The effective operation of any machinery relies heavily on understanding how different elements come together to create a seamless system. For those looking to maintain or repair equipment, having a clear overview of the necessary mechanical pieces is crucial. By familiarizing yourself with the arrangement and purpose of each component, you can ensure smooth performance and identify any issues quickly.

Whether you’re troubleshooting a specific problem or simply performing regular upkeep, knowing the proper placement and connection of various mechanical elements helps improve efficiency. This guide offers valuable insights into the organization of essential equipment pieces, allowing for easy reference during maintenance tasks.

With a well-structured visual aid, pinpointing specific components becomes more intuitive. This approach simplifies the process of locating and replacing vital parts when needed, ultimately enhancing the overall functionality and longevity of your machinery.

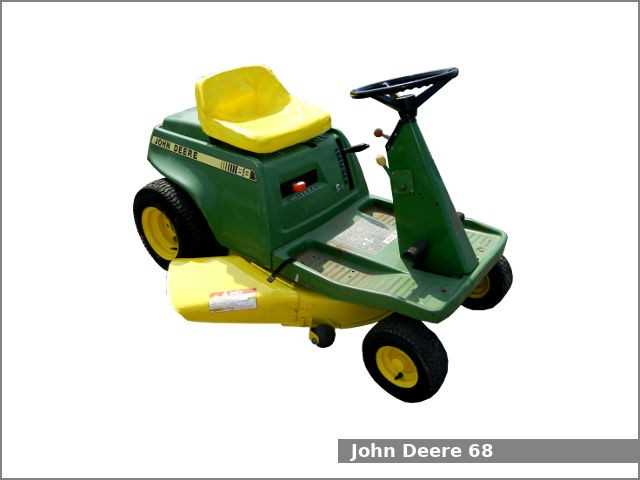

Overview of John Deere 68 Components

The model 68 features a range of key mechanical elements that work together to ensure its smooth operation. Understanding the various components is essential for maintaining functionality and ensuring optimal performance over time. This section provides a detailed look at the most significant mechanical systems, helping users get a clear understanding of their roles in the overall operation.

Engine System: The core of the machine, this system is responsible for providing the necessary power. Proper maintenance ensures long-term efficiency and reliability.

Transmission Mechanism: This crucial element ensures that power is effectively transferred to the wheels, allowing smooth movement. Regular checks can help maintain smooth functionality and prevent breakdowns.

Steering Assembly: The steering system allows the operator to control direction effortlessly, ensuring accurate movements and adjustments during operation.

Maintenance of these components is crucial to

Key Features of the John Deere 68

This model stands out due to its remarkable characteristics designed to offer efficient performance and reliability. It includes features that enhance functionality and ease of use, making it suitable for various tasks.

- Compact Design: The model’s structure is optimized for maneuverability in smaller spaces, offering great control and adaptability.

- Durability: Built with long-lasting materials, it ensures a robust operational life, even under demanding conditions.

- Easy Maintenance: Access to key components allows for simplified upkeep, reducing downtime and extending the machine’s longevity.

- Fuel Efficiency: The engine is designed to minimize fuel consumption while maintaining strong power output, balancing performance with cost-effectiveness.

- Gearbox: Responsible for adjusting the speed and torque output from the engine.

- Clutch: Engages and disengages the power between the engine and transmission.

- Drive Shaft: Transmits rotational energy from the gearbox to the axles.

- Differential: Allows the wheels to rotate at different speeds while turning.

- Axles: Provide the final drive to the wheels, ensuring proper movement.

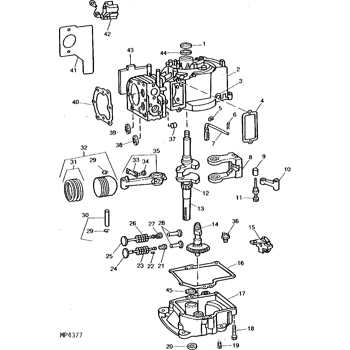

Understanding the Function of Engine Parts

The operation of internal components in an engine is key to its overall performance. Each component plays a role in ensuring smooth, efficient functioning. Recognizing how these mechanisms work together helps to maintain optimal operation.

Internal mechanisms are designed to convert energy into motion. The coordination between these elements ensures the machine runs effectively. Proper understanding of their roles and interactions can greatly improve troubleshooting and maintenance efforts.

Various mechanical elements work in harmony, influencing factors like power output, fuel efficiency, and longevity. Understanding these dynamics is crucial for any maintenance tasks or performance improvements.

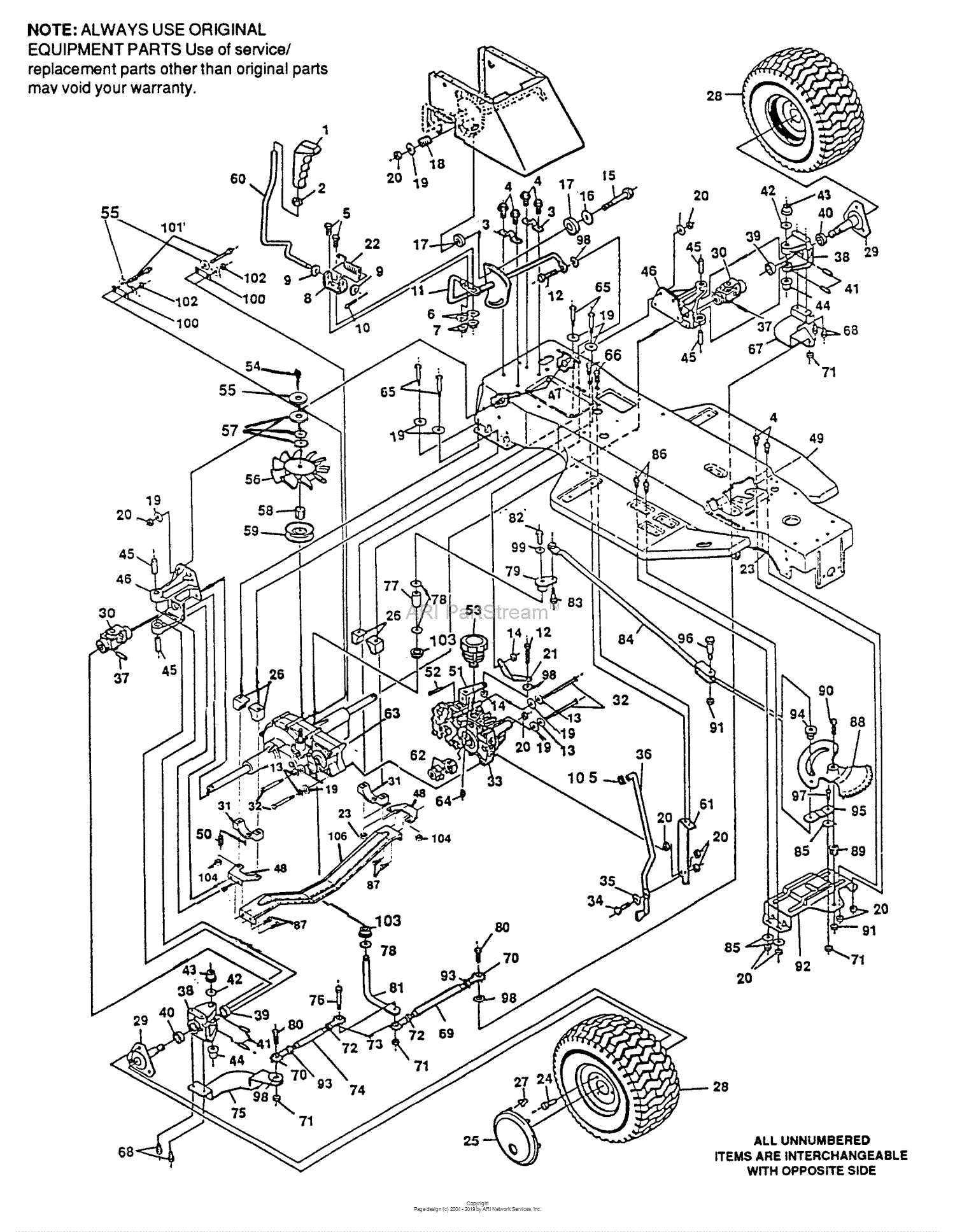

Identifying Transmission System Components

The transmission system is essential for transferring power from the engine to the wheels, enabling smooth vehicle operation. Understanding the key elements of this system is crucial for proper maintenance and troubleshooting. By recognizing the individual components, one can ensure efficient performance and longevity of the machine.

Each of these components plays a specific role in the overall function of the transmission system. Regular inspection and maintenance can prevent potential issues and extend the lifespan of the

Steering Mechanism Breakdown

The steering system is a crucial component that allows the operator to control the direction of the machine efficiently. It consists of various interconnected elements designed to ensure smooth movement and accurate response during operation. Understanding the internal structure of this system is essential for diagnosing potential issues and maintaining optimal performance.

Key Components of the Steering System

Within the steering mechanism, several important parts work together to enable directional control. Each component plays a specific role in ensuring the system functions reliably under different conditions. Below is an overview of these key elements.

| Component | Function | |||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steering Wheel | Allows the operator to input directional commands. | |||||||||||||||||||||||||||||||||||||||

| Steering Shaft | Connects the wheel to the steering gear and transmits motion. | |||||||||||||||||||||||||||||||||||||||

| Steering Gear | Converts rotational movement from the sh

Chassis and Frame Diagram ExplainedThe chassis and frame are the foundation of any vehicle, providing the structural support needed for various components. Understanding the layout of these critical parts is essential for proper maintenance and repair. This section will explore how the frame functions and its key elements, which contribute to the vehicle’s stability and performance. Components of the Frame

The frame is made up of several key elements that work together to support the weight of the vehicle and withstand the stresses encountered during operation. These components are carefully designed to ensure durability and safety.

Importance of the Chassis DesignA well-designed chassis not only supports the vehicle but also contributes to the overall handling and safety. The arrangement of components within the frame must be precise to avoid excessive wear, enhance maneuverability, and prevent undue stress on the structure. Electrical System Parts OverviewThe electrical system of a machine is crucial for its proper functioning, ensuring smooth operation of key components. It includes various elements responsible for power distribution, control, and protection. Understanding the essential components of this system helps in identifying issues and ensuring efficient performance. Power Supply Unit is responsible for delivering energy throughout the system. It is the heart of the electrical setup, converting mechanical energy into usable electrical power. Wiring and Connectors facilitate communication between different parts of the system. These components transmit signals and power, making them vital for the overall operation of the equipment. Control Modules play an essential role in managing the flow of electricity. These units ensure that each part receives the correct amount of power according to its specific function. Protective Elements, such as fuses and circuit breakers, safeguard the system from electrical overloads. They prevent damage to sensitive components by disconnecting power when needed. Overall, each section of the electrical system works together to provide reliability, safety, and efficiency for the equipment. Fuel System Components for John Deere 68The fuel delivery system in machinery is vital for efficient engine performance. It ensures that the correct amount of fuel is supplied to the engine for combustion, optimizing power output and fuel efficiency. Various elements work together to ensure a seamless fuel flow and prevent any interruptions in operation. Below is an overview of these essential components.

Maintenance Parts for John Deere 68Proper upkeep of machinery is essential for its optimal performance and longevity. Regular replacement of key components ensures that the equipment operates smoothly, reducing the risk of breakdowns and improving efficiency. By understanding which elements require attention, owners can maintain the functionality of their equipment while minimizing downtime. Essential Components for Regular Maintenance

Among the critical elements to focus on are the engine filters, which help to keep the engine clean and running efficiently. Air and fuel filters prevent dirt and debris from entering the system, contributing to smoother operation and reducing wear. Additionally, the spark plugs should be checked regularly to ensure consistent ignition. Lubrication and Cooling SystemsThe lubrication system plays a key role in maintaining smooth movement of mechanical parts. Regular checks and changes of the oil and lubricants help to reduce friction and prevent overheating. The coolant system should also be maintained, ensuring that the engine stays within optimal temperature ranges during operation. Blade and Mower Deck Parts GuideUnderstanding the components of a lawn cutting system is crucial for maintaining optimal performance. Each section of the cutting mechanism plays a vital role in ensuring smooth and efficient operation. From the rotating blades to the protective housing, every element must be in good condition for the system to function properly. Key Components of the Cutting AssemblyThe rotating blades are the core of the system, designed to create a clean cut and ensure a well-maintained lawn. The deck, which houses the blades, acts as a protective cover and directs grass clippings away from the mower. Other essential components, such as the belt and pulleys, transfer the power from the engine to the blades, enabling the system to work effectively. Maintenance and Care TipsRegular inspection of the cutting blades and deck is important to identify wear and tear. Ensuring that the blades are sharp and the deck is free from debris will help prevent unnecessary strain on the engine and improve cutting efficiency. Additionally, keeping the moving parts lubricated can extend the lifespan of the entire cutting system. Commonly Replaced Parts in John Deere 68Maintaining the optimal performance of agricultural machinery often requires replacing components that experience regular wear. Understanding which components are most frequently swapped out can help with proactive maintenance and ensure seamless operation. Below is a list of common components that tend to require attention over time. Key Components That Wear OutCertain items are known to wear out more quickly due to their frequent use and exposure to tough working conditions. Regularly checking these parts and replacing them when needed can prevent unexpected breakdowns and costly repairs.

Preventative Measures and Maintenance

In addition to regular part replacement, performing routine checks on these components can prolong their life and keep the machinery in good working order. Using high-quality replacement parts and staying on top of servicing schedules can reduce the risk of major failures. |