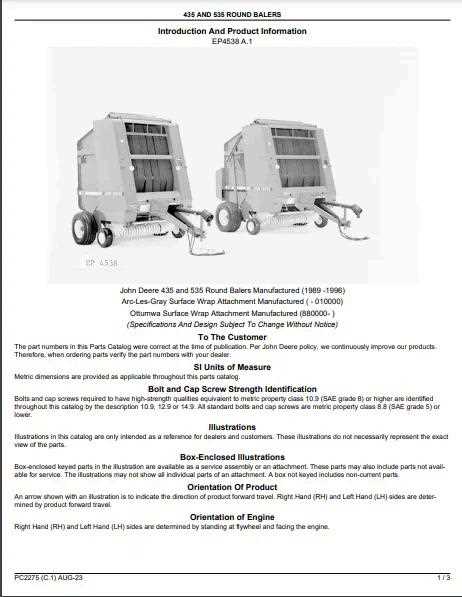

In the realm of farming equipment, comprehending the structure and functionality of machinery is essential for optimal performance and maintenance. Recognizing how various elements interact within a specific model can significantly enhance operational efficiency and reduce downtime during critical periods.

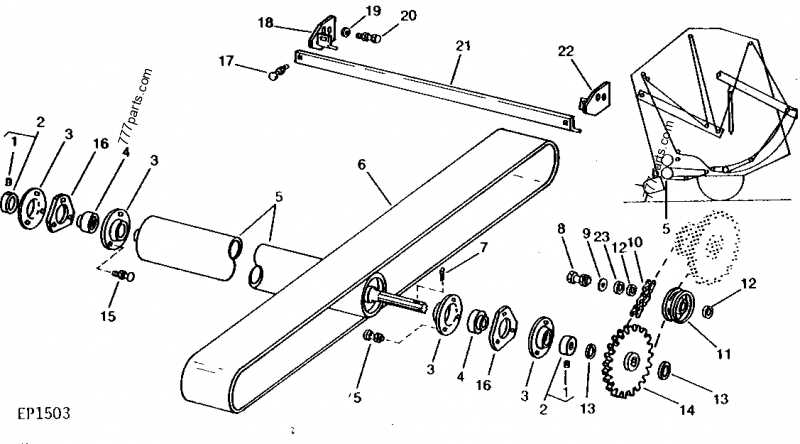

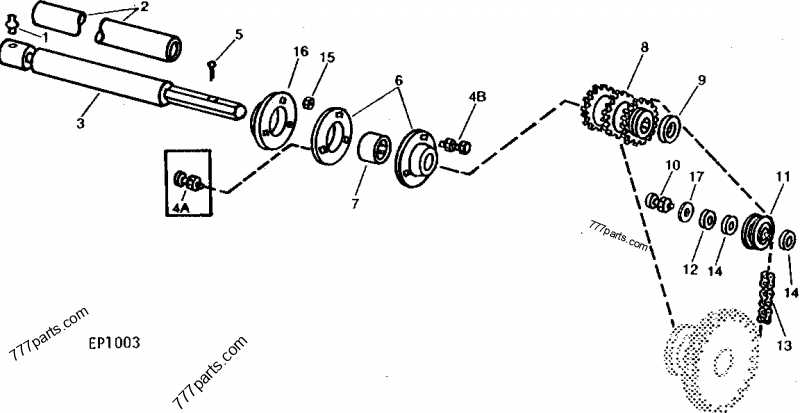

Detailed illustrations serve as valuable resources for operators and technicians alike. They facilitate a deeper understanding of the internal workings and allow for more straightforward troubleshooting and repair processes. Familiarity with these visual aids can empower users to perform maintenance tasks confidently and effectively.

By studying comprehensive visuals of essential machinery components, users can ensure their equipment remains in peak condition. This knowledge not only contributes to smoother operations but also extends the lifespan of vital agricultural assets.

This section aims to provide a comprehensive understanding of a specific type of agricultural machinery. It focuses on the essential components that contribute to its operation, ensuring efficiency and reliability in the field. By delving into the various elements, users can better appreciate how each part plays a vital role in the overall functionality.

Key features of this machinery include:

- Durable construction for long-lasting performance

- Innovative design for enhanced usability

- Versatile applications in different agricultural settings

In this overview, the following aspects will be discussed:

- Functionality of major components

- Maintenance tips for optimal performance

- Common issues and troubleshooting methods

Understanding these aspects will enable users to operate the machine more effectively, ensuring that it meets the demands of various tasks in the agricultural sector.

Key Features and Specifications

This section outlines the essential characteristics and technical details of the specific machinery, highlighting its functionality and performance attributes.

- Engine Power: The equipment boasts robust engine power, ensuring efficient operation and reliability during heavy-duty tasks.

- Dimensions: Compact dimensions facilitate maneuverability in various working environments.

- Weight: The unit’s weight is optimized for stability while maintaining transportability.

- Capacity: Designed with high capacity to handle substantial workloads, enhancing productivity.

- Durability: Built with premium materials, ensuring longevity and resistance to wear and tear.

- Maintenance: Features easy access points for routine maintenance, minimizing downtime and enhancing operational efficiency.

These attributes collectively contribute to the machinery’s effectiveness in agricultural applications, making it a valuable asset for users.

Common Issues with Baler Parts

Understanding frequent challenges associated with agricultural machinery components is essential for maintaining optimal performance. Operators often encounter various malfunctions that can hinder efficiency and lead to costly repairs. Recognizing these issues early can prevent further complications and downtime.

One prevalent problem involves wear and tear on moving elements, which can result in diminished functionality. Additionally, misalignment or improper adjustments may cause inconsistent operation, affecting the overall output. Regular inspections and timely replacements can help mitigate these risks.

Another common concern is the accumulation of debris and material clogs, which can obstruct normal operation. Ensuring that machinery is cleaned and maintained frequently can reduce the likelihood of such occurrences. Operators should also be vigilant about potential leaks or damaged seals, as these can lead to more significant mechanical failures over time.

Maintenance Tips for Longevity

Proper upkeep of agricultural machinery is essential for ensuring optimal performance and extending its lifespan. By implementing regular maintenance practices, operators can prevent costly repairs and enhance efficiency. Here are some key strategies to maintain equipment effectively.

Regular Inspection and Cleaning

- Conduct thorough inspections before and after each use to identify any wear or damage.

- Clean all components, including the exterior and internal parts, to prevent buildup of debris.

- Check belts and chains for signs of fraying or excessive wear, and replace them as needed.

Lubrication and Adjustments

- Regularly lubricate moving parts to reduce friction and prevent rust formation.

- Adjust tension on belts and chains to ensure proper operation.

- Follow the manufacturer’s recommendations for lubrication intervals and types of grease.

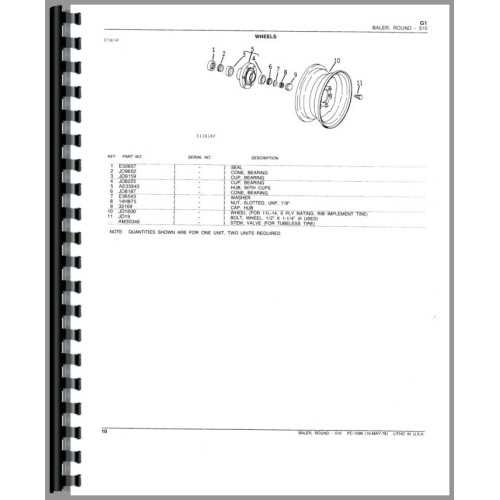

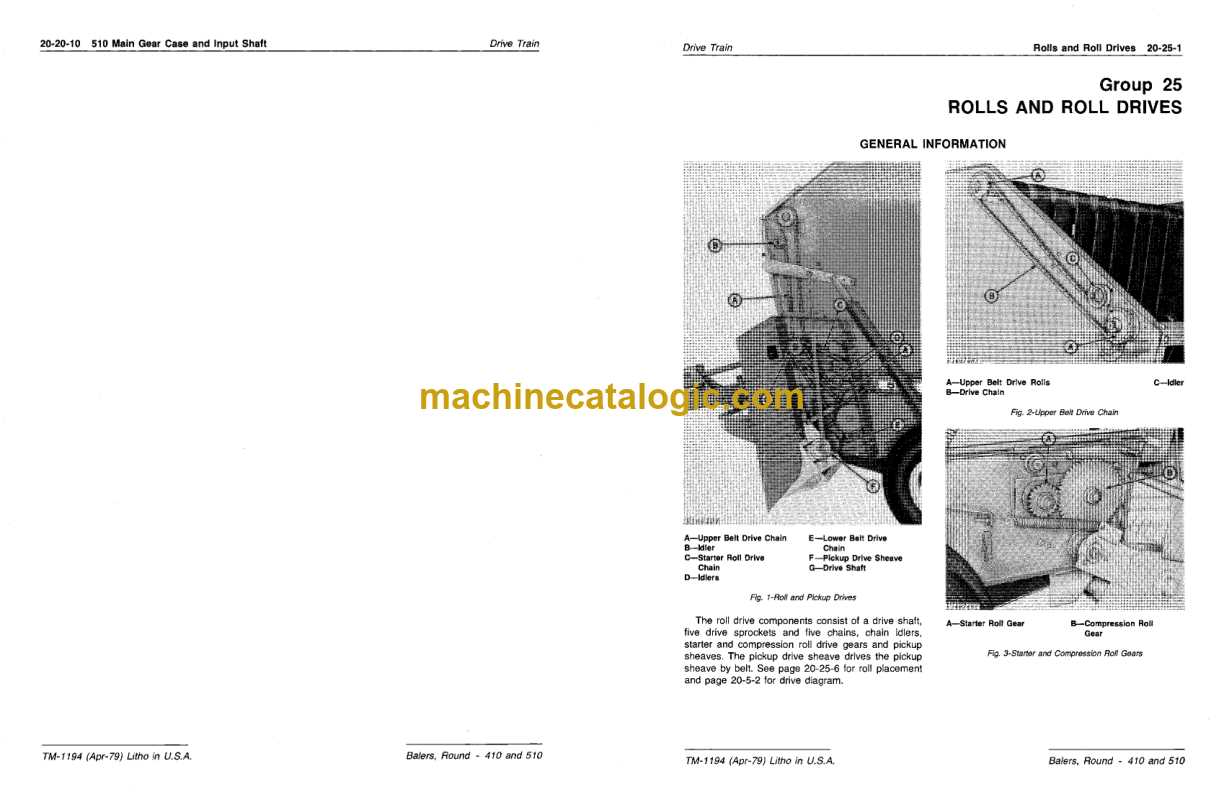

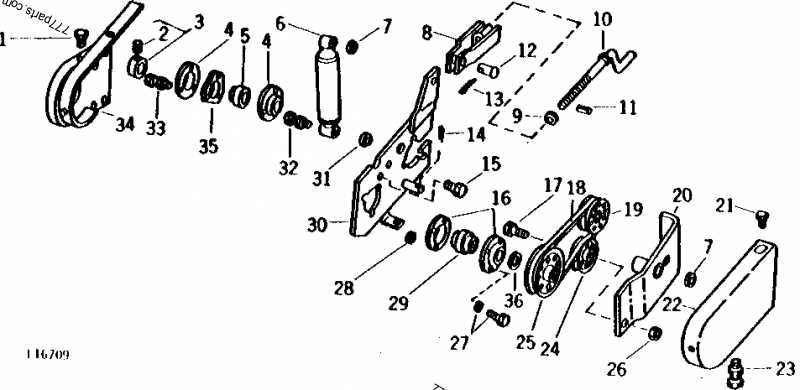

Understanding the Parts Diagram

The visual representation of components is essential for anyone looking to maintain or repair machinery. By examining these illustrations, users can gain insights into the structure and function of various elements, enabling informed decisions regarding upkeep and modifications.

Key Features: Each section of the illustration serves a specific purpose, outlining the relationship between different components. This clarity helps in identifying potential issues and understanding how each part contributes to the overall operation.

Benefits of Familiarity: Being well-versed in the component layout not only streamlines maintenance tasks but also enhances troubleshooting efficiency. Recognizing the location and role of each element can significantly reduce downtime and ensure optimal performance.

Critical Components of the Baler

The functionality of a harvesting machine relies heavily on its essential elements. Understanding these key components is vital for effective operation and maintenance. Each element plays a specific role in ensuring optimal performance and longevity.

Main Operational Elements

Among the crucial components are the mechanisms that facilitate the compression and tying processes. These systems are designed to manage the flow of material efficiently, ensuring that the end product is compact and secure. Regular inspections of these mechanisms are recommended to prevent breakdowns and maintain productivity.

Structural Components

The frame and supporting structures form the backbone of the equipment, providing stability during operation. These elements must be robust enough to withstand the rigors of heavy use while ensuring that all other components function seamlessly. Periodic maintenance is essential to detect any wear or damage that may compromise the integrity of the machine.

Replacement Parts Availability

Ensuring the functionality of agricultural equipment is crucial for optimal performance and productivity. Access to quality replacement components is essential for maintaining machinery in excellent working condition. This section explores the availability of such items, focusing on various options for sourcing them.

Sources for Components

- Authorized Dealers: Many manufacturers offer certified retailers that provide genuine items, ensuring compatibility and reliability.

- Aftermarket Suppliers: Numerous companies specialize in producing high-quality alternatives at competitive prices, catering to different needs.

- Online Retailers: E-commerce platforms have become increasingly popular for purchasing machinery components, offering convenience and a wide selection.

- Local Salvage Yards: For cost-effective solutions, salvage yards may have used equipment and components available for purchase.

Considerations for Purchasing

- Compatibility: Always verify that the selected items are suitable for the specific model of machinery.

- Quality Assurance: Look for warranties and guarantees to ensure the longevity of the purchased components.

- Pricing: Compare prices from different sources to find the best value without compromising quality.

- Customer Reviews: Research feedback from other users to assess the reliability of suppliers and the components they offer.

Installation Process for New Parts

Installing new components in agricultural machinery is a critical task that requires careful attention to detail and adherence to safety protocols. This section outlines the essential steps involved in the process, ensuring that the equipment operates efficiently and reliably.

Before starting the installation, it is important to gather all necessary tools and replacement components. Ensuring that everything is ready beforehand will streamline the process and minimize downtime.

| Step | Description |

|---|---|

| 1 | Disconnect the machine from the power source to ensure safety during the installation. |

| 2 | Remove the old component carefully, taking note of how it is connected to facilitate the installation of the new item. |

| 3 | Inspect surrounding areas for any signs of wear or damage that may need attention before proceeding. |

| 4 | Install the new component, ensuring that it is secured correctly to avoid operational issues. |

| 5 | Reconnect the power source and perform a test run to confirm that the installation was successful. |

Following these steps carefully will help ensure that the new components function as intended, contributing to the overall performance of the machinery.

Safety Precautions During Repairs

When engaging in maintenance activities on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Understanding potential hazards and taking appropriate measures can significantly enhance the repair process and ensure a secure environment for the technician.

Always wear protective gear, such as gloves, goggles, and sturdy footwear, to safeguard against physical harm and exposure to hazardous materials. Proper attire reduces the risk of injuries and enhances overall safety while working.

Ensure that the equipment is powered down and disconnected from any energy sources before commencing any repairs. This precautionary step minimizes the chances of accidental activation, which could lead to severe injuries.

Utilize tools properly and ensure that they are in good condition. Damaged or inappropriate tools can contribute to accidents during repairs. Regularly inspect and maintain your tools to ensure they operate safely and effectively.

Maintain a clean and organized workspace to prevent slips, trips, and falls. Keeping tools and parts neatly arranged not only enhances efficiency but also reduces the likelihood of accidents caused by clutter.

Be aware of your surroundings and communicate clearly with any team members involved in the repair process. Maintaining vigilance can help identify potential hazards early and foster a collaborative safety culture.

Resources for Technical Support

Accessing reliable support materials is essential for maintaining and troubleshooting equipment effectively. Various resources can assist users in understanding machinery and addressing any challenges that may arise during operation. These resources range from manuals to online communities, offering diverse ways to enhance knowledge and resolve issues.

User Manuals and Guides

Comprehensive documentation serves as a fundamental resource for operators. These manuals typically include detailed instructions on operation, maintenance, and troubleshooting. Users are encouraged to download or request physical copies of these guides to ensure they have the necessary information readily available.

Online Forums and Communities

Engaging with online platforms allows users to connect with fellow operators and technical experts. These forums often provide a space for sharing experiences, solutions, and advice. Participating in such communities can be invaluable for gaining insights and discovering innovative approaches to common problems.