In the realm of machinery maintenance, having access to detailed visual references is essential for effective troubleshooting and repair. This section aims to provide insights into the intricate layouts and illustrations that outline various mechanical elements and their interconnections. Such resources empower users to identify components with ease, ensuring that any necessary replacements or adjustments can be carried out with confidence.

When working with complex equipment, a clear representation of each segment can significantly streamline the repair process. Visual guides not only enhance understanding but also serve as invaluable tools for both novice users and seasoned professionals. By leveraging these informative illustrations, one can navigate through assembly and disassembly tasks more efficiently, ultimately leading to improved machinery performance.

Furthermore, these resources often highlight the specific functionalities of each element, contributing to a comprehensive grasp of the overall system. As users delve deeper into the specifics of their machinery, they can develop a more intuitive understanding of how each part contributes to the unit’s operation. This knowledge is crucial for maintaining optimal performance and extending the lifespan of the equipment.

Understanding John Deere 425 Components

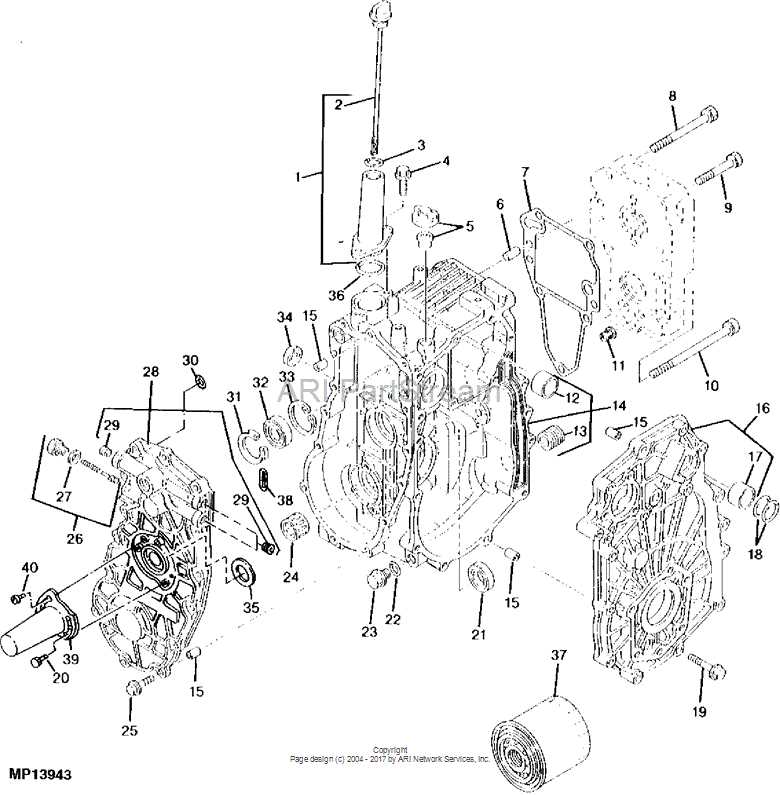

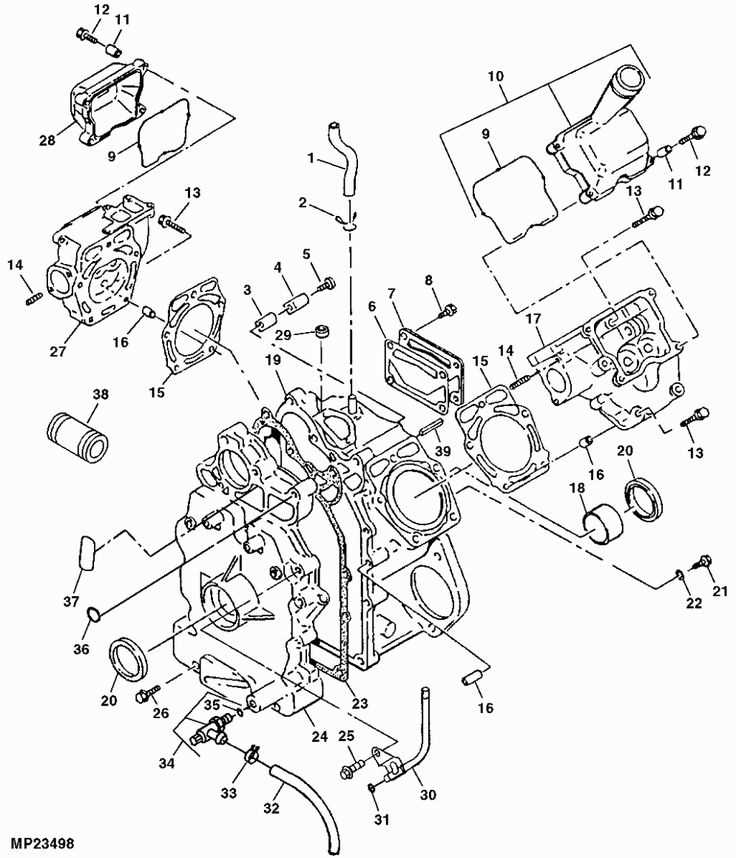

Exploring the intricacies of machinery reveals the essential elements that contribute to its functionality. This section delves into the various constituents that make up a specific model of equipment, offering insights into their roles and interactions within the system. By comprehending these components, users can enhance their maintenance practices and optimize performance.

Key Elements of the System

The primary constituents of the machinery encompass numerous crucial sections. Each part serves a specific purpose, from providing structural integrity to facilitating movement. For instance, the engine acts as the powerhouse, generating the necessary energy, while the transmission efficiently transfers that energy to the wheels, ensuring effective mobility.

Importance of Regular Maintenance

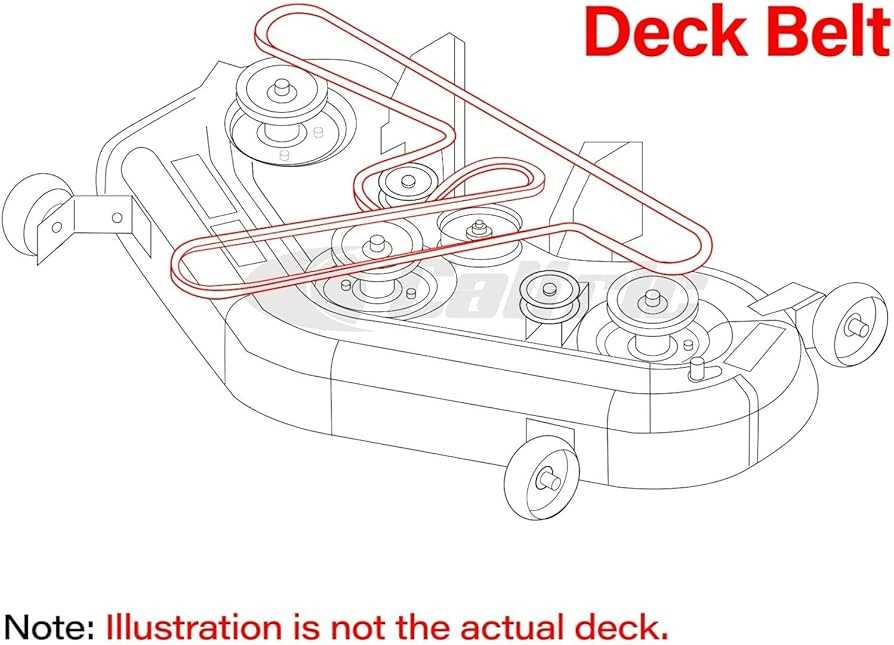

Understanding the individual roles of these components emphasizes the significance of consistent upkeep. Regular inspections can prevent wear and tear, ensuring longevity and optimal functionality. Users should pay special attention to filters, belts, and hydraulic systems, as these parts often require more frequent checks to maintain operational efficiency.

Importance of Parts Diagrams

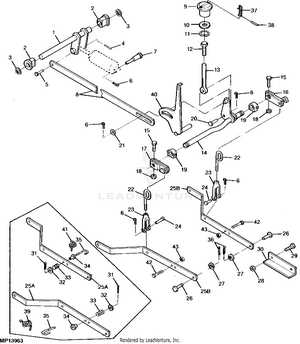

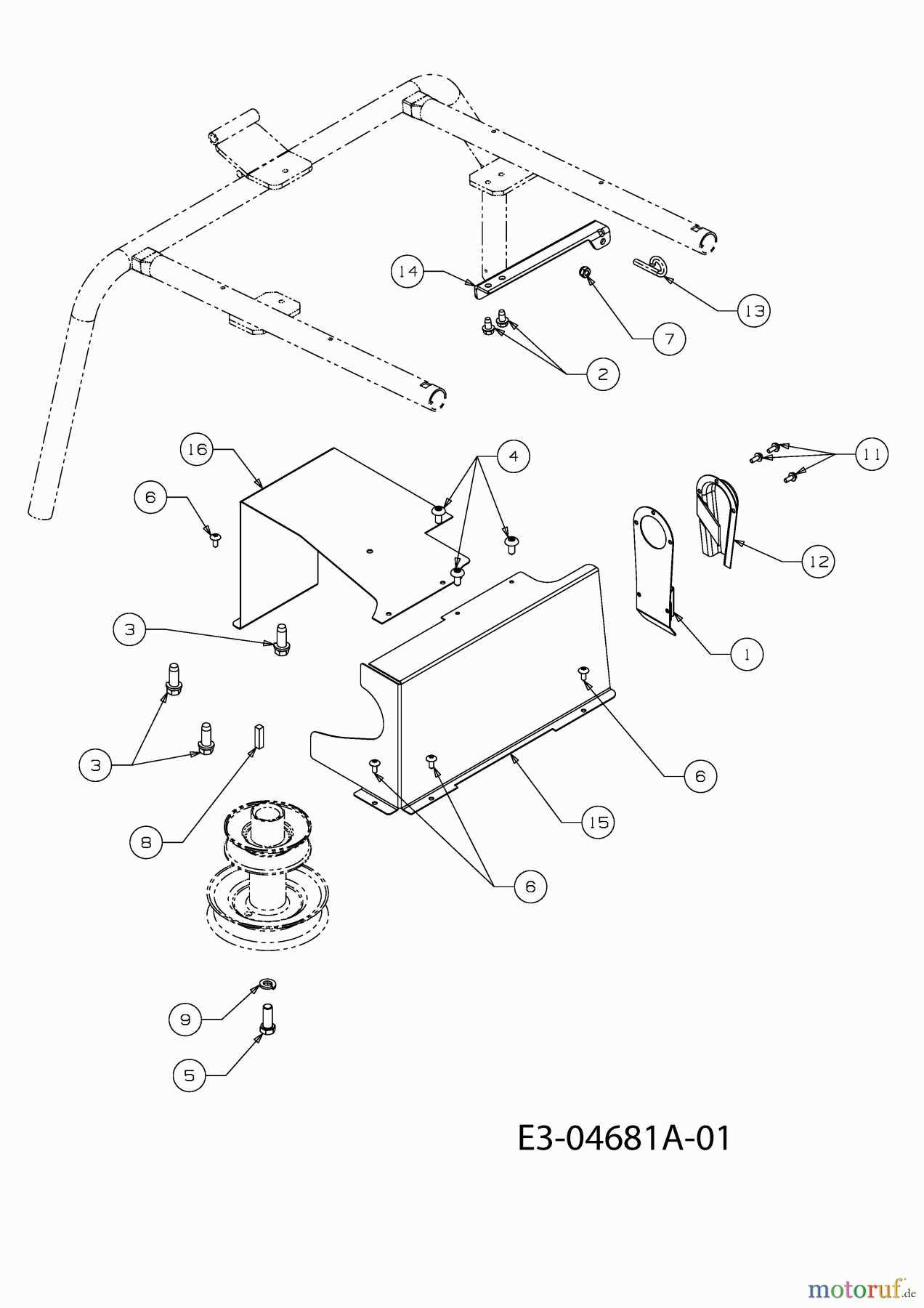

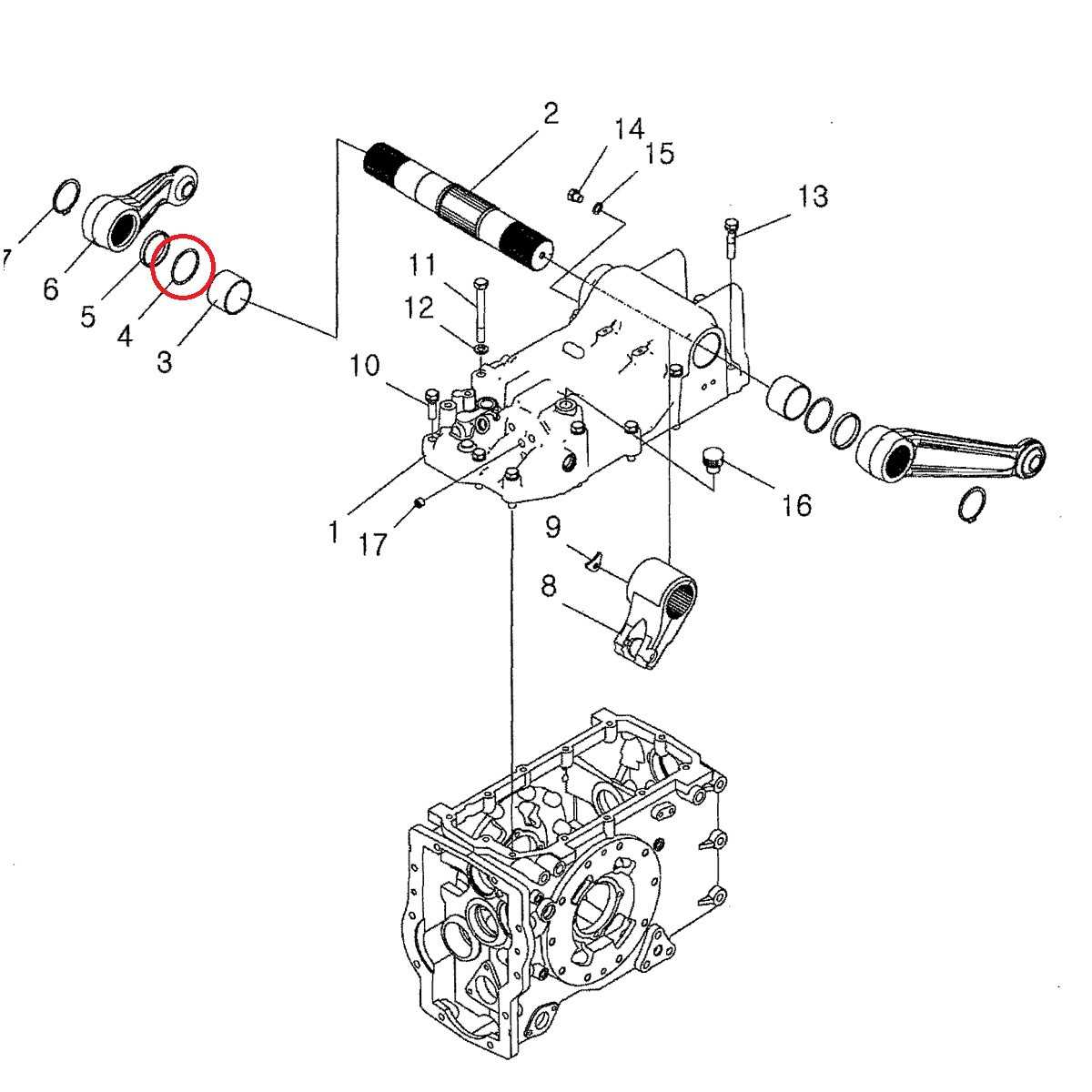

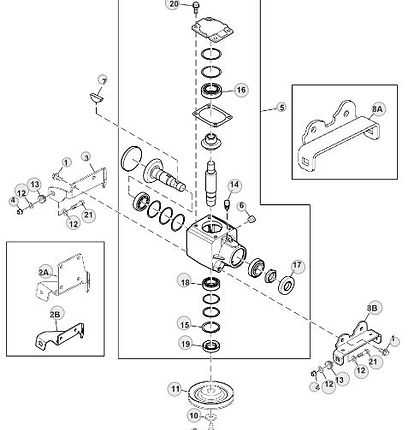

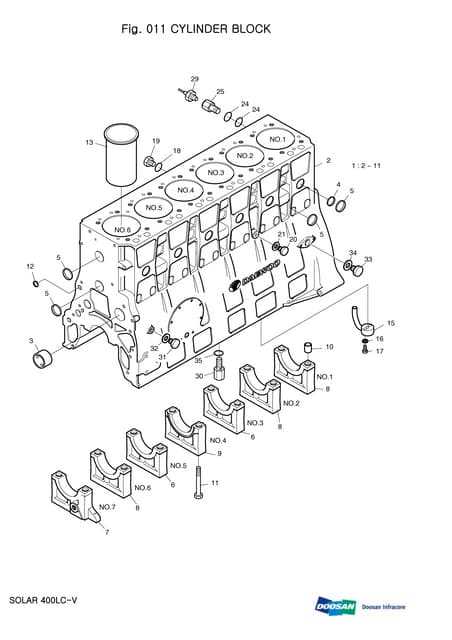

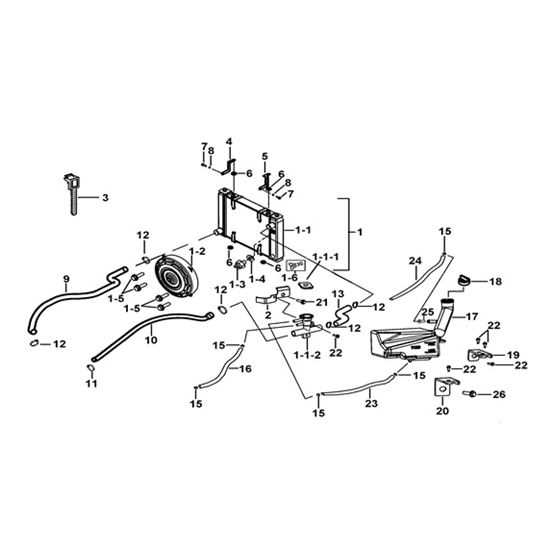

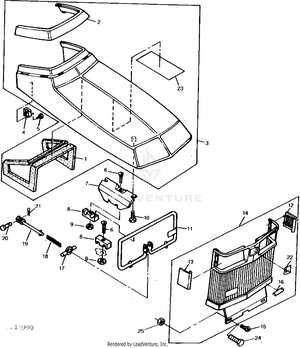

Understanding the components and their relationships within a machine is essential for effective maintenance and repair. Visual representations of these elements can significantly enhance the comprehension of how each part interacts with others, leading to improved troubleshooting and assembly processes.

Facilitating Repairs

One of the primary advantages of these visual aids is their ability to simplify the repair process. By providing a clear overview, they help technicians quickly identify the necessary components and their locations. This can save valuable time and reduce frustration during repairs.

- Streamlined identification of components

- Reduced risk of missing crucial elements

- Enhanced understanding of assembly procedures

Improving Maintenance

Regular maintenance is vital for prolonging the life of machinery. Having access to accurate visual guides allows operators to perform checks and servicing with confidence. They can follow the recommended procedures and ensure that all aspects of the machinery are addressed appropriately.

- Helps in scheduling routine maintenance tasks

- Encourages proactive measures for component care

- Promotes efficient use of resources during upkeep

How to Read Diagrams Effectively

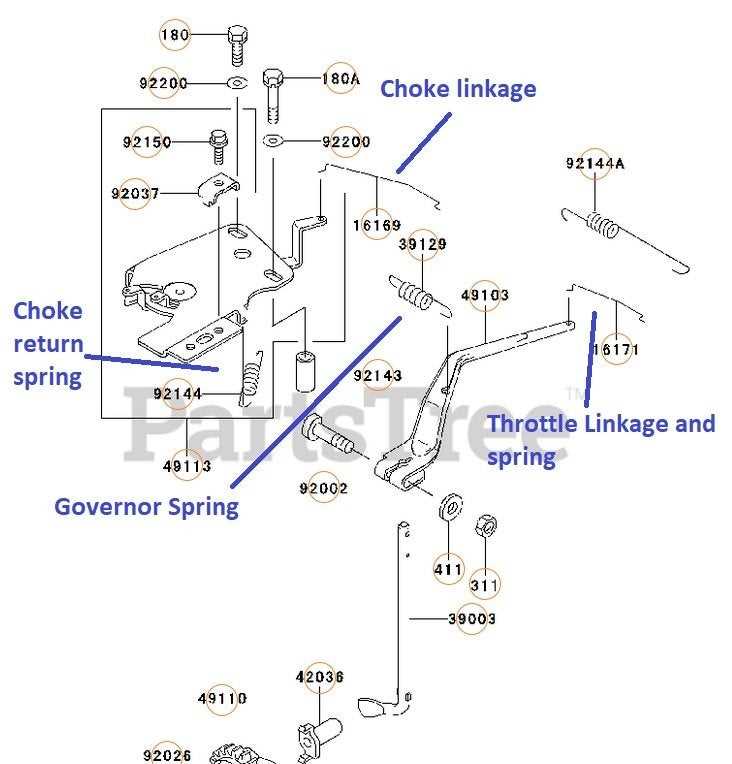

Understanding visual representations can greatly enhance your ability to grasp complex systems and components. By familiarizing yourself with various symbols and notations, you can more easily interpret the information presented, leading to improved maintenance and troubleshooting skills.

Key Components of Effective Interpretation

- Symbols: Familiarize yourself with common icons and their meanings.

- Legends: Always refer to the legend for clarification on symbols used.

- Connections: Pay attention to how elements are interconnected.

Tips for Better Comprehension

- Start by examining the overall layout before focusing on individual components.

- Identify the main sections to understand the structure.

- Practice with different representations to enhance your skills over time.

Commonly Used Parts for Maintenance

Regular upkeep of machinery relies on the availability of essential components that ensure smooth operation and longevity. Familiarity with commonly utilized elements is crucial for effective maintenance routines. These items not only facilitate repairs but also enhance overall performance, minimizing downtime.

Essential Components

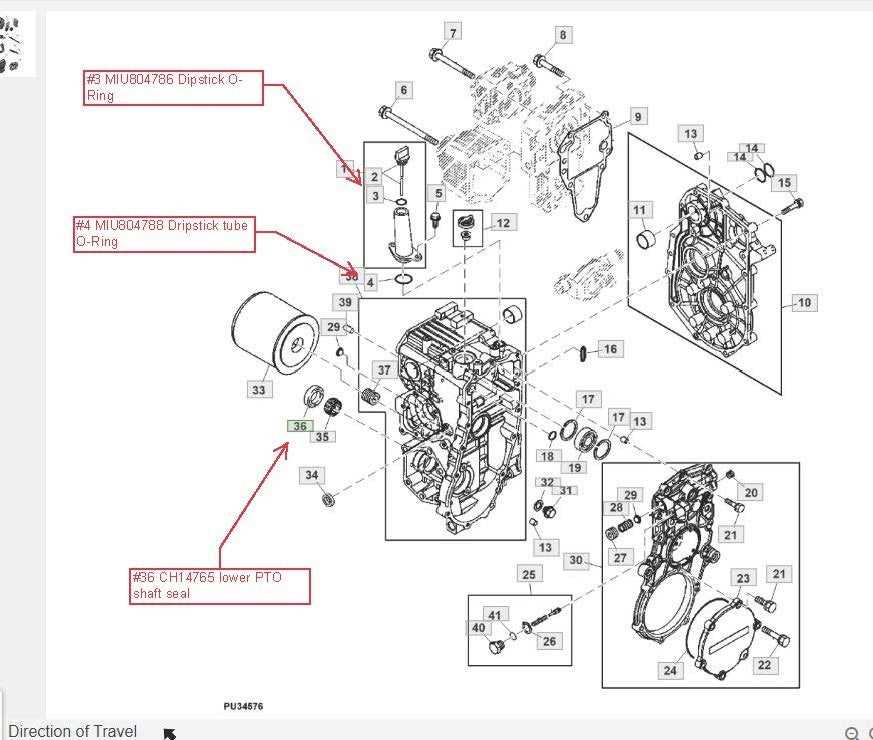

Key elements frequently required include filters, belts, and seals. Filters help maintain fluid cleanliness, preventing contaminants from causing damage. Belts are vital for transferring power between engine components, while seals prevent leaks and ensure proper functioning. Regular inspection and timely replacement of these items are fundamental for optimal performance.

Accessories for Enhanced Functionality

In addition to basic components, certain accessories can significantly improve the functionality of equipment. Lubricants, cleaning agents, and diagnostic tools are indispensable for maintaining peak performance. Lubricants reduce friction, ensuring smoother operation, while cleaning agents help remove dirt and debris, contributing to the overall health of the machinery. Diagnostic tools assist in identifying issues before they escalate, facilitating proactive maintenance strategies.

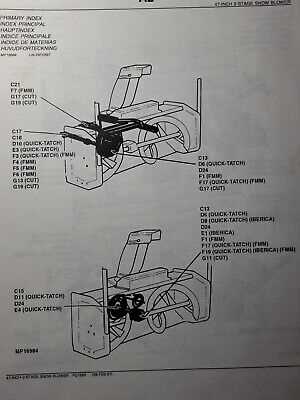

Identifying Replacement Parts Easily

Recognizing the components needed for your equipment can be a straightforward process with the right approach. Understanding the structure and functionality of various elements enables efficient identification, ensuring that you can maintain optimal performance.

To simplify the task of locating the necessary components, consider the following steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the equipment model and its specifications to understand which elements may require replacement. |

| 2 | Utilize resource guides or online databases that provide visual references for each component, aiding in quick identification. |

| 3 | Consult with local suppliers or online marketplaces to verify availability and compatibility of the required components. |

| 4 | Maintain a record of past replacements, as this information can assist in future maintenance and ensure you have the right parts on hand. |

Sources for Accurate Diagrams

Finding reliable illustrations for machinery components is essential for effective maintenance and repair. Access to precise visuals helps users identify the necessary elements for various tasks, ensuring that they can address issues efficiently. Whether for troubleshooting or part replacement, having trustworthy resources is crucial.

One of the best places to begin is the official manufacturer’s website. They often provide comprehensive manuals and visual aids that cover the specifics of each model. Additionally, many online forums and communities dedicated to machinery enthusiasts can serve as valuable sources. Members frequently share their experiences, offering insights and images that can assist in understanding the assembly and function of different components.

Another excellent option is to explore specialized parts suppliers or retailers. These businesses often include extensive catalogs with illustrations that depict the various elements available for purchase. Utilizing these resources ensures that users can acquire the correct items, thereby enhancing the longevity and performance of their equipment.

Furthermore, consulting repair guides and maintenance books dedicated to machinery can provide in-depth knowledge along with clear visuals. Such publications often break down complex systems into understandable parts, making it easier for individuals to navigate repairs or modifications.

In summary, leveraging a variety of resources will help users obtain accurate illustrations, ultimately supporting their efforts in maintaining and enhancing their machinery effectively.

Comparison of OEM and Aftermarket Parts

When maintaining machinery, one important decision revolves around the choice between original equipment manufacturer components and those produced by third-party suppliers. Each option presents unique advantages and considerations that can impact both performance and cost-effectiveness.

Advantages of OEM Components

OEM components are designed specifically for certain machines, ensuring compatibility and reliability. They often come with warranties and are backed by the manufacturer, which can provide peace of mind. Additionally, these parts are tested to meet the original performance standards, which is crucial for maintaining operational efficiency.

Benefits of Aftermarket Components

Aftermarket components can offer significant cost savings compared to their OEM counterparts. They often come with a wide range of options, allowing users to choose parts that may enhance performance or durability. However, quality can vary, making it essential to research reputable suppliers.

| Criteria | OEM Components | Aftermarket Components |

|---|---|---|

| Compatibility | Designed for specific models | Varies by manufacturer |

| Cost | Generally higher | Usually lower |

| Warranty | Often includes warranty | Varies by supplier |

| Performance | Guaranteed to meet specifications | May exceed or fall short of OEM standards |

Tips for Ordering Replacement Parts

Acquiring components for machinery can be a straightforward task if approached methodically. Understanding what to look for and how to effectively source these items is crucial for ensuring optimal performance and longevity of your equipment.

Here are some practical suggestions to enhance your ordering experience:

- Identify the Specific Component: Before placing an order, ensure you know the exact item needed. This may include checking model numbers or specifications.

- Consult the Manufacturer’s Documentation: Review any manuals or guides available. These documents often provide valuable insights into compatible components.

- Use Reputable Suppliers: Choose vendors with a solid reputation for selling quality items. This can save time and reduce the likelihood of errors.

- Check Availability: Ensure the desired components are in stock. Consider lead times for delivery when planning your maintenance schedule.

- Consider OEM vs. Aftermarket: Decide whether to purchase original equipment manufacturer (OEM) items or aftermarket alternatives based on your budget and requirements.

- Compare Prices: Don’t settle for the first price you see. Comparing costs from different suppliers can help find the best deal.

- Ask for Assistance: If unsure about what you need, reach out to experts or customer service representatives who can provide guidance.

By following these tips, you can streamline the process of acquiring the necessary components, ensuring that your equipment remains in excellent working condition.

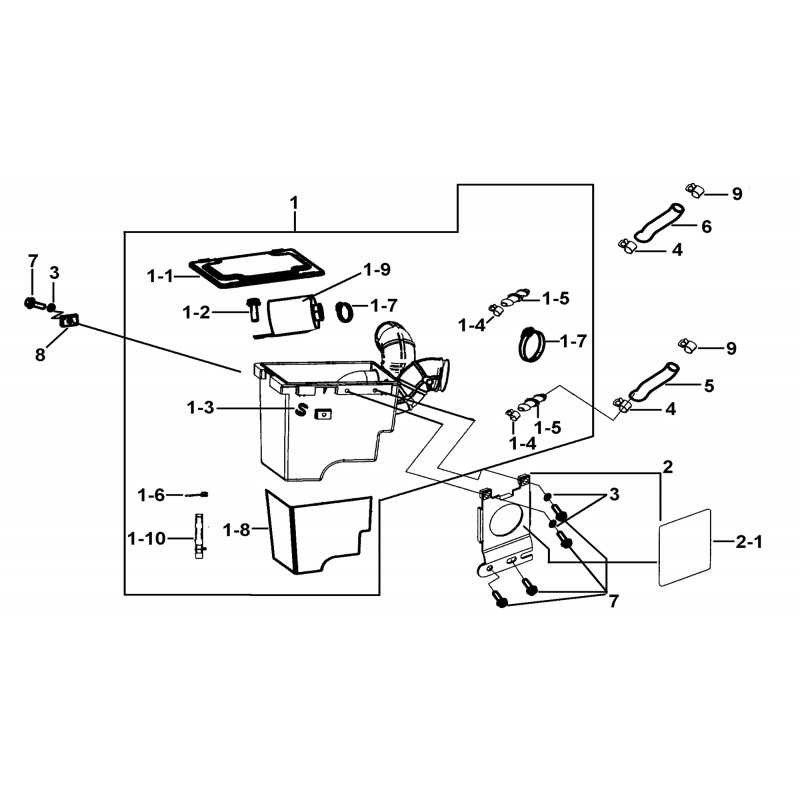

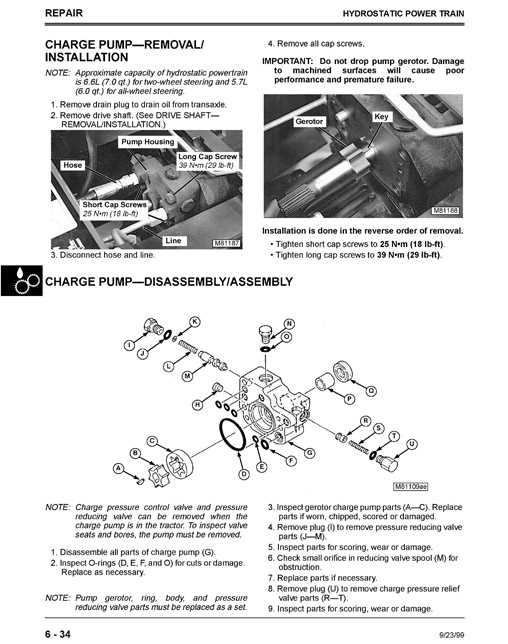

Understanding Assembly and Disassembly

Mastering the process of putting together and taking apart machinery is crucial for effective maintenance and repair. A solid comprehension of how components fit together can significantly enhance operational efficiency and extend the lifespan of equipment. This section aims to clarify the essential techniques and considerations involved in the assembly and disassembly of various mechanical units.

When approaching assembly, it’s vital to recognize the sequence of steps required to ensure that each part aligns correctly. Proper alignment not only facilitates smoother operation but also prevents potential damage during use. Additionally, familiarity with the tools and hardware necessary for the task is essential, as they play a key role in achieving a secure fit.

Conversely, during the disassembly phase, attention to detail is paramount. Carefully removing components while keeping track of their arrangement can simplify reassembly and avoid misplacement. Utilizing a systematic approach, such as labeling parts or documenting the order of disassembly, can greatly assist in this process.

In conclusion, having a thorough understanding of both assembly and disassembly techniques empowers individuals to maintain and repair equipment effectively, ensuring optimal performance and longevity.

Utilizing Online Resources and Forums

Accessing digital platforms and community discussions can greatly enhance the search for replacement components and maintenance information. These resources provide users with valuable insights, visual aids, and a sense of community support, which can be particularly beneficial for troubleshooting and upgrades.

Various websites offer extensive databases where users can explore component layouts and specifications. Engaging with online forums allows for the exchange of experiences and advice among fellow enthusiasts and professionals. These interactions can lead to practical solutions and tips tailored to specific models.

| Resource Type | Description | Examples |

|---|---|---|

| Manufacturer Websites | Official platforms that provide detailed information on products, including manuals and support. | Company X, Company Y |

| Community Forums | Online discussion boards where users share their experiences and troubleshooting advice. | Forum A, Forum B |

| Parts Retailers | Online shops that offer a variety of components and accessories, often with detailed diagrams. | Shop 1, Shop 2 |

| Video Tutorials | Visual guides that demonstrate installation, repairs, and maintenance techniques. | YouTube Channel A, YouTube Channel B |

Keeping Your Equipment in Top Shape

Maintaining machinery in excellent condition is crucial for optimal performance and longevity. Regular upkeep not only enhances efficiency but also prevents unexpected breakdowns, ensuring that your investments continue to serve you well over time.

Regular Maintenance Checks

Conducting routine inspections is essential for identifying potential issues before they escalate. Check fluid levels, filters, and belts to ensure everything functions smoothly. Addressing minor concerns early can save time and money in the long run.

Utilizing Quality Components

When replacing parts, always choose high-quality components that meet or exceed manufacturer specifications. Using superior materials and accessories not only enhances performance but also contributes to the overall durability of your equipment. Investing in quality is investing in the future.