When preparing your machinery for the colder months, it’s essential to understand the various tools and add-ons that can enhance its functionality. Specialized accessories designed for clearing paths and dealing with icy surfaces play a vital role in ensuring effective performance during harsh weather.

Each component involved in these setups works together to provide reliability and efficiency. Whether you’re maintaining walkways or larger spaces, choosing the right configurations will significantly improve your equipment’s durability and utility during wintertime operations.

Understanding the assembly and placement of these elements ensures smooth operation, and it is crucial to keep all mechanisms in optimal condition for consistent results in challenging environments.

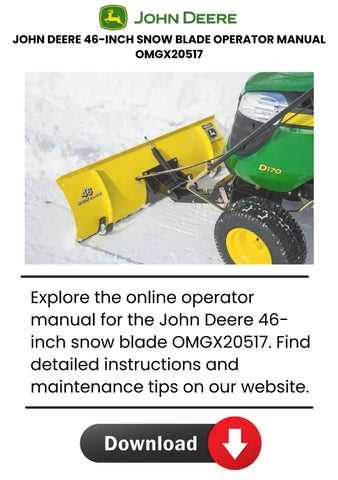

John Deere 46 Snow Blade Overview

Designed to tackle challenging winter conditions, this equipment offers an efficient way to manage accumulated precipitation on various surfaces. It’s built for reliability and ensures that heavy work is completed smoothly and effectively, making it an essential tool for clearing driveways, roads, and other outdoor areas.

This implement is characterized by its sturdy construction and precision in handling difficult weather scenarios. It allows users to control ground coverage effectively while being robust enough to withstand the toughest tasks. Its functionality ensures a clean and safe environment during the colder months.

With easy attachment features and adaptable positioning, this tool is suited for a wide range of outdoor maintenance tasks. The adjustable design enhances usability, while the durable materials ensure longevity, even after repeated use in harsh conditions.

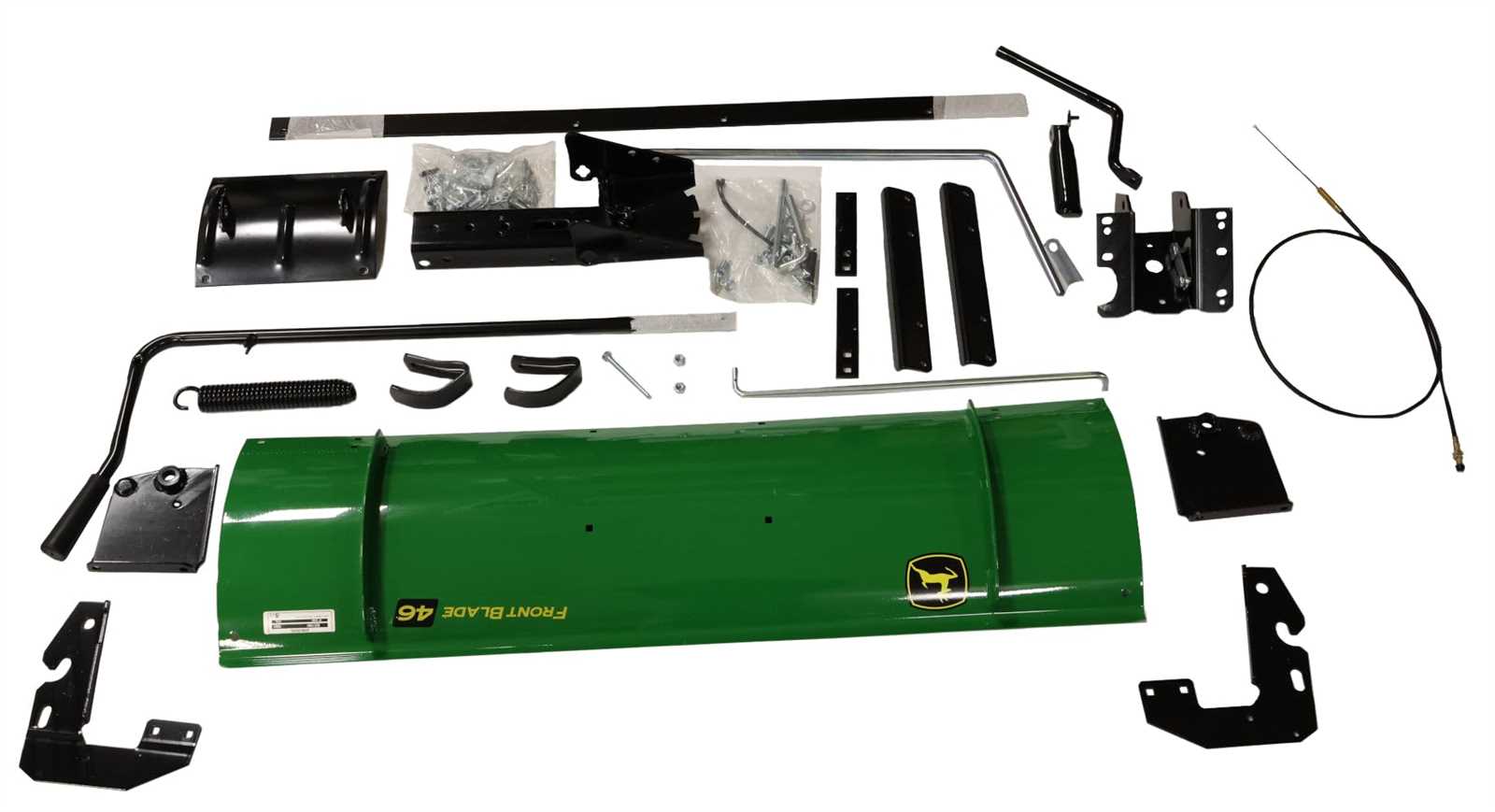

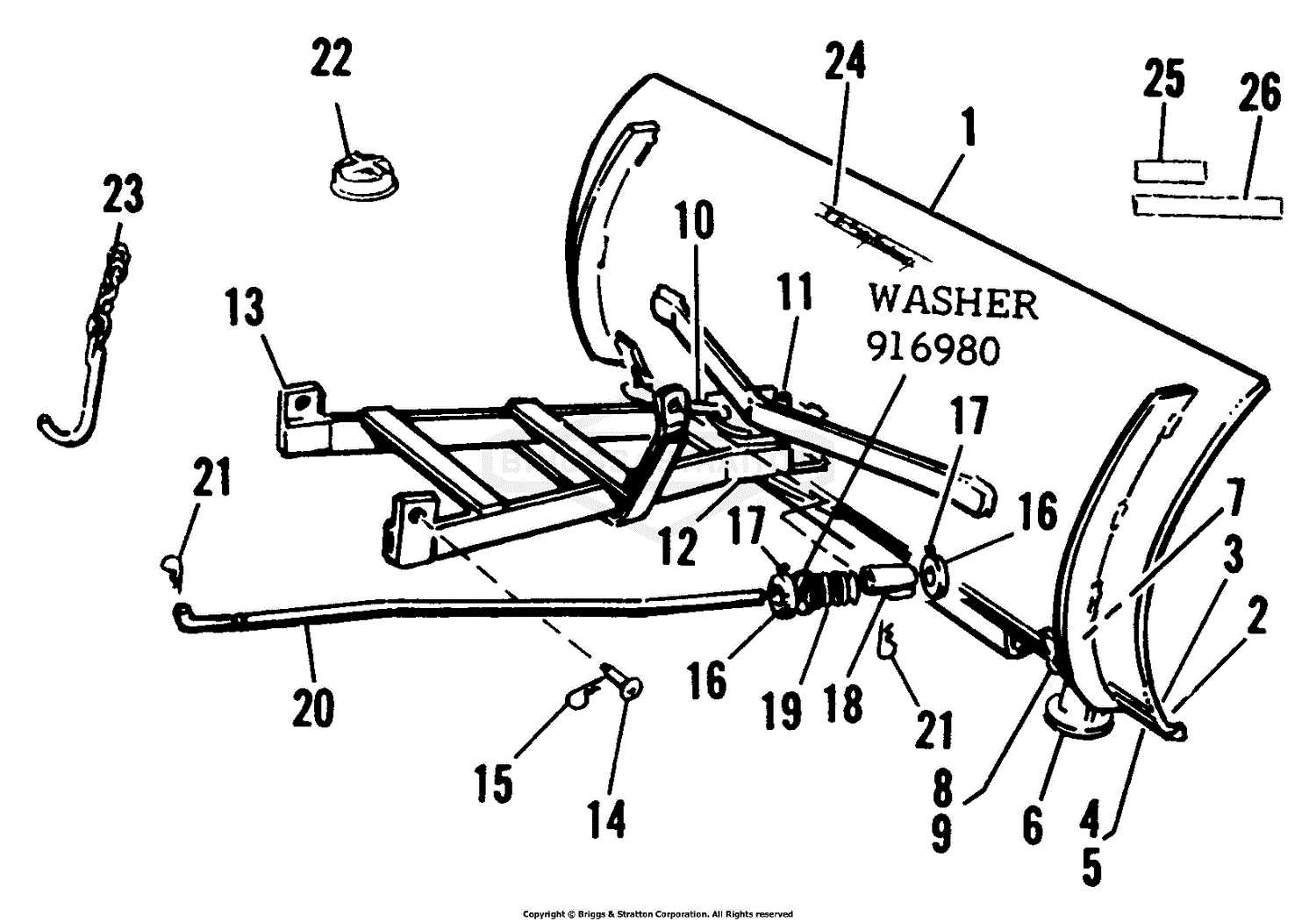

Essential Components of the 46 Snow Blade

Understanding the key elements of this attachment is crucial for effective operation and maintenance. Each part of the structure plays a specific role in ensuring smooth performance during use. Below, we explore the primary mechanical sections that work together to provide stability and control.

Cutting Edge: This reinforced strip along the bottom edge ensures proper ground contact, allowing for effective material displacement. It’s designed for durability and efficiency in challenging conditions.

Mounting Frame: The core structure that attaches the unit to the equipment, offering secure and reliable support. Its design ensures a tight fit and flexibility during movement.

Hydraulic Mechanism: The system responsible for adjusting the angle and position of the device, ensuring that the operator can maneuver with precision. The hydraulic setup allows for smooth adjustments without excessive manual effort.

Control Levers: These allow the operator to control the angle and height of the unit. The easy-to-use levers provide precision adjustments during operation, enhancing the overall usability of the attachment.

Support Brackets: Essential for stability, these brackets secure the entire

How to Identify Worn Snow Blade Parts

Understanding when certain components need replacement is crucial for maintaining the efficiency of your equipment. Identifying signs of wear early on can prevent larger, more costly issues. Below are some common indicators of wear that can help you assess the condition of key elements.

- Uneven Cutting Edge: Check if the cutting surface is no longer smooth or if it shows significant wear on one side. This can affect performance and efficiency.

- Excessive Rust or Corrosion: Rust weakens metal parts over time, reducing their durability. Look for corrosion, especially on areas exposed to moisture.

- Loose Fasteners: Inspect bolts and other connectors. If they frequently become loose, it may indicate a need for replacement or re-tightening.

- Deformation or Bending: Components may show signs of bending or twisting due to heavy use. If any part appears misshaped, it can hinder functionality.

- Cracks or Breakage: Visible cracks or fractures are a

Replacing the Cutting Edge on the Snow Removal Attachment

The cutting edge is a crucial component that wears down over time and requires replacement to maintain optimal performance of your snow removal equipment. Proper maintenance and timely replacement of this part ensures smooth and efficient operation during winter months. In this section, we’ll cover the essential steps for safely replacing the cutting edge, ensuring your attachment continues to perform as expected.

Steps for Removing the Old Cutting Edge

Begin by parking your vehicle on a level surface and ensuring the attachment is properly secured. Carefully inspect the existing edge for signs of wear, such as cracks or uneven surfaces. If replacement is necessary, follow these steps:

Step Description 1 Loosen and remove the bolts securing the current edge in place. 2 Carefully detach the worn cutting edge from the mounting frame. 3 Inspect the mounting area for debris or damage, cleaning if necessary. Installing the New Cutting Edge

Common Issues with Snow Blade Attachment

When attaching a winter implement to your equipment, several problems may arise due to improper installation, wear, or environmental factors. Identifying these issues early can help ensure smooth operation and prevent costly repairs.

- Misalignment: If the attachment is not properly aligned with the machine, it can cause uneven wear and affect its performance.

- Hydraulic Malfunctions: Leaking or damaged hoses may reduce functionality, causing the attachment to move slower or stop responding entirely.

- Connection Failure: Loose bolts or improper mounting can lead to detachment, creating safety risks and operational delays.

- Rust and Corrosion: Exposure to moisture and salt can result in rust, weakening critical components and affecting their longevity.

- Wear and Tear: Frequent use in tough conditions can cause parts to wear out faster, leading to breakdowns if not maintained regularly.

By addressing these potential issues early, you can improve the longevity and efficiency of your equipment’s attachment during winter months.

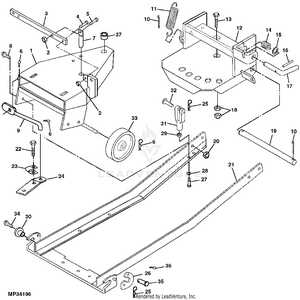

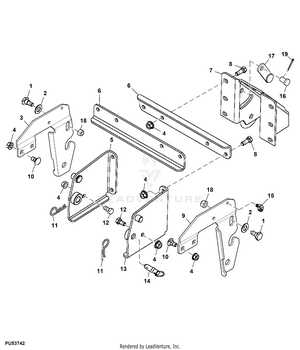

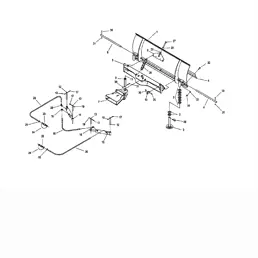

Understanding the Blade Mounting Mechanism

The attachment system for the front implement is crucial for ensuring effective operation and versatility in various tasks. A robust and well-designed mounting mechanism allows for seamless attachment and detachment, facilitating the swift exchange of equipment as needed. This section will explore the fundamental aspects of how these systems work, focusing on the various components and their roles in providing stability and reliability during use.

At the core of this mechanism lies a series of connectors and supports designed to secure the implement to the main frame. These elements must work in unison to distribute weight evenly, reducing the risk of failure during operation. Understanding these components can aid in identifying potential issues and implementing effective maintenance strategies.

The mounting hardware typically includes brackets, pins, and locking mechanisms, each serving a specific purpose. For instance, the brackets provide the primary connection points, while pins ensure that the implement remains securely fastened during operation. Properly maintaining these components is essential to prolong the lifespan of the equipment and ensure optimal performance.

Maintenance Tips for the Snow Blade Frame

Proper upkeep of your equipment’s framework is crucial for optimal performance and longevity. Regular attention not only ensures efficient operation but also extends the life of your machinery. Following a systematic maintenance routine can prevent common issues and save you time and money in the long run.

Routine Inspections

Conducting regular checks on the structure is essential. Look for signs of wear, rust, or damage. Pay special attention to the joints and connections, as these areas are prone to stress. Ensuring that all bolts and fasteners are tightened can help maintain stability during use.

Cleaning and Lubrication

Keep the framework clean from debris and snow buildup. Use a brush or air compressor to remove dirt and grime that can hinder performance. Additionally, applying appropriate lubricants to moving parts will reduce friction and wear, promoting smoother operation. Regular maintenance of these components will lead to better efficiency and prevent unnecessary repairs.

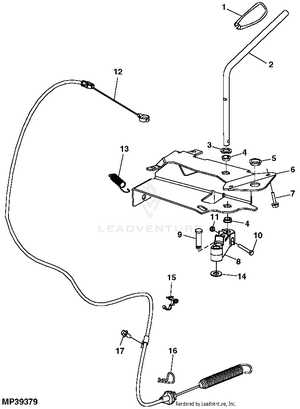

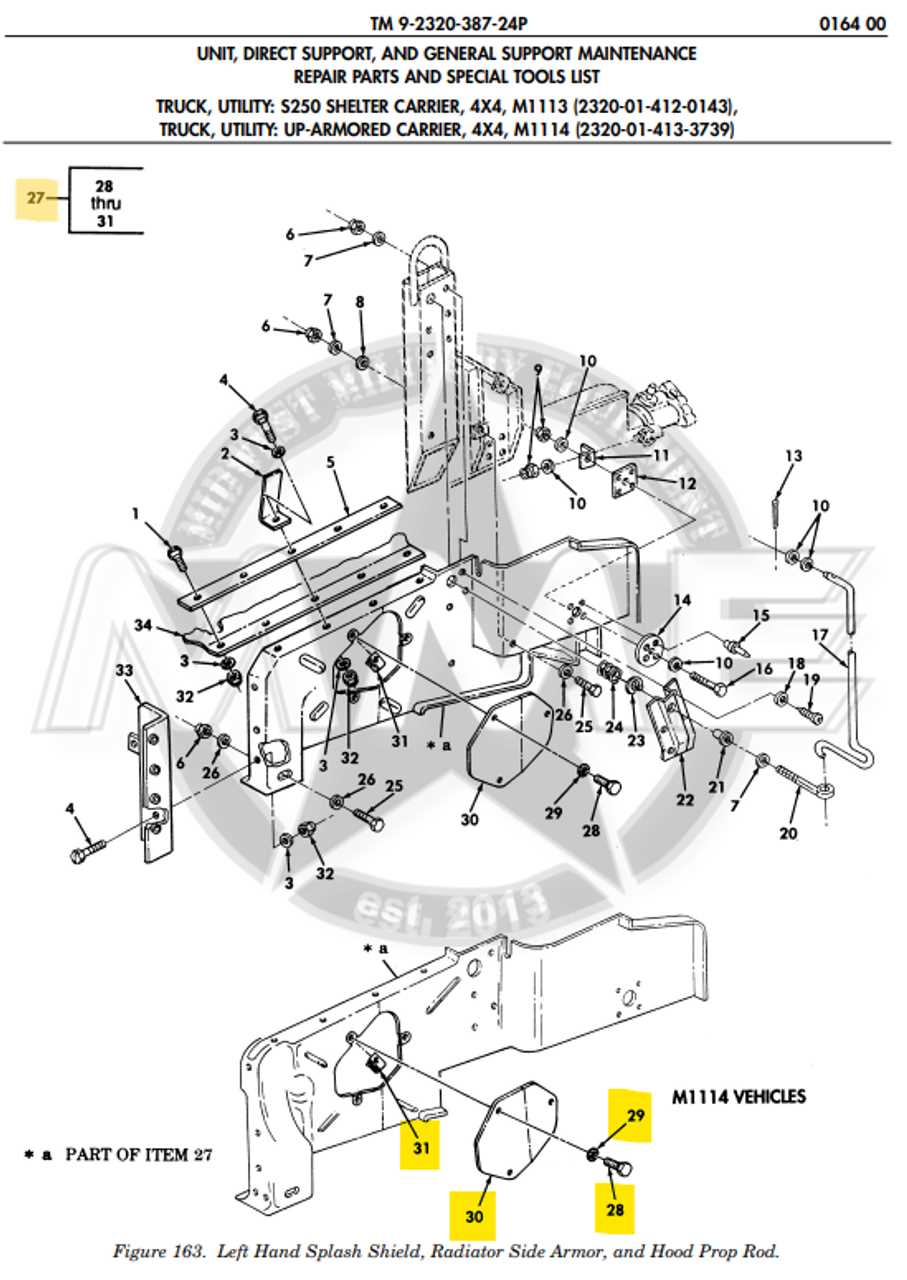

Exploring Hydraulic Lift and Angle Systems

The functionality of equipment in various agricultural and construction settings heavily relies on advanced systems for lifting and angling implements. These hydraulic mechanisms provide enhanced control and efficiency, allowing operators to adjust attachments with precision according to the demands of the task. Understanding these systems is crucial for effective equipment management and maintenance.

Key Components of Hydraulic Systems

Hydraulic lift and angle systems consist of several essential parts that work in harmony to facilitate smooth operations. The main components include:

- Hydraulic Cylinder: This device converts hydraulic energy into mechanical force, enabling the lift or angle adjustments.

- Hydraulic Pump: Responsible for generating flow and pressure in the hydraulic system, the pump ensures that fluid reaches the cylinders effectively.

- Control Valves: These valves manage the flow of hydraulic fluid, allowing the operator to direct the movement of the equipment as needed.

- Fluid Reservoir: A storage unit that holds hydraulic fluid, ensuring a constant supply to the system.

Benefits of Hydraulic Systems

Utilizing hydraulic systems for lifting and angling offers several advantages:

- Precision Control: Operators can make fine adjustments to the position of implements, enhancing accuracy in various applications.

- Increased Efficiency: Hydraulic systems operate quickly and effectively, reducing the time required for tasks.

- Enhanced Durability: Designed to withstand demanding conditions, these systems typically require less maintenance than mechanical alternatives.

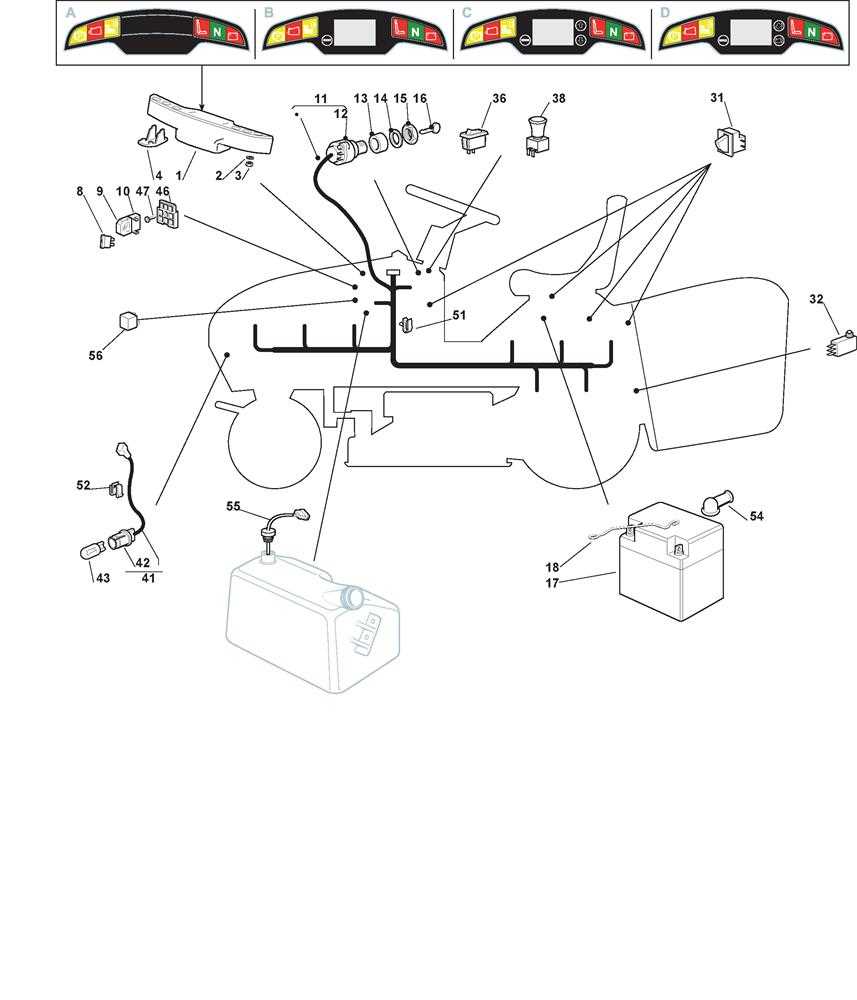

Compatible Parts for John Deere 46 Blade

Understanding the essential components that fit a specific model can significantly enhance performance and functionality. This section delves into the various compatible elements designed for effective operation and maintenance, ensuring optimal performance in various conditions.

Essential Components

Key components include attachment hardware, replacement wear strips, and support brackets. These elements are crucial for ensuring durability and reliability during use. Choosing high-quality alternatives can lead to improved efficiency and extended lifespan.

Aftermarket Options

Several aftermarket solutions are available that provide excellent performance without sacrificing quality. These options often come with competitive pricing, making them an appealing choice for users looking to enhance their equipment without breaking the bank.

Guidelines for Adjusting Blade Angle

Properly setting the angle of your implement can significantly enhance its effectiveness during operation. Ensuring the correct alignment allows for optimal performance, making tasks easier and more efficient. This section outlines essential practices to adjust the angle correctly, ensuring that your equipment operates smoothly and meets your specific requirements.

1. Assess Your Terrain: Before making any adjustments, evaluate the surface you will be working on. Different types of ground require varying angles for effective results. Flat surfaces may need less angle, while sloped areas might require a more pronounced adjustment.

2. Locate the Adjustment Mechanism: Identify the mechanism used to change the angle. This could involve a lever, pin, or hydraulic system, depending on your equipment. Familiarize yourself with its operation for seamless adjustments.

3. Make Incremental Adjustments: Start by making small changes to the angle and test the performance. Gradually increase or decrease the angle based on your observations. This iterative approach helps find the most effective setting without overcompensating.

4. Monitor Performance: After each adjustment, observe how the implement interacts with the surface. Look for signs of effective material movement or any issues that may arise. Adjust accordingly to achieve optimal results.

5. Maintain Consistency: Once you find the ideal angle, ensure it is maintained during operation. Regular checks can prevent unintentional shifts that could affect performance. Consistency is key to achieving the best outcomes in your tasks.

6. Consult the Manual: Always refer to the equipment manual for specific recommendations regarding angle adjustments. This resource can provide valuable insights and guidelines tailored to your particular model.

Safety Precautions for Blade Operation

Operating the blade requires careful attention to safety measures to ensure smooth and secure handling of the equipment. Before engaging in any maneuvers, it is crucial to understand and implement the necessary precautions.

1. Awareness and Preparation

- Ensure thorough understanding of operational guidelines.

- Familiarize yourself with the safety features and mechanisms.

- Inspect the surrounding area for obstacles and hazards.

2. Proper Gear and Maintenance

- Wear appropriate safety gear, including protective clothing and gloves.

- Regularly inspect the blade and associated equipment for any signs of wear or malfunction.

- Keep all components well-maintained and lubricated to ensure optimal performance.

By adhering to these precautions, operators can enhance safety and efficiency during blade operations, promoting a secure working environment without compromise.

Upgrading the Snow Blade for Better Performance

Enhancing the efficiency of your winter attachment can significantly improve its functionality and durability. By making thoughtful upgrades, you can ensure that your equipment operates at peak performance, allowing for more effective snow removal. Whether it’s through improved materials, advanced designs, or enhanced features, every modification contributes to a smoother experience during harsh weather conditions.

Material Improvements

One of the most impactful changes involves using high-quality materials that withstand wear and tear. Opting for hardened steel or specialized composites can lead to increased longevity and reduced maintenance. These materials not only resist rust and corrosion but also enhance the overall strength of the device, ensuring it can tackle even the heaviest accumulations.

Enhanced Features

Incorporating additional features such as adjustable angles or quick-release mechanisms can greatly enhance usability. Adjustable angles allow for better maneuverability, while quick-release options make attachment and detachment effortless. Investing in these enhancements can lead to a more versatile and user-friendly experience, ultimately improving productivity during snow clearing tasks.

Storage and Care Tips for the Snow Blade

Proper maintenance and storage of your equipment ensure longevity and reliable performance during winter seasons. Keeping your snow blade in optimal condition requires regular attention and care.

Cleaning After Use

After clearing snow, thoroughly clean the blade to remove any debris, salt residue, or moisture that could lead to corrosion. Use a brush or gentle cloth to wipe down the blade surface.

Storage Environment

Store the blade in a dry, sheltered area to protect it from harsh weather conditions and UV exposure. Ensure it is elevated to prevent contact with moisture and ground contaminants.

Regular Inspection of the blade’s components such as bolts, hinges, and hydraulic systems helps detect wear and tear early, preventing costly repairs and ensuring safe operation.

By following these storage and care tips, you can prolong the lifespan and efficiency of your snow-clearing equipment.