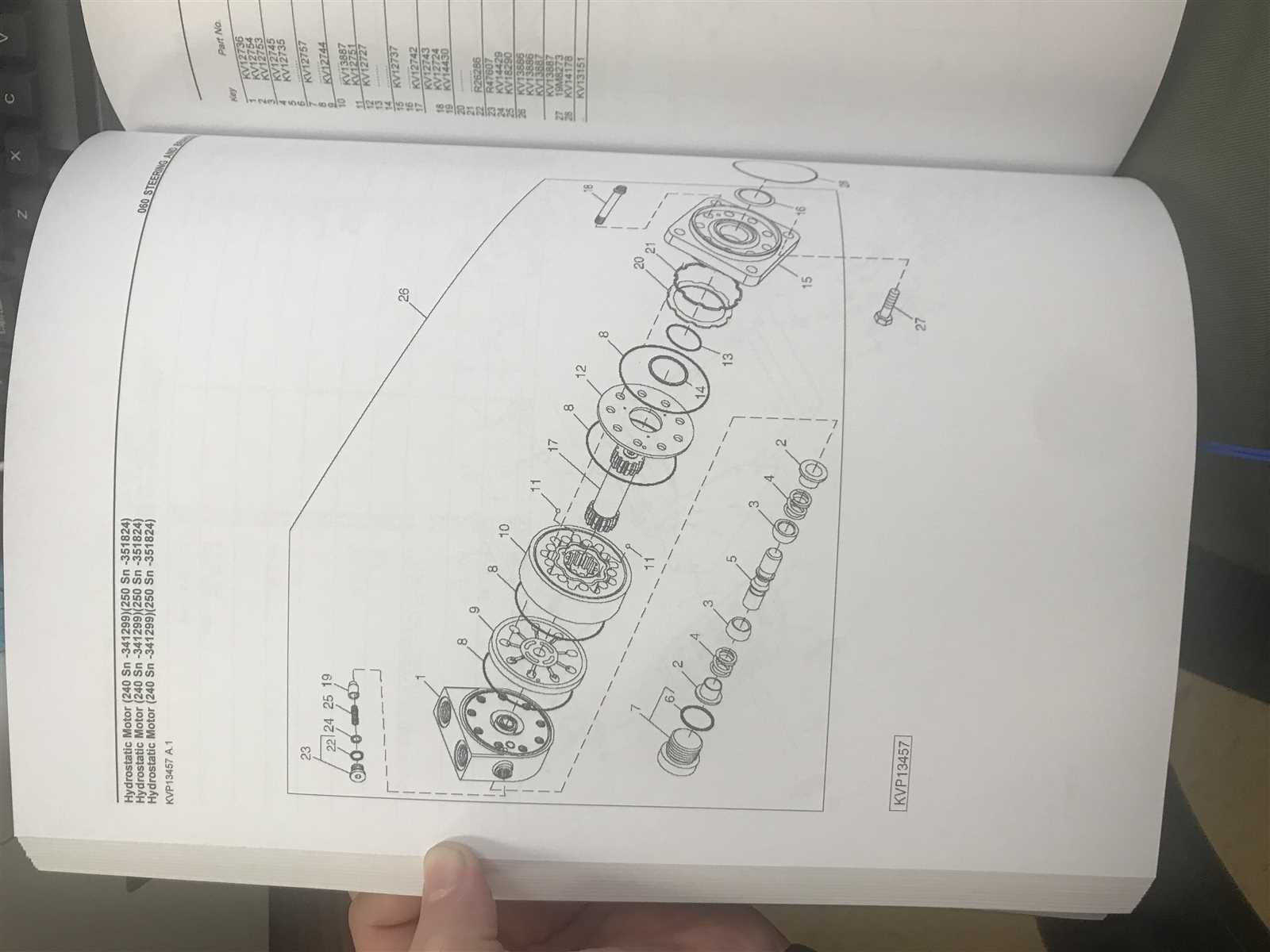

Regular upkeep is vital for sustaining the performance of this machinery. Operators should familiarize themselves with the essential components that require routine checks, such as hydraulic systems and engine oil levels. By prioritizing maintenance, users can extend the lifespan of their equipment and ensure optimal functionality throughout its use.

Key Features of the 250 Model

This section explores the standout attributes of this versatile machinery, highlighting its robust design and efficiency. Users can expect a blend of power and agility, making it suitable for various applications.

The unit boasts a compact build that enhances maneuverability in tight spaces while maintaining a significant lifting capacity. This combination allows operators to tackle demanding tasks with ease.

Additionally, the machine features advanced hydraulic systems that optimize performance and provide smooth operation. This efficiency translates into increased productivity on job sites.

Durability is another hallmark, as the model is constructed with high-quality materials, ensuring longevity even in challenging environments. Regular maintenance is straightforward, allowing for minimal downtime.

Furthermore, user-friendly controls enhance the overall experience, making it accessible for both seasoned professionals and newcomers. This intuitive interface promotes safety and efficiency during operation.

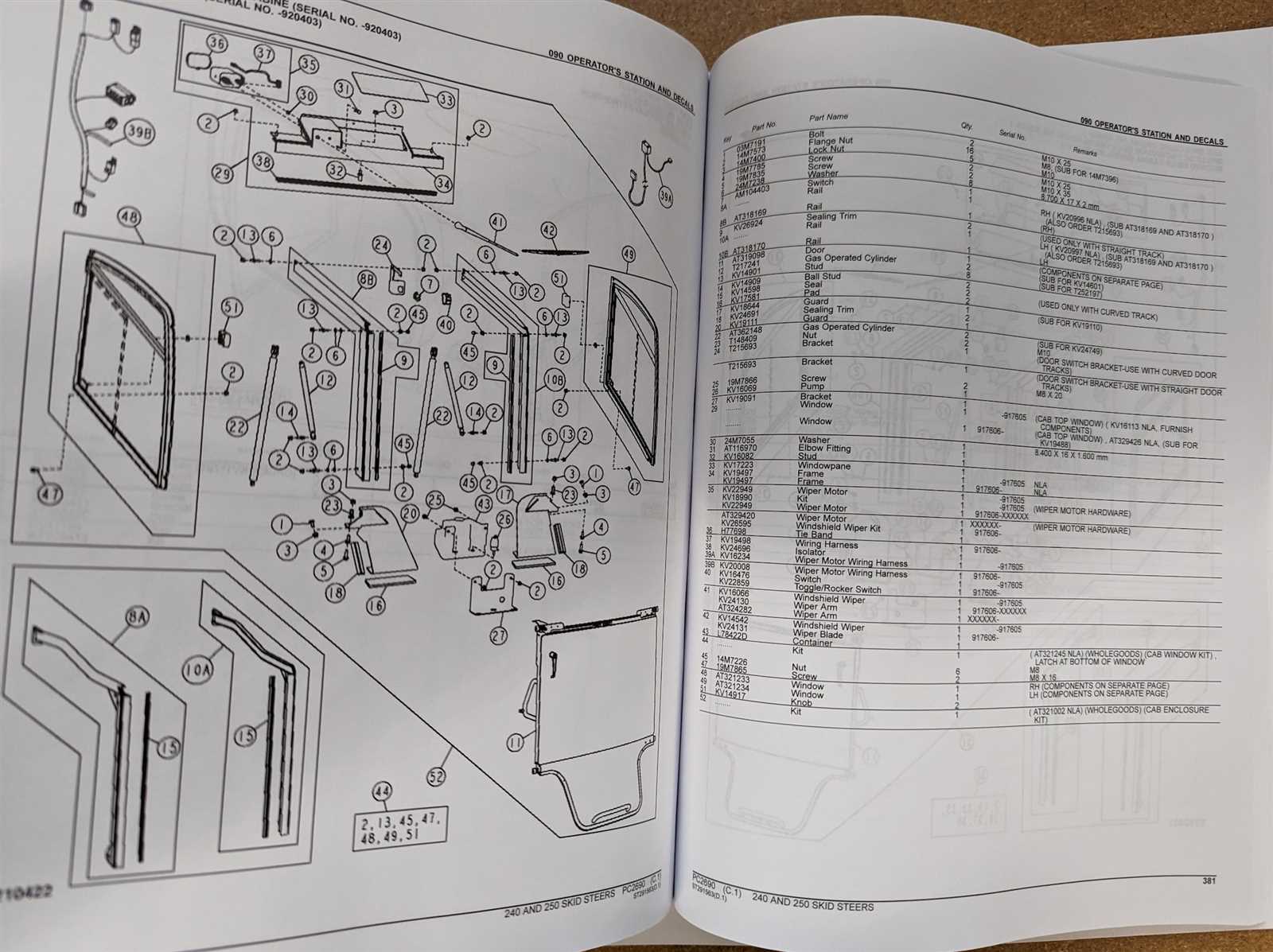

Importance of Parts Diagrams

Understanding the intricacies of machinery is crucial for maintenance and repair. Visual representations of components play a vital role in ensuring efficient operation and troubleshooting.

- Facilitate accurate identification of components

- Enhance understanding of assembly and disassembly processes

- Support effective communication among technicians

- Streamline inventory management for replacements

By exploring these visual tools, users can ultimately improve their skills and knowledge, leading to better machine longevity and performance.

Common Replacement Parts Explained

In any machinery, certain components often require attention due to wear and tear. Understanding these essential elements can enhance performance and longevity, ensuring that equipment operates efficiently.

Key Components to Monitor

Regular inspection of critical elements can prevent unexpected failures. Below are some commonly replaced items that play a vital role in maintaining optimal functionality.

| Component | Function | Signs of Wear |

|---|---|---|

| Hydraulic Filters | Maintain fluid cleanliness | Reduced efficiency, unusual noises |

| Belts | Power transfer | Cracking, fraying |

| Tracks | Traction and stability | Excessive wear, cracking |

Maintenance Tips

To prolong the lifespan of these components, regular maintenance is crucial. Scheduled checks can help identify issues early, ensuring reliable performance over time.

Maintenance Tips for Longevity

Ensuring the extended life of heavy machinery requires consistent attention and care. Regular maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns. Here are several key practices to keep your equipment in optimal condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Checks | Every 50 hours | Regularly inspect and replace hydraulic, engine, and transmission fluids to prevent wear and tear. |

| Filter Replacements | Every 100 hours | Change air, fuel, and oil filters to maintain optimal engine performance and efficiency. |

| Greasing | Weekly | Apply grease to all moving parts to reduce friction and prevent corrosion. |

| Visual Inspections | Daily | Conduct a thorough inspection for any signs of damage or wear before operation. |

| Tire Pressure Checks | Weekly | Ensure proper tire inflation to enhance traction and fuel efficiency. |

Implementing these maintenance strategies will not only prolong the lifespan of your machinery but also ensure it operates at peak performance, contributing to greater productivity on the job site.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. This guide will help you navigate through these illustrations with ease.

Here are some key steps to follow:

- Identify Sections: Look for distinct areas that represent different systems or functions.

- Locate Symbols: Familiarize yourself with common icons that signify various components.

- Refer to Labels: Pay attention to annotations that provide names and specifications for each item.

By mastering these elements, you can ensure a smooth and successful approach to component identification and troubleshooting.

Identifying OEM vs. Aftermarket Parts

When maintaining machinery, understanding the differences between original equipment manufacturer components and those produced by third-party suppliers is crucial. Each option has distinct advantages and potential drawbacks that can affect performance, longevity, and overall value. This section will guide you through recognizing these differences to make informed decisions for your equipment needs.

Characteristics of OEM Components

Original equipment manufacturer components are designed and produced by the same company that manufactured the machinery. These components typically adhere to strict quality standards and specifications set by the manufacturer, ensuring compatibility and reliability. Often, they come with warranties that cover defects, providing peace of mind for users concerned about performance and safety.

Benefits and Considerations of Aftermarket Options

Aftermarket components are produced by independent manufacturers and may offer a range of alternatives at various price points. These parts can often be less expensive than their OEM counterparts, making them attractive for cost-conscious consumers. However, quality can vary significantly among aftermarket suppliers, and users should be diligent in researching the reliability and performance history of these components before making a purchase.

Common Issues and Solutions

This section addresses frequent challenges encountered with compact machinery, offering practical solutions to enhance performance and longevity. Understanding these common problems can help operators maintain their equipment more effectively.

Hydraulic System Problems

- Symptoms: Reduced lifting capacity, sluggish movement.

- Solutions:

- Check hydraulic fluid levels and top up if necessary.

- Inspect hoses for leaks or damage.

- Replace filters to ensure proper fluid flow.

Electrical System Failures

- Symptoms: Inconsistent starting, malfunctioning lights.

- Solutions:

- Examine battery connections and clean terminals.

- Test fuses and replace any blown units.

- Inspect wiring for wear or short circuits.

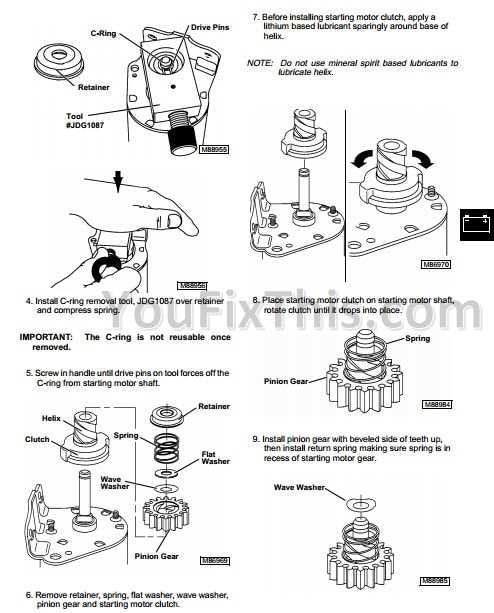

Tools Needed for Repairs

When undertaking maintenance or repairs on any machinery, having the right tools is essential for efficiency and effectiveness. Proper equipment not only facilitates the repair process but also ensures that tasks are completed safely and accurately.

Essential Tools

- Wrenches: A variety of sizes is necessary for loosening or tightening bolts.

- Sockets and Ratchets: Ideal for accessing hard-to-reach fasteners.

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

- Utility Knife: Useful for cutting through various materials during disassembly.

- Pliers: Handy for gripping and manipulating components.

Safety Equipment

- Gloves: Protect hands from sharp edges and chemicals.

- Safety Glasses: Shield eyes from debris and dust.

- Steel-Toed Boots: Provide foot protection while working under or around heavy equipment.

- Ear Protection: Important when working with loud machinery.

Having these tools readily available will greatly improve the repair experience, allowing for a smoother and more productive workflow.

Where to Find Replacement Parts

Locating suitable components for your machinery can be crucial for maintaining optimal performance. There are several reliable sources to consider when searching for these items.

- Authorized Dealers: Visiting an authorized dealer ensures you receive genuine products that meet manufacturer standards.

- Online Retailers: Numerous online platforms specialize in heavy equipment supplies, offering a wide range of options at competitive prices.

- Local Salvage Yards: Salvage yards can be treasure troves for used components, often available at a fraction of the cost.

- Manufacturer’s Website: Many manufacturers provide catalogs or online stores where you can directly purchase required items.

By exploring these avenues, you can efficiently find the necessary replacements for your equipment, ensuring its longevity and reliability.

Cost Considerations for Parts

When assessing expenses associated with replacement components, it’s crucial to understand various factors that influence pricing. The choice between genuine and aftermarket options can significantly affect your budget, as can the availability of specific items and their sourcing location.

Factors Influencing Costs

Several elements contribute to the final price of components. Quality, brand reputation, and warranty options play vital roles in determining value. Additionally, shipping costs and delivery times may also impact overall expenditure.

Comparison of Options

| Type | Average Cost | Quality |

|---|---|---|

| OEM | $100 – $300 | High |

| Aftermarket | $50 – $200 | Variable |

| Reconditioned | $75 – $250 | Moderate |

Enhancing Performance with Upgrades

Upgrading machinery can significantly boost efficiency and productivity. Implementing enhancements not only improves functionality but also extends the lifespan of equipment. Below are key considerations for optimizing performance through strategic upgrades.

- Engine Enhancements: Upgrading the engine can lead to increased horsepower and improved fuel efficiency.

- Hydraulic System: Enhancing the hydraulic components ensures better lifting capacity and faster response times.

- Attachments: Investing in specialized attachments can expand the versatility of your machine, allowing it to tackle various tasks.

- Electrical Systems: Modernizing electrical systems can enhance control and improve overall functionality.

By focusing on these areas, operators can delve into a realm of improved performance, ultimately achieving greater productivity and efficiency in their operations.

Customer Reviews of the 250 Skid Steer

Feedback from users provides valuable insights into the performance and reliability of this versatile machinery. Owners often share their experiences, highlighting both strengths and areas for improvement. Understanding these perspectives can help potential buyers make informed decisions.

Many customers praise the machine for its robust build and ease of use, noting its efficiency in various tasks. However, some reviews also mention common challenges that users encounter. Below is a summary of key points extracted from customer feedback.

| Aspect | Positive Feedback | Negative Feedback |

|---|---|---|

| Performance | Powerful engine; handles heavy loads easily. | Can struggle on very soft ground. |

| Durability | Sturdy construction; withstands tough conditions. | Some users report wear on certain components over time. |

| Comfort | Ergonomic controls; comfortable cab. | Limited visibility in certain situations. |

| Maintenance | Easy to access most parts for servicing. | Some parts can be costly to replace. |

Overall, customer experiences reveal a machine that is generally well-regarded, with specific attributes making it a preferred choice for various applications. The balance of advantages and drawbacks highlighted in reviews can guide users in optimizing their experience with this equipment.