In the realm of modern farming, machinery plays a pivotal role in enhancing productivity and efficiency. An intricate system of components works together to ensure that operations run smoothly, allowing for optimal harvesting and processing of crops. A comprehensive understanding of these elements is essential for farmers and technicians alike, enabling them to maintain equipment effectively and troubleshoot issues that may arise.

Focusing on a specific model, one can uncover a wealth of information regarding its operational mechanisms. By exploring the intricate layouts and configurations, users can gain insights into how each segment interacts with others. This knowledge not only aids in the proper functioning of the machine but also extends its lifespan, ultimately contributing to better agricultural outcomes.

Detailed illustrations serve as valuable resources for anyone looking to familiarize themselves with the inner workings of agricultural equipment. They provide clarity on the arrangement and roles of various components, simplifying the maintenance process and enhancing repair efficiency. Embracing this understanding empowers users to navigate challenges with confidence and precision.

Overview of John Deere 468 Baler

This section provides a comprehensive look at a particular model of agricultural machinery designed for efficient harvesting and baling of various crops. Understanding its design and functionality is essential for optimizing its use in the field.

Key Features

- Robust construction for durability

- High-capacity operation for increased productivity

- Advanced technology for precise bale formation

- User-friendly controls for ease of operation

Benefits

- Enhanced efficiency during harvesting seasons

- Improved quality of bales for better storage and transport

- Reduced maintenance needs due to superior design

- Versatility to handle various crop types

Importance of Baler Maintenance

Regular upkeep of agricultural machinery is crucial for optimal performance and longevity. Ensuring that every component functions correctly minimizes downtime and enhances efficiency during operations. Neglecting maintenance can lead to costly repairs and decreased productivity, impacting overall output.

Consistent inspections allow for early detection of wear and tear, enabling timely interventions that prevent further damage. Implementing a routine maintenance schedule fosters reliability and ensures that the equipment meets the demands of seasonal work. Ultimately, a proactive approach not only safeguards investments but also enhances operational success.

Common Issues with 468 Balers

Operators often encounter several frequent challenges when working with these machinery types. Understanding these issues can enhance performance and extend the lifespan of the equipment.

- Jamming: Material can become lodged, causing interruptions in operation.

- Misalignment: Components may shift over time, affecting the overall efficiency.

- Worn Components: Parts can degrade with use, leading to decreased functionality.

- Hydraulic Problems: Issues in the hydraulic system can hinder movement and operation.

Regular maintenance and timely repairs can significantly mitigate these problems, ensuring optimal performance.

Key Components of the Baler

Understanding the fundamental elements of a hay compression machine is essential for efficient operation and maintenance. These core parts work in harmony to ensure the machine performs its primary function effectively, transforming loose forage into compact bales.

| Component | Description |

|---|---|

| Feed Mechanism | This system transports the material into the chamber for compression, ensuring a steady flow for optimal operation. |

| Compression Chamber | The central area where the material is compacted into a dense form, essential for creating bales of uniform size. |

| Tie Mechanism | This component secures the bales by wrapping them with twine or netting, providing stability during handling and transport. |

| Pickup Header | A crucial part that gathers material from the ground and directs it into the feed system, maximizing efficiency. |

| Drive System | The mechanism that powers all operational functions, typically involving belts, gears, or hydraulic components to facilitate movement. |

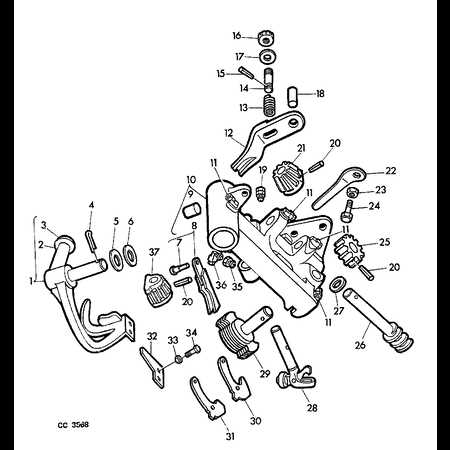

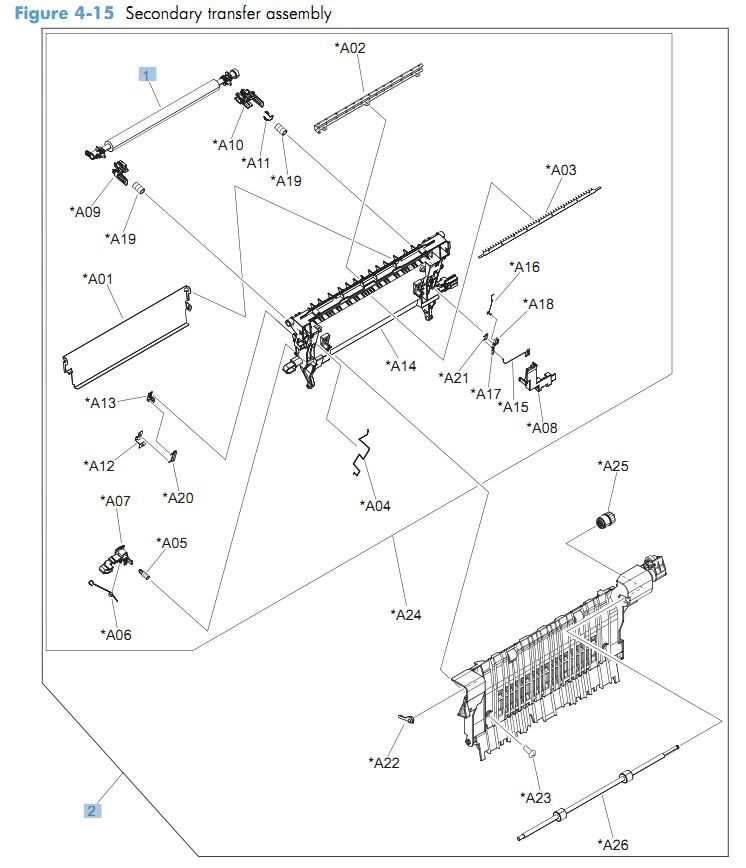

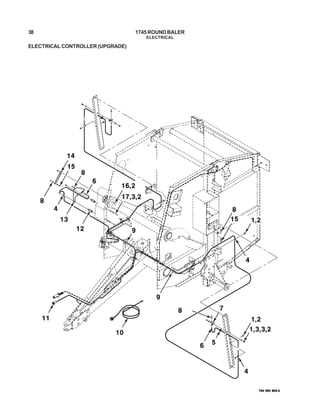

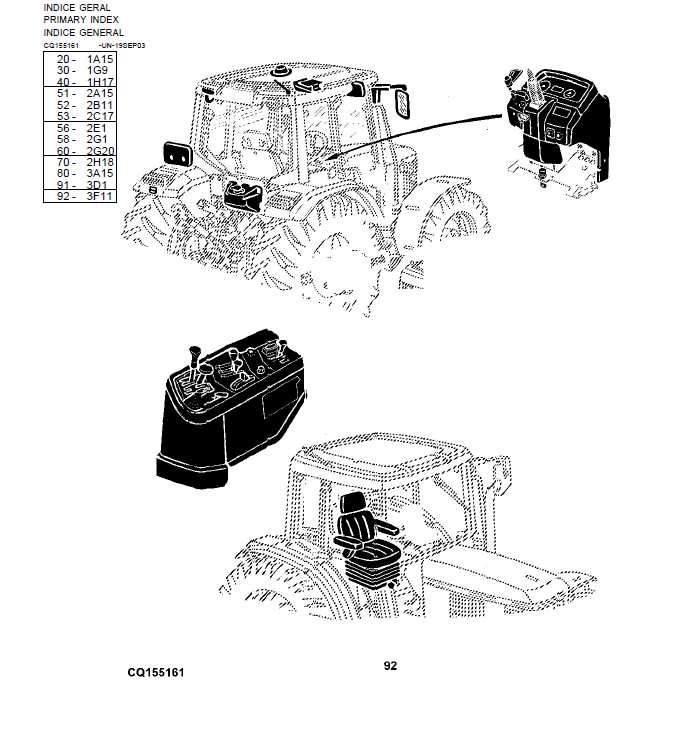

Understanding Baler Parts Diagram

Recognizing the components of machinery used for harvesting and processing materials is essential for effective operation and maintenance. A comprehensive overview of these elements helps users identify each part’s function, facilitating repairs and enhancing performance.

Components are typically organized in a visual representation, providing clarity on their arrangement and interconnections. This graphical layout serves as a valuable tool for both novice and experienced operators, enabling them to troubleshoot issues and perform routine upkeep efficiently.

| Component Name | Description |

|---|---|

| Feed System | Guides material into the machine for processing. |

| Compression Chamber | Where the material is compacted into a manageable form. |

| Drive Mechanism | Powers the operation of the machine and its various components. |

| Discharge System | Releases the finished product from the machine. |

| Control Panel | Allows operators to manage settings and monitor performance. |

Understanding the arrangement and function of these components is crucial for maximizing efficiency and ensuring the longevity of the equipment. Familiarity with this visual guide empowers users to maintain their machines effectively and make informed decisions during operation.

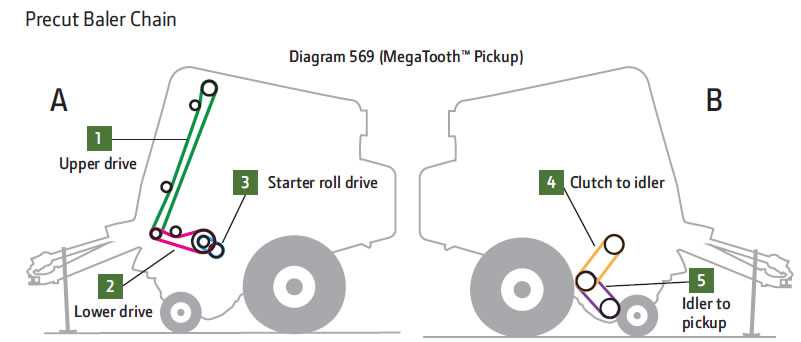

How to Read the Diagram

Understanding a schematic representation of machinery is crucial for effective maintenance and repair. These visuals provide detailed information about components and their relationships, making it easier to identify issues and locate necessary parts.

To effectively interpret these illustrations, follow these steps:

- Familiarize Yourself with Symbols: Each icon represents a specific component. Make sure to learn what each symbol means.

- Follow the Flow: Diagrams often show the sequence of operations. Trace the lines to understand how parts interact.

- Check the Legend: Most visuals include a key that explains symbols and color codes. Refer to it frequently.

- Identify Groupings: Look for clusters of components that work together. This helps in troubleshooting specific areas.

By mastering these techniques, you will enhance your ability to troubleshoot and repair effectively, ensuring optimal performance of your machinery.

Replacement Parts for the 468

Maintaining optimal performance in agricultural machinery requires timely replacements of essential components. Understanding the various elements that contribute to the functionality of these machines is crucial for ensuring efficient operation and longevity.

Common Components to Consider

When assessing the necessary elements for replacement, several key components frequently require attention. These may include drive belts, bearings, and hydraulic systems, all of which play a vital role in the overall efficiency of the equipment.

Replacement Options and Availability

Finding suitable options for replacements can significantly enhance performance. Many suppliers offer a range of components designed to meet the specific needs of agricultural machines. Below is a table outlining some of the commonly replaced components along with their typical specifications:

| Component | Specification | Recommended Supplier |

|---|---|---|

| Drive Belt | Heavy-duty, 1.5 inches wide | Supplier A |

| Bearing | Ball bearing, 6204 size | Supplier B |

| Hydraulic Cylinder | Double-acting, 2 inches diameter | Supplier C |

Identifying Worn Components

Recognizing deteriorated elements in agricultural machinery is crucial for maintaining optimal performance and longevity. Understanding the signs of wear can prevent breakdowns and enhance efficiency.

Common Indicators of Wear

- Visible cracks or breaks

- Increased noise during operation

- Unusual vibrations

- Excessive heat generation

Inspection Checklist

- Examine all moving parts for irregularities.

- Check for signs of rust or corrosion.

- Look for any misalignments or loose fittings.

- Monitor performance changes during use.

Best Practices for Repairs

When it comes to maintaining and restoring machinery, adhering to effective strategies is essential for ensuring optimal performance and longevity. Utilizing the right techniques can minimize downtime and enhance overall efficiency during repair processes.

1. Thorough Inspection

Before initiating any repair work, conducting a comprehensive inspection of the equipment is crucial. This step allows for the identification of all potential issues, not just the obvious ones. Documentation of these findings will aid in prioritizing repairs and ensuring no critical areas are overlooked.

2. Use Quality Components

Employing high-quality replacement components is vital for the success of any repair. Investing in durable materials will not only enhance the functionality of the equipment but also reduce the likelihood of future breakdowns. Always opt for reputable suppliers to ensure reliability and compatibility with your machinery.

Tools Needed for Maintenance

Proper upkeep of agricultural machinery requires specific implements to ensure efficiency and longevity. Having the right tools at hand facilitates smooth operation and timely repairs, minimizing downtime during critical periods of use.

Essential tools typically include wrenches and sockets for tightening and loosening bolts, pliers for gripping and bending, and screwdrivers for adjusting various components. Additionally, a comprehensive set of lubricants and greases is vital for maintaining moving parts and preventing wear.

For more intricate repairs, specialized tools such as torque wrenches, alignment tools, and diagnostic equipment may be necessary. These instruments help ensure that every aspect of the machinery functions optimally, contributing to overall productivity.

Lastly, safety gear, including gloves and goggles, should not be overlooked, as they protect operators from potential hazards during maintenance tasks. A well-equipped toolkit is the foundation for successful machinery management.

Where to Find Parts Online

In the search for components for agricultural machinery, the internet offers a vast array of options. Numerous platforms cater to those seeking to restore or maintain their equipment efficiently. Utilizing online resources can save time and ensure access to the necessary items for optimal functionality.

Specialized Retailers

Many online retailers focus exclusively on machinery supplies. These specialized stores often provide detailed catalogs and expert advice, making it easier to locate specific items. Exploring reviews and ratings can also help ensure a reliable purchasing experience.

Marketplace Platforms

Additionally, popular marketplace platforms feature numerous sellers offering a wide range of components. Comparing prices and checking seller ratings is crucial when navigating these sites. Engaging with community forums can also lead to recommendations for trustworthy vendors.

Comparing Models: 468 vs. Others

This section explores the distinctions and similarities among various models in the same category, highlighting key features and functionalities that can influence purchasing decisions.

When assessing these machines, several factors should be considered:

- Performance: Evaluate how each model handles different tasks and conditions.

- Efficiency: Look at fuel consumption and output levels.

- Durability: Consider the longevity and maintenance requirements of each option.

In addition to these criteria, comparing specific aspects can offer insights:

- Technology: Review the advanced features and automation in newer models.

- Capacity: Assess the size and volume capabilities of each machine.

- Cost: Analyze the initial investment versus long-term savings.

By delving into these comparisons, users can make informed decisions that suit their agricultural needs.

Tips for Efficient Baling Operations

Optimizing the process of creating compact bundles of forage or crop residue requires careful planning and execution. By employing effective techniques and maintaining equipment, operators can enhance productivity and reduce waste.

| Tip | Description |

|---|---|

| Regular Maintenance | Ensure machinery is serviced regularly to prevent breakdowns and ensure peak performance. |

| Proper Timing | Bale at the optimal moisture level to enhance quality and reduce spoilage. |

| Efficient Workflow | Organize operations to minimize downtime, including strategic positioning of equipment. |

| Operator Training | Invest in training to ensure all operators understand best practices and equipment features. |

| Monitor Conditions | Stay aware of weather conditions and adjust operations accordingly for best results. |