When delving into the intricacies of heavy machinery, comprehending the intricate network of components is essential for effective maintenance and operation. Each element plays a pivotal role in ensuring optimal performance, making familiarity with their layout and function vital for operators and technicians alike.

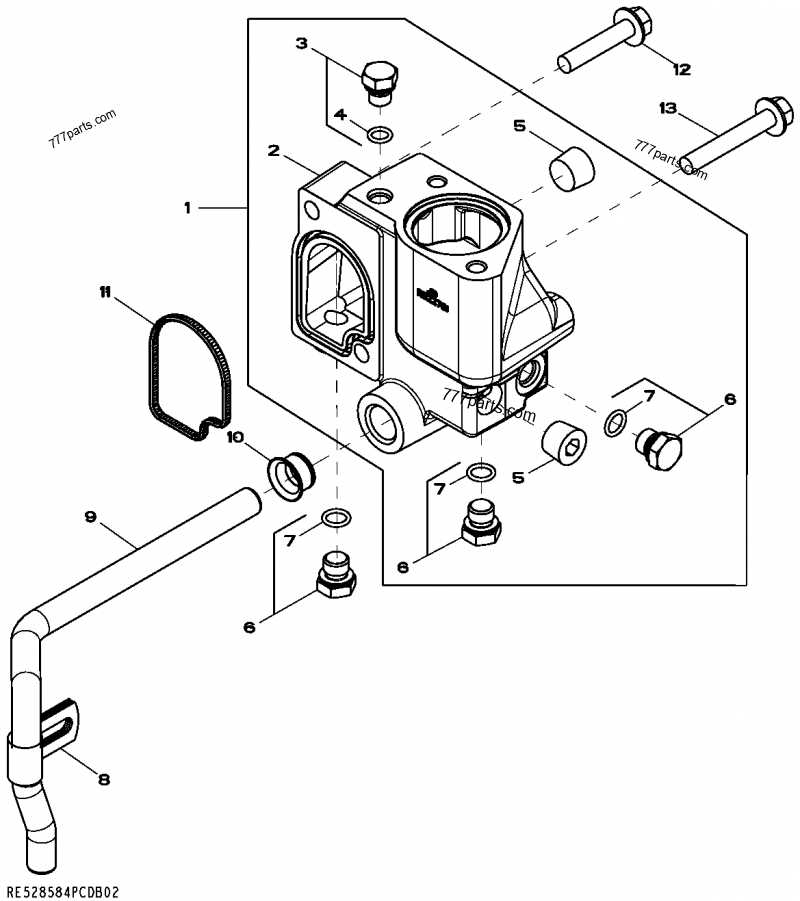

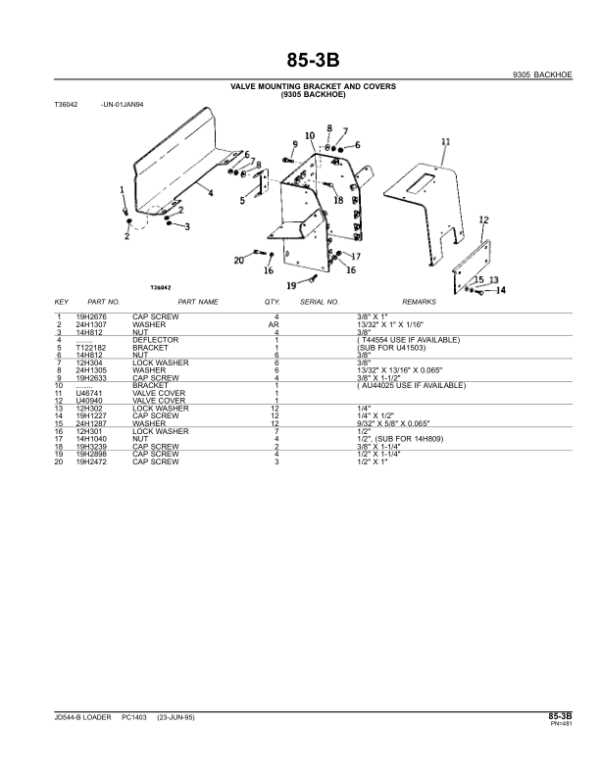

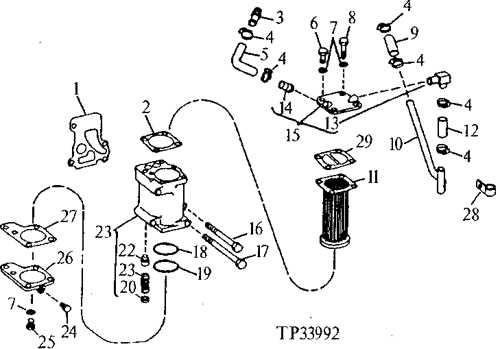

The visual representation of these elements serves as a roadmap, guiding users through the assembly and functionality of the equipment. By examining these schematics, one can quickly identify specific sections and their respective roles within the machine, enhancing both troubleshooting and repair efforts.

Whether you’re a seasoned professional or a newcomer to the field, grasping the structure and arrangement of these crucial components can significantly impact the efficiency and longevity of your machinery. Emphasizing the importance of clarity in these representations allows for better preparation and informed decision-making in maintenance tasks.

Understanding John Deere 544B Model

This section aims to explore the features and functionalities of a specific loader model, highlighting its significance in various industrial applications. By examining its components and capabilities, readers can gain insight into how it enhances efficiency in operations.

Key Features

- Robust construction for heavy-duty tasks

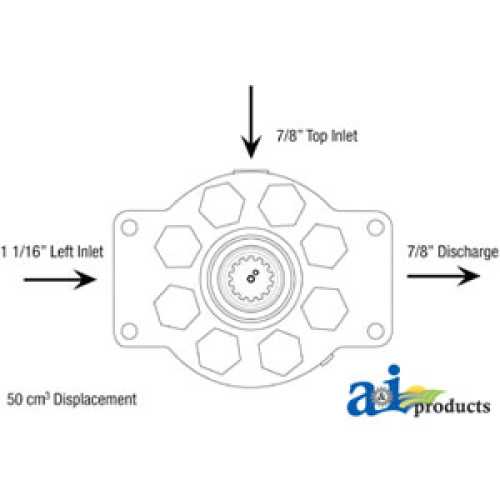

- Advanced hydraulic system for improved performance

- User-friendly controls for ease of operation

- Versatile attachments for multiple applications

Applications

- Construction projects

- Agricultural operations

- Material handling

- Landscaping tasks

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repair. Visual representations serve as essential tools, enabling technicians to identify individual elements quickly and accurately. This knowledge ultimately enhances the longevity and performance of equipment.

Benefits of Visual Representations

- Facilitates accurate identification of components.

- Simplifies the repair process, reducing downtime.

- Enhances communication among team members.

Optimizing Maintenance Practices

- Provides a reference for troubleshooting issues.

- Assists in inventory management of necessary components.

- Ensures compliance with safety standards during repairs.

Common Issues with 544B Components

When dealing with heavy machinery, certain components can exhibit recurring problems that may affect overall performance and reliability. Understanding these common issues is essential for maintaining efficiency and ensuring the longevity of the equipment. Below are some typical challenges faced by operators and mechanics.

Hydraulic System Failures

Hydraulic systems are crucial for the operation of various functions within the machinery. Common problems include leaks, which can lead to a drop in pressure and reduced effectiveness. Additionally, contamination of hydraulic fluid can cause components to wear prematurely, resulting in costly repairs.

Electrical Component Malfunctions

Electrical systems are integral to the functionality of modern machines. Issues often arise with wiring, fuses, and connectors, leading to intermittent failures or complete shutdowns. Regular inspection of these components can prevent unexpected breakdowns and ensure smooth operation.

Essential Tools for Repairs

When it comes to maintaining and fixing machinery, having the right tools at your disposal is crucial. These instruments not only enhance efficiency but also ensure safety during the repair process. A well-equipped toolkit can make a significant difference in the ease and success of your repair tasks.

Basic Hand Tools

- Wrenches: Adjustable and socket types for various bolt sizes.

- Screwdrivers: Flathead and Phillips for handling different screw types.

- Pliers: Needle-nose and standard for gripping and twisting.

- Hammers: Claw and rubber mallets for various striking needs.

Power Tools

- Drills: Electric or cordless for making holes or driving screws.

- Impact Wrenches: Useful for loosening stubborn fasteners.

- Grinders: For cutting, polishing, or shaping materials.

- Saws: Reciprocating or circular saws for more complex cuts.

Having these essential tools on hand will prepare you for most repair tasks, ensuring a smoother and more effective workflow.

Where to Find OEM Parts

Finding original equipment manufacturer components is essential for maintaining the performance and longevity of your machinery. These authentic parts ensure compatibility and reliability, making them a wise investment for any operator. Here are some effective ways to source these items:

- Authorized Dealers: Visit local or online dealers who are certified to sell original components. They typically offer a wide selection and expert advice.

- Manufacturer Websites: Check the official website of the manufacturer for a catalog or online store where you can order directly.

- Online Marketplaces: Utilize platforms like eBay or Amazon, ensuring you filter for authentic items. Read reviews and check seller ratings.

- Specialty Retailers: Explore stores that focus on machinery and heavy equipment. They often carry a range of OEM options.

- Trade Shows: Attend industry events and expos where manufacturers showcase their products, often providing exclusive offers.

By utilizing these resources, you can confidently acquire high-quality components that meet the specific requirements of your equipment.

Interpreting the Parts Diagram

Understanding the layout of components in machinery is essential for effective maintenance and repair. A visual representation provides insight into the arrangement and relationships between different elements, allowing users to quickly identify and locate specific pieces. Mastering this tool not only facilitates repairs but also enhances overall efficiency in managing equipment.

Key Elements of the Visual Representation

Each section of the illustration is typically numbered or labeled, correlating with a specific component in the machinery. These identifiers are crucial for referencing parts in manuals or for ordering replacements. Familiarity with this structure enables users to navigate the image with confidence and precision, reducing downtime and ensuring smooth operations.

Tips for Effective Interpretation

When analyzing the visual guide, start by familiarizing yourself with the general layout. Identify major groups of components before zooming in on individual parts. Take note of any annotations or notes that may provide additional context. Regular practice in interpreting these visuals will enhance your understanding and speed in identifying necessary repairs or replacements.

Key Features of the 544B

This section highlights the essential characteristics of a prominent model in the heavy machinery sector, showcasing its versatility and reliability. The design elements and capabilities ensure it meets various operational demands effectively.

Performance and Efficiency

The machine is engineered for optimal power delivery and fuel economy, making it a top choice for contractors and operators. Its robust engine ensures high productivity while minimizing operational costs.

Durability and Maintenance

Constructed with high-quality materials, this model promises longevity and reduced wear. Easy access to components simplifies maintenance, allowing for swift servicing and reduced downtime.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine for demanding tasks |

| Load Capacity | Impressive capacity for heavy loads |

| Maneuverability | Superior control in tight spaces |

| Operator Comfort | Ergonomic design for reduced fatigue |

Maintenance Tips for Longevity

Ensuring the durability of machinery involves a series of proactive measures that focus on regular upkeep and care. These practices not only enhance performance but also extend the lifespan of the equipment, ultimately saving time and resources in the long run.

Regular inspections are essential to identify wear and tear early. Checking fluid levels, filters, and belts can prevent minor issues from escalating into major repairs. Keeping the machinery clean helps avoid buildup that can lead to malfunctions.

Using quality lubricants and adhering to recommended service intervals can significantly reduce friction and wear. Additionally, following the manufacturer’s guidelines for maintenance tasks ensures that all components function optimally.

Training operators on proper usage techniques is crucial. Understanding how to handle equipment effectively minimizes the risk of damage and maximizes efficiency. Encouraging a culture of care can lead to better maintenance habits.

Lastly, documenting maintenance activities provides valuable insights into performance trends. This record helps in making informed decisions about necessary upgrades or replacements, ultimately contributing to the machinery’s longevity.

Upgrading Components for Performance

Enhancing machinery efficiency often involves the strategic selection and modification of various elements. By focusing on upgrading specific components, operators can significantly boost overall functionality and output, ensuring that their equipment meets the demands of modern tasks.

Identifying Key Areas for Improvement

To optimize performance, it is essential to pinpoint which parts are underperforming or outdated. Prioritizing enhancements in areas such as hydraulics, engine systems, and transmission can yield substantial benefits. Improved efficiency often translates to reduced operational costs and increased productivity.

Choosing the Right Upgrades

When selecting upgrades, consider options that offer durability and compatibility with existing systems. High-quality replacements not only enhance reliability but also prolong the lifespan of the equipment. Investing in top-tier components can ultimately lead to a more robust and efficient operation.

Cost Considerations for Replacement Parts

When it comes to maintaining heavy machinery, understanding the financial implications of component replacement is crucial. Evaluating the expenses associated with acquiring new elements can significantly influence operational budgets and overall efficiency.

First and foremost, quality plays a pivotal role in determining cost. High-quality components may come at a premium but often lead to longer lifespans and reduced downtime. In contrast, cheaper alternatives might save money upfront but can result in frequent failures and additional expenses in the long run.

Another factor to consider is availability. Components that are readily available typically come at a lower cost due to competitive pricing. Conversely, rare or specialized items can carry inflated prices, making it essential to assess the supply chain before making a purchase decision.

Additionally, it’s important to factor in labor costs associated with installation. If a replacement requires significant expertise or specialized tools, these expenses can quickly add up. Investing in training or hiring skilled technicians may be necessary to ensure proper installation, impacting overall project costs.

Lastly, it is wise to consider warranty options. Some manufacturers offer warranties that can mitigate risks associated with premature failure. Investing in components backed by solid warranties may lead to greater peace of mind and financial savings in the event of unexpected issues.

Visual Aids in Repair Processes

In the realm of maintenance and restoration, visual resources play a crucial role in enhancing understanding and efficiency. These tools provide clarity, ensuring that individuals can grasp complex assemblies and procedures with ease.

Types of Visual Resources

Several forms of visual aids are utilized in repair workflows, each serving a unique purpose:

| Type | Description |

|---|---|

| Illustrations | Detailed drawings that depict components and their relationships. |

| Flowcharts | Graphical representations of processes, outlining steps and decision points. |

| Photographs | Real-life images that provide context and clarity for specific tasks. |

Benefits of Utilizing Visual Aids

Incorporating these resources can significantly reduce errors and improve the overall effectiveness of repair efforts. Visual aids facilitate better communication and foster a deeper understanding of technical details.

Expert Recommendations for Owners

Maintaining heavy machinery requires diligence and a proactive approach to ensure longevity and optimal performance. Here are some essential tips for operators to consider for enhanced upkeep and reliability.

- Regular Inspections: Schedule routine check-ups to identify wear and tear before it becomes a major issue.

- Quality Lubrication: Utilize high-grade oils and greases to minimize friction and extend the life of moving components.

- Proper Storage: Keep the equipment in a sheltered area to protect it from harsh weather and potential damage.

Additionally, it’s crucial to stay updated on manufacturer guidelines and consult experts for tailored advice:

- Follow recommended maintenance schedules strictly.

- Invest in reliable replacement components when necessary.

- Seek professional assistance for complex repairs to ensure safety and efficiency.

By implementing these strategies, owners can significantly enhance the performance and lifespan of their machinery.

FAQs about John Deere 544B Parts

This section addresses common inquiries related to components for a specific model of machinery, offering clarity on availability, compatibility, and maintenance.

Where can I find replacement components?

Many authorized dealers and online retailers specialize in machinery components. It’s advisable to check both local suppliers and trusted e-commerce platforms for the best options.

How do I ensure compatibility with my machinery?

Always verify the model number and specifications when selecting components. Consulting the manufacturer’s guidelines or seeking expert advice can ensure the right fit for your equipment.