In the realm of farming equipment, a comprehensive grasp of the various components is essential for optimal functionality. Each piece plays a vital role in ensuring efficiency and productivity during harvest seasons. As machinery evolves, understanding these intricate systems becomes increasingly important for operators and technicians alike.

Illustrating the inner workings of specific models not only aids in maintenance but also enhances the user’s overall experience. By examining these illustrations, one can gain valuable insights into the design and arrangement of each essential element, enabling better decision-making in repairs and upgrades.

Ultimately, a thorough exploration of these visual representations empowers individuals to delve deeper into the mechanics, promoting a more effective approach to machinery management. Familiarity with the construction can lead to significant improvements in both performance and longevity.

Understanding John Deere 346 Baler

This section aims to explore the essential features and components of a well-known agricultural implement designed for efficient crop handling. By examining its construction and functionality, users can enhance their understanding and optimize its performance in the field.

| Component | Function |

|---|---|

| Feeder Mechanism | Guides material into the compression chamber for baling. |

| Compression Chamber | Compacts the crop into a dense form for easier handling. |

| Twine System | Secures the finished bundle for transport and storage. |

| Pickup Header | Collects the material from the ground efficiently. |

Understanding these components can significantly improve maintenance practices and operational efficiency, ensuring a productive farming experience.

Overview of Baler Functions

This section explores the essential roles played by machinery designed for the efficient collection and compression of agricultural materials. Understanding these functions helps optimize operations and improve overall productivity in farming activities.

Key Operations

The primary operations include gathering, compressing, and tying off materials into manageable bundles. Each function is critical to ensure smooth workflow and effective handling of various crops.

Components and Their Roles

| Component | Function |

|---|---|

| Feeder System | Collects and directs materials into the machine. |

| Compression Chamber | Compresses materials to create dense bundles. |

| Tying Mechanism | Secures bundles for easy handling and storage. |

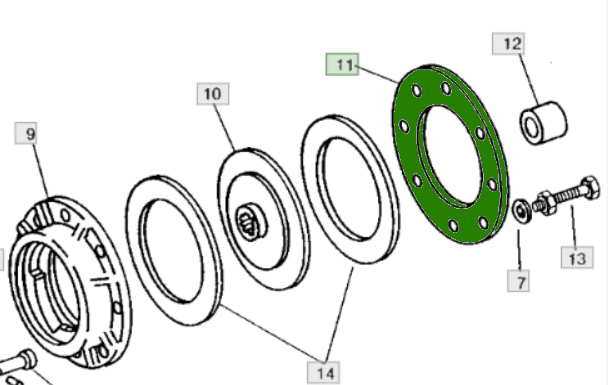

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations not only enhance comprehension but also streamline the process of identifying specific elements within a complex system. This clarity can significantly reduce downtime and improve efficiency.

Enhanced Troubleshooting

Clear illustrations assist technicians in quickly diagnosing issues. By referencing these visuals, they can locate malfunctioning components without unnecessary guesswork, leading to timely solutions.

Effective Communication

Diagrams serve as a universal language among technicians and operators, facilitating better discussions and instructions. This shared understanding fosters collaboration and ensures that everyone is aligned on repair or maintenance tasks.

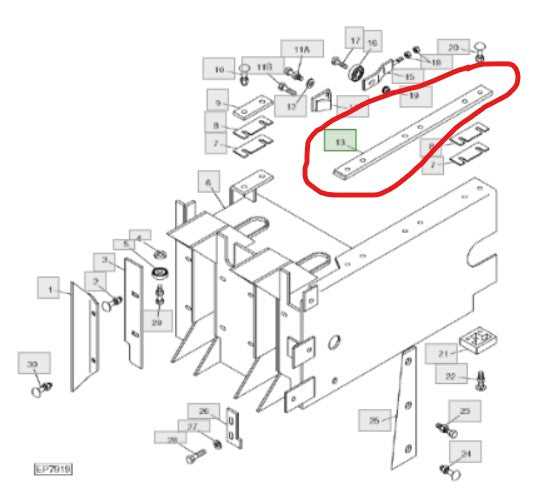

Key Components of the 346 Baler

This section explores the essential elements that contribute to the efficient operation of a specific type of harvesting equipment. Understanding these vital components enhances overall performance and ensures optimal functionality during use.

Feeding System: The mechanism responsible for drawing in materials is crucial. It typically includes rollers and belts that facilitate the smooth intake of crops.

Compression Chamber: This area is where the material is compacted into bales. Its design influences the density and size of the final product, making it a pivotal feature.

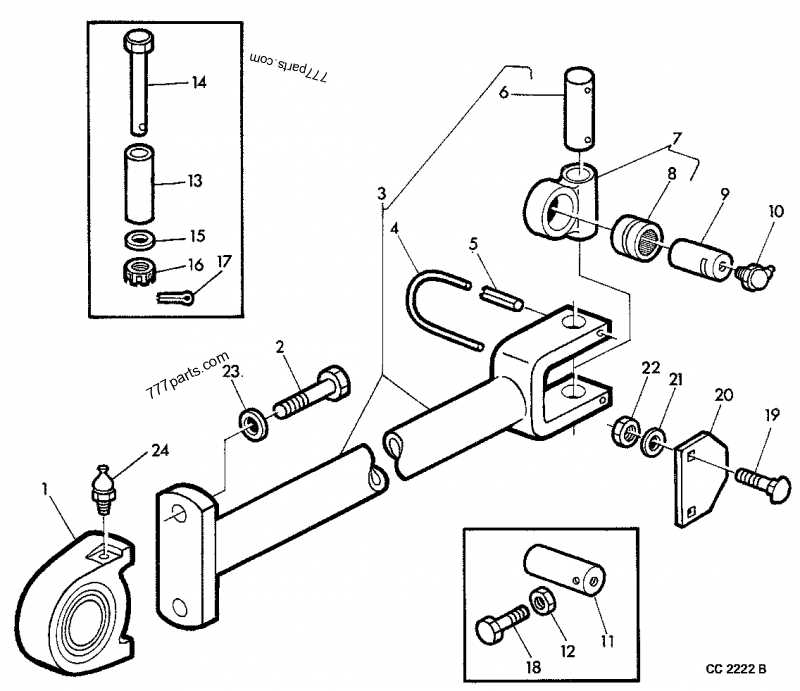

Tie Mechanism: The system used to secure the bales after compression. Various options exist, including twine and netting, each offering different advantages.

Power Transmission: This aspect refers to the components that transfer energy from the engine to the operational parts. Gears and belts are often involved in ensuring seamless movement.

Frame Structure: The foundational framework provides stability and support for all other components. Its durability is essential for long-term use in diverse conditions.

Common Maintenance Tips

Regular upkeep is essential for optimal performance and longevity of agricultural equipment. Proper maintenance practices not only enhance efficiency but also prevent unexpected breakdowns.

- Check fluid levels frequently to ensure smooth operation.

- Inspect belts and chains for wear and replace as needed.

- Clean the machinery regularly to remove debris and prevent rust.

- Lubricate moving parts to reduce friction and wear.

- Examine tires for proper inflation and tread depth.

By following these basic maintenance tips, operators can ensure their equipment runs efficiently and reliably throughout the working season.

Finding Replacement Parts

When it comes to maintaining agricultural machinery, locating suitable components is crucial for optimal performance. The right replacement elements not only enhance efficiency but also prolong the lifespan of the equipment. Understanding where to source these items can save time and reduce operational downtime.

Identifying the Right Components

Start by determining the specific elements required for your machinery. Consult the user manual or manufacturer’s resources to identify compatible items. This information serves as a foundation for your search, ensuring you acquire the correct substitutes.

Where to Source Components

Numerous avenues exist for obtaining replacements. Local dealers often provide direct access to genuine items, while online platforms offer a broader selection, including aftermarket options. Additionally, consider visiting salvage yards, where you might find pre-owned components at a fraction of the cost. Engaging with community forums can also yield valuable insights and recommendations.

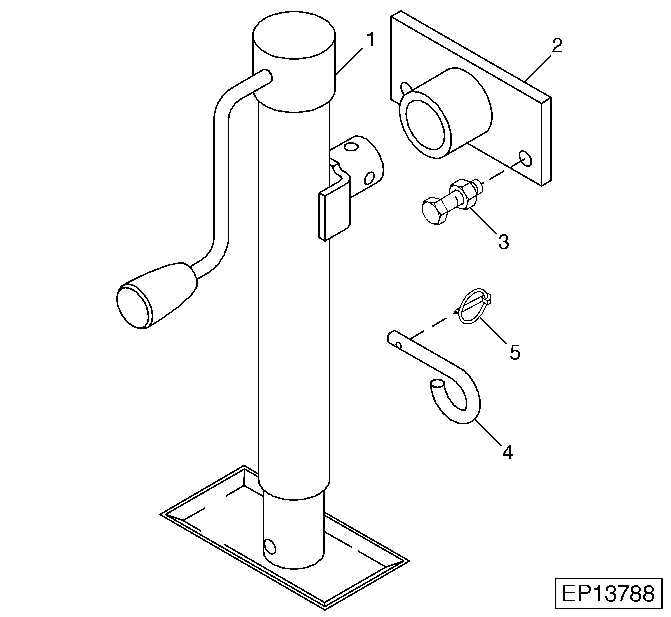

How to Read Parts Diagrams

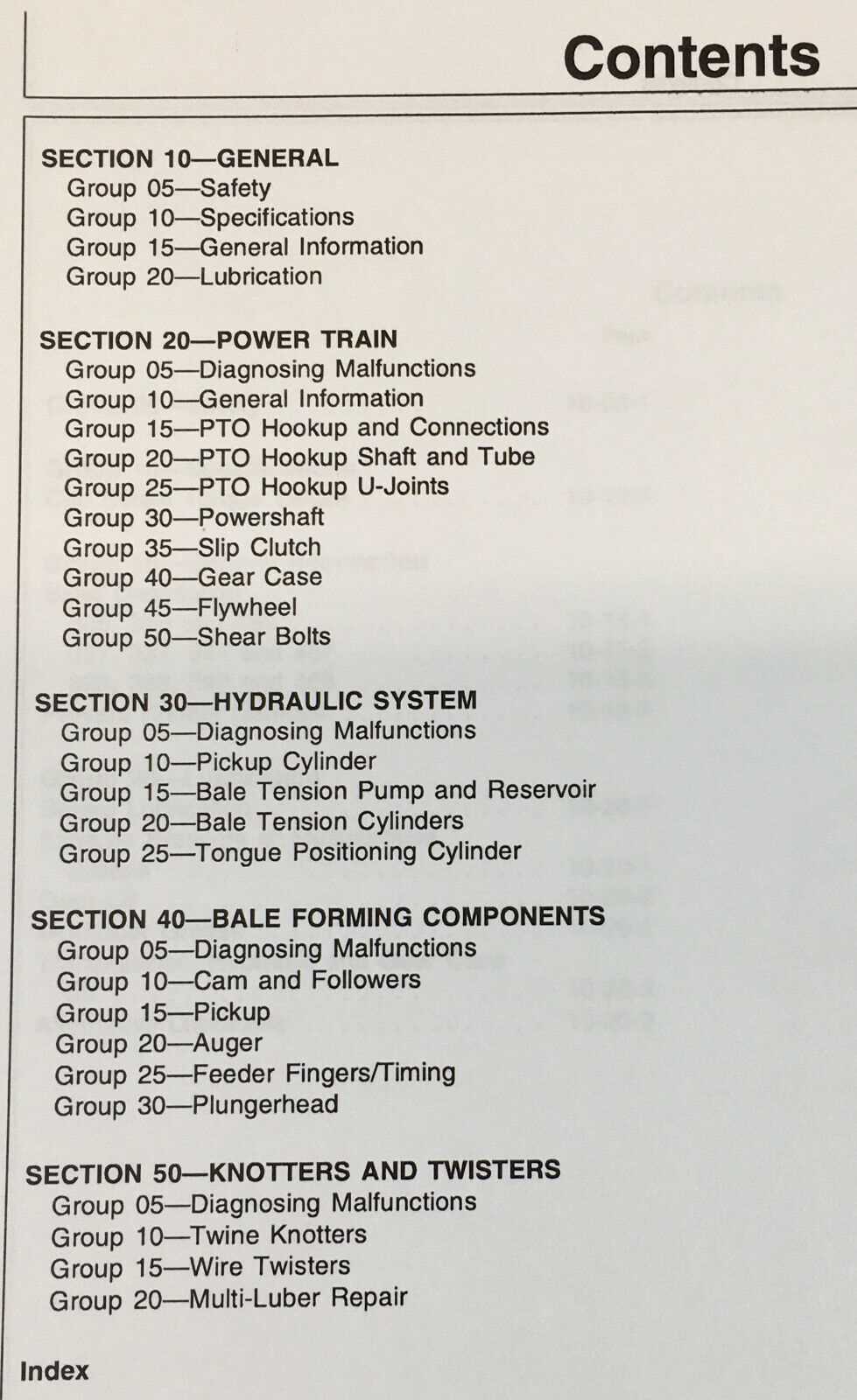

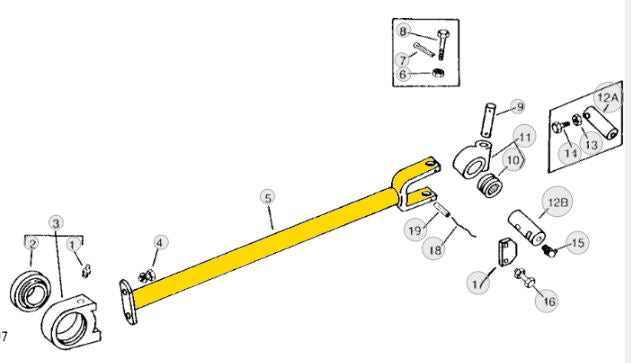

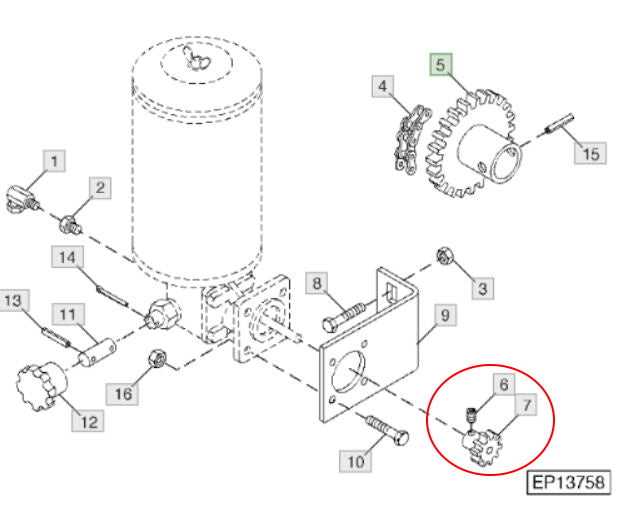

Understanding technical illustrations is essential for effective maintenance and repairs. These visual guides provide a comprehensive overview of components and their relationships within a machine, allowing users to identify necessary elements efficiently. Familiarity with these visuals can significantly enhance troubleshooting and replacement processes.

To interpret these illustrations, begin by familiarizing yourself with the various symbols and notations used. Each element typically corresponds to a specific component, often numbered for easy reference. Cross-referencing these numbers with accompanying documentation can clarify the function and specifications of each item.

Pay attention to the layout, as it usually indicates the assembly order and interconnections between components. This spatial understanding aids in visualizing how parts fit together, making disassembly and reassembly more intuitive. Lastly, always ensure you have the most current illustration, as updates may occur with newer models or versions.

Typical Issues and Solutions

In the realm of agricultural machinery, operators often encounter various challenges that can hinder performance and efficiency. Addressing these common problems effectively can lead to smoother operations and enhanced productivity. Understanding the typical issues and their corresponding solutions is essential for maintaining optimal functionality.

Common Mechanical Failures

Mechanical failures may arise from wear and tear, leading to decreased efficiency. Regular maintenance checks can prevent such issues. Inspecting components for damage and replacing worn parts promptly can help maintain operational integrity.

Feeding Problems

Feeding irregularities can disrupt the workflow and cause delays. Ensuring proper alignment and adjustment of the feeding mechanisms is crucial. Implementing routine cleaning and checks can also minimize obstructions and enhance material flow.

Tools Needed for Repairs

When it comes to maintaining agricultural machinery, having the right tools is crucial for efficient and effective repairs. The proper equipment not only facilitates smoother operations but also ensures longevity and optimal performance of the machinery.

Essential Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Socket set

- Pliers

- Hammer

Specialized Equipment

- Torque wrench

- Grease gun

- Diagnostic tools

- Safety goggles

- Work gloves

Having these tools at your disposal will allow you to tackle most repair tasks with confidence and precision.

Upgrading Your Baler

Enhancing your harvesting equipment can significantly improve efficiency and output. By incorporating advanced components and technology, you can achieve better performance and reliability. Investing in upgrades not only extends the lifespan of your machinery but also optimizes your operations for increased productivity.

Consider evaluating the current features and identifying areas for enhancement. Modern attachments and upgrades can provide superior functionality, addressing specific needs in your agricultural processes. This proactive approach ensures that your equipment remains competitive and meets evolving demands.

Research available options and consult with experts to determine the best modifications suited to your operational requirements. Upgrading can lead to improved user experience, reduced downtime, and greater overall satisfaction with your equipment’s performance.

Resources for Parts Diagrams

Accessing reliable sources for equipment schematics is essential for effective maintenance and repairs. Understanding the layout and functionality of various components can greatly enhance efficiency and reduce downtime. This section aims to provide a comprehensive overview of available resources that assist in locating these valuable illustrations.

Online Databases

Numerous online platforms offer extensive collections of schematics and manuals. Websites dedicated to agricultural machinery often feature searchable databases where users can find specific models and their respective component layouts. These resources typically include detailed illustrations and descriptions that are invaluable for troubleshooting and repairs.

Manufacturer Support

Many manufacturers provide official documentation through their websites. By visiting the support section, users can access a variety of resources, including service manuals and exploded views. Engaging with customer service can also lead to additional insights and assistance in obtaining the necessary schematics.

Comparative Analysis with Other Models

This section explores the distinctions and similarities between a specific machine and its contemporaries, focusing on functionality, efficiency, and component design. By examining these aspects, users can gain insights into which model may best suit their operational needs.

Performance Metrics

When analyzing performance, it becomes clear that various models may excel in different areas. For instance, some machines offer enhanced speed and throughput, while others prioritize fuel efficiency. Understanding these metrics is crucial for users aiming to optimize their productivity.

Component Design

The architecture of each model can significantly impact maintenance and repair processes. Robust construction in certain units may lead to longer service intervals, whereas others might incorporate modular components for easier replacement. Evaluating these features can help operators make informed decisions regarding their investments.

Owner Testimonials and Experiences

This section highlights the real-life experiences of users who have engaged with their machinery. Their insights reveal the effectiveness and reliability of equipment in various agricultural tasks.

- Efficiency: Many users report significant improvements in productivity, allowing them to manage their time better.

- Durability: Owners frequently praise the longevity of their machines, emphasizing how well they withstand heavy use.

- Support: Customer service experiences are often highlighted, with positive feedback on responsiveness and assistance.

Gathering feedback from diverse users helps potential buyers make informed decisions about their equipment investments.

- “My machine has consistently delivered excellent results, even in challenging conditions.”

- “I appreciate the straightforward maintenance process; it saves me time and effort.”

- “The support team was incredibly helpful when I had questions about my equipment.”

These testimonials serve as valuable resources for understanding the true value of investing in reliable agricultural machinery.