Agricultural equipment requires precise engineering to function efficiently, and understanding how its various elements fit together is essential for both operators and technicians. Identifying key elements and their placement allows for easier maintenance and repairs, ensuring smooth operations throughout the harvesting season.

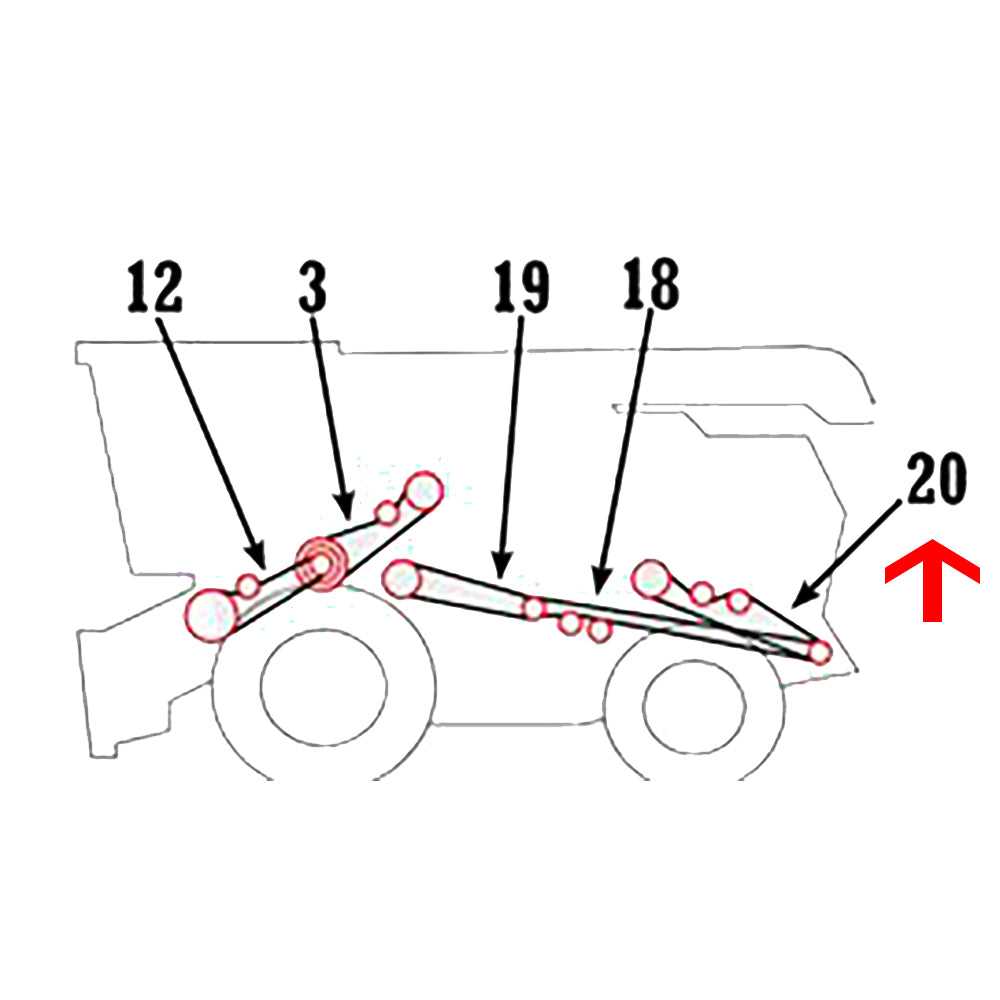

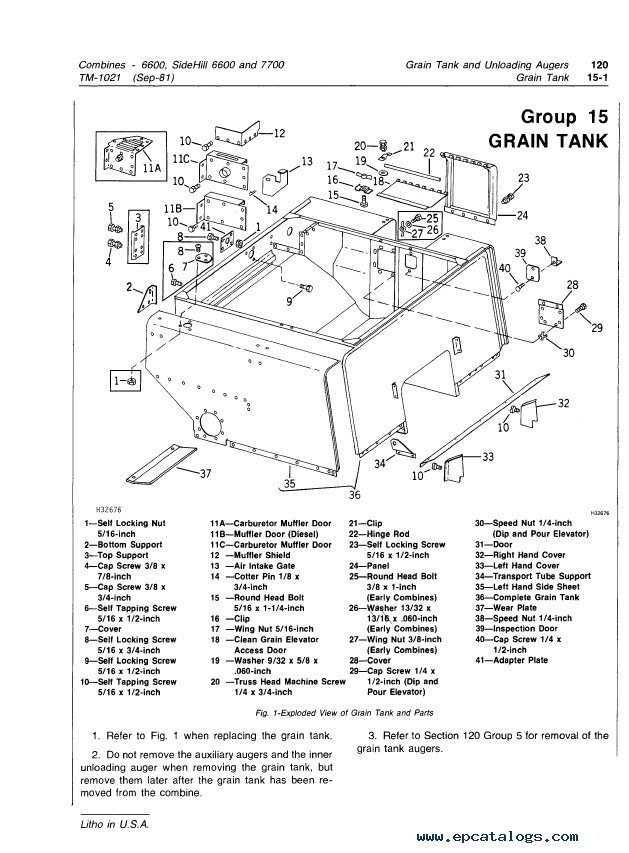

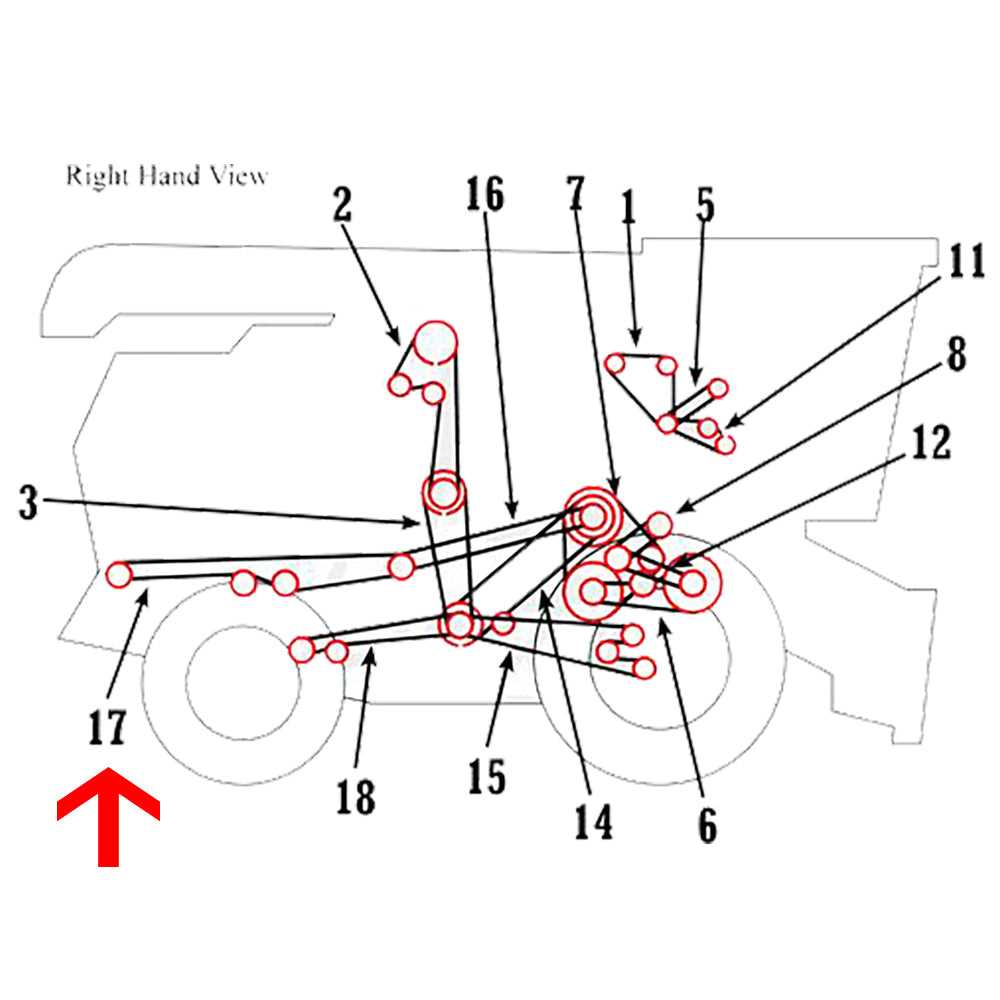

Detailed visual guides offer valuable insight into how individual mechanisms connect and operate within the machinery. These illustrations assist in locating specific sections quickly, reducing downtime when servicing is needed. They also enhance the overall understanding of how different systems interact

John Deere 6600 Parts Overview

Agricultural equipment relies on numerous essential components to function effectively in the field. These machines are designed with a variety of systems that work together to ensure optimal performance, durability, and efficiency. Understanding the structure of these elements helps operators maintain and repair their machinery with greater precision.

Engine assemblies are at the heart of these machines, delivering the power required to operate multiple systems. Efficient cooling mechanisms, along with filtration units

Essential Components of the 6600 Combine

This machinery relies on a variety of interconnected systems to ensure efficient operation in the field. Each section plays a specific role, contributing to the smooth processing of crops from entry to storage. Understanding these essential elements helps maintain the equipment’s performance and longevity.

- Threshing Unit: Separates grain from the plant material through controlled impact and friction.

- Cleaning System: Uses sieves and fans to remove unwanted debris, ensuring only clean kernels remain.

- Regular Inspection: Frequently check belts and chains for signs of wear, such as fraying, cracking, or elongation. Look for any unusual noises during operation, which may indicate problems.

- Proper Tension: Ensure that belts are correctly tensioned. Loose belts can slip, while overly tight belts may cause premature wear on both the belt and associated components.

- Lubrication: Maintain appropriate lubrication for chains to minimize friction and wear. Use the recommended lubricant to ensure compatibility and effectiveness.

- Cleaning: Keep belts and chains free from debris and contaminants. Regularly clean them to prevent dirt buildup, which can lead to faster deterioration.

- Replacement Schedule: Follow a replacement schedule based on usage and manufacturer recommendations. Proactive replacement can avoid unexpected breakdowns.

- Alignment Checks: Ensure proper alignment of belts and chains with their respective pulleys or sprockets. Misalignment can lead to excessive wear and potential failure.

- Block: The main structure housing various components.

- Cylinder Head: Covers the top of the cylinders, housing valves and camshafts.

- Crankshaft: Converts linear motion into rotational motion.

- Timing Belt/Chain: Synchronizes the rotation of the crankshaft and camshaft.

- Oil Pan: Collects and stores oil for lubrication.

- Intake and Exhaust Manifolds: Direct air and fuel into the cylinders and expel exhaust gases.

Hydraulic System Parts and Functions

The hydraulic system plays a critical role in ensuring smooth and reliable operation of agricultural machinery. It manages fluid power to control various movements, making the equipment more efficient and easier to operate. This section explores key components involved in the system and their purposes.

Main Components of the Hydraulic System

A hydraulic setup includes multiple essential elements, each contributing to the overall functionality. These elements work together to transfer energy and regulate pressure, ensuring precise control over different tasks. Below is a summary of the primary components used in

Electrical System Diagram and Details

The electrical framework ensures seamless operation by connecting essential components through circuits and control units. Proper understanding of the system helps in identifying potential issues, optimizing functionality, and ensuring safety during maintenance tasks.

Wiring layout is designed to distribute power efficiently across all key elements. This

How to Identify Gearbox Components

A gearbox contains various elements that work together to manage power transmission efficiently. Understanding how to recognize these components is essential for maintaining performance and troubleshooting issues. Each part plays a specific role, ensuring the smooth transfer of energy and proper operation of the machinery.

Key Structural Elements

The structural components typically include the housing, shafts, and bearings. The casing

Belts and Chains Maintenance Tips

Proper upkeep of belts and chains is crucial for the optimal performance and longevity of machinery. Regular maintenance helps prevent wear and tear, ensuring that these components function efficiently and reliably. Below are some essential guidelines to keep in mind for effective maintenance.

By following these maintenance tips, you can enhance the reliability and efficiency of your machinery, ultimately extending the lifespan of critical components.

Engine Parts Layout and Placement

The organization and positioning of engine components play a crucial role in the overall efficiency and functionality of the machinery. A well-structured arrangement ensures optimal performance, easier maintenance, and better accessibility for repairs. Understanding the layout is essential for operators and technicians to effectively manage and service the engine.

Key elements of the engine assembly typically include the following components:

Each component’s position is designed to maximize airflow, lubrication, and ease of access. Proper placement minimizes wear and tear while enhancing the engine’s longevity and reliability.

For effective servicing, it is beneficial to familiarize oneself with the layout, which often includes:

- Identifying the sequence of assembly and disassembly.

- Understanding the function of each component.

- Recognizing potential areas for maintenance and inspection.

A clear grasp of the engine’s organization helps in troubleshooting issues and ensures that repairs are conducted efficiently, ultimately contributing to the optimal operation of the entire system.

Replacing Filters and Fluids Efficiently

Maintaining optimal performance in agricultural machinery involves regular upkeep of essential components. Efficiently replacing filters and fluids is crucial for ensuring that equipment operates smoothly and lasts longer. This process not only enhances functionality but also reduces the likelihood of unexpected breakdowns.

Understanding the Importance of Regular Maintenance

Regular maintenance plays a vital role in the longevity and efficiency of machinery. Over time, filters can become clogged with dirt and debris, leading to reduced performance. Similarly, fluids can degrade, affecting lubrication and cooling systems. By routinely replacing these elements, operators can ensure that their equipment functions at its best.

Steps for Efficient Replacement

To facilitate the replacement process, it is beneficial to follow a systematic approach:

- Gather all necessary tools and replacement materials before beginning.

- Carefully remove old filters and fluids, ensuring proper disposal according to environmental regulations.

- Install new filters and refill fluids, taking care to adhere to recommended specifications.

- Run the equipment briefly to circulate the new fluids and check for any leaks.

By adhering to these steps, operators can maintain the efficiency of their machinery while minimizing downtime.

Common Issues with 660

Various challenges can arise when operating agricultural machinery, affecting efficiency and performance. Understanding these potential problems can aid in timely maintenance and repairs, ensuring optimal functionality.

- Engine Performance: Issues such as stalling or reduced power may indicate fuel system problems or air intake restrictions.

- Hydraulic System: Leaks or insufficient pressure can lead to inadequate lifting capabilities or slow response times.

- Electrical Components: Malfunctions in wiring or sensors may result in warning lights activating or equipment not functioning as intended.

Regular inspections and proper care are essential to mitigate these problems. Implementing routine checks can prolong the lifespan of the equipment and enhance productivity.