In the realm of farming equipment, a specific model stands out for its efficiency and reliability. This machine plays a vital role in optimizing the hay-making process, providing farmers with the tools they need for successful operations. A thorough comprehension of its various elements is essential for maintenance and repair, ensuring that the machinery continues to perform at its best.

The intricate design of this equipment includes numerous components that work in harmony to achieve the desired results. Each part has a unique function, contributing to the overall performance and effectiveness of the machine. Familiarizing oneself with these individual elements not only aids in troubleshooting potential issues but also enhances the ability to carry out timely repairs and replacements.

For anyone involved in agricultural practices, understanding the structure and function of this equipment is invaluable. It enables operators to make informed decisions regarding upkeep, thereby extending the lifespan of the machine. By grasping the relationships between the various components, users can optimize their productivity and achieve greater success in their endeavors.

This section provides a comprehensive overview of a specific agricultural machine, detailing its components and functionality. Understanding the various elements that comprise this machinery is essential for effective maintenance and operation. A well-organized approach to examining these elements can enhance the efficiency and longevity of the equipment.

Key Components of the Machinery

- Cutting Mechanism

- Drive System

- Frame Structure

- Hitch and Attachment Points

- Safety Features

Maintenance Tips for Optimal Performance

- Regular Inspection of Cutting Blades

- Checking Fluid Levels

- Ensuring Proper Lubrication

- Verifying Tire Pressure

- Cleaning After Use

By focusing on these critical areas, operators can ensure that their machinery operates smoothly and efficiently throughout its lifespan. Familiarity with the structural elements will contribute to better handling and reduced downtime.

Key Features of the Moco Model

This section highlights the distinctive characteristics of a popular cutting machine model, emphasizing its advantages and innovative design elements. The equipment is engineered for optimal performance in hay and forage production, making it a valuable asset for agricultural operations.

Innovative Design Elements

The model boasts a streamlined design that enhances maneuverability and reduces operational fatigue. Its robust frame and adjustable components allow for seamless integration into various farming setups, ensuring efficiency during use.

Operational Efficiency

With advanced technology incorporated into its mechanics, this machine delivers superior cutting performance. It features user-friendly controls that facilitate quick adjustments and settings, optimizing the harvesting process.

| Feature | Description |

|---|---|

| Frame Design | Sturdy construction providing durability and stability. |

| Cutting Mechanism | Efficient blade system ensuring clean cuts. |

| Adjustability | Customizable height and angle for different terrains. |

| User Interface | Intuitive controls for easy operation and setup. |

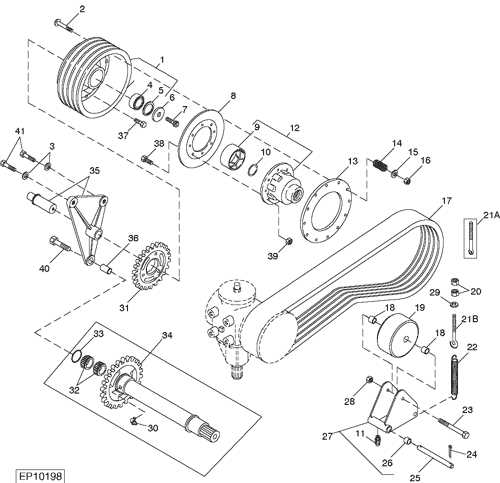

Components Breakdown and Functions

This section delves into the various elements of agricultural machinery and their specific roles within the system. Understanding how each component interacts enhances efficiency and maintenance.

Each element plays a crucial role in the overall operation. Drive mechanisms provide the necessary power for movement, while cutting assemblies ensure precision in performance. Additionally, control systems facilitate operator input, allowing for adjustments based on field conditions.

Furthermore, support structures contribute to stability, ensuring that the equipment can withstand the rigors of heavy usage. Proper knowledge of these components not only aids in effective troubleshooting but also enhances the longevity of the machinery.

Importance of Proper Maintenance

Effective upkeep of agricultural machinery is crucial for ensuring optimal performance and longevity. Regular attention to maintenance not only enhances the efficiency of the equipment but also minimizes the risk of unexpected failures, which can lead to costly repairs and downtime.

Enhancing Equipment Efficiency

Proper care and servicing of machinery significantly improve operational efficiency. By adhering to scheduled maintenance routines, operators can ensure that all components are functioning as intended, reducing energy consumption and maximizing productivity. This proactive approach allows for smoother operations and better overall performance.

Preventing Costly Repairs

Investing time in regular inspections and servicing can prevent major breakdowns and the associated repair costs. Addressing minor issues promptly before they escalate into larger problems safeguards the machinery’s integrity and extends its lifespan. As a result, operators can maintain their equipment in optimal condition, ensuring reliable performance throughout its use.

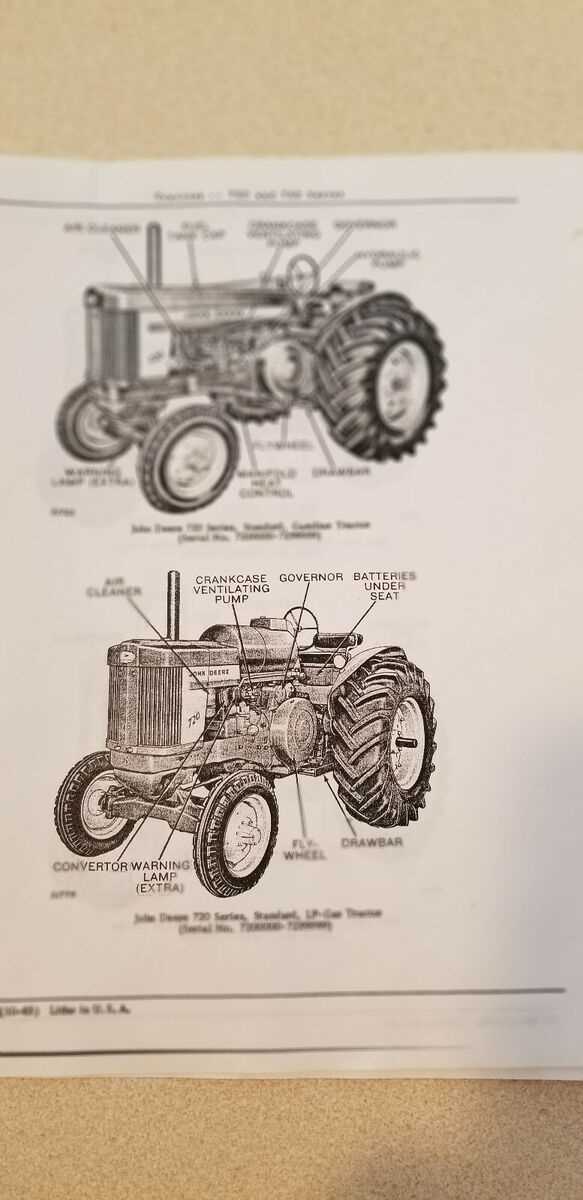

How to Read the Parts Diagram

Understanding an assembly illustration is crucial for efficient maintenance and repair tasks. This visual representation serves as a guide, highlighting various components and their relationships within the equipment. By familiarizing yourself with the layout and symbols, you can effectively navigate the intricacies of the machinery.

Identifying Components

Begin by examining the labeled sections of the illustration. Each part is typically numbered or marked, allowing you to correlate the visuals with corresponding reference materials. This clarity helps in locating specific elements when ordering replacements or conducting repairs.

Understanding Connections

Pay attention to how different parts are interconnected. Lines or arrows may indicate how components interact or fit together. Grasping these relationships is essential for reassembly and ensuring optimal functionality after any maintenance work.

Common Issues and Solutions

When operating agricultural machinery, various challenges may arise that can hinder performance and efficiency. Identifying these common problems and understanding their solutions is essential for maintaining optimal functionality. Addressing these issues promptly can prevent further complications and ensure smooth operation.

One frequent concern is the accumulation of debris in the cutting system, which can lead to decreased effectiveness and uneven cutting. Regular inspection and cleaning of this area can significantly mitigate this problem. Additionally, ensuring that the blades are sharp and properly aligned will enhance cutting performance.

Another common issue involves the hydraulic system, which may experience leaks or reduced pressure. Checking all connections and hoses for wear and tear, and replacing damaged components, can resolve these hydraulic concerns. It’s also advisable to maintain proper fluid levels to ensure optimal functioning.

Finally, electrical malfunctions can occur, often due to faulty wiring or connections. Conducting routine checks of the electrical components and ensuring that all connections are secure can help prevent these types of issues. If problems persist, consulting a professional technician may be necessary to diagnose and rectify the situation.

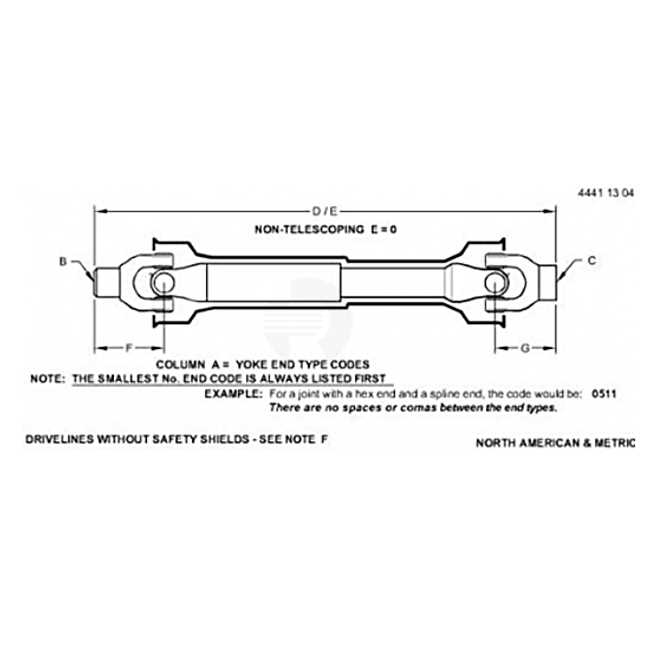

Replacement Parts and Compatibility

When maintaining agricultural machinery, understanding the various components and their interchangeability is crucial. Properly identifying the necessary replacements can enhance the machine’s performance and extend its lifespan. This section provides insights into the available alternatives and compatibility considerations for optimal functionality.

Identifying Suitable Alternatives

Finding appropriate substitutes for worn or damaged components is essential for ensuring seamless operation. Many suppliers offer a wide range of compatible options that meet or exceed the original specifications. It is advisable to verify the quality and reliability of these alternatives before purchasing.

Compatibility Considerations

Compatibility among various components is vital for successful integration into the machinery. Before selecting replacements, one should consider factors such as model specifications, manufacturing standards, and intended use. Consulting the equipment’s documentation or a knowledgeable dealer can provide guidance in choosing the right options.

Assembly Instructions for Moco Parts

This section provides detailed guidance on the assembly of essential components for efficient operation. Understanding the correct arrangement and integration of each element is crucial for optimal functionality.

Before beginning the assembly, ensure that all necessary components are available and in good condition. Begin by identifying the main units that require connection, paying close attention to the alignment of each section.

Step 1: Start by securing the primary framework, making sure all bolts are tightened properly. This forms the foundation for further installations.

Step 2: Next, attach the secondary elements, ensuring they fit snugly and are oriented correctly. Refer to your reference materials for specific alignment details.

Step 3: Once all components are connected, conduct a thorough inspection. Check for any loose fittings or misalignments that could affect performance.

Following these steps will help ensure a smooth assembly process and enhance the overall efficiency of the equipment.

Tips for Troubleshooting Problems

When faced with operational issues in agricultural machinery, systematic troubleshooting is essential for effective resolution. Understanding the common challenges and employing methodical approaches can significantly enhance the efficiency and longevity of the equipment.

Identify the Symptoms

Begin by observing the specific symptoms exhibited by the machine. Pay attention to any unusual sounds, vibrations, or performance drops. Keeping a detailed log of these observations can aid in pinpointing the exact nature of the malfunction.

Check Key Components

Inspect critical components such as belts, gears, and hydraulic systems for wear or damage. Ensuring that these parts are in good condition can often eliminate many common issues. Regular maintenance and timely replacements can prevent minor problems from escalating into major repairs.

Where to Find Genuine Parts

Locating authentic components for agricultural machinery is essential for ensuring optimal performance and longevity. Various reliable sources can assist in obtaining high-quality replacements that meet specific requirements.

Authorized dealerships often provide the most dependable selection of original components, ensuring compatibility and performance standards. These establishments usually have knowledgeable staff who can assist in identifying the right items for your machinery.

Online retailers also offer a vast array of authentic replacements, allowing for convenient comparisons and purchasing from the comfort of your home. It is crucial to verify the seller’s reputation to ensure the authenticity of the products.

Moreover, specialized forums and community groups can be valuable resources for recommendations and tips on where to source genuine items. Engaging with fellow machinery owners can lead to discovering lesser-known suppliers and insights into obtaining the best deals.

Frequently Asked Questions About Moco

This section addresses common inquiries regarding the maintenance and operation of a specific type of agricultural machinery. Understanding these aspects can enhance efficiency and prolong the lifespan of the equipment.

Many users wonder about the essential components that contribute to optimal performance. It is crucial to recognize the significance of routine inspections and timely replacements to avoid unexpected breakdowns.

Another frequent question pertains to compatibility with various models. Users are advised to consult official resources or experienced professionals to ensure they acquire the right elements for their specific machinery.

Additionally, operators often seek advice on troubleshooting common issues. Familiarity with potential malfunctions and their remedies can significantly reduce downtime and improve productivity.

Finally, it’s important to know the recommended maintenance schedules. Adhering to these guidelines ensures that the machinery operates smoothly and effectively throughout its service life.