In the world of agriculture, the efficiency and longevity of machinery play a crucial role in productivity. Understanding the various elements that comprise these machines is essential for effective maintenance and repair. Each component has a specific function, contributing to the overall operation and performance of the equipment.

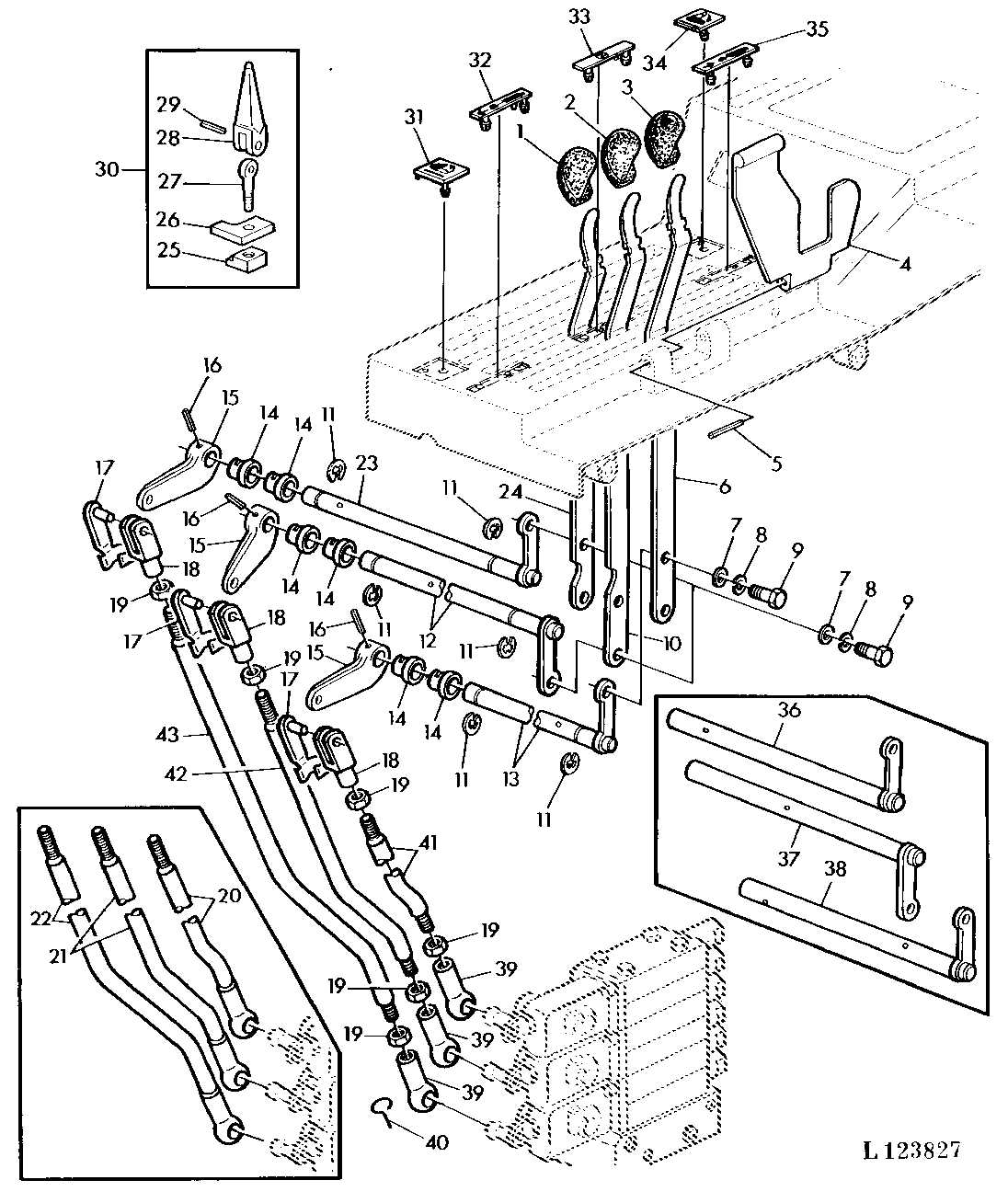

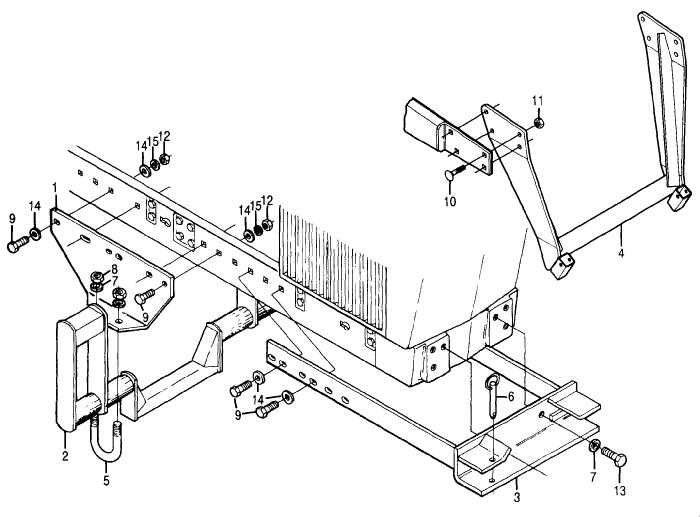

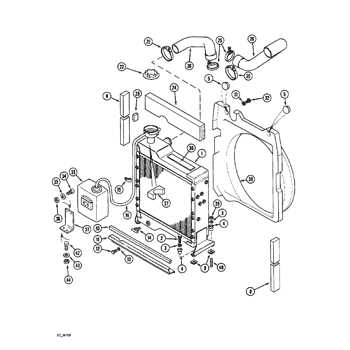

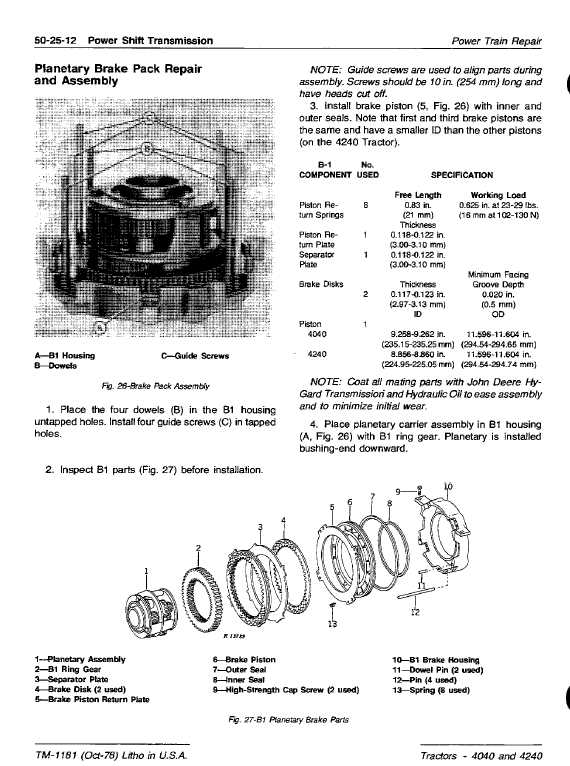

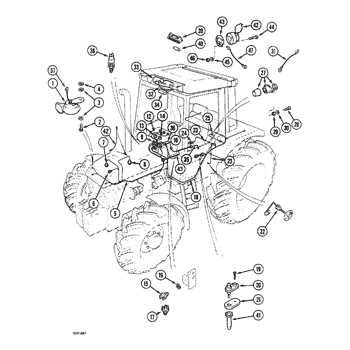

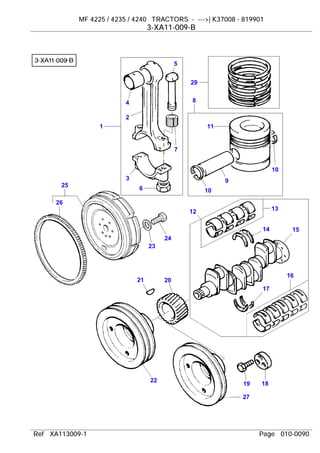

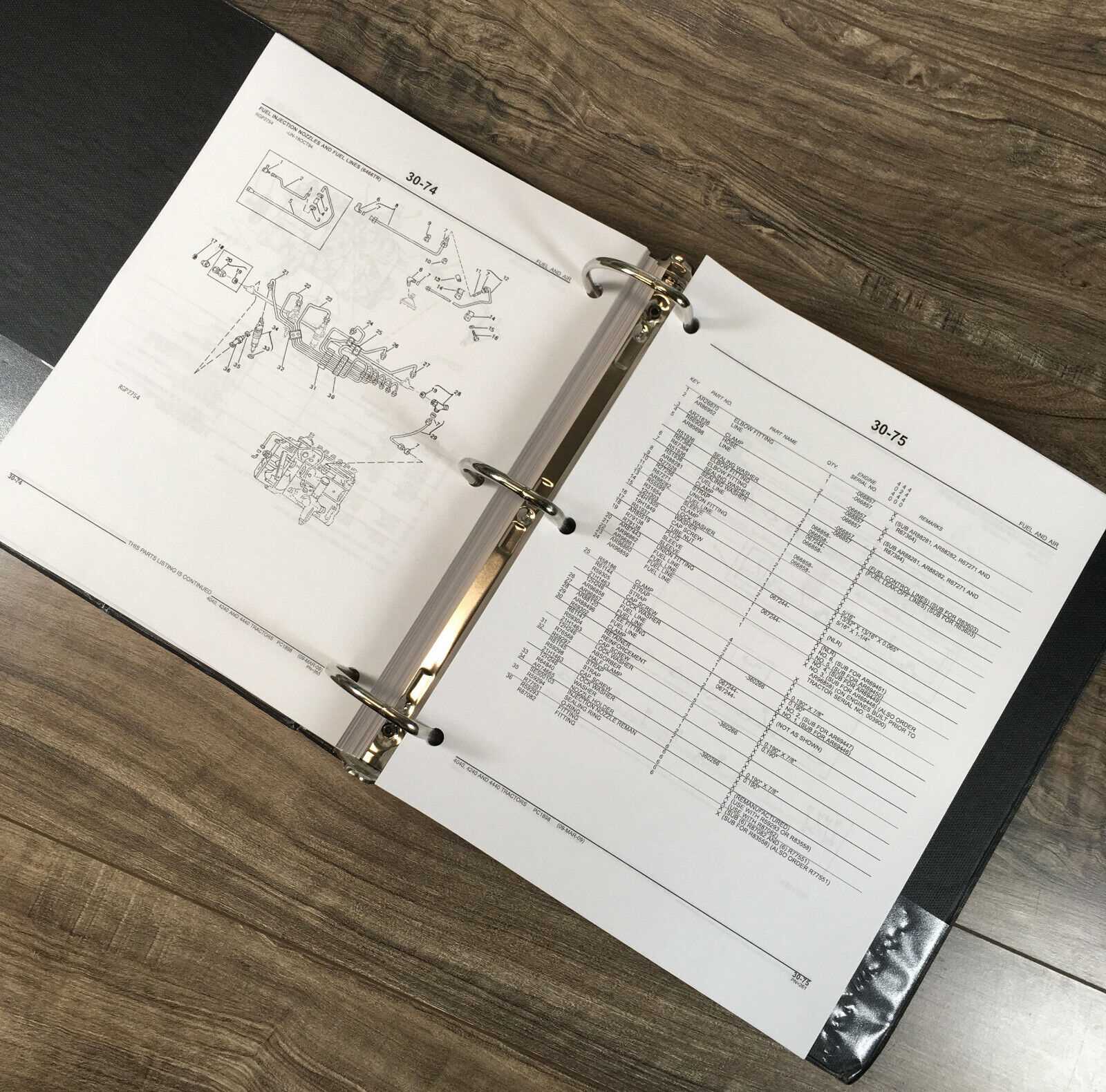

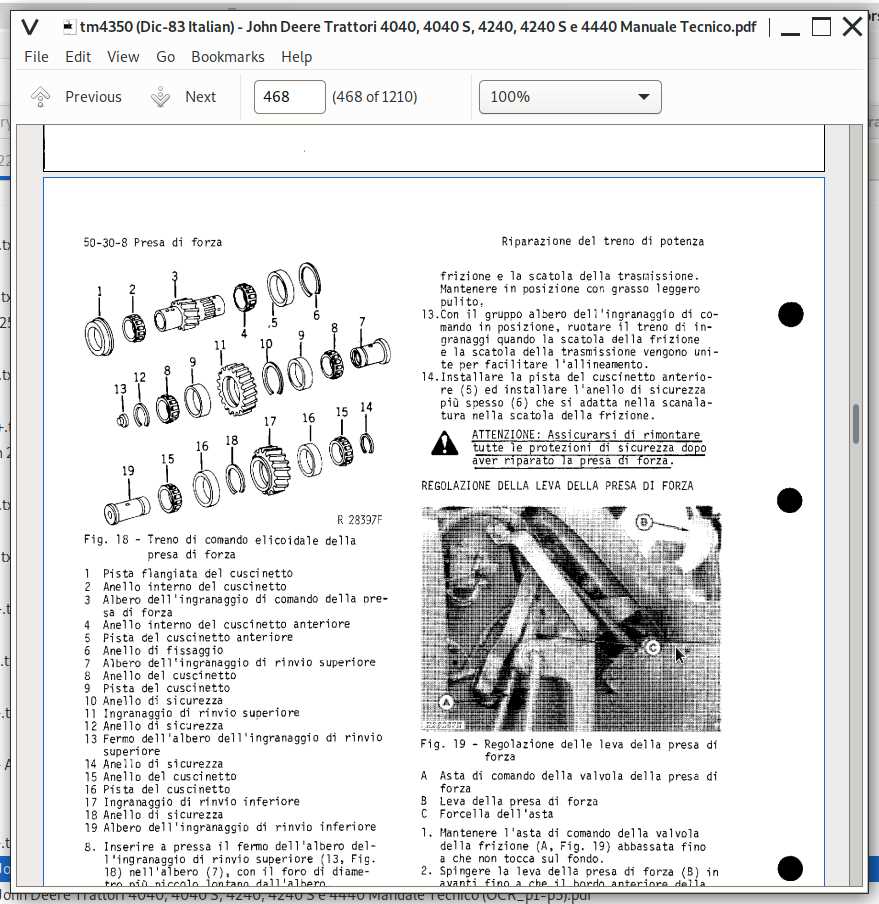

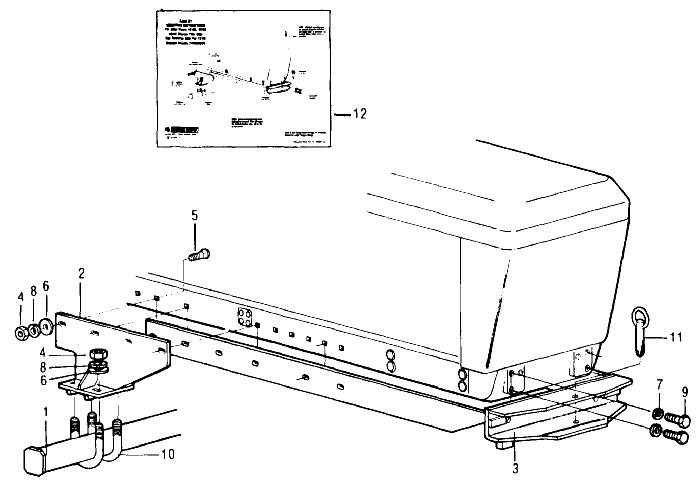

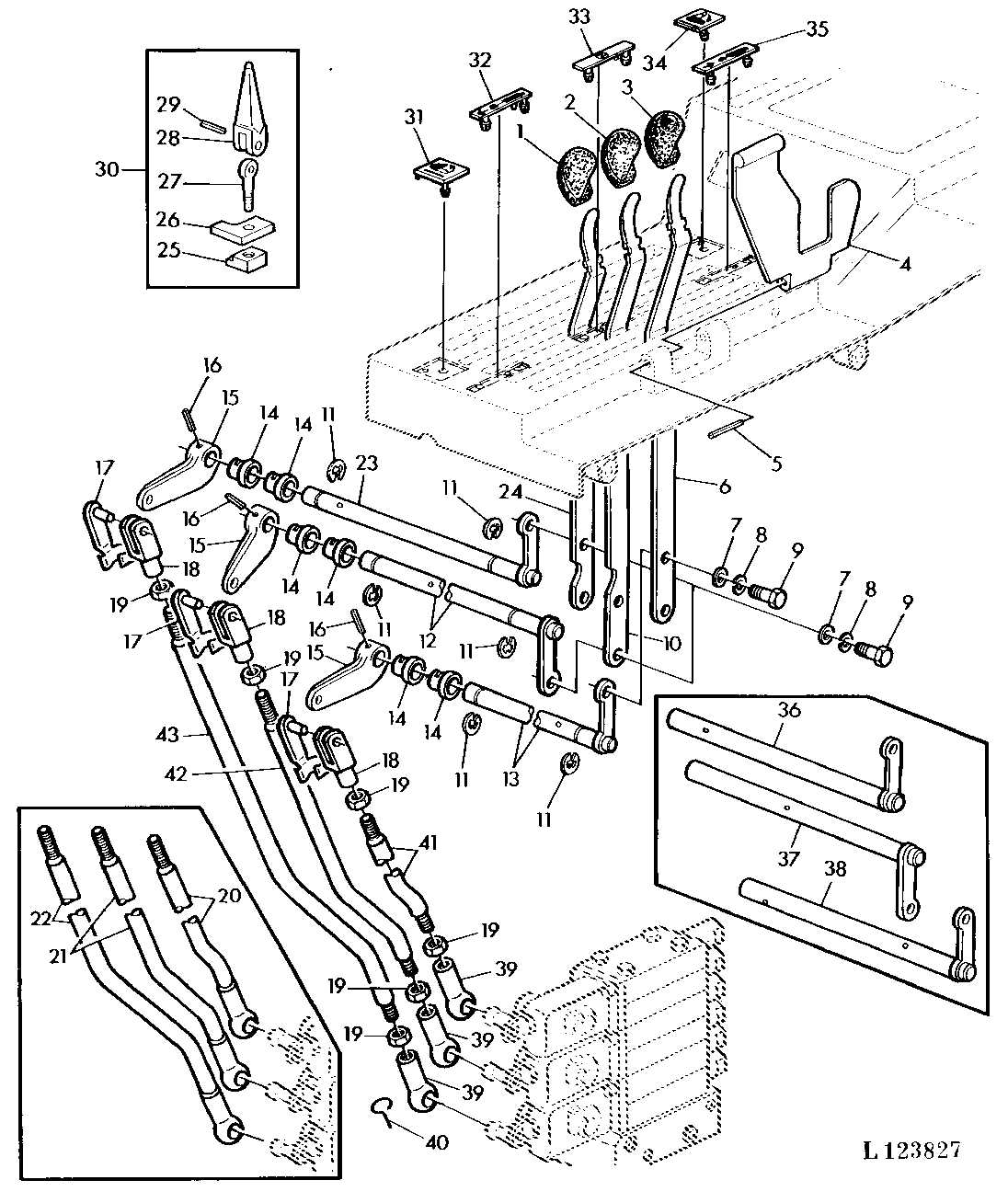

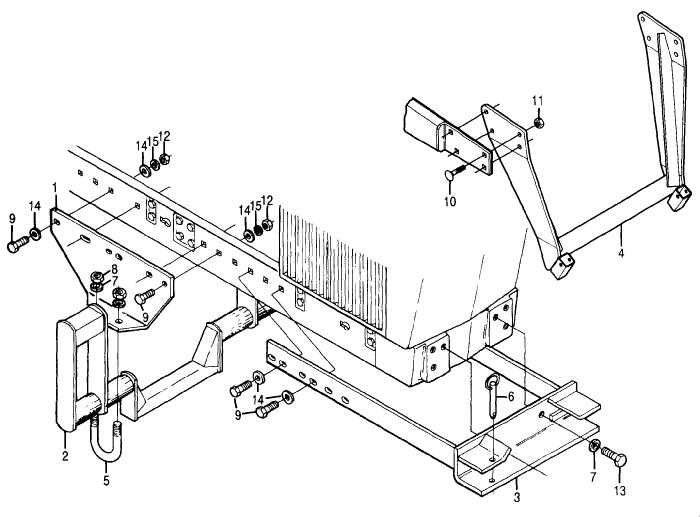

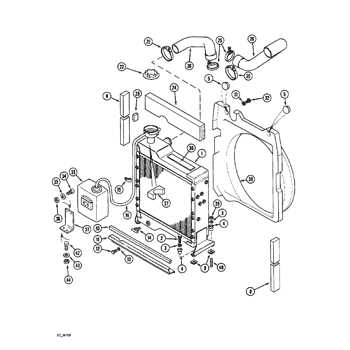

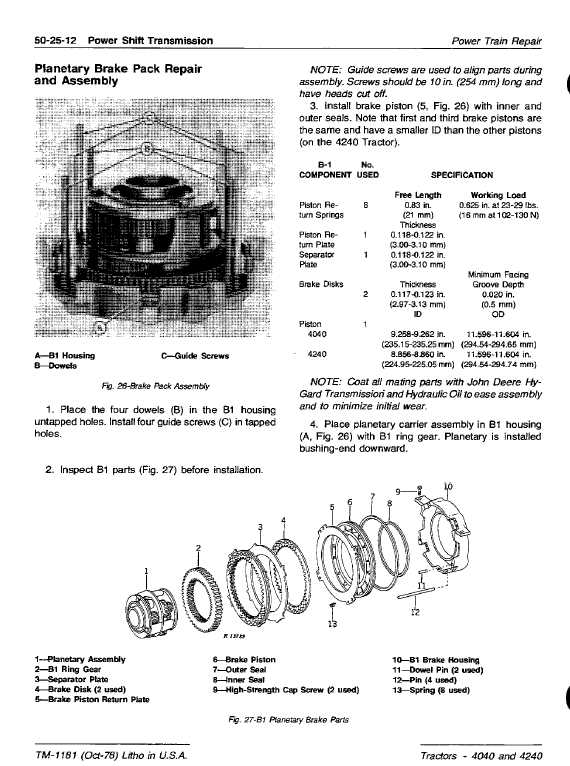

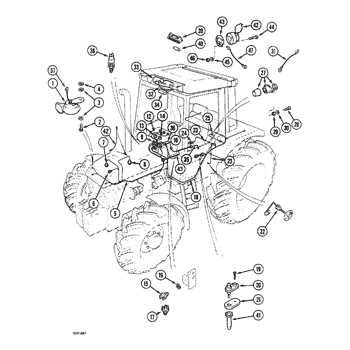

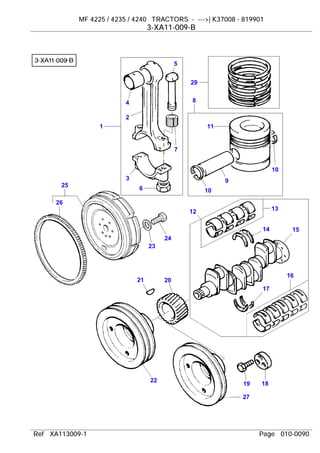

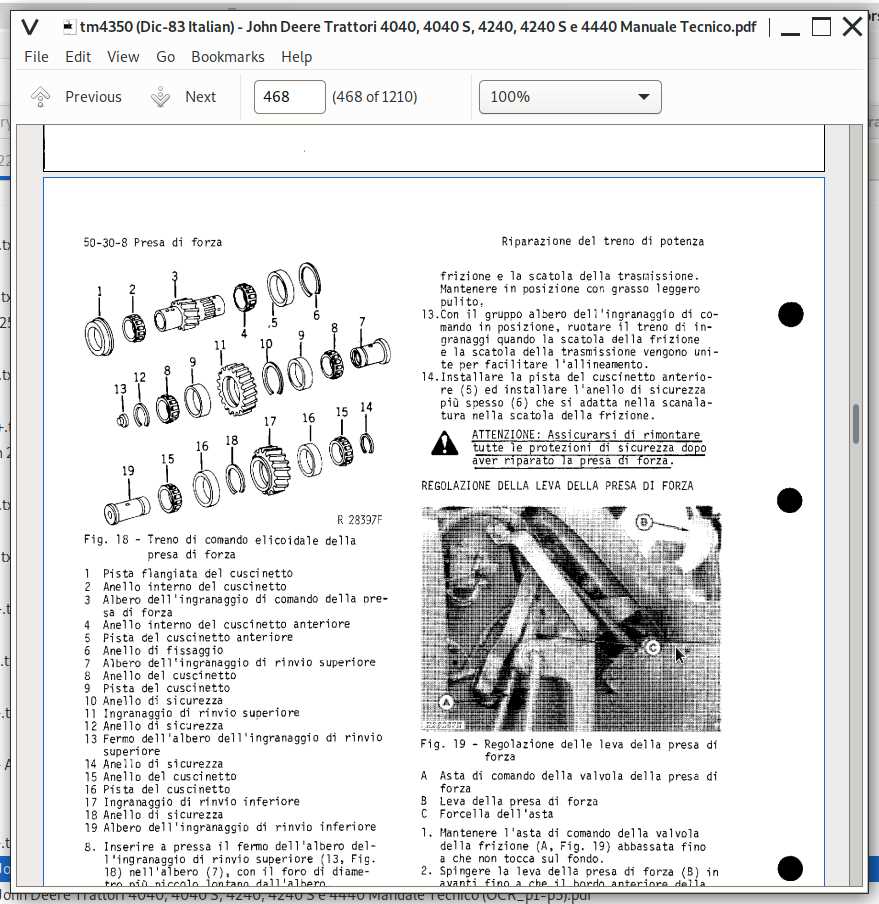

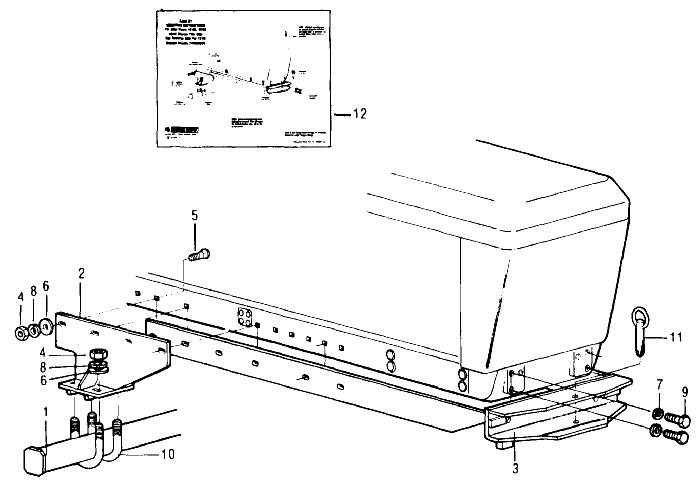

The intricate arrangement of mechanical parts can often be overwhelming, especially for those unfamiliar with their specific roles. Visual representations of these elements serve as valuable tools, allowing operators and technicians to identify and locate individual pieces swiftly. This clarity enhances the ability to perform routine checks and necessary replacements, ensuring optimal functionality.

Furthermore, having a comprehensive view of the system not only aids in troubleshooting but also promotes a deeper understanding of how these machines work together. This knowledge empowers users to make informed decisions regarding maintenance schedules and upgrades, ultimately leading to increased efficiency and reduced downtime.

Understanding John Deere 4240 Parts

Grasping the components of machinery is essential for effective maintenance and repair. A thorough comprehension of the various elements contributes to enhanced performance and longevity. Recognizing how each section interacts and functions together enables operators to diagnose issues accurately and make informed decisions regarding service and replacement.

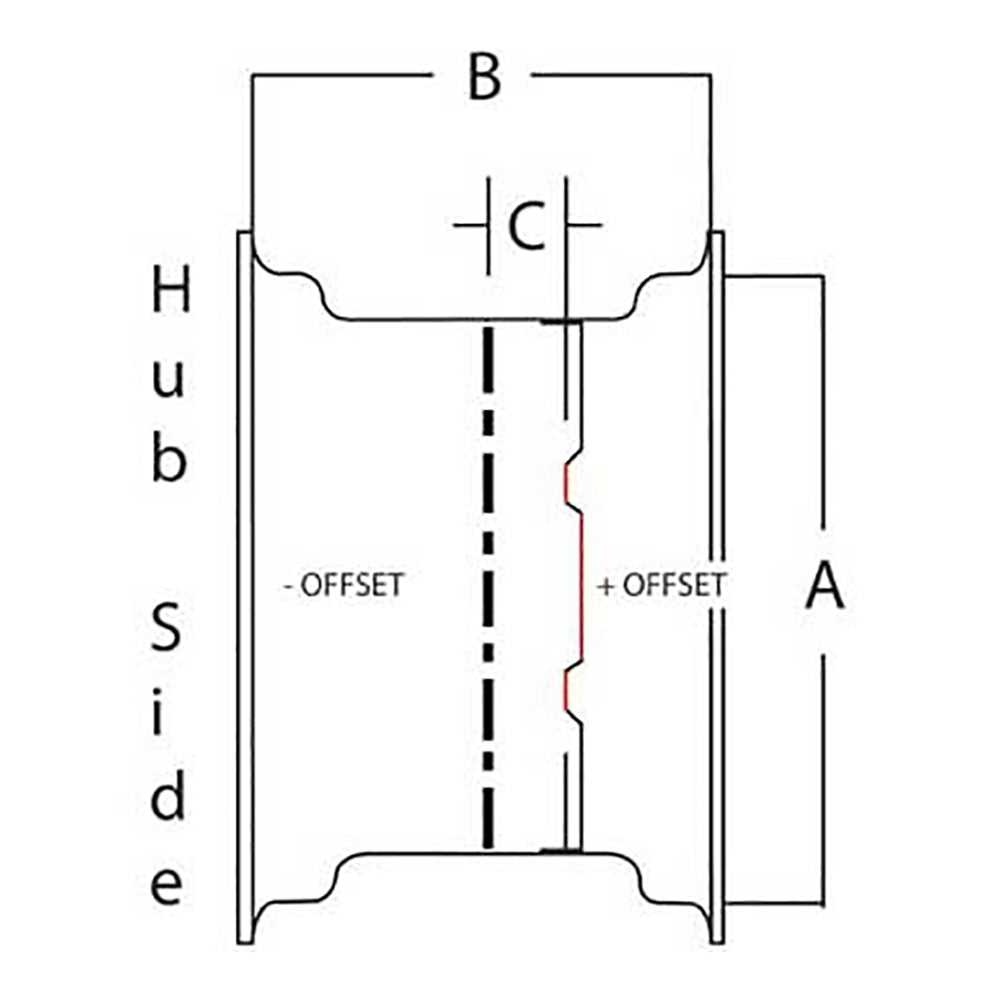

One effective way to familiarize oneself with these elements is through the use of detailed visual aids that showcase their arrangement and relationship. These resources assist in identifying specific components, allowing for easier troubleshooting and ensuring that maintenance tasks are carried out with precision.

| Component |

Description |

| Engine |

Power unit that drives the entire system, converting fuel into mechanical energy. |

| Transmission |

Mechanism that transfers power from the engine to the wheels, facilitating speed and torque adjustments. |

| Hydraulic System |

Fluid-driven system used for various operations, including lifting and moving attachments. |

| Electrical System |

Network responsible for powering lights, ignition, and various electronic components. |

| Chassis |

Framework that supports all other components, providing stability and structure. |

By delving into the specifics of these elements, users can develop a robust understanding that aids in effective machinery management and troubleshooting. Each segment plays a pivotal role in the overall operation, and awareness of their functions is vital for optimal use.

Importance of Accurate Diagrams

Precise illustrations play a crucial role in various fields, particularly in mechanical and technical industries. They provide a visual representation that simplifies complex information, allowing users to understand intricate systems and components with ease. Accurate schematics not only enhance comprehension but also facilitate effective communication among professionals and enthusiasts alike.

Enhanced Understanding

Well-crafted visuals enable individuals to grasp the functionality and interrelationships of different elements within a system. When users can see how components fit together, it significantly reduces confusion and the likelihood of errors during assembly or maintenance. Clear illustrations act as a roadmap, guiding users through processes that might otherwise be overwhelming.

Efficiency in Maintenance

In technical settings, the efficiency of repairs and upkeep largely hinges on the availability of reliable visuals. When a technician can refer to a detailed representation, they can quickly identify parts that require attention or replacement. This leads to faster diagnostics and minimizes downtime, ultimately saving time and resources for businesses and individuals alike.

Key Components of the 4240 Model

This section explores the essential elements that contribute to the functionality and efficiency of this renowned agricultural machinery. Understanding these vital components enhances the overall operational experience and maintenance practices.

Engine: The powerhouse of the machine, the engine delivers the necessary horsepower to perform various tasks. Its robust design ensures durability and reliability in the field.

Transmission: This system plays a crucial role in transferring power from the engine to the wheels, allowing for smooth transitions between different speed settings and enhancing maneuverability.

Hydraulic System: Vital for powering implements, the hydraulic system ensures efficient operation of attachments, providing the ultimate flexibility in diverse farming applications.

Chassis: The sturdy frame supports all components, ensuring stability and strength during operation, which is essential for handling heavy loads.

Electrical System: This network controls various functions, from starting the engine to operating lights and sensors, playing a key role in the overall efficiency of the equipment.

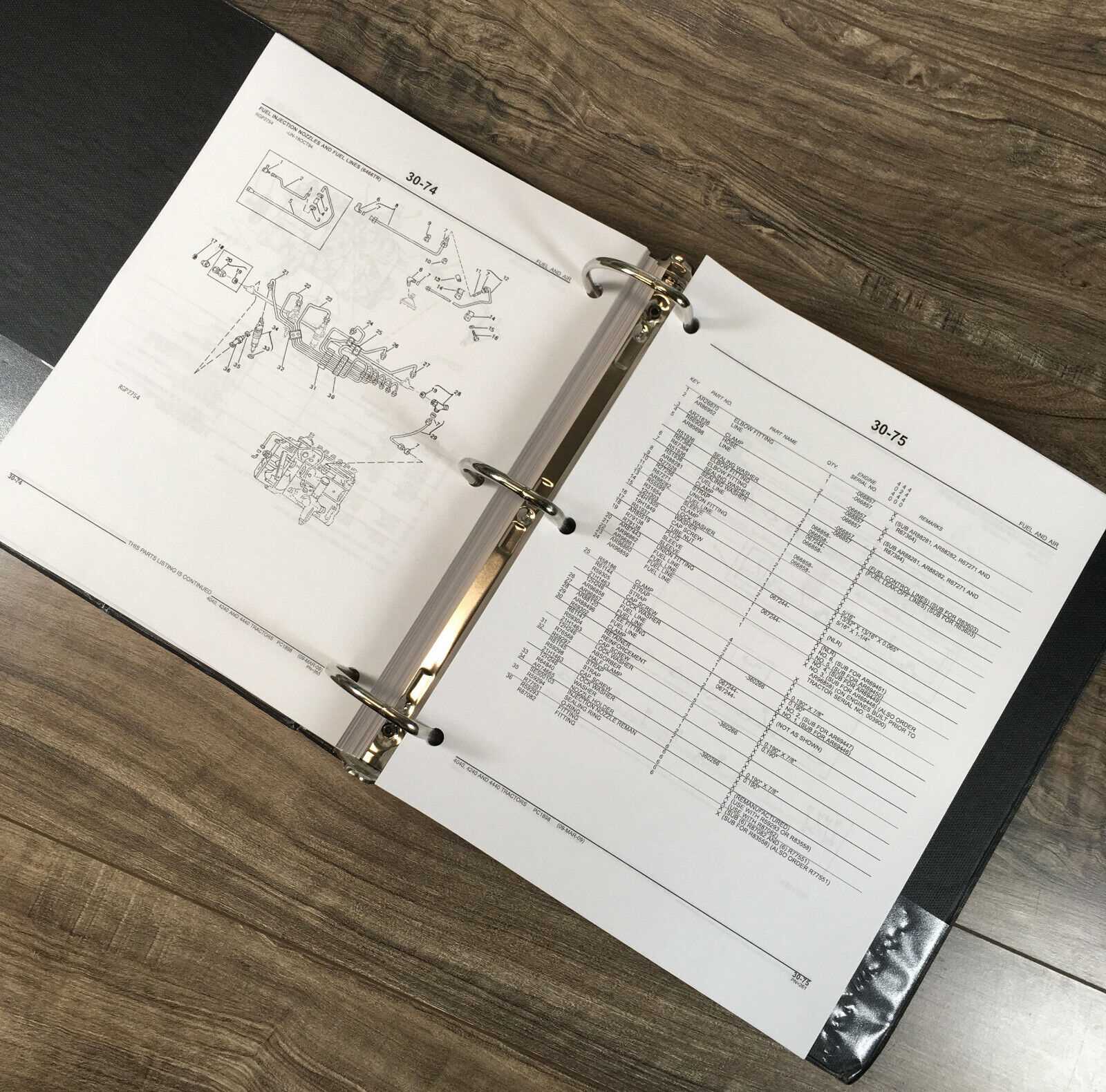

How to Access Parts Diagrams

Accessing visual breakdowns of machinery components is essential for effective maintenance and repair. These illustrations provide detailed views, allowing users to identify and source necessary elements for optimal performance.

Online Resources

Many manufacturers offer online platforms where users can find visual representations of their machinery. These resources typically include searchable databases and downloadable PDFs.

Local Dealers

Visiting local dealerships can also yield valuable resources. Dealers often have physical copies of breakdowns and knowledgeable staff who can assist in locating specific components.

| Resource Type |

Description |

| Manufacturer Website |

Searchable database with downloadable visuals. |

| Local Dealership |

Physical copies and expert assistance available. |

| Online Forums |

User-shared diagrams and tips for locating parts. |

Common Issues with 4240 Components

Mechanical systems often face wear and tear, which can lead to operational inefficiencies or breakdowns. Various elements within older models may require attention due to age, heavy use, or environmental factors. Identifying and addressing these common problems can extend the lifespan of the machinery and ensure smoother functionality.

Hydraulic System Challenges

One of the more frequent concerns involves the hydraulic system, where fluid leaks or pressure loss can impact performance. Components like hoses, pumps, and seals are especially susceptible to wear. Regular inspection and timely replacement can prevent further damage.

Transmission Troubles

Transmission systems in aging equipment often suffer from worn gears or clutches. Issues like grinding noises or difficulty in shifting can signal deeper problems. Regular maintenance of the transmission fluid and replacing worn parts early can help mitigate these issues.

| Issue |

Symptoms |

Solution |

Identifying Replacement Parts Easily

Finding the right components for your machinery can be straightforward when approached correctly. Understanding how to recognize the necessary pieces and match them with your equipment’s specifications ensures smoother repairs and maintenance.

Matching Components to Specifications

To simplify the process of locating the correct elements, it’s essential to focus on the specifications of each component. Pay attention to model compatibility and technical details to ensure that the selected part will fit seamlessly into your machine. Consulting manuals or online resources can provide crucial insights.

Using Online Resources for Precision

Today, various online platforms offer tools that can assist in narrowing down suitable replacements based on equipment models and technical requirements. By entering relevant data, you can quickly find the perfect match, reducing the risk of errors. Always double-check the item details to guarantee compatibility.

Tools for Maintenance and Repair

Proper maintenance and effective repair of machinery require the right tools. Having a well-organized set of equipment ensures that both routine upkeep and unexpected repairs can be handled efficiently. Below are essential categories of tools that every mechanic or technician should consider for various tasks.

- Wrenches and Sockets: A versatile set of wrenches and sockets is crucial for loosening and tightening bolts and nuts. It’s important to have a range of sizes to accommodate different fasteners.

- Torque Wrenches: These are essential for ensuring that bolts are tightened to the correct specification, preventing over- or under-tightening, which could cause damage or failure.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for dealing with screws of various shapes and sizes.

- Pliers: Needle-nose, slip-joint, and locking pliers provide a strong grip for handling wires, hoses, and small parts during repairs.

- Impact Tools: Pneumatic or electric impact wrenches can speed up the process of loosening stubborn or rusted bolts.

Resources for Purchasing Components

When maintaining or upgrading equipment, finding reliable sources for acquiring essential items is crucial. It’s important to choose from trusted outlets that offer quality products, ensuring long-term efficiency and durability. Whether you’re seeking specialized items or general replacements, numerous platforms and sellers are available to meet your needs.

Online Marketplaces

Online platforms provide a wide range of options for those looking for various mechanical elements. These marketplaces often include user reviews, ensuring transparency and helping you make informed decisions. Many vendors also offer warranties and return policies, adding an extra layer of security to your purchase.

Local Distributors

Local suppliers can be a convenient option for immediate needs. These distributors often provide personalized customer service, making it easier to find the right components. Additionally, local shops

Understanding Part Numbering Systems

Part numbering systems play a critical role in identifying and cataloging components for machines and equipment. These systems ensure that each component can be accurately recognized, tracked, and replaced when necessary. By assigning unique identifiers to each item, manufacturers can maintain consistency in inventory management and servicing.

A well-organized numbering system allows for easy reference, whether you are ordering replacements, conducting maintenance, or analyzing the components of a machine. The structure of these numbers often follows specific conventions, indicating details such as the type, category, and size of the component. Understanding how these codes work can simplify the process of locating and selecting the right component for your needs.

Best Practices for Part Installation

When working with machinery, ensuring a smooth and efficient installation process is essential to maintaining long-term functionality and reducing the risk of future breakdowns. Following the right techniques and understanding the essential steps can significantly improve the outcome of your maintenance efforts.

Preparation Before Installation

Before starting, it’s crucial to gather all necessary tools and review the equipment’s specifications. Double-check the compatibility of each component to prevent errors during assembly. Clean all surfaces thoroughly, ensuring there is no debris or old material that might interfere with the proper fitting of new elements.

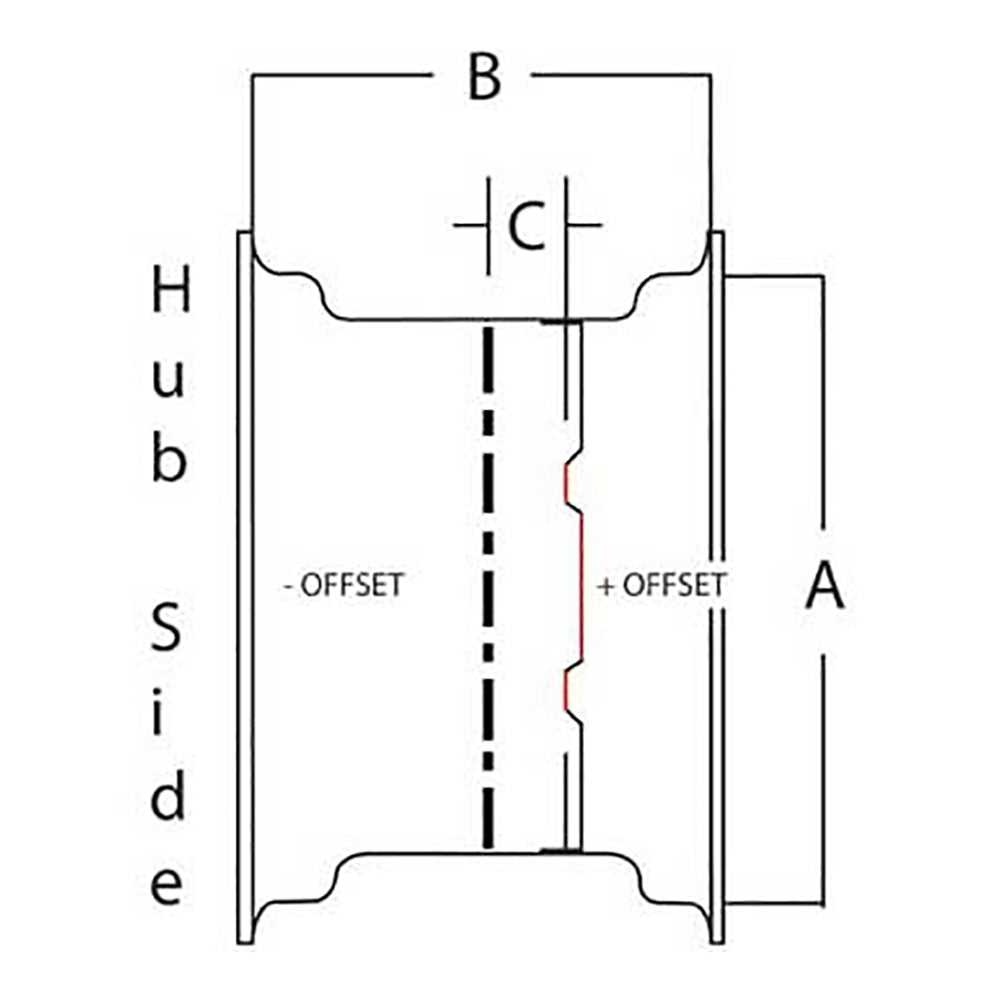

Ensuring Proper Fit and Alignment

Aligning components precisely is key to avoiding future mechanical issues. Use appropriate measuring tools to confirm that everything is positioned correctly. Tighten fasteners gradually and evenly to maintain balanced pressure, avoiding potential damage from over-tightening. After installation, test the movement of all components to ensure everything operates smoothly.

Upgrading vs. Replacing Parts

When maintaining or improving machinery, one of the key decisions is whether to upgrade existing components or replace them entirely. Each approach offers its own advantages depending on the condition of the equipment, the goals of the operator, and the cost implications involved.

Benefits of Upgrading Components

Upgrading is often the preferred choice when looking to enhance performance without completely overhauling the system. This method allows for modernizing specific elements while retaining the core structure, offering benefits such as improved efficiency, durability, and compatibility with newer technologies.

- Cost-effective solution for minor improvements

- Increased lifespan of current systems

- Access to modern features without full replacement

When to Consider Full Replacement

In some cases, replacing outdated or malfunctioning elements may be the better option. This is especially

Expert Tips for 4240 Maintenance

Ensuring the smooth operation of agricultural machinery requires a diligent maintenance routine. By addressing common wear and tear, operators can extend the lifespan of their equipment and prevent costly repairs. The following guidelines offer practical advice for keeping your equipment in optimal condition.

Check Fluid Levels Regularly

One of the most important aspects of maintaining heavy machinery is monitoring fluid levels. Consistent checks of engine oil, hydraulic fluid, and coolant help to ensure that your machine runs efficiently and avoids unnecessary strain on its components. Top up fluids as needed and always use the recommended types for optimal performance.

Inspect Moving Components

Moving parts, such as belts and pulleys, are subject to regular stress. Regular inspection of these areas is crucial to avoid breakdowns. Look for signs of wear, such as cracks, looseness, or unusual noises. If needed, tighten or replace components to maintain the machine’s smooth operation.

By adhering to these expert tips, you can keep your equipment in excellent condition, ensuring reliability and peak performance throughout its use.