In the realm of heavy equipment maintenance, having a clear visual representation of a machine’s internal structure is essential. Such illustrations serve as valuable guides, enabling technicians and operators to identify and access various elements with ease. This foundational knowledge streamlines repair processes and enhances overall efficiency in operations.

When delving into the specifics of machinery, recognizing the interrelationships between different components can significantly impact performance and longevity. A well-organized schematic not only highlights the positioning of each item but also underscores the importance of regular inspections and timely replacements. By comprehending these layouts, individuals can make informed decisions, ultimately extending the life of their equipment.

Furthermore, a detailed breakdown of mechanical elements fosters a deeper understanding of the technology at hand. By examining these visuals, users can familiarize themselves with the intricacies of their machinery, leading to more effective troubleshooting and maintenance practices. This knowledge empowers operators, ensuring they are better prepared to handle any challenges that may arise during operation.

Understanding John Deere 828D

In the realm of machinery, there exists a remarkable piece of equipment designed for efficiency and performance. This machine is celebrated for its robust construction and adaptability across various tasks, making it a favorite among operators. Grasping the intricacies of this model is essential for maximizing its potential in diverse applications.

Key Features

This exceptional vehicle boasts an array of features tailored for both productivity and ease of use. Its powerful engine ensures that heavy-duty tasks can be tackled with ease, while its ergonomic design provides comfort during prolonged operation. The intuitive controls allow for seamless navigation and operation, enhancing the overall user experience.

Maintenance and Care

Regular upkeep is vital for sustaining the functionality and longevity of this equipment. Understanding the various components and their interactions can help in identifying issues before they escalate. Utilizing reliable resources to obtain replacement elements can significantly contribute to the maintenance process, ensuring that this machinery remains in peak condition.

Key Features of 828D Model

This model is designed with several outstanding attributes that enhance its functionality and performance. Users can expect a robust and efficient experience, making it suitable for various applications.

- Powerful Engine: Equipped with a high-performance engine that ensures optimal power output.

- Advanced Hydraulics: Features a sophisticated hydraulic system for enhanced lifting capabilities.

- Durability: Built with premium materials for longevity and resilience in tough environments.

- Comfortable Operator Space: Designed with an ergonomic cabin to enhance user comfort and visibility.

- Versatile Attachments: Compatible with a wide range of tools and accessories for various tasks.

These characteristics combine to deliver an ultimate user experience, making the model a top choice in its category.

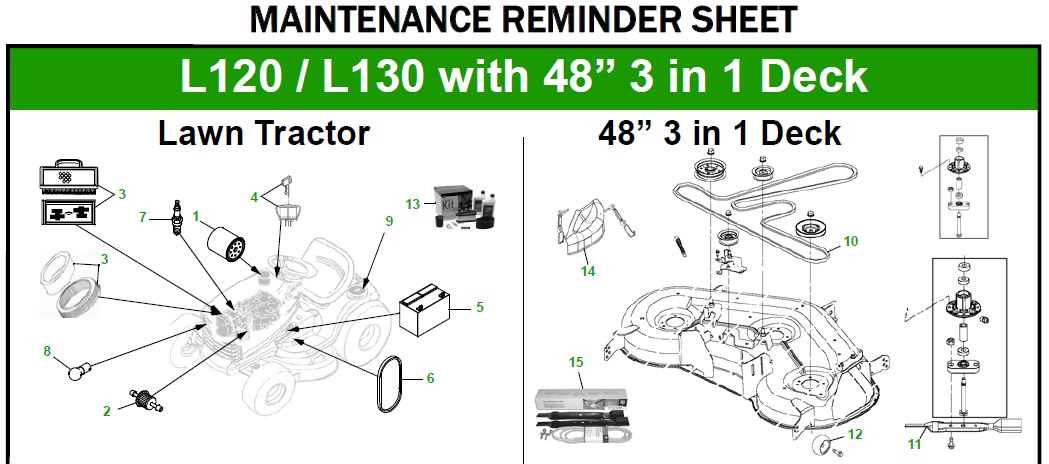

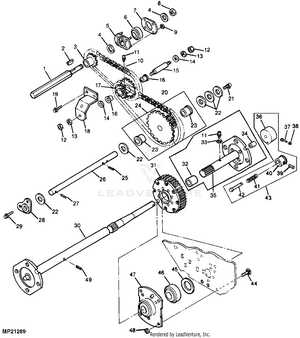

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and functionality of machinery. They serve as essential tools for technicians and operators, simplifying the process of identifying and locating various elements within complex systems.

These illustrations not only enhance the efficiency of maintenance and repair tasks but also improve communication among team members. By providing a clear view of the arrangement and relationships between different components, they help to minimize errors during assembly and disassembly processes.

Moreover, having access to detailed visuals can significantly reduce downtime. When individuals can quickly reference these guides, they can diagnose issues more effectively and procure the necessary replacements without delay. This leads to improved operational efficiency and longer equipment lifespan.

Ultimately, these visual aids are invaluable in fostering a deeper understanding of machinery, ensuring that users can manage and maintain their equipment with confidence and accuracy.

Common Parts for John Deere 828D

This section highlights essential components commonly associated with the model, offering insights into their functions and significance. Understanding these elements is crucial for maintenance and operational efficiency.

| Component | Description |

|---|---|

| Engine Assembly | The core unit providing power, essential for the functionality of the entire machine. |

| Hydraulic System | A critical system enabling fluid power, facilitating various movements and operations. |

| Transmission | This element manages the power transfer from the engine to the wheels, influencing speed and torque. |

| Chassis | The framework supporting all components, providing stability and structure. |

| Cooling System | Ensures the engine operates within optimal temperature ranges, preventing overheating. |

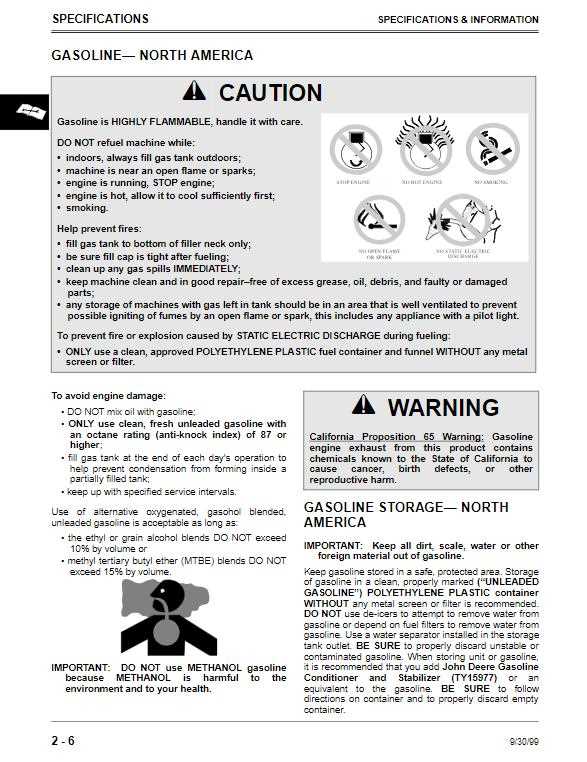

| Fuel System | Delivers fuel to the engine, playing a vital role in its performance and efficiency. |

| Electrical System | Comprises wiring, batteries, and controls, essential for starting and operating various functions. |

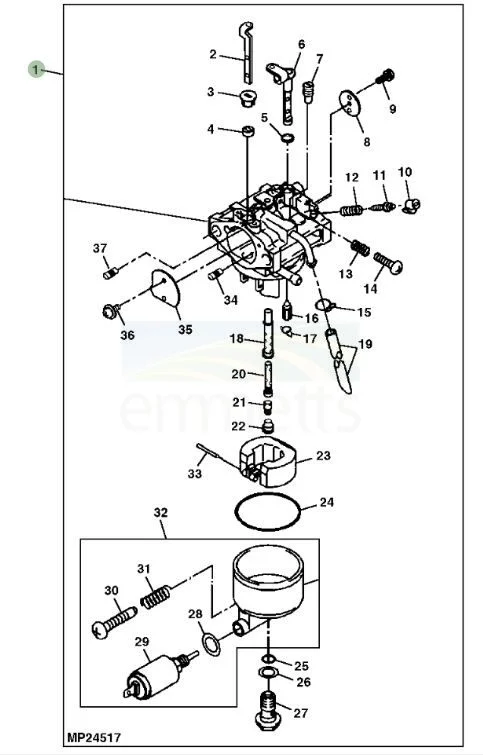

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a clear view of how various elements fit together, enabling users to identify necessary pieces quickly. Mastering this skill can significantly enhance troubleshooting efficiency and overall project success.

Familiarizing with Symbols

Every visual guide uses specific symbols and notations. Take time to learn what each icon represents, as this knowledge is crucial for accurately interpreting the layout. Recognizing these elements will help you grasp the structure and function of the assembly.

Following the Flow

Pay attention to the arrangement and connections between components. Often, a sequential flow is depicted that guides you through the assembly process. Understanding this flow will allow you to visualize how to assemble or disassemble the entire system effectively.

Maintenance Tips for 828D Equipment

Ensuring optimal performance of your machinery requires regular upkeep and attention to detail. Proper maintenance not only extends the life of your equipment but also enhances its efficiency and safety. Below are essential tips to keep your machinery in top shape.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Checks | Weekly | Inspect oil, coolant, and hydraulic fluid levels to prevent overheating and mechanical failure. |

| Filter Replacements | Every 200 Hours | Change air, fuel, and hydraulic filters to ensure clean operation and prevent contaminants. |

| Belt Inspections | Monthly | Check for wear and tension to avoid breakdowns during operation. |

| Greasing | Every 50 Hours | Lubricate moving parts to reduce friction and wear. |

| Visual Inspections | Before Each Use | Look for leaks, loose connections, or signs of wear that could impact performance. |

Finding Replacement Parts Online

Locating suitable components for your machinery can be a straightforward task when you utilize online resources effectively. With the vast array of websites dedicated to equipment and machinery, finding the right replacements has never been easier. This guide will help you navigate the digital marketplace, ensuring that you can source quality items that meet your operational needs.

Utilizing Online Marketplaces

Numerous online platforms specialize in selling machinery components. These marketplaces often feature user-friendly search functions that allow you to filter results based on specific criteria such as model number, type, or brand. Additionally, many sites provide detailed descriptions and customer reviews, giving you insights into the reliability and performance of the products.

Manufacturer Websites and Authorized Dealers

Another reliable approach is to visit the official websites of manufacturers or authorized distributors. These sources typically offer the most accurate and up-to-date information regarding available components. Furthermore, you can often find warranty details and ensure that you are purchasing genuine items, which can save you time and money in the long run.

Official John Deere Resources

Access to reliable and authoritative materials is essential for maintaining and repairing equipment. Official sources provide comprehensive documentation, ensuring users have the most accurate information for efficient operation.

Manufacturer Websites are invaluable, offering downloadable manuals, product specifications, and updates. Users can delve into various resources to find detailed guidance on their machinery.

Customer Support is another critical component, with dedicated teams ready to assist with inquiries, parts identification, and troubleshooting. Engaging with these services leads to enhanced performance and longevity of equipment.

Additionally, online forums and community groups serve as platforms for users to share experiences, tips, and best practices. These interactions enrich knowledge and provide practical insights.

Aftermarket Parts Overview

Exploring the realm of alternative components can significantly enhance the performance and longevity of machinery. These options often provide viable solutions for maintenance and repair, offering quality comparable to original equipment.

- Cost-effective solutions

- Availability of a wide variety of components

- Enhanced performance features

- Compatibility with different models

When considering these alternatives, it’s essential to evaluate:

- Quality and reliability

- Warranty options

- Customer reviews and feedback

- Supplier reputation

Ultimately, opting for alternative components can lead to better value and improved operational efficiency.

Installation Guidelines for Key Components

Proper installation of essential components is crucial for optimal performance and longevity. Following precise guidelines ensures that each element functions harmoniously within the system, minimizing the risk of malfunctions and enhancing overall efficiency.

Preparation Steps

Before beginning the installation process, gather all necessary tools and components. Ensure that the workspace is clean and organized, allowing for easy access to parts. Review the manufacturer’s recommendations for specific requirements related to each component to prevent any oversight.

Installation Process

Start by securely fastening the key components in their designated locations, ensuring that all bolts and fasteners are tightened to the specified torque. Utilize alignment tools as needed to guarantee accurate positioning. After installation, conduct a thorough inspection to confirm that all components are correctly installed and functioning as intended.

Frequently Asked Questions

This section addresses common inquiries related to the components and technical details of specific machinery. Whether you’re seeking clarification on maintenance, availability, or functionality, the following information should prove helpful.

General Inquiries

- What are the most essential components of this machinery?

- How can I determine if a specific part needs replacement?

- Where can I find high-quality components for my equipment?

Maintenance and Support

- What regular maintenance tasks should be performed to ensure optimal performance?

- Are there any recommended practices for troubleshooting common issues?

- How can I access customer support for assistance with repairs or parts?

Owner Experiences and Reviews

This section delves into the insights and feedback from users who have engaged with their machinery. Real-life experiences provide a valuable perspective, shedding light on reliability, performance, and overall satisfaction.

Positive Feedback

- Reliable performance in diverse conditions.

- Ease of use for both novice and experienced operators.

- Durability and low maintenance costs.

Challenges Faced

- Occasional difficulties in sourcing specific components.

- Learning curve for advanced features.

- Need for periodic upgrades to maintain efficiency.