In the realm of agricultural equipment, a comprehensive grasp of the various elements that constitute a specific model is essential for effective maintenance and repair. By examining the intricate assembly of these mechanical systems, users can ensure optimal performance and longevity of their machinery.

This exploration provides insight into the crucial components, illustrating how each part contributes to the overall functionality. With a clear visual representation, operators can easily identify and understand the relationship between different elements, enhancing their ability to troubleshoot and resolve issues.

Ultimately, delving into the specifics of these components empowers users to make informed decisions about repairs and upgrades. This knowledge not only facilitates efficient operations but also fosters a deeper appreciation for the engineering behind modern agricultural tools.

Understanding John Deere 317 Components

Grasping the intricate elements of agricultural machinery is essential for effective maintenance and operation. Familiarity with the various components enhances functionality and ensures longevity, providing an edge in agricultural practices. This section will delve into the essential parts that contribute to the overall performance of the equipment.

Key Elements of the Machinery

Each segment of the machinery plays a crucial role in its operation. From the engine to the transmission, understanding these components helps in troubleshooting and optimizing performance. Regular maintenance of these vital elements is necessary for achieving the ultimate efficiency.

Importance of Component Familiarity

Being well-versed in the machinery’s architecture allows operators to identify potential issues early on. This proactive approach not only saves time and resources but also enhances the overall productivity of agricultural tasks. Investing time in understanding these components pays off significantly in the long run.

Importance of Parts Diagrams

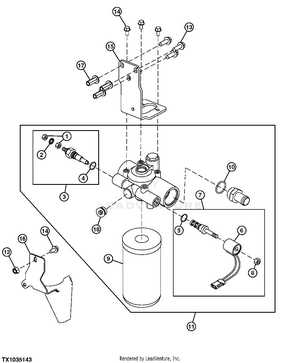

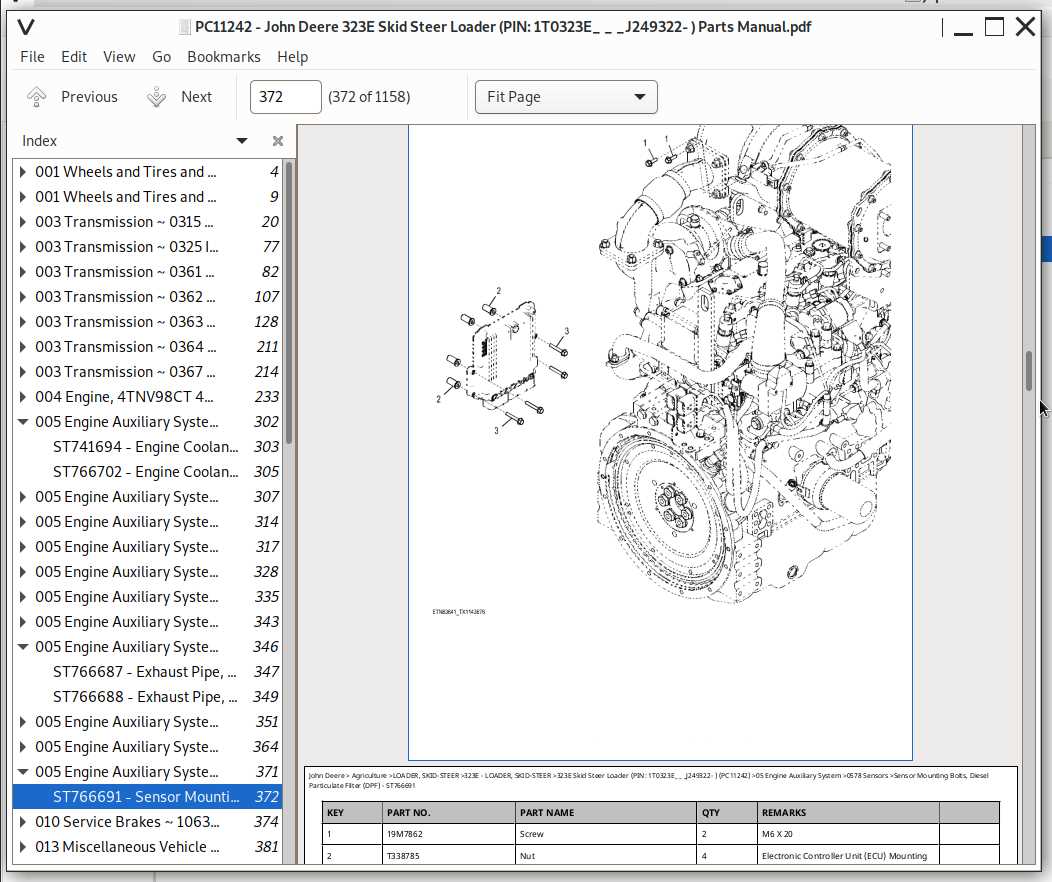

Understanding the layout of components in machinery is essential for maintenance and repairs. Visual representations enable users to identify each element’s role and location, ensuring efficient assembly and troubleshooting.

These illustrations serve multiple purposes, enhancing clarity in complex systems and minimizing the risk of errors during service. By examining these resources, technicians can streamline their workflows and improve overall performance.

| Benefits | Description |

|---|---|

| Clarity | Provides clear visual guidance for locating and identifying components. |

| Efficiency | Speeds up repair processes by eliminating guesswork. |

| Accuracy | Reduces the likelihood of misassembly and errors. |

| Training | Acts as a valuable tool for training new technicians on machinery. |

Key Features of John Deere 317

This section highlights the essential characteristics of a well-known compact utility vehicle designed for diverse agricultural and landscaping tasks. Understanding these features can help users appreciate its capabilities and efficiency in various settings.

Powerful Engine Performance

The vehicle is equipped with a robust engine that ensures reliable performance under challenging conditions. This powertrain not only delivers impressive torque but also optimizes fuel efficiency, making it suitable for both heavy-duty tasks and routine maintenance.

User-Friendly Design

The ergonomic layout of controls and comfortable seating enhances the operator’s experience. This thoughtful design reduces fatigue during extended use, allowing for increased productivity. Additionally, its compact dimensions facilitate maneuverability in tight spaces, making it ideal for urban landscaping and smaller farms.

Overall, the combination of power and user-centric features makes this machine a valuable asset for anyone looking to tackle a variety of outdoor projects.

Common Maintenance Practices for 317

Regular upkeep is essential for optimal performance and longevity of any machinery. Implementing effective maintenance strategies can prevent costly repairs and enhance efficiency.

- Routine Inspections: Check vital components regularly to identify wear and tear.

- Fluid Checks: Ensure oil, coolant, and hydraulic fluids are at appropriate levels.

- Filter Replacement: Replace air and fuel filters as recommended to maintain clean operations.

- Greasing: Apply grease to moving parts to minimize friction and prevent breakdowns.

- Tire Maintenance: Inspect tire pressure and tread to ensure stability and performance.

By adhering to these practices, users can enhance the functionality and extend the service life of their equipment.

Where to Find Parts Diagrams

Locating detailed schematics for equipment components can significantly enhance maintenance and repair efforts. These illustrations serve as essential references for identifying individual elements and understanding their interconnections. Whether you are a seasoned technician or a DIY enthusiast, having access to comprehensive visual guides can streamline your work and ensure accuracy.

Online Resources: Numerous websites specialize in offering technical documentation for machinery. Manufacturer websites often provide downloadable resources, while third-party platforms may host user-generated content, including tutorials and schematics. Utilize search engines to discover these valuable assets tailored to your specific model.

Forums and Community Groups: Engaging with online communities can yield insights and assistance from fellow users. Many enthusiasts share their own diagrams and repair experiences, which can be particularly helpful. Participating in discussions can lead you to rare documents and tips not widely available elsewhere.

Local Dealers and Service Centers: Authorized dealers often maintain archives of technical documents. Visiting a local dealership can provide access to printed or digital schematics, along with professional advice tailored to your machinery’s needs. Establishing a rapport with service personnel may also lead to helpful recommendations.

Service Manuals: Purchasing or accessing a service manual specific to your equipment can be an invaluable investment. These manuals typically include detailed illustrations and comprehensive information, making them a reliable resource for repairs and maintenance tasks.

By utilizing these various sources, you can enhance your understanding of the machinery and effectively tackle any maintenance or repair challenges that arise.

Interpreting the Parts Diagram

Understanding a schematic representation of components is crucial for effective maintenance and repairs. This visual guide provides a comprehensive overview, enabling users to identify and locate various elements with ease. Familiarity with the layout can enhance troubleshooting efficiency and ensure proper assembly.

Each section of the illustration typically corresponds to a specific area of the machinery, allowing for targeted examination. Pay attention to numbering or labeling, as it aids in cross-referencing with service manuals. Recognizing common symbols and color codes can further facilitate the interpretation process.

When analyzing the graphic, it is beneficial to approach it methodically. Start from a known component and work outward, noting how each part interacts with others. This systematic approach will ultimately lead to a deeper understanding of the equipment’s functionality.

Replacement Parts for John Deere 317

Maintaining machinery often requires finding suitable components to ensure optimal performance. Whether for routine upkeep or repairs, sourcing high-quality replacements is essential. This guide aims to provide insights into options available for your equipment, enhancing longevity and reliability.

Types of Components Available

When looking for suitable replacements, various categories can be considered:

- Engines and related accessories

- Transmission elements

- Hydraulic systems

- Electrical components

- Chassis and structural parts

Where to Find Quality Replacements

Locating reliable suppliers is crucial. Here are some recommended sources:

- Authorized dealers that specialize in agricultural machinery

- Online marketplaces offering a wide range of options

- Local hardware stores with dedicated sections for machinery

- Salvage yards that provide used but functional components

By exploring these avenues, you can ensure that your machinery remains in top condition, ready to tackle any task with efficiency.

Frequently Replaced Components

This section highlights essential elements that often require replacement due to wear and tear or performance issues. Understanding these components can help maintain optimal functionality and extend the lifespan of the equipment.

Commonly Changed Parts

- Filters

- Belts

- Hoses

- Battery

- Electrical Components

Maintenance Tips

- Regularly inspect components for signs of damage.

- Follow the manufacturer’s guidelines for replacements.

- Keep a log of replaced parts for future reference.

Tips for Ordering Replacement Parts

When it comes to acquiring components for machinery, understanding the process can significantly enhance efficiency and satisfaction. Having a clear strategy in place will ensure that you receive the correct items in a timely manner, minimizing downtime and maintaining optimal performance.

First, always verify the model number and specifications before placing an order. This prevents the confusion that can arise from similar products. Additionally, consulting the manufacturer’s resources or trusted dealers can provide invaluable guidance.

It’s also beneficial to compare prices across various suppliers. While cost is important, consider the quality and warranty offered, as these factors can affect long-term value. Building a reliable relationship with a supplier can lead to better service and exclusive deals.

Lastly, maintain an organized record of previous purchases and any relevant documentation. This will facilitate future orders and help in identifying recurring issues with specific components. Being prepared will ultimately save time and effort when replacements are necessary.

Impact of Genuine Parts on Performance

The utilization of authentic components plays a crucial role in enhancing the functionality and longevity of machinery. Quality materials and precise engineering ensure that equipment operates at its peak, reducing the risk of breakdowns and extending overall lifespan.

Benefits of Authentic Components

- Improved Efficiency: Genuine items are designed for optimal compatibility, leading to better performance.

- Longevity: High-quality materials resist wear and tear, prolonging the life of the machinery.

- Safety Assurance: Authentic components meet rigorous safety standards, reducing risks during operation.

- Warranty Protection: Using original parts often helps maintain warranty coverage, protecting your investment.

Consequences of Using Imitation Parts

- Reduced Performance: Non-genuine items may not fit properly, leading to inefficiencies.

- Increased Repair Costs: Imitation parts can cause additional damage, resulting in higher maintenance expenses.

- Shorter Lifespan: Inferior quality often leads to faster degradation and frequent replacements.

Understanding Model Variations

Exploring the distinctions among different machinery models is essential for ensuring compatibility and functionality. Each variant often comes with unique specifications and features that cater to diverse operational needs. By grasping these differences, users can make informed decisions about maintenance, upgrades, and replacements.

Model variations may include changes in engine types, component sizes, or operational capacities. Recognizing these factors can greatly influence performance and efficiency. Furthermore, understanding the specific configurations helps in troubleshooting and sourcing suitable replacements when necessary.

Additionally, variations may stem from advancements in technology or shifts in design philosophy over time. This evolution impacts not only the machinery’s capabilities but also its overall user experience. Keeping abreast of these changes is crucial for maximizing the effectiveness of the equipment in various applications.

DIY Repair Insights for Owners

Maintaining machinery can seem daunting, but with the right information and a little hands-on experience, owners can tackle many common issues themselves. This approach not only saves money but also fosters a deeper understanding of the equipment. Below are some insights and tips to empower owners in their repair journey.

Understanding Your Equipment

Before diving into repairs, it’s essential to familiarize yourself with the inner workings of your machinery. Study the user manual and look for guides that explain the functions of different components. This foundational knowledge will help you diagnose problems more effectively. Keep a log of any issues you encounter, as this can aid in identifying recurring problems and determining the best course of action.

Essential Tools and Resources

Having the right tools at your disposal is critical for successful repairs. Invest in quality tools that are designed for the specific tasks you need to perform. Online forums and communities can also be invaluable resources; they offer advice, share experiences, and provide step-by-step instructions for various repairs. Additionally, consider watching tutorial videos to visualize the processes, making them easier to understand.

Resources for Technical Support

Accessing reliable assistance is essential for maintaining and troubleshooting equipment effectively. A variety of resources can aid users in resolving issues and ensuring optimal performance.

- Official Manufacturer Websites: Explore the support section for manuals and troubleshooting guides.

- Online Forums: Join community discussions where experienced users share solutions and insights.

- Video Tutorials: Platforms like YouTube offer step-by-step visual guides for repairs and maintenance.

- Local Dealers: Authorized dealers can provide specialized knowledge and access to genuine components.

- Customer Support Hotlines: Reach out to dedicated support teams for direct assistance with technical queries.

Utilizing these resources can ultimately enhance your understanding and management of your equipment, leading to improved efficiency and longevity.