Agricultural machinery is designed with intricate systems, making it essential to understand the key elements that contribute to its efficiency and performance. Whether you’re performing maintenance or assembling new attachments, a clear understanding of each component and how they interact ensures smoother operation.

Each piece of equipment comes with its own unique structure, but the basic principles of organization and connectivity remain consistent. Knowing the internal structure and the function of individual components allows for better troubleshooting and enhanced long-term reliability.

Recognizing component connections and layout structures is fundamental when working with complex machinery. By understanding the assembly and relationship between parts, you can improve your ability to maintain and repair your equipment effectively, ensuring that it performs at its best in the field.

John Deere 54 Plow Overview

The equipment discussed here is a versatile and reliable tool designed for efficient soil management. With its robust build, it provides excellent durability and performance, making it a trusted companion in various agricultural tasks. Its unique features allow for easy adaptation to different terrains, ensuring smooth and consistent operation in diverse conditions.

| Feature | Description |

|---|---|

| Durability | Built from high-quality materials to withstand long-term use. |

| Performance | Engineered for efficient soil turning and cultivation. |

| Adaptability | Can be adjusted to work on various types of terrain and soil conditions. |

| Ease of Use | Simple design for quick setup and easy operation. |

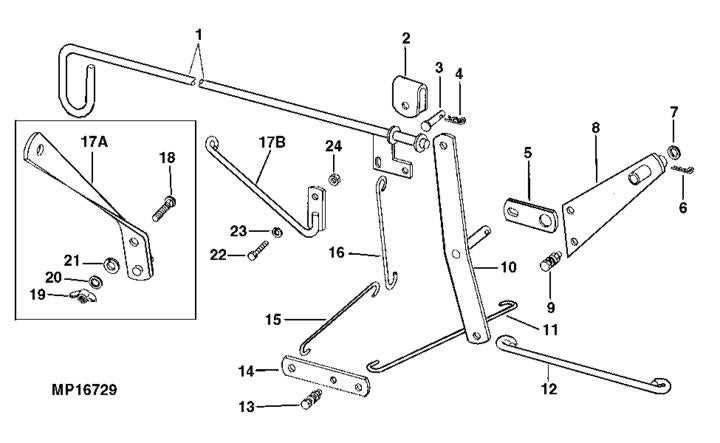

Essential Components of the John Deere 54 Plow

The functionality of any heavy-duty agricultural tool relies on key mechanisms designed to enhance efficiency and durability. In this section, we will explore the fundamental parts that contribute to the reliable operation of such equipment. These critical elements are designed to ensure smooth soil penetration, easy handling, and consistent performance during fieldwork.

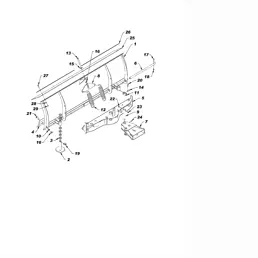

Main Structural Elements

The core of the system is composed of various durable sections that provide stability and support during operation. These components are carefully engineered to handle the stresses of field conditions, maintaining both the balance and depth required for effective work.

Auxiliary Mechanisms

Additional parts work together to improve maneuverability and adjustability. These include systems that regulate the depth of cut, as well as elements that allow for quick adaptations to different soil types and terrain. This flexibility ensures the tool’s compatibility with a wide range of farming requirements.

| Component | Function |

|---|---|

| Frame Assembly | Supports the overall structure, providing stability and strength. |

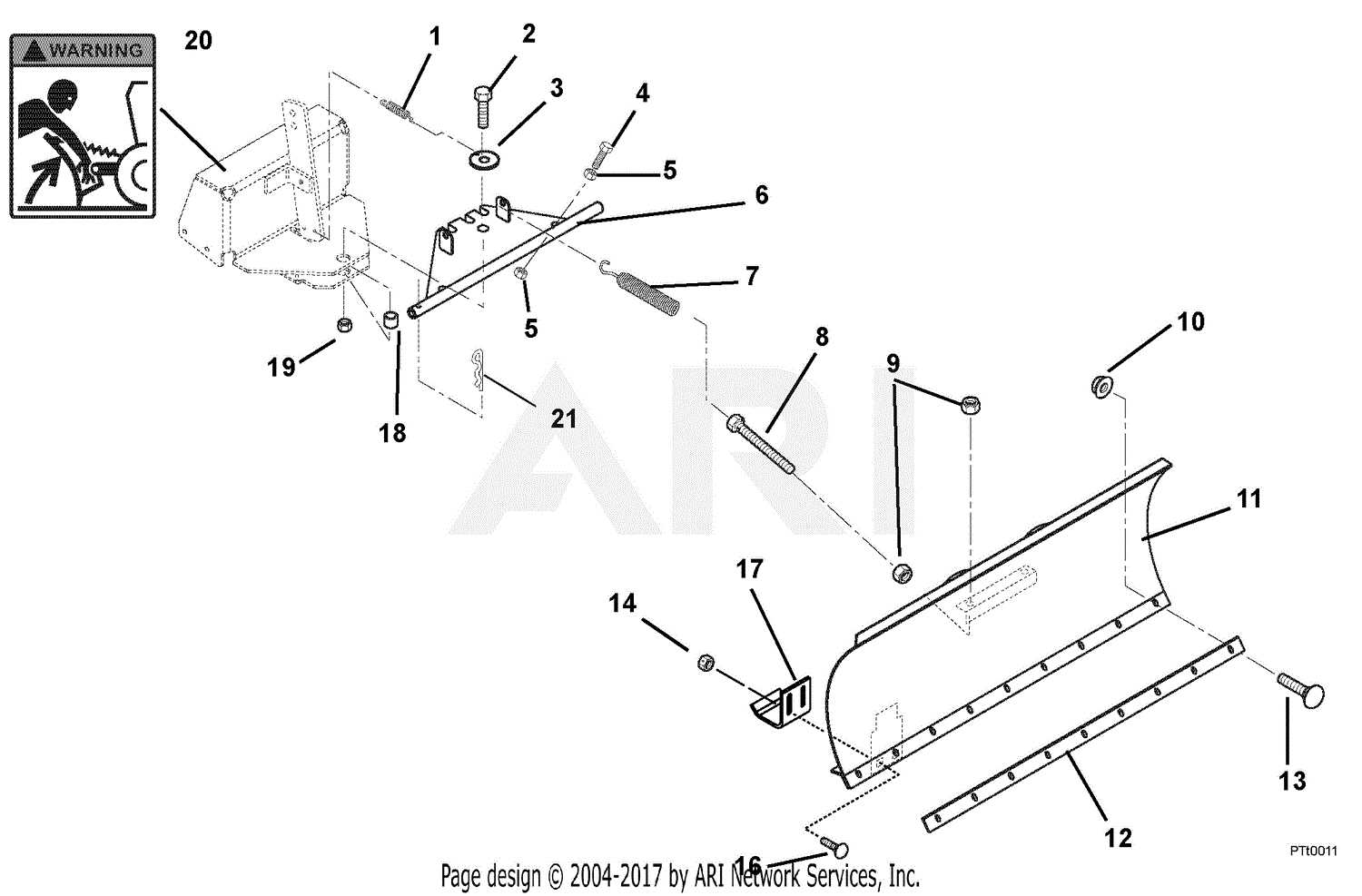

| Cutting Edge | Responsible for penetrating the soil, ensuring efficient tillage. |

| Adjustment Mechanisms | Allows operators to modify settings for different field conditions. |

| Mounting Points | Connects the equipment to tractors or other machinery for towing. |

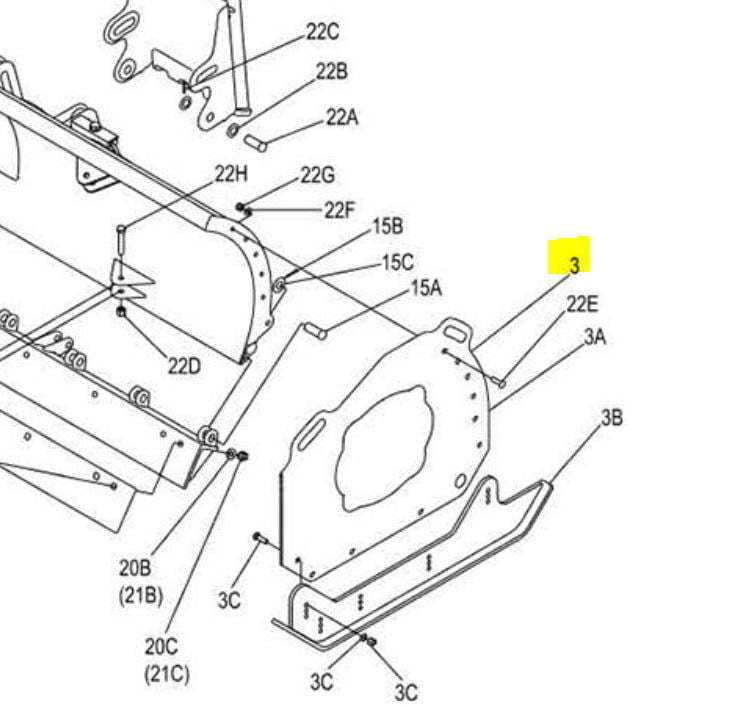

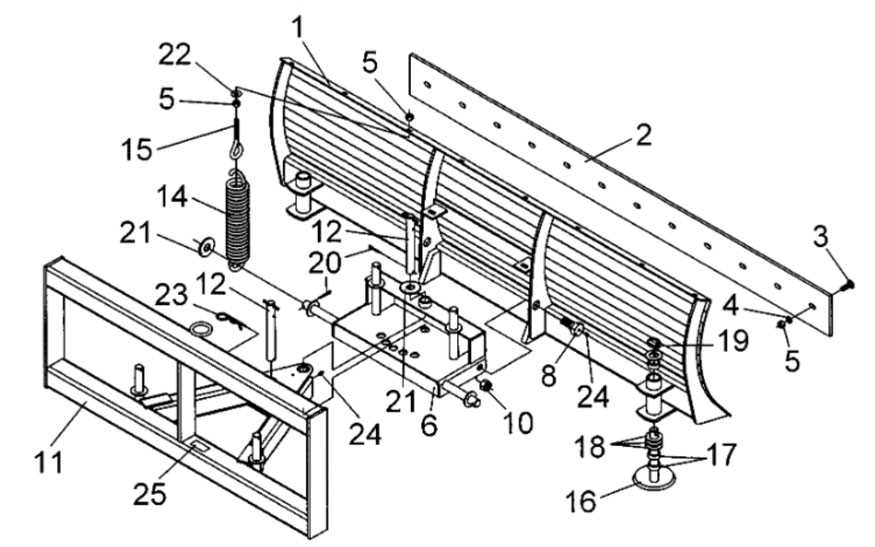

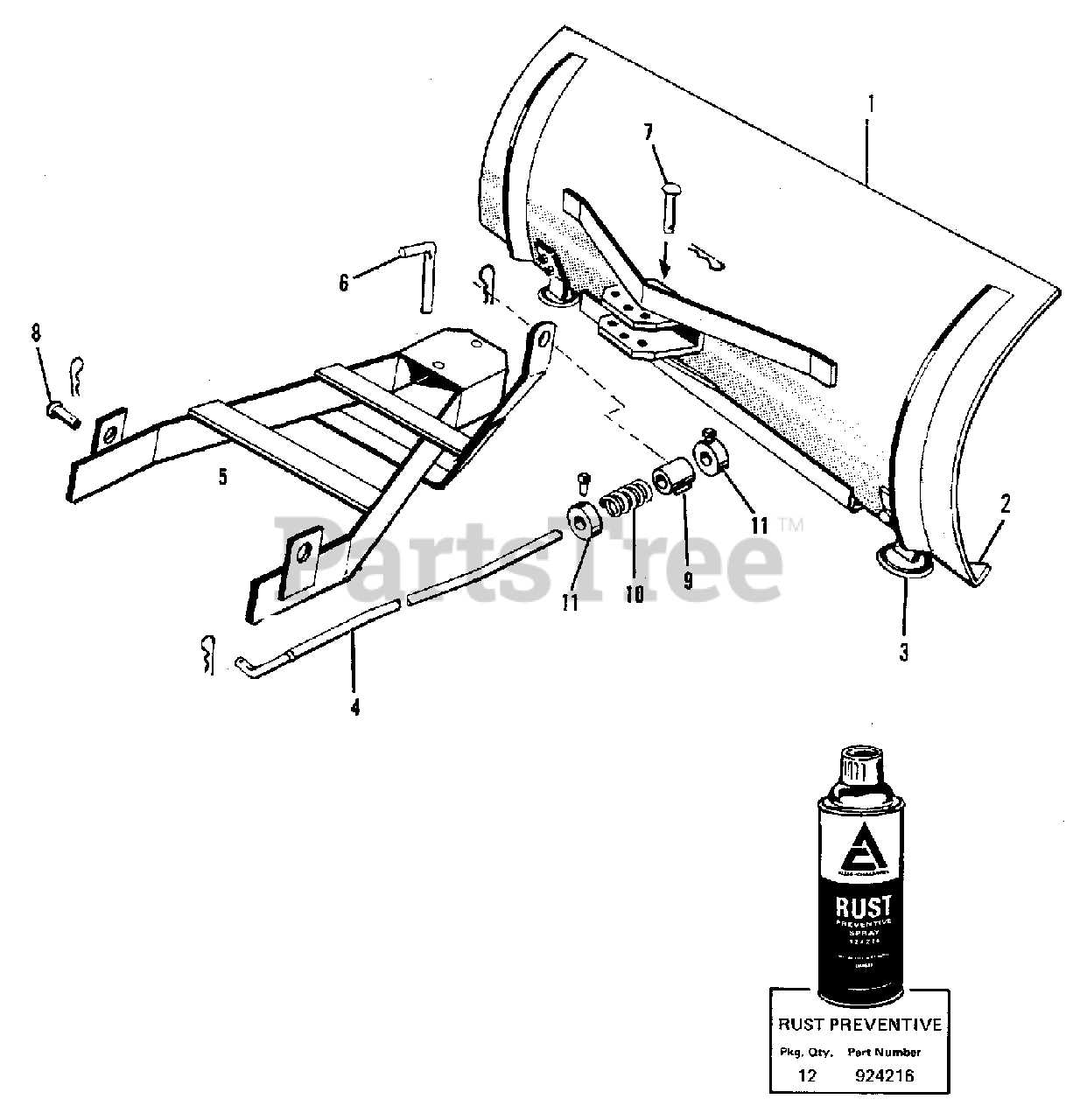

Plow Blade Structure and Functionality

The cutting edge of agricultural equipment is essential for breaking up soil and preparing fields for planting. Its design ensures efficient soil penetration and smooth operation, making it a crucial component for land cultivation. Understanding the blade’s structure helps maximize performance and durability.

Key Elements of the Blade Design

The blade typically consists of a hardened steel edge to resist wear and provide long-lasting sharpness. Its curvature and thickness are carefully engineered to handle different soil types, ensuring efficient slicing through the earth. A reinforced backing adds strength, allowing it to withstand heavy forces during operation.

Optimizing for Specific Conditions

Depending on the terrain, the blade’s size and shape can vary. Adjustments in these parameters allow for better adaptability, whether working with soft soil or tougher ground conditions. Regular maintenance, including sharpening and replacing worn components, ensures optimal functionality over time.

Adjusting the Depth Control

Proper adjustment of the depth control is essential for ensuring efficient operation and achieving optimal performance in the field. By carefully calibrating this mechanism, operators can maintain consistent results across varying soil conditions, enhancing overall productivity.

- Inspect the mechanism: Before making any adjustments, ensure that the control system is free from debris and that all components are functioning correctly.

- Set the control lever: Position the lever in a neutral state, which allows for more precise calibration during operation.

- Test in small increments: Adjust the control in small steps to avoid abrupt changes that may affect balance and soil interaction.

- Monitor performance: After each adjustment, monitor the impact on depth and adjust further if needed for consistency.

Careful attention to these steps will help maintain efficiency, preventing unnecessary strain on the machinery while delivering the best results in the field.

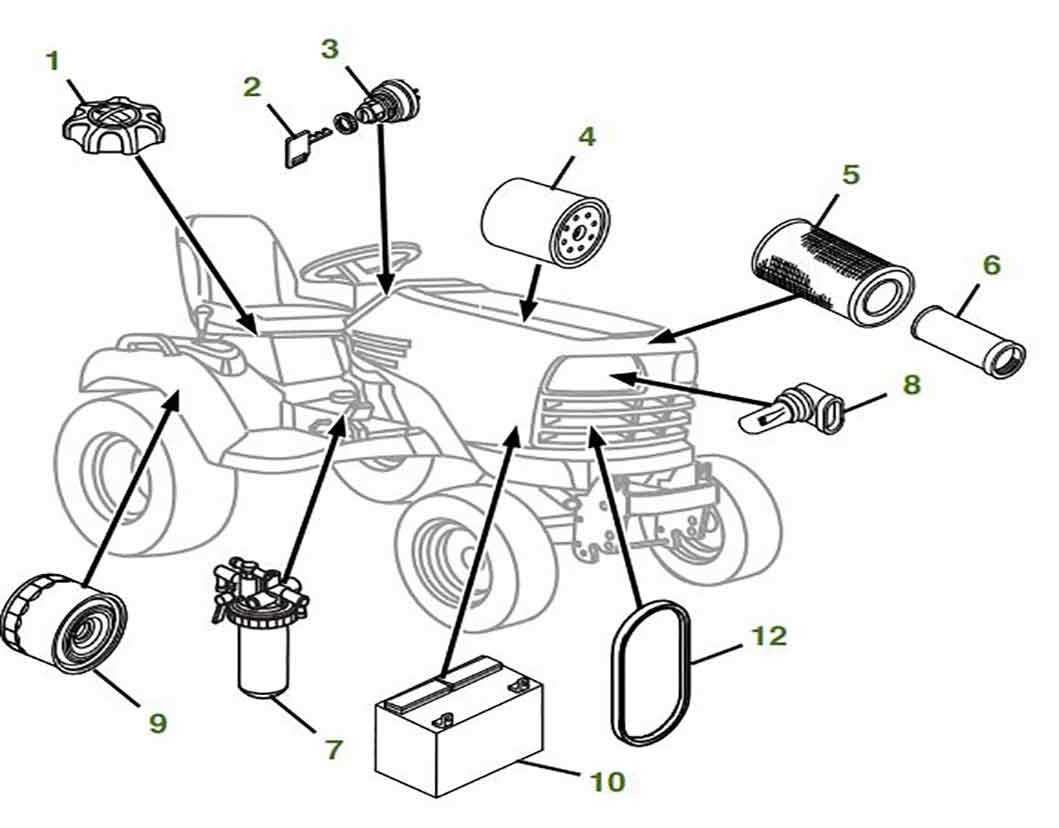

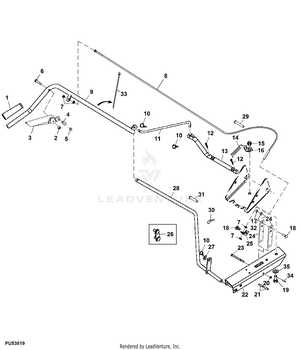

Hydraulic System in John Deere 54 Plow

The hydraulic system plays a critical role in ensuring efficient operation of agricultural equipment. It provides the necessary power to lift, lower, and adjust attachments smoothly, making fieldwork much easier. With a well-designed hydraulic setup, the equipment can handle various tasks with precision and minimal effort from the operator. Understanding how this system functions can help in troubleshooting and maintaining its optimal performance.

Key Components of the hydraulic system include the pump, hoses, and cylinders. The pump generates pressure, while the hoses transfer fluid to the cylinders, enabling movement. Proper alignment and sealing of these components are crucial for preventing leaks and ensuring consistent operation.

To maintain efficiency, it is essential to regularly inspect the hydraulic fluid level and ensure all connections are secure. Proper maintenance not only extends the life of the system but also prevents potential breakdowns during use. Regularly checking for wear and tear on the hoses and fittings can help avoid costly repairs and downtime.

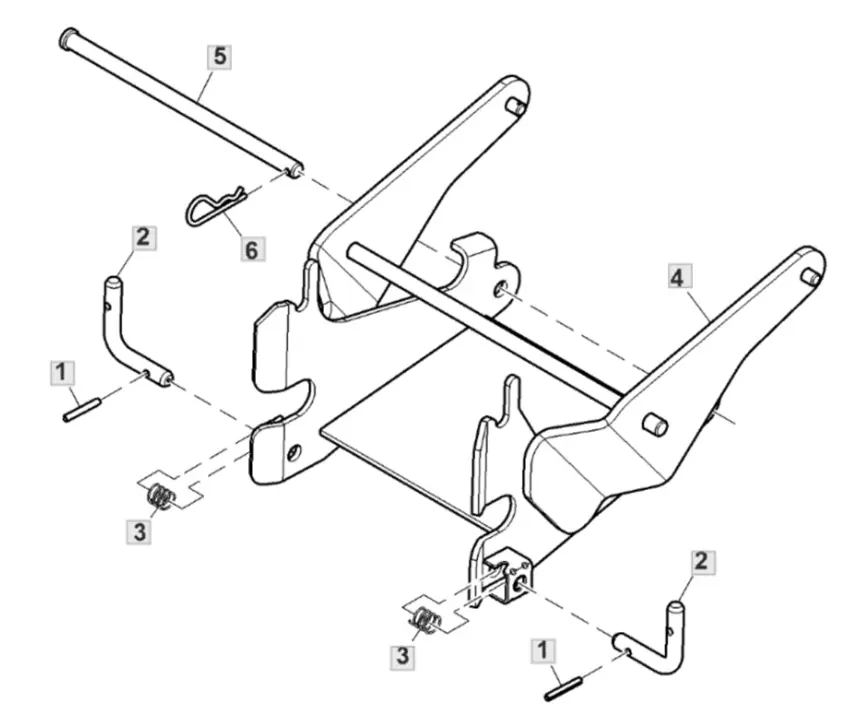

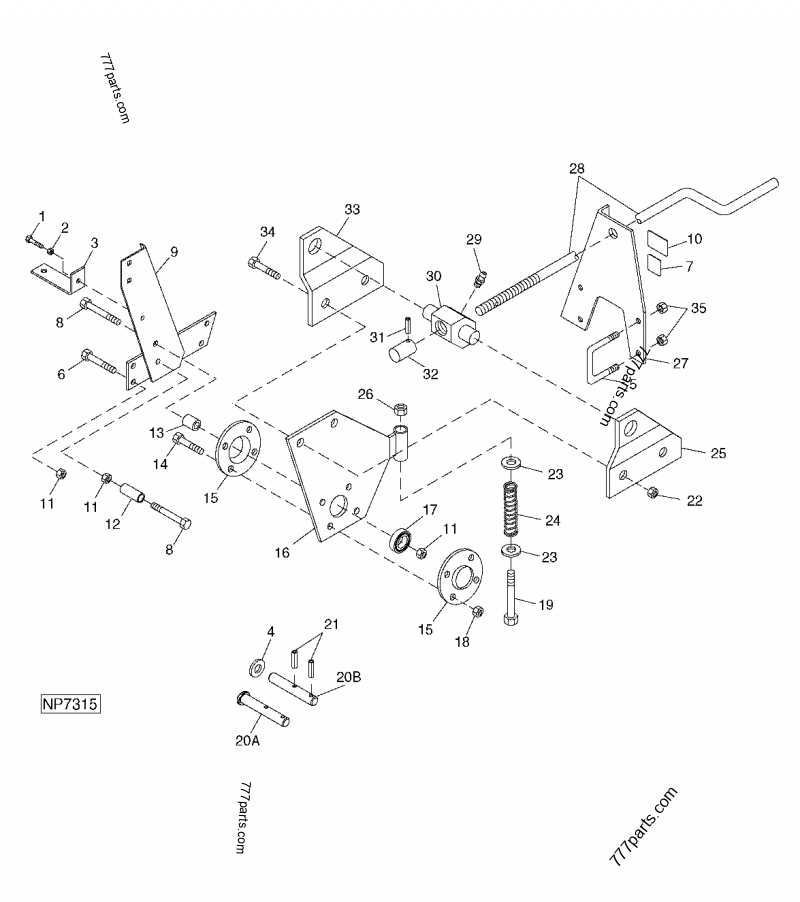

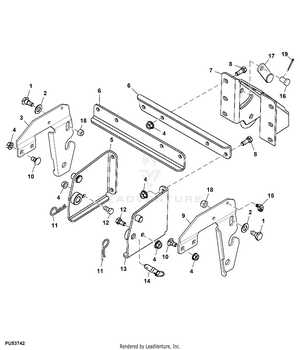

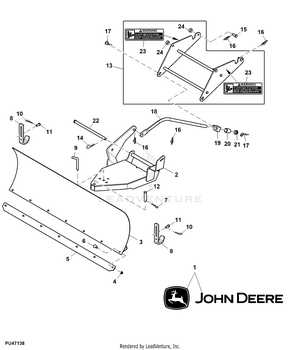

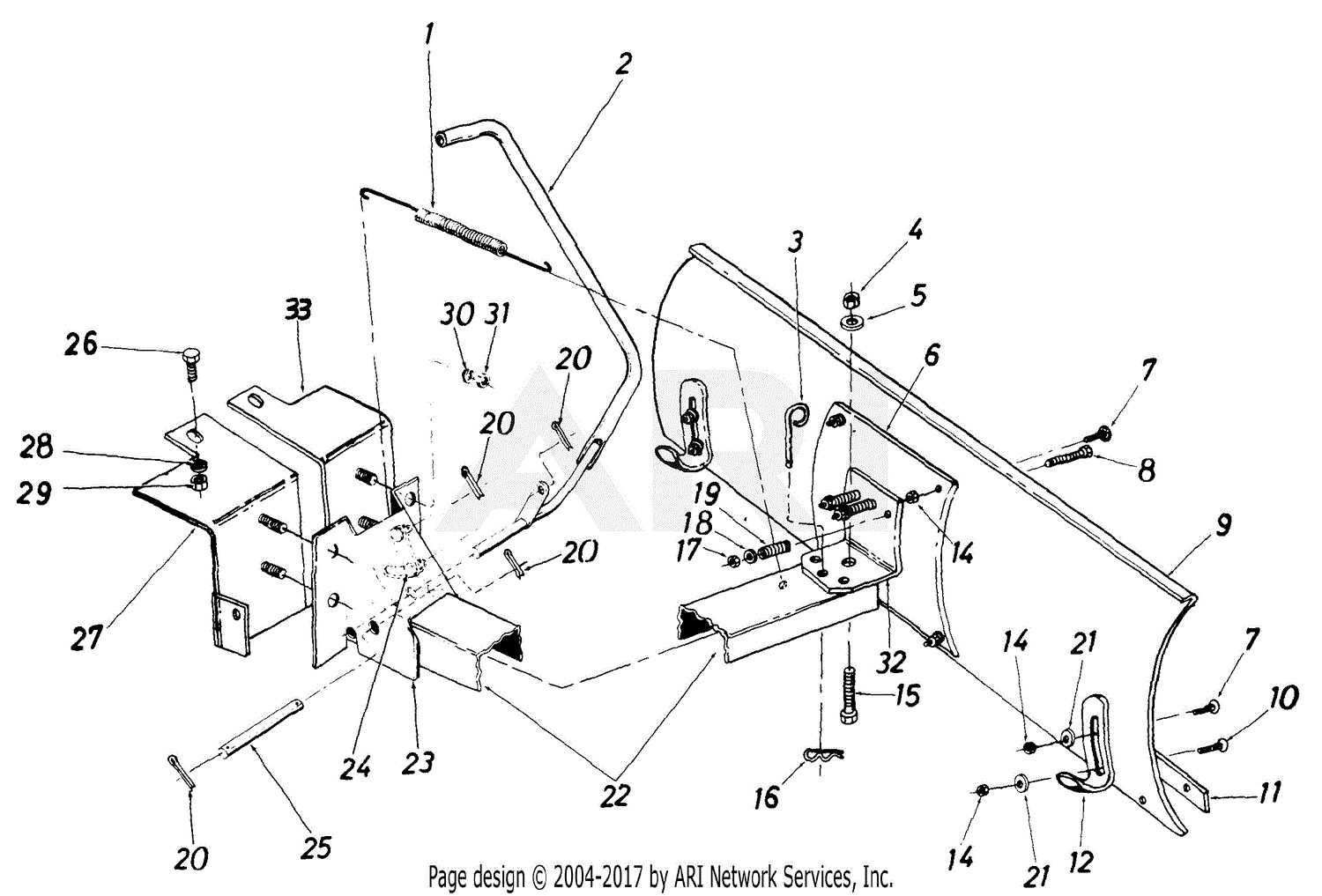

Hitch Assembly and Mounting Details

The hitch system is a critical component in the functionality of various agricultural implements, facilitating their connection to tractors and ensuring optimal performance during use. Proper assembly and mounting are essential for maintaining stability and efficiency while working in the field.

This section provides an overview of the key components involved in the hitch assembly, including their functions and proper installation techniques. Understanding these details can significantly enhance the effectiveness of your equipment.

| Component | Description | Installation Steps |

|---|---|---|

| Hitch Bracket | Connects the implement to the tractor, providing structural support. | Align with mounting holes on the tractor frame and secure with bolts. |

| Pins | Facilitates the connection between the hitch and the implement. | Insert through the bracket and implement holes, securing with clips. |

| Safety Chains | Provides additional security to prevent detachment during operation. | Attach to designated points on both the tractor and implement. |

| Adjustable Links | Allows for adjustments in height and alignment for optimal operation. | Loosen the locking nuts, adjust to the desired length, and retighten. |

Ensuring that each component is properly installed and adjusted is vital for the effective operation of agricultural machinery. Regular maintenance and inspection of the hitch assembly can prevent issues and prolong the lifespan of your equipment.

Replacing the Wear Parts of the Plow

Maintaining the efficiency and performance of agricultural equipment is essential for achieving optimal results in the field. One crucial aspect of this maintenance is the timely replacement of components that experience significant wear during operation. By understanding how to identify and replace these critical elements, operators can ensure their machinery remains in peak condition, ultimately enhancing productivity and extending the equipment’s lifespan.

Identifying Worn Components

Regular inspections are vital for detecting signs of deterioration. Look for cracks, bends, or excessive thinning in the components. Visual checks can help determine whether a part needs to be replaced or if it can still perform its function effectively. Additionally, consider the operational efficiency; if the machinery is not functioning as expected, it may indicate that a key element requires attention.

Steps for Replacement

Once worn components are identified, follow these steps for a successful replacement:

- Gather the necessary tools: Ensure you have the right equipment on hand, including wrenches, sockets, and replacement components.

- Remove the damaged component: Carefully detach the worn element, making sure to follow safety protocols to avoid injury.

- Install the new component: Align and secure the replacement part, ensuring it fits snugly and is properly fastened.

- Test the equipment: After installation, run the machinery briefly to ensure everything is functioning smoothly.

By proactively addressing wear and tear, operators can maintain the reliability of their machinery, ultimately supporting their agricultural operations effectively.

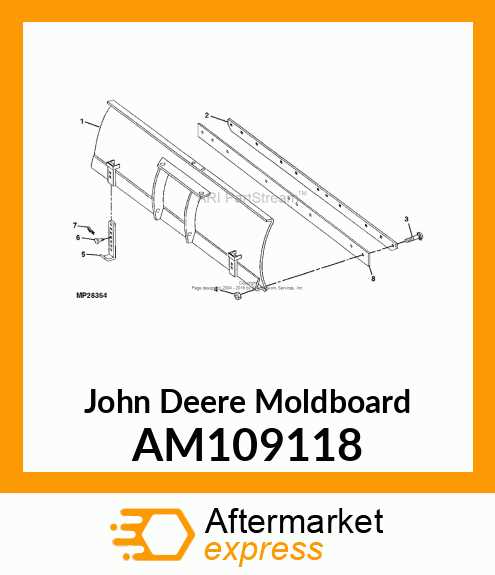

Steel vs Poly Moldboard Options

When selecting the ideal moldboard for cultivation equipment, two prominent materials often come into consideration: steel and poly. Each material boasts unique characteristics that influence performance, durability, and maintenance, making it essential to understand their respective advantages and disadvantages.

Advantages of Steel Moldboards

- Durability: Steel moldboards are known for their robust construction, making them highly resistant to wear and tear over time.

- Weight: The heavier nature of steel can improve penetration and provide better traction in challenging soil conditions.

- Repairability: Steel can be welded and repaired easily, extending the lifespan of the equipment.

Benefits of Poly Moldboards

- Weight Reduction: Poly moldboards are significantly lighter, which can enhance maneuverability and reduce fuel consumption.

- Corrosion Resistance: Unlike steel, poly does not rust, making it a suitable choice for wet or corrosive environments.

- Non-Stick Surface: The smooth finish of poly helps prevent soil from adhering, leading to cleaner operation and less drag.

Choosing between steel and poly moldboards ultimately depends on individual farming needs, environmental conditions, and personal preferences regarding maintenance and performance. Each option presents distinct benefits, ensuring that users can find a suitable solution tailored to their specific requirements.

Proper Maintenance for Extended Plow Life

Ensuring longevity and optimal performance of your agricultural equipment requires consistent care and attention. By following systematic maintenance practices, you can enhance the efficiency and durability of your machinery, reducing the likelihood of unexpected breakdowns and costly repairs.

Regular Inspections

Frequent evaluations of your equipment are essential. Look for signs of wear, corrosion, or damage that may affect performance. Check all components, including the structural framework, attachment points, and any moving parts. Identifying issues early can prevent more significant problems down the line.

Lubrication and Cleaning

Proper lubrication is vital to minimize friction and wear on moving components. Use high-quality lubricants recommended by the manufacturer to ensure optimal functionality. Additionally, cleaning the equipment after each use helps prevent dirt and debris buildup, which can lead to mechanical failure.

Common Issues and Troubleshooting Tips

When operating agricultural equipment, it’s crucial to be aware of potential challenges that may arise during use. Proper maintenance and understanding of common issues can help ensure optimal performance and longevity of the machinery. This section provides insights into frequent problems and offers practical solutions for effective resolution.

Frequent Problems

Operators often encounter various difficulties that can hinder the efficiency of their equipment. Some of the most prevalent issues include:

- Inconsistent functionality due to wear and tear.

- Difficulty in attachment adjustments, leading to improper operation.

- Hydraulic system malfunctions that may result in insufficient power transfer.

Troubleshooting Solutions

Addressing these challenges requires a systematic approach. Here are some troubleshooting tips to consider:

- Regular Inspections: Conduct routine checks to identify any signs of wear or damage, ensuring all components are functioning properly.

- Hydraulic Fluid Maintenance: Ensure that the hydraulic system is filled with the appropriate fluid and free of contaminants to maintain optimal performance.

- Adjusting Attachments: Regularly review and adjust attachments to ensure they are secured correctly and functioning as intended.

By implementing these troubleshooting practices, users can effectively mitigate common issues and enhance the reliability of their agricultural machinery.

Upgrading the John Deere 54 Plow

Enhancing your agricultural implement can significantly improve its efficiency and performance. Upgrading various components can lead to better soil penetration, increased durability, and an overall more productive farming experience. This section explores essential upgrades that can be made to achieve optimal results in your agricultural tasks.

Key Components for Upgrade

- Cutting Edge: Replacing the cutting edge with a high-quality material can enhance durability and reduce wear over time.

- Hitch System: Upgrading to a more robust hitch can improve stability and allow for better weight distribution.

- Shank Design: Consider installing an improved shank design that allows for deeper penetration and reduces soil compaction.

- Adjustable Features: Implement adjustable components that can be modified for different soil types and conditions, enhancing versatility.

Benefits of Upgrading

- Increased efficiency in field operations.

- Improved soil health through better aeration and reduced compaction.

- Enhanced longevity of the equipment, leading to cost savings in the long run.

- Greater adaptability to varying agricultural tasks, ensuring versatility in operations.

Investing in upgrades for your implement not only improves performance but also ensures that your equipment remains competitive and effective in modern agricultural practices.