When working with industrial equipment, having a clear and detailed map of its individual elements is essential for smooth maintenance and repairs. Whether you’re an operator or technician, knowing how various parts are interconnected can make a significant difference in the efficiency and safety of the work.

Recognizing the right components within such machinery requires not only technical knowledge but also access to accurate resources. In this guide, we will explore how to efficiently identify the crucial elements of large mechanical systems and understand their functionality in greater depth.

Learning how each part functions together within the machine’s framework can simplify tasks such as assembly, troubleshooting, and regular upkeep, ensuring optimal performance and longevity of the equipment.

Understanding the John Deere 350 Dozer

Exploring this robust piece of heavy equipment reveals its key role in various earthmoving and construction tasks. Known for its durability and strength, this machine is designed to handle tough terrain and challenging projects. It provides the operator with the necessary power and precision to move soil, clear land, and handle a range of materials.

With a reputation for reliability, this model features components and mechanisms that ensure consistent performance in demanding environments. Whether on a construction site or in agricultural fields, its adaptability allows it to meet different operational needs.

Main Components of the John Deere 350

The structure of this machine consists of several essential systems working together to ensure efficient performance. These systems combine mechanical and hydraulic elements to provide power, control, and durability in various tasks. Below is an overview of the primary elements that make this equipment reliable and versatile in challenging environments.

Engine and Transmission

The engine serves as the powerhouse, converting fuel into the necessary energy to drive the vehicle. The transmission system allows for the smooth transfer of this power to the tracks, enabling forward and backward movement. It ensures precise control over the machine’s speed and direction, adapting to different terrains and workloads.

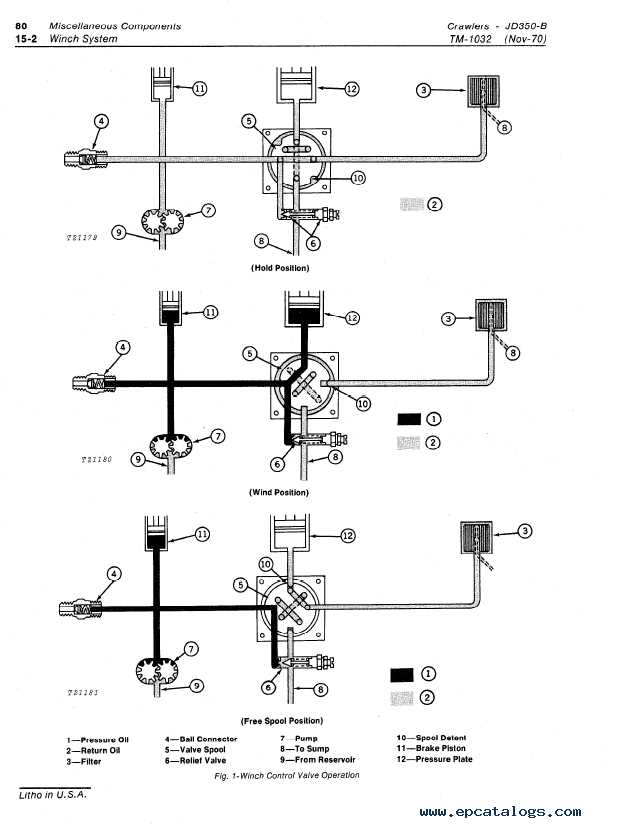

Hydraulic and Steering Systems

The hydraulic system operates key functions, such as lifting and adjusting attachments, providing the machine with flexibility during operation. Steering is controlled through a combination of levers that manage the direction, ensuring accurate turns and maneuverability, even in tight spaces.

| Component | Function | |||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine | Supplies power to all mechanical systems | |||||||||||||||||||||||||||||||

| How the Undercarriage Works

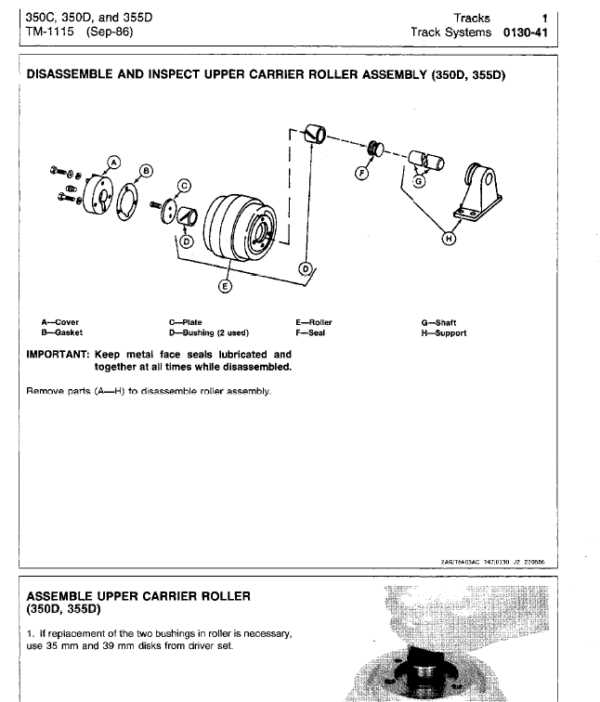

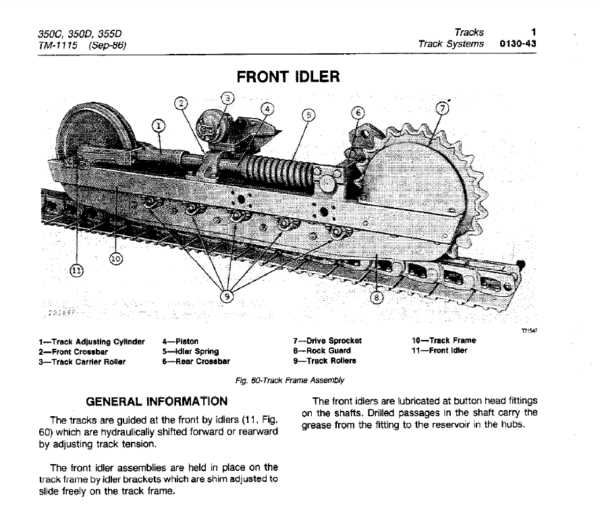

The undercarriage plays a crucial role in the overall functionality and stability of heavy machinery. It comprises several key components that work together to support the vehicle’s weight, enhance mobility, and provide traction on various terrains. Understanding how these elements interact is essential for effective maintenance and operation. At the heart of the undercarriage system are the tracks, which are designed to distribute the weight of the machine evenly. This feature reduces ground pressure and minimizes the risk of sinking into soft surfaces. The rollers and idlers support the track while ensuring smooth movement, allowing for improved handling and maneuverability.

Regular inspection and maintenance of these components are vital to ensure optimal performance and longevity. Keeping the undercarriage in good condition not only enhances the efficiency of the equipment but also contributes to overall safety during operation. Identifying Hydraulic System PartsUnderstanding the components of the hydraulic system is essential for maintaining optimal functionality. This system plays a crucial role in the overall performance of the machinery, enabling efficient operation through the transfer of fluid power. Recognizing the various elements involved can aid in troubleshooting and enhance the effectiveness of maintenance efforts. Main Components of the Hydraulic System

The hydraulic system consists of several key components that work together to ensure proper operation. Familiarity with these elements will assist operators and technicians in identifying issues and implementing solutions efficiently.

Maintenance Tips for the Hydraulic SystemRegular inspection and maintenance of the hydraulic components are vital for preventing failures. Operators should check fluid levels, inspect hoses for leaks, and ensure that filters are clean. Keeping the system in good condition will prolong its life and enhance overall performance. Common Engine Parts for John Deere 350

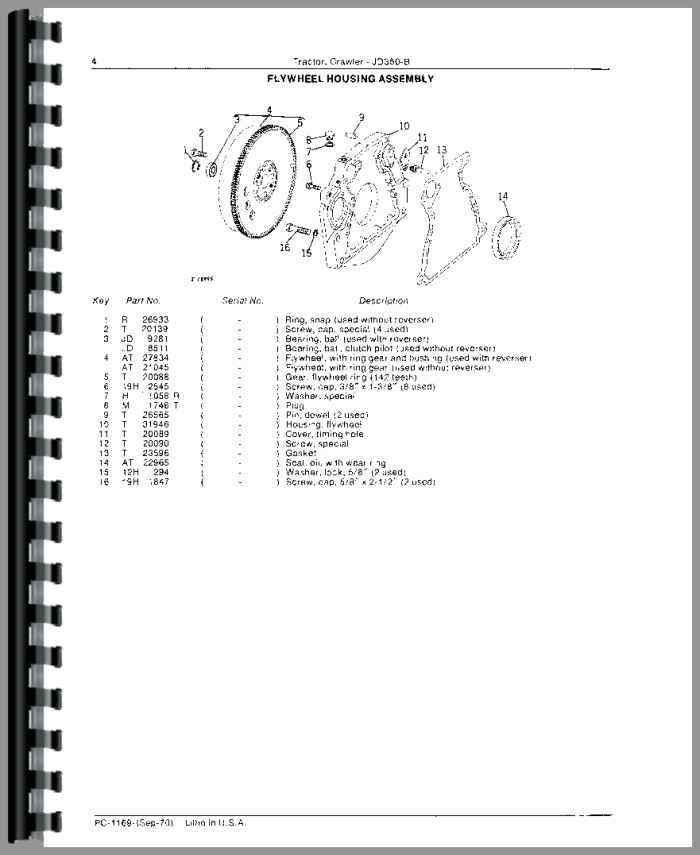

Understanding the fundamental components of an engine is essential for effective maintenance and repair. Various elements work together to ensure optimal performance, contributing to the overall efficiency and durability of the machine. Familiarity with these critical components helps operators identify potential issues and streamline service procedures. Key Components

Among the primary elements are the cylinder head, which houses valves and spark plugs, and the crankshaft, essential for converting linear motion into rotational force. Another significant part is the oil pump, responsible for circulating lubricant throughout the engine to reduce friction and heat. Additional ElementsAdditionally, the fuel injectors play a crucial role in delivering the right amount of fuel for combustion, while the timing belt ensures that all moving parts operate in sync. Regular inspection and maintenance of these components are vital for prolonging the lifespan of the engine and enhancing its performance. Transmission System Overview

The transmission mechanism is a vital component that facilitates the transfer of power from the engine to the tracks. This system ensures that the machine operates efficiently under various conditions, enabling it to perform a wide range of tasks effectively. Key Functions

Components Involved

Understanding the intricacies of this system is crucial for effective maintenance and repair, ensuring optimal functionality and longevity of the equipment. Tracks and Rollers: Key Elements

The efficiency and stability of heavy machinery are significantly influenced by their undercarriage components. Among these, the elements responsible for movement and support play a crucial role in ensuring optimal performance in various terrains. Understanding the functionality and maintenance of these components can enhance the longevity and effectiveness of the equipment. Functionality of TracksTracks serve as the primary means of propulsion for these machines, providing traction and stability. Their design allows for better weight distribution, reducing ground pressure and improving maneuverability. Key features include:

Importance of RollersRollers play an essential role in supporting the weight of the machine and facilitating smooth movement. They help maintain proper alignment and prevent excessive wear on the tracks. Key considerations include:

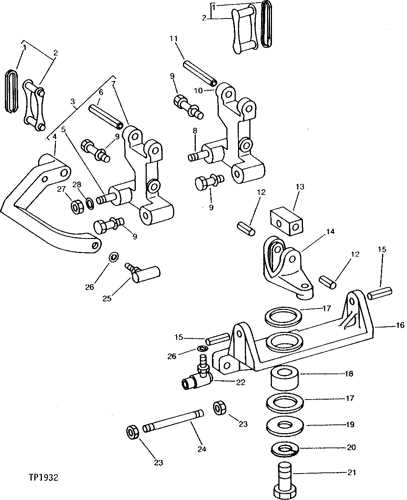

Blade and Lifting Mechanism Components

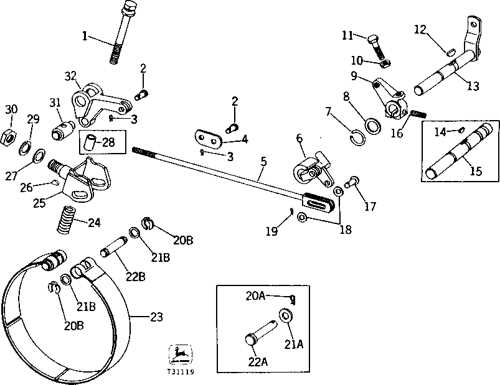

The efficiency of a construction machine is significantly influenced by its cutting edge and elevation system. These components work in harmony to facilitate various tasks, from land leveling to material handling. Understanding the essential elements that constitute these mechanisms is vital for maintenance and optimal performance. The primary elements involved in the cutting and lifting processes include the blade, lift arms, and hydraulic cylinders. The blade is crucial for material displacement, while the lift arms support the blade’s movement, enabling it to adjust its height according to operational requirements. Furthermore, the hydraulic cylinders play a pivotal role in controlling the lift and angle of the blade, ensuring precision and effectiveness in various working conditions. Regular inspection and maintenance of these components are essential to prevent wear and tear. Neglecting them can lead to decreased functionality and costly repairs. By understanding the roles and interactions of these key parts, operators can enhance the machine’s productivity and extend its lifespan. Steering System BreakdownThe steering mechanism is essential for the precise control and maneuverability of heavy machinery. Understanding its components and functionality is crucial for maintaining optimal performance and ensuring safety during operation. Key Components

Functionality Overview

The operation of the steering system involves several interconnected elements working together to facilitate directional changes. The hydraulic cylinder, activated by the steering wheel, transmits force to the linkage assembly, allowing for efficient navigation. Proper maintenance and timely repairs of each component are vital for sustaining the effectiveness of the steering system. Cooling System Components Explained

The efficiency of machinery heavily relies on its ability to regulate temperature. A crucial aspect of this process is the cooling system, which ensures that the engine operates within optimal temperature ranges. Understanding the components involved can enhance maintenance practices and improve overall performance. Key Elements of the Cooling System

The cooling system comprises various components that work in harmony to dissipate heat. Each part plays a vital role in maintaining the engine’s temperature and preventing overheating.

Importance of Regular MaintenanceTo ensure the longevity and efficiency of the cooling system, routine checks and maintenance are essential. Regular inspections can help identify potential issues before they escalate, contributing to the reliable operation of the machinery. Electrical System: Key ElementsThe electrical framework of heavy machinery plays a crucial role in ensuring optimal functionality and reliability. It encompasses various components that work collaboratively to power the equipment, facilitate communication between systems, and maintain operational efficiency. Understanding these fundamental elements is essential for effective maintenance and troubleshooting. Essential Components

Control Systems

Control units are integral to managing the equipment’s electrical functions. These systems oversee critical tasks, such as starting the engine and regulating various operations. Proper functioning of these control systems is vital for ensuring safe and efficient performance, highlighting the importance of regular checks and maintenance. Fuel System Parts Overview

This section provides an insight into the components that make up the fuel delivery system. Understanding these elements is crucial for maintaining optimal performance and efficiency in machinery operation. Key Components of the Fuel SystemThe fuel delivery system consists of several essential components, including the fuel tank, pump, filters, and injectors. Each part plays a vital role in ensuring a steady flow of fuel, preventing contaminants from entering the system, and enabling effective combustion. Importance of Regular MaintenanceRoutine inspection and servicing of the fuel system components are necessary to avoid performance issues. Regular checks can help identify wear or potential failures, ensuring the longevity and reliability of the equipment. Maintaining the John Deere 350 DozerProper upkeep of heavy machinery is essential for optimal performance and longevity. Regular maintenance ensures that equipment remains functional and efficient, preventing costly repairs and downtime. Understanding the specific components and their care requirements is vital for achieving this goal. Routine InspectionsConducting frequent checks of critical components is key to identifying potential issues early. Examine hydraulic systems, tracks, and engine components to ensure everything operates smoothly. Regular lubrication of moving parts reduces wear and tear, enhancing overall efficiency. Fluid Management

Monitoring and changing fluids, such as oil and hydraulic fluid, is crucial for maintaining functionality. Clean fluids contribute to better performance and reduce the risk of breakdowns. Implement a schedule for fluid changes based on usage to keep the machinery running efficiently. |