In the realm of agricultural machinery, having a clear visualization of the various components is crucial for effective maintenance and repair. A comprehensive layout serves as a valuable resource for technicians and operators alike, enabling them to identify and manage the intricate elements of their equipment. By examining these illustrations, users can gain insight into the organization and functionality of each part, ensuring smoother operations.

Whether you’re a seasoned professional or a newcomer to the field, familiarizing yourself with the arrangement of essential elements can enhance your understanding and troubleshooting capabilities. These visual guides not only assist in locating specific pieces but also facilitate efficient repairs by highlighting connections and interdependencies. With such knowledge at hand, users can ensure optimal performance and longevity of their machinery.

As you delve into the details of these schematics, you’ll find that they offer more than just a reference; they embody a roadmap for successful equipment management. This exploration will equip you with the necessary tools to maintain and restore functionality, ultimately contributing to the overall productivity of your agricultural endeavors.

Understanding the John Deere 2955 Model

This section delves into the key features and specifications of a notable agricultural machine, providing insights into its design and functionality. By examining the various components and their roles, operators can gain a comprehensive understanding of how this equipment supports farming tasks effectively.

Key Features

This model is renowned for its durability and versatility in the field. With a robust engine and reliable transmission, it is designed to handle a wide range of agricultural operations. The thoughtful engineering allows for seamless integration of implements, enhancing productivity and efficiency.

Specifications Overview

| Specification | Details |

|---|---|

| Engine Type | Diesel |

| Horsepower | Approx. 70 HP |

| Transmission | Synchro-Shift |

| Weight | 5,800 lbs |

| Drive Type | 2WD/4WD options |

Understanding these characteristics helps operators make informed decisions when selecting and maintaining their machinery, ultimately ensuring optimal performance in various agricultural settings.

Importance of Parts Diagrams

Understanding the structure and components of machinery is crucial for effective maintenance and repairs. Visual representations serve as essential tools for technicians and operators, facilitating a clearer comprehension of how different elements interact within a system.

Utilizing these illustrations offers several benefits:

- Enhanced Clarity: Visuals simplify complex arrangements, making it easier to identify each component and its function.

- Improved Efficiency: Quick reference to these images can expedite the troubleshooting process, reducing downtime.

- Accurate Repairs: Knowing the exact location of each element minimizes the risk of errors during assembly or disassembly.

- Training Aid: These visuals are valuable resources for educating new personnel about the machinery’s layout and functions.

- Inventory Management: They help in keeping track of required items, ensuring that replacements are readily available.

In conclusion, these visual aids are indispensable for anyone involved in the operation, maintenance, or repair of mechanical systems. They not only enhance understanding but also promote a more organized approach to managing equipment effectively.

Key Components of the 2955 Tractor

The functionality and efficiency of this agricultural machine rely on various essential elements that work in harmony. Understanding these key components can enhance maintenance and operational practices, ensuring longevity and performance.

Engine: At the heart of this vehicle lies a powerful engine, responsible for converting fuel into mechanical energy. Its design emphasizes reliability and efficiency, providing the necessary power for demanding tasks.

Transmission: This system facilitates the transfer of power from the engine to the wheels. With multiple gears, it allows operators to adjust speed and torque, optimizing performance for various farming applications.

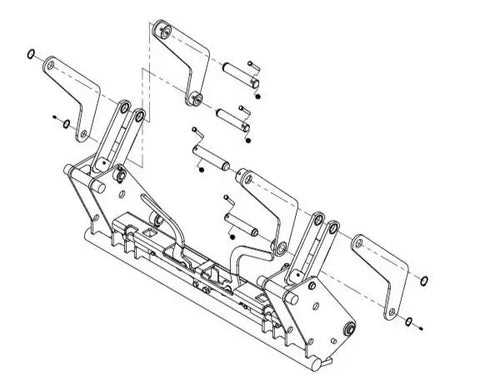

Hydraulic System: A robust hydraulic system enables the operation of implements and attachments, making it crucial for tasks like lifting and digging. Its efficiency significantly enhances the tractor’s versatility in the field.

Chassis: The chassis provides structural integrity, supporting the engine and other components. Designed for stability, it ensures that the machine can handle heavy loads and rough terrain with ease.

Wheels and Tires: These elements play a vital role in traction and maneuverability. The choice of tires can affect the tractor’s performance across different soil types and conditions, making them a critical consideration for operators.

Electrical System: This component powers essential functions, including lighting and ignition. A reliable electrical system is vital for the smooth operation of the machine, especially during nighttime or in low-visibility conditions.

By familiarizing oneself with these integral parts, operators can better appreciate their importance in enhancing productivity and ensuring effective agricultural practices.

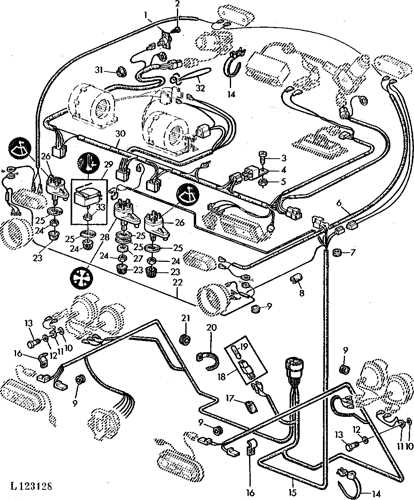

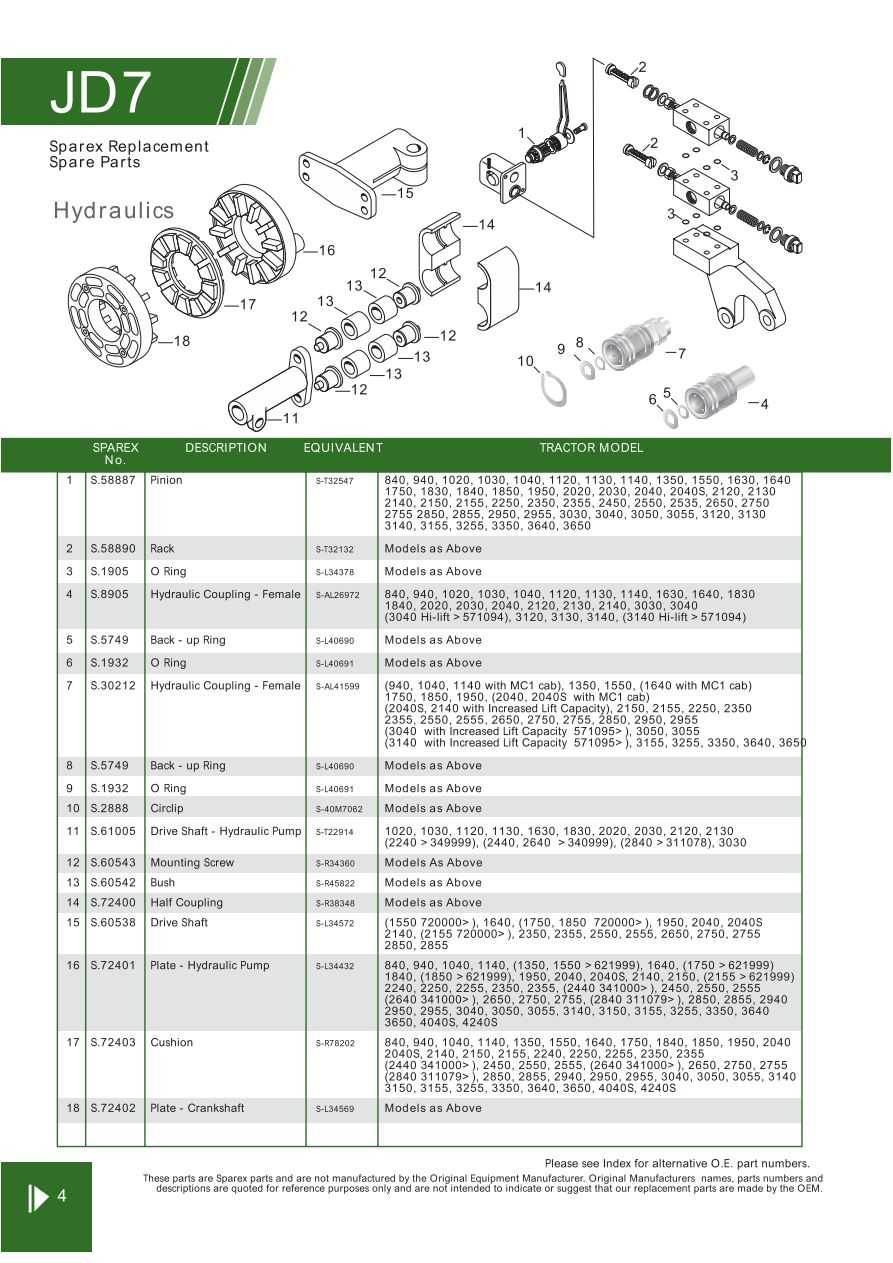

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair. These illustrations provide a detailed representation of components, making it easier to identify and locate each piece within a system. Familiarity with the layout and symbols used in these visuals can significantly enhance your ability to work on machinery.

Begin by identifying the key sections of the visual. Typically, these are organized to show how various elements fit together, often including labels for each item. Take note of any reference numbers or codes that correspond to a list of components, as these will be crucial for sourcing replacements or understanding specifications.

Pay attention to the orientation and positioning of parts. This can help you visualize how components interact and the order in which they should be assembled or disassembled. Look for color coding or shading that may indicate different categories or functions within the system.

Finally, cross-reference the schematic with the accompanying documentation. This will provide additional insights and ensure that you grasp the purpose of each component, enhancing your overall comprehension and effectiveness in addressing any issues that may arise.

Common Replacement Parts for 2955

When it comes to maintaining and repairing agricultural machinery, understanding the frequently replaced components is essential. These elements play a critical role in ensuring the optimal performance and longevity of the equipment. Familiarity with the common items that often require attention can help operators keep their machines running smoothly.

Engine Components

One of the primary areas of focus is the engine. Key elements such as filters and belts often need replacement due to wear and tear. Regular maintenance of these items not only enhances performance but also prevents more significant issues down the line. Oil filters and fuel filters are particularly crucial, as they ensure that the engine runs cleanly and efficiently.

Hydraulic System Parts

Another vital aspect to consider is the hydraulic system. Components like hoses and cylinders can degrade over time, affecting the machine’s ability to operate effectively. Regular inspections and timely replacements of these parts can significantly improve functionality and reduce downtime. Seals and valves are also important to check, as they play a major role in maintaining hydraulic pressure.

Where to Find Diagrams Online

Accessing visual schematics for machinery can greatly enhance your repair and maintenance processes. Fortunately, various online resources provide detailed illustrations and documentation that can assist you in identifying components and understanding assembly. Below are some reliable sources for obtaining these valuable resources.

- Manufacturer’s Website: Many manufacturers offer a dedicated section on their official sites where users can access manuals and schematics specific to their equipment.

- Online Marketplaces: Websites like eBay and Amazon often have listings for manuals and guides that include useful visuals.

- Forums and Communities: Engaging in machinery forums can yield user-shared resources. Communities often post links to diagrams or share their own scanned copies.

- Technical Service Providers: Certain websites specialize in providing repair guides and schematics for a variety of machinery, often for a small fee.

- YouTube Tutorials: Many enthusiasts and professionals upload video guides that may include visual references to parts and assembly, offering a practical approach to learning.

By exploring these options, you can efficiently find the illustrations you need to maintain and repair your equipment effectively.

Troubleshooting with Parts Diagrams

Understanding the intricacies of machinery can be challenging, especially when issues arise. Utilizing visual representations of components can significantly streamline the process of identifying and resolving problems. These illustrations serve as a guide, allowing users to pinpoint specific areas of concern and take appropriate action.

Benefits of Visual References

Visual aids enhance comprehension by breaking down complex systems into manageable parts. By consulting these resources, operators can quickly locate malfunctioning elements and assess their condition. This approach not only saves time but also reduces the risk of misdiagnosis.

Common Issues and Solutions

| Issue | Description | Possible Solution |

|---|---|---|

| Engine Overheating | High temperatures may indicate cooling system failure. | Check coolant levels and inspect for leaks. |

| Unresponsive Controls | Controls not responding can point to electrical issues. | Examine wiring and connections for damage. |

| Strange Noises | Unusual sounds may suggest mechanical wear or misalignment. | Inspect bearings and gears for signs of wear. |

Maintenance Tips for Your Tractor

Regular upkeep is essential for ensuring the longevity and efficiency of your agricultural machinery. By adhering to a systematic maintenance routine, you can prevent costly repairs and enhance performance, making your work smoother and more productive.

1. Routine Inspections: Frequently check critical components such as the engine, transmission, and hydraulic systems. Look for any signs of wear or damage, and address issues promptly to avoid more significant problems down the line.

2. Fluid Levels: Ensure that all fluid levels–engine oil, coolant, and hydraulic fluid–are maintained within the recommended range. Regularly changing these fluids as per the manufacturer’s guidelines helps prevent overheating and ensures optimal operation.

3. Air Filter Maintenance: A clean air filter is vital for optimal engine performance. Inspect and replace the air filter periodically to ensure the engine receives an adequate supply of clean air, which enhances fuel efficiency and power.

4. Tire Care: Proper tire pressure is crucial for traction and stability. Regularly check tire inflation and inspect for any signs of damage or excessive wear. Rotating the tires can also help extend their lifespan.

5. Battery Check: Examine the battery terminals for corrosion and ensure the connections are secure. Cleaning the terminals and checking the battery charge can prevent starting issues and prolong battery life.

6. Belts and Hoses: Inspect belts for signs of cracking or fraying, and check hoses for leaks or brittleness. Replacing worn belts and hoses before they fail can save you from unexpected breakdowns.

7. Storage Practices: When not in use, store your machinery in a clean, dry environment. Consider using covers to protect against dust and moisture, which can cause premature wear and tear.

By following these maintenance tips, you can ensure your tractor remains reliable and efficient, enabling you to tackle any task with confidence.

Aftermarket Parts vs. OEM Components

When it comes to maintaining machinery, enthusiasts often face a critical decision: whether to choose original manufacturer components or opt for alternative solutions. This choice can significantly impact performance, reliability, and cost-effectiveness. Understanding the differences between these two categories is essential for making informed decisions that align with individual needs and budget constraints.

OEM components are produced by the original manufacturer and are designed specifically for their machines. These components often guarantee a perfect fit and consistent quality, ensuring that machinery operates as intended. On the other hand, aftermarket options are made by third-party manufacturers. They can provide various advantages, including lower prices and greater availability, but may sometimes compromise on fit or longevity.

Ultimately, the decision hinges on factors such as budget, the importance of warranty coverage, and the specific requirements of the task at hand. Evaluating the pros and cons of each type can lead to better choices that enhance both performance and satisfaction.

Enhancing Performance with Upgrades

Improving the functionality and efficiency of your machinery can lead to significant benefits in productivity and longevity. Upgrading specific components not only boosts performance but also ensures that the equipment operates at its best, minimizing downtime and maintenance costs.

Key Areas for Upgrades

- Engine Enhancements: Upgrading the engine can lead to better fuel efficiency and increased power output.

- Hydraulic Systems: Optimizing hydraulic components can improve lifting capacity and response times.

- Transmission Improvements: Modernizing the transmission system may enhance speed control and overall handling.

- Electrical Components: Updating wiring and electronic systems can lead to better functionality and reduced energy consumption.

Benefits of Upgrading

- Increased productivity due to improved performance.

- Enhanced reliability and reduced frequency of repairs.

- Higher resale value when equipment is maintained with modern upgrades.

- Improved fuel efficiency, leading to cost savings over time.

Investing in upgrades not only enhances the performance of your equipment but also ensures that it remains competitive and capable of meeting evolving operational demands.