In the realm of modern agriculture, the efficient functioning of machinery plays a crucial role in enhancing productivity. A thorough understanding of the various components within these machines is essential for optimal performance and maintenance. Each element is intricately designed to work in harmony, ensuring that operations run smoothly and effectively.

The intricacies of machinery often necessitate a detailed overview of their inner workings. By examining the relationships between individual elements, operators can gain insights into potential areas for improvement or repair. This knowledge empowers users to tackle issues proactively, thereby extending the lifespan of their equipment and minimizing downtime.

Whether one is a seasoned farmer or new to the industry, familiarizing oneself with the structure of these machines fosters confidence and competence. A well-informed approach not only enhances operational efficiency but also contributes to overall agricultural sustainability. Understanding how each component interacts within the larger system is key to maximizing both performance and productivity.

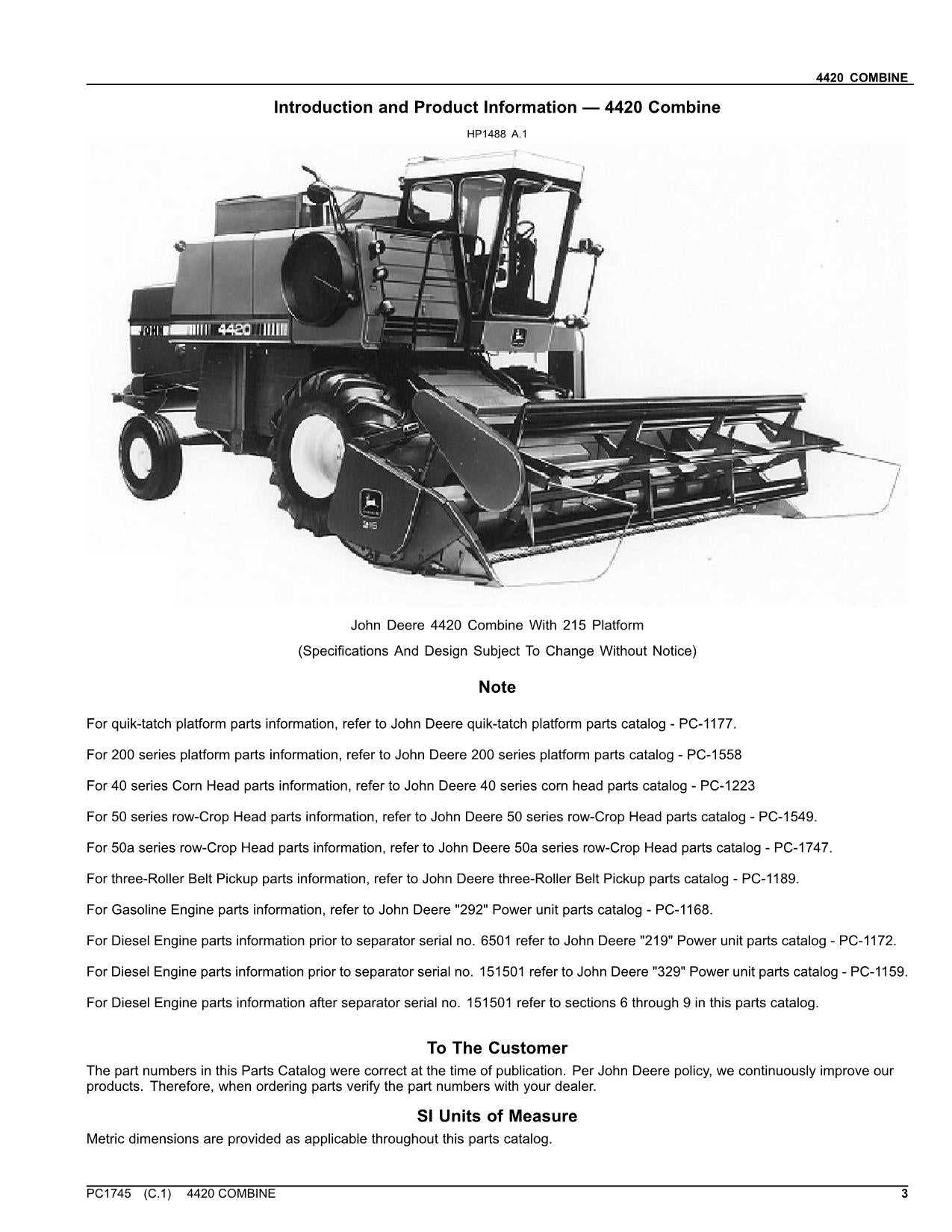

This section aims to provide a comprehensive look at a specific agricultural machine known for its efficiency and reliability. This equipment plays a crucial role in harvesting operations, designed to optimize productivity in the field. Understanding the various components of this machinery is essential for effective maintenance and operation, ensuring it performs at its best during critical harvesting periods.

| Component | Description | Function |

|---|---|---|

| Engine | A powerful unit designed for high performance. | Drives the entire machine, providing the necessary power for various operations. |

| Harvesting Header | Attached at the front, specifically designed for cutting crops. | Efficiently gathers and cuts the crop for processing. |

| Grain Tank | Storage area for harvested grains. | Holds collected produce until it can be unloaded. |

| Separator | Mechanism that separates grain from chaff. | Ensures the grains are clean and ready for storage. |

| Auger | Spiral component for moving materials. | Transfers harvested crops from the header to the grain tank. |

| Hydraulic System | System for power transmission through fluids. | Operates various components such as the header lift and steering. |

| Cab | Operator’s compartment, equipped for comfort and visibility. | Provides a controlled environment for the operator to manage operations. |

| Drive System | Includes tracks or wheels for mobility. | Facilitates movement across different terrains in the field. |

| Cleaning System | Series of screens and fans to remove debris. | Keeps the harvested grains clean and ready for market. |

| Control Panel | Interface for operating the machine. | Allows the operator to monitor and adjust various settings during operation. |

| Safety Features | Includes guards and sensors to prevent accidents. | Ensures the safe operation of the machine for the operator and bystanders. |

Key Features of the 4420 Model

The 4420 model stands out in its category, showcasing a blend of advanced technology and robust design. This exceptional machinery is engineered for efficiency and productivity, making it a preferred choice among operators. Its innovative features cater to diverse agricultural needs, ensuring reliable performance across various conditions.

Efficiency and Performance

One of the most significant attributes of this model is its ability to optimize performance while minimizing fuel consumption. The intelligent engineering behind the system allows for seamless operation, enhancing productivity during harvesting seasons. With a powerful engine and optimized drivetrain, users can expect swift and effective results in the field.

User-Friendly Design

The thoughtful design of the 4420 enhances user experience, providing easy access to controls and maintenance points. Operators benefit from ergonomic seating and intuitive interfaces, allowing them to manage operations with minimal effort. Additionally, the spacious layout contributes to comfort during long working hours, promoting overall efficiency.

Importance of Parts Identification

Accurate recognition of components is essential for effective maintenance and repair of machinery. Understanding each element’s function and location enhances efficiency and reduces downtime. This knowledge not only aids in prompt troubleshooting but also extends the lifespan of the equipment.

Benefits of Proper Identification

- Enhanced Efficiency: Knowing specific elements helps streamline repair processes, minimizing operational interruptions.

- Cost-Effectiveness: Correct identification prevents unnecessary purchases and reduces wastage by ensuring the right components are selected.

- Improved Safety: Familiarity with each part’s role contributes to safer operation and maintenance practices, reducing the risk of accidents.

Strategies for Effective Identification

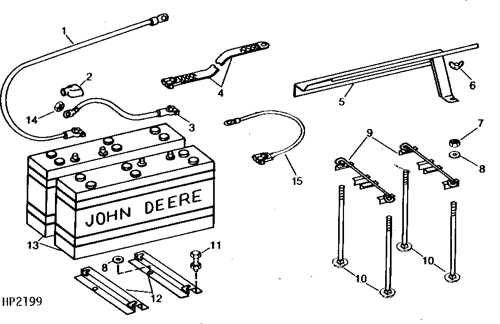

- Utilize Manuals: Refer to user manuals and guides for detailed information on machinery elements.

- Maintain a Reference Library: Keep a collection of diagrams and catalogs that can assist in recognizing various components.

- Engage with Experts: Consult with knowledgeable technicians or industry professionals to clarify any uncertainties regarding specific parts.

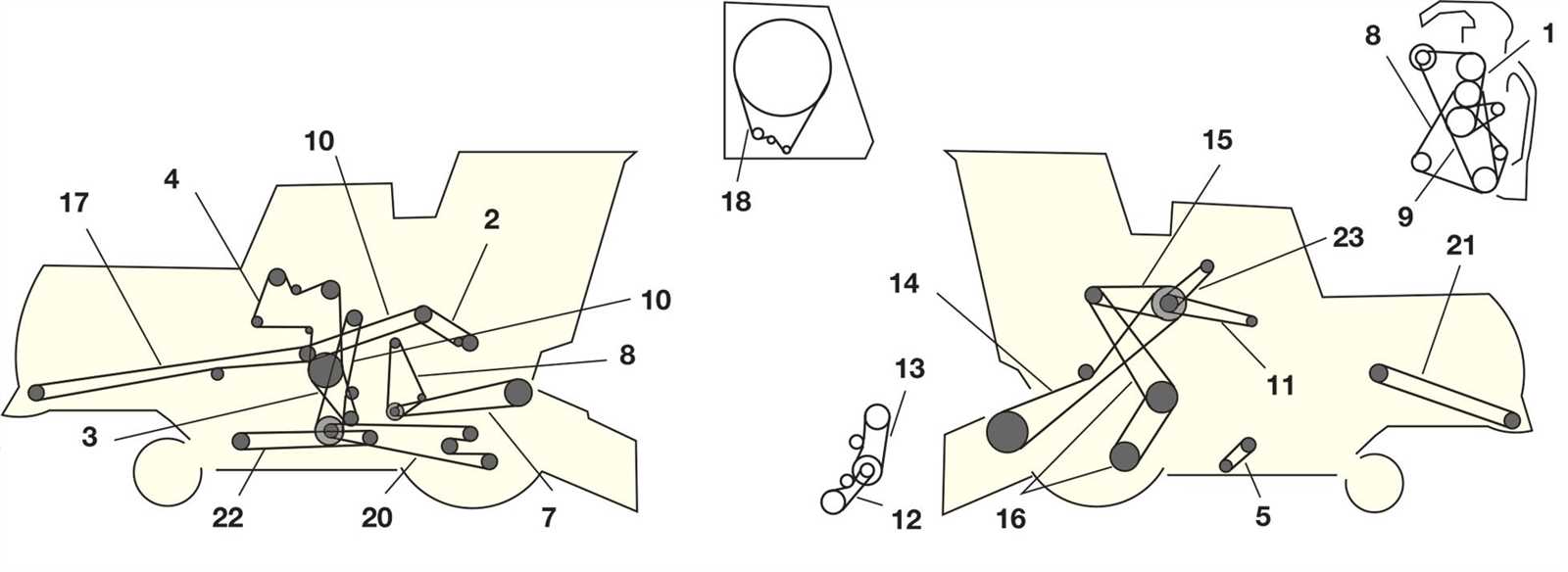

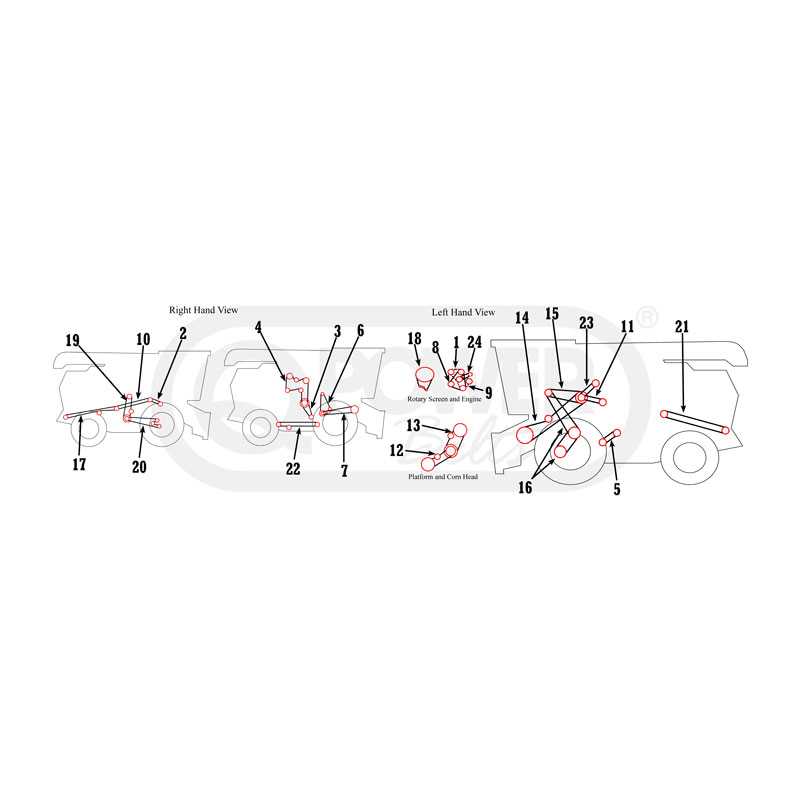

Detailed Parts Diagram Description

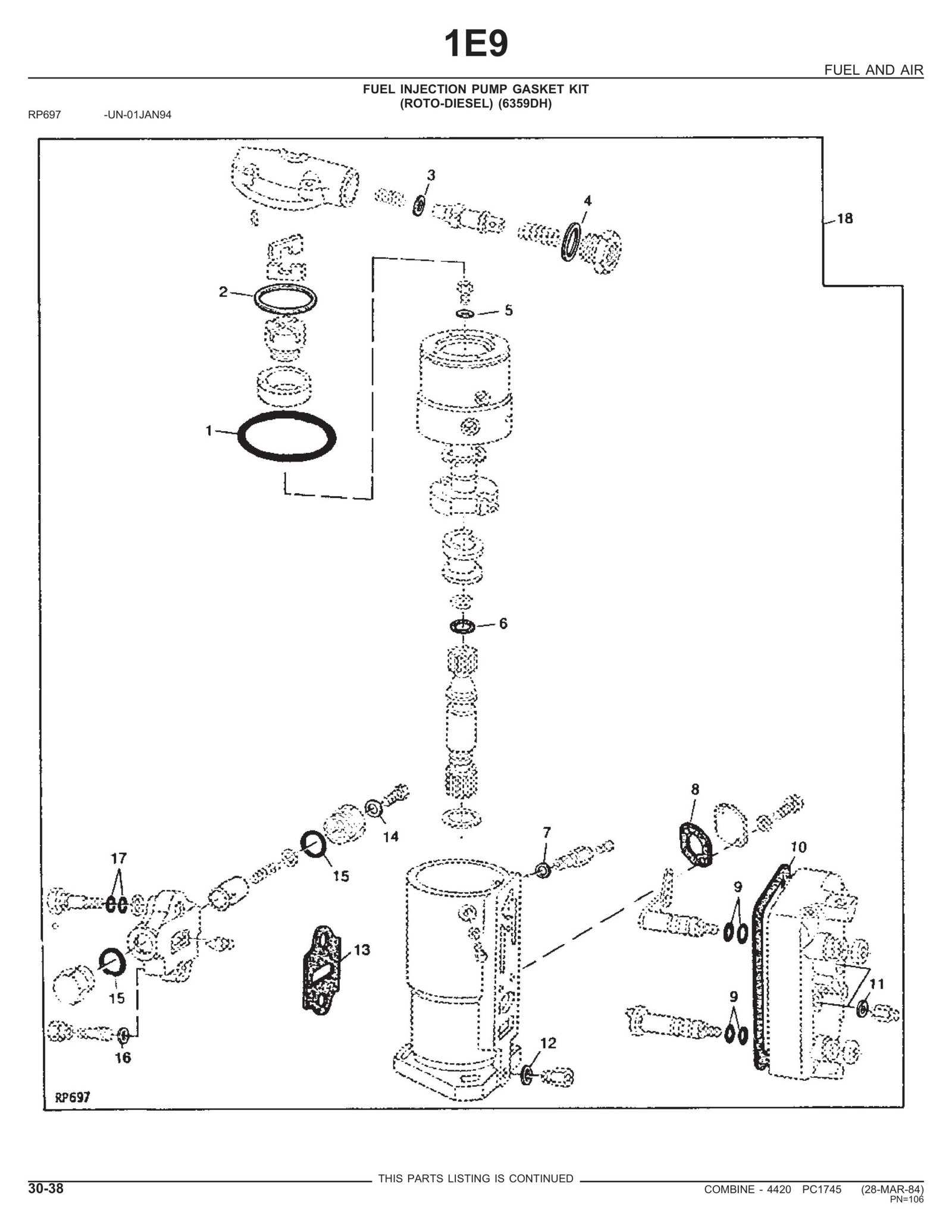

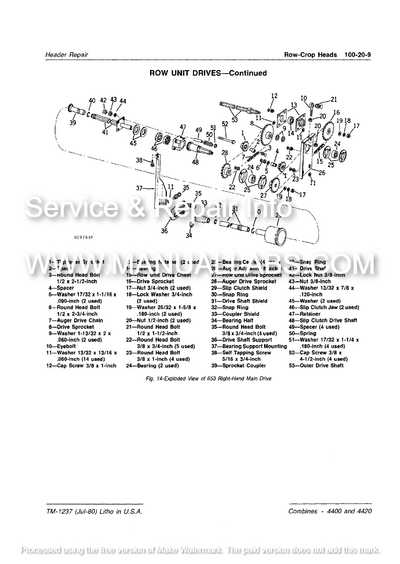

This section provides an in-depth exploration of the components and their relationships within the machine, offering a visual representation that aids in understanding its complex structure. A comprehensive overview is essential for maintenance and repairs, ensuring users can efficiently identify and address any issues.

Every element is meticulously illustrated, highlighting its function and placement within the system. The visual representation allows users to grasp the interconnectedness of various components, making it easier to pinpoint specific areas that may require attention. For instance, understanding the positioning of mechanical elements can significantly simplify troubleshooting processes.

Moreover, this detailed illustration serves as a valuable reference for operators and technicians alike. By having a clear depiction of the assembly, it becomes more manageable to plan service tasks and anticipate potential challenges. Users are encouraged to familiarize themselves with the layout, as this knowledge enhances operational efficiency and contributes to the longevity of the equipment.

In conclusion, an accurate and detailed representation of the components is vital for effective maintenance and repair work. It empowers users with the information needed to navigate the intricacies of the machinery confidently.

Common Issues and Troubleshooting

In agricultural machinery, various challenges can arise during operation, potentially hindering efficiency and performance. Understanding these common complications can facilitate timely interventions, minimizing downtime and repair costs. This section provides insights into typical problems faced by operators and effective solutions for troubleshooting.

Engine Performance Issues

One frequent concern involves engine performance, which can manifest as reduced power, unusual noises, or stalling. Regular maintenance, such as changing the air and fuel filters, can greatly enhance engine efficiency. Additionally, checking for any leaks or blockages in the fuel system is essential. Proper lubrication and monitoring engine temperature can also prevent overheating and ensure optimal functioning.

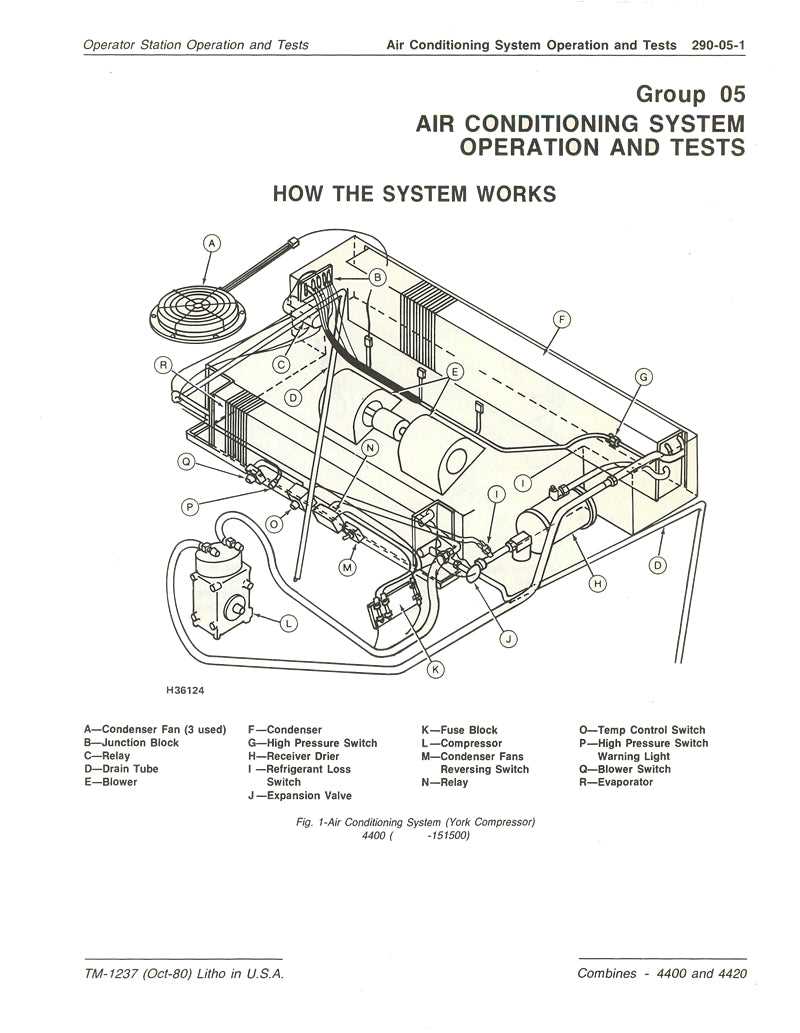

Hydraulic System Failures

The hydraulic system plays a crucial role in the functionality of machinery. Symptoms of malfunction may include slow or unresponsive operation of attachments. Operators should inspect hydraulic fluid levels and look for any signs of leaks in hoses and connections. Replacing worn seals and ensuring that filters are clean can help restore system performance and prevent further issues.

Replacement Parts Availability

Ensuring the longevity and optimal performance of agricultural machinery often requires access to suitable components. For those seeking to maintain or restore functionality, understanding the sources and options for procuring these essential elements is crucial. This section highlights the various avenues available for obtaining replacements, ensuring that operators can effectively manage their equipment.

Authorized Dealers

Authorized dealers are a reliable source for obtaining high-quality replacements. They typically offer genuine components, ensuring compatibility and performance standards are met. Engaging with these dealers often provides additional support, such as expert advice on installation and maintenance.

Aftermarket Suppliers

Aftermarket suppliers present an alternative for those looking for cost-effective options. These vendors provide a range of components, often designed to meet or exceed original specifications. While quality may vary, many aftermarket choices offer competitive pricing without sacrificing performance, making them an attractive option for operators on a budget.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the smooth operation and longevity of agricultural machinery. By adhering to a consistent maintenance routine, operators can prevent unexpected breakdowns and enhance the efficiency of their equipment. Below are some essential practices to keep in mind for optimal performance.

Routine Inspections

Conducting frequent inspections is crucial for identifying potential issues before they escalate. Check fluid levels, belts, and hoses for signs of wear. Ensure that all components are securely fastened and free from debris. This proactive approach helps maintain peak functionality.

Cleaning and Lubrication

Keep the machinery clean to prevent the buildup of dirt and grime, which can hinder performance. Regularly lubricate moving parts to reduce friction and wear. Utilize appropriate lubricants recommended by the manufacturer for optimal results. Remember that proper care will lead to increased reliability and efficiency in the long run.

Upgrading Components for Efficiency

Enhancing the performance of agricultural machinery involves strategic improvements to various components. By focusing on key elements, operators can significantly boost productivity and reduce downtime, ensuring a more streamlined harvesting process.

Investing in updated components can lead to several benefits:

- Improved fuel efficiency

- Enhanced operational speed

- Increased reliability and longevity

- Reduced maintenance costs

When considering upgrades, focus on the following areas:

- Engine Performance: Upgrading the engine can lead to better power output and efficiency. Consider enhancements such as performance tuning or installing a more advanced power unit.

- Hydraulic Systems: Modernizing hydraulic components can enhance lifting capabilities and responsiveness, leading to smoother operation.

- Electrical Systems: Implementing advanced electronic controls can optimize machinery operation and diagnostics, making it easier to monitor performance.

- Cutting Technology: Upgrading to higher-quality cutting heads or blades can improve the effectiveness of harvesting, ensuring cleaner cuts and less crop loss.

In summary, focusing on component upgrades is essential for maximizing efficiency in agricultural equipment. By making informed choices, operators can experience a noticeable improvement in overall performance and productivity.

Comparing with Other Combine Models

When evaluating different harvesting machines, it is essential to consider the unique features and specifications that set each model apart. Understanding the distinctions can help users make informed decisions based on their specific agricultural needs and preferences.

One popular alternative in the market offers advanced technology that enhances operational efficiency. Key aspects to compare include:

- Engine Performance: Evaluate the horsepower and fuel efficiency, as these factors directly impact productivity.

- Cutting Width: The size of the header can influence the amount of crop harvested in one pass.

- Grain Capacity: Consider the tank size and unloading speed to optimize workflow during busy harvest seasons.

- Comfort and Ergonomics: The design of the operator’s cabin, including visibility and ease of controls, can greatly affect user experience during long working hours.

Additionally, examining the technology integration in each model is vital. Features such as GPS guidance, yield monitoring, and automated settings can significantly enhance productivity. Understanding how these elements compare can provide valuable insights for potential buyers.

Ultimately, selecting the right harvesting equipment requires thorough research and comparison. By analyzing various models, operators can identify which machine aligns best with their operational goals and farming practices.

User Experiences and Feedback

This section highlights the insights and opinions of users regarding their experiences with the agricultural machinery. Understanding feedback from operators and owners can provide valuable perspectives on functionality, reliability, and overall performance. Many individuals share their thoughts on usability, maintenance challenges, and enhancements that could improve efficiency in the field.

General Impressions

Users often express satisfaction with the machine’s capabilities, noting its robust design and effectiveness in various farming tasks. Efficiency is a recurring theme in reviews, with many operators praising how it handles large volumes of work while maintaining high performance. However, some feedback points to areas for improvement, particularly regarding certain components that may require more frequent attention.

Suggestions for Improvement

Feedback from the community frequently includes suggestions for enhancements. Operators recommend better access to certain mechanisms for maintenance, as well as improvements in specific features that can streamline operations. Constructive criticism plays a vital role in informing manufacturers about user needs, ultimately leading to better products and experiences for future owners.

Resources for Parts and Service

Finding reliable resources for maintenance and replacement components is crucial for ensuring the longevity and optimal performance of your agricultural machinery. Whether you are seeking manuals, suppliers, or community support, there are various avenues to explore that can help streamline your service needs.

Here are some valuable options for accessing necessary components and service information:

| Resource Type | Description | Website/Contact |

|---|---|---|

| Manufacturer’s Website | Official site providing detailed specifications, service manuals, and updates on available items. | www.example.com |

| Local Dealers | Authorized dealerships offering a wide selection of genuine items and expert service. | Contact your nearest dealer |

| Online Retailers | Various e-commerce platforms specializing in agricultural machinery supplies, often featuring competitive pricing. | www.partsstore.com |

| Forums and Communities | Online groups where enthusiasts and professionals share advice, experiences, and recommendations on service and components. | www.agriculturalforum.com |

Future of John Deere Combines

The evolution of agricultural machinery is crucial for enhancing productivity and sustainability in farming. Innovations in technology and design are leading to advanced solutions that cater to the changing needs of the agricultural industry. This section explores the potential developments and trends that could shape the next generation of harvesting equipment.

Technological Advancements

Emerging technologies, such as precision agriculture and automation, are transforming the way harvesting is conducted. The integration of smart sensors, data analytics, and artificial intelligence will enable operators to make informed decisions, improving efficiency and reducing waste. These innovations promise to streamline operations and enhance yield quality.

Sustainability Initiatives

As environmental concerns grow, the push for more sustainable agricultural practices becomes paramount. Future machinery is expected to prioritize eco-friendly features, including fuel efficiency and reduced emissions. The incorporation of renewable energy sources and sustainable materials in design will also play a significant role in shaping the future of these machines.

| Innovation | Description |

|---|---|

| Automation | Implementation of autonomous systems for enhanced operational efficiency. |

| Data Analytics | Utilization of big data for optimizing harvest strategies and resource allocation. |

| Eco-Friendly Features | Design improvements aimed at reducing environmental impact and promoting sustainability. |