The intricate assembly of agricultural machinery plays a crucial role in ensuring optimal performance and efficiency. This section delves into the various elements that contribute to the functionality of these machines, providing a comprehensive overview of their organization and structure.

By examining the configurations of essential components, operators and technicians can enhance their understanding of how each element interacts within the system. This knowledge is vital for effective maintenance and troubleshooting, ultimately leading to improved operational reliability.

In this exploration, we will highlight the significant features and arrangements of various machine components. A clear grasp of these aspects empowers users to make informed decisions regarding repairs and upgrades, fostering a deeper appreciation for the machinery they rely on in their agricultural endeavors.

Overview of John Deere 835 Moco

The model in question is a highly efficient agricultural implement designed for cutting and conditioning grass and similar crops. Its robust construction and advanced features make it a popular choice among farmers looking to enhance their hay and forage operations. This equipment not only ensures a clean cut but also facilitates quick drying, which is essential for high-quality forage production.

Key Features

- Durable build quality for extended service life

- Advanced cutting technology for optimal performance

- Efficient conditioning systems that enhance drying time

- User-friendly controls for ease of operation

- Compatibility with various tractor models for versatile use

Benefits of Using the Implement

- Increased productivity through faster cutting and conditioning

- Improved forage quality due to efficient drying

- Reduced operational costs with efficient fuel consumption

- Minimized maintenance needs thanks to quality engineering

- Enhanced crop management capabilities for better yields

Key Components of the Moco

This section delves into the essential elements that comprise the machinery used for cutting and conditioning forage. Understanding these components is vital for optimal performance and maintenance, ensuring efficient operation during harvesting tasks.

Primary Elements

The core constituents of this equipment play a pivotal role in its functionality. They include various mechanical parts that work in unison to facilitate the cutting and processing of vegetation. Each component is designed with precision to enhance the overall efficiency of the system, thereby contributing to effective fieldwork.

Maintenance Considerations

Regular inspection and upkeep of these crucial elements are necessary to prevent malfunctions. Operators should be aware of wear and tear, as well as the need for timely replacements, to maintain peak operational standards. Understanding the layout and function of each part aids in troubleshooting and ensures the longevity of the machine.

Functionality of Major Parts

This section explores the key components of a particular agricultural machine, highlighting their roles and contributions to overall performance. Understanding these elements is crucial for optimizing functionality and ensuring efficient operation during fieldwork.

Cutting Mechanism

The cutting mechanism is essential for achieving a clean and efficient cut. This assembly is designed to slice through vegetation with precision, ensuring that the material is processed effectively. The sharp blades, combined with the appropriate angle and speed, facilitate a smooth operation, reducing the effort required from the machine.

Drive System

The drive system plays a pivotal role in transmitting power from the engine to various components. It comprises gears and belts that work together to maintain optimal speed and torque. This component ensures that the cutting mechanism operates seamlessly, providing consistent performance regardless of the terrain or conditions.

By understanding the functionality of these major components, operators can make informed decisions regarding maintenance and operation, ultimately enhancing the machine’s productivity and longevity.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure that agricultural machinery operates at peak efficiency. Implementing a systematic maintenance schedule can prolong the lifespan of equipment and enhance its overall functionality. By focusing on key areas of care, operators can minimize downtime and optimize productivity.

Key Maintenance Practices

- Conduct regular inspections to identify any wear or damage.

- Clean components thoroughly to prevent buildup of dirt and debris.

- Lubricate moving parts to reduce friction and wear.

- Check fluid levels and replace them as necessary for smooth operation.

Seasonal Checks

- Before the start of each season, assess the condition of cutting equipment.

- Inspect belts and chains for signs of wear and tension adjustment.

- Review safety features and ensure they are functioning correctly.

- Store machinery properly when not in use to protect it from the elements.

Adhering to these maintenance recommendations will help achieve reliable performance and efficiency, ensuring that your agricultural tasks are completed effectively.

Identifying Replacement Parts

Understanding how to locate and recognize essential components for agricultural machinery is crucial for efficient maintenance and operation. Ensuring the correct selection of these elements can significantly enhance performance and longevity, thereby reducing downtime and repair costs.

Understanding Component Functionality

Before attempting to substitute any element, it is vital to grasp the function of each component within the system. Familiarity with the roles these items play will assist in identifying suitable replacements that meet the specific requirements of the machinery.

Utilizing Reference Guides

Reference materials, including manuals and online resources, can provide valuable insights into compatible components. These guides often include illustrations and specifications that facilitate the selection of appropriate alternatives, ensuring compatibility and optimal performance.

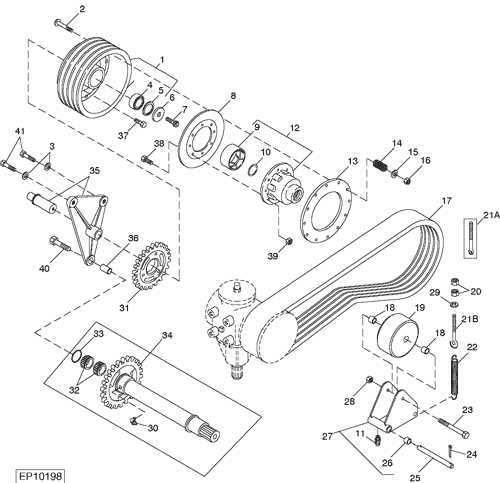

Diagram Navigation and Usage

Understanding the layout and components of agricultural machinery is crucial for efficient operation and maintenance. This section focuses on how to effectively interpret and utilize visual representations that outline the essential elements of such equipment. Navigating these illustrations can enhance your comprehension of the assembly and contribute to better troubleshooting and repair processes.

Interpreting the Layout

When examining these visual guides, pay attention to the various sections and labels that indicate specific functions and locations. Familiarize yourself with the symbols and color codes used to represent different components. This foundational knowledge allows for quicker identification of parts and their interconnections, facilitating a more streamlined workflow.

Practical Applications

Utilizing these visual aids can significantly improve your ability to diagnose issues and perform maintenance tasks. By following the illustrated pathways and connections, you can methodically approach repairs and replacements, ensuring that all elements are correctly aligned. This systematic approach not only saves time but also minimizes the risk of errors during assembly or disassembly.

Common Issues and Solutions

In the realm of agricultural machinery, various challenges can arise that may hinder optimal performance and efficiency. Understanding these common obstacles and their corresponding remedies is essential for maintaining smooth operations and prolonging equipment lifespan. Below are some frequent issues encountered, along with practical solutions to address them.

Hydraulic System Leaks

One prevalent issue involves leaks within the hydraulic system, which can lead to a decrease in functionality and potential damage if left unaddressed. Regularly inspecting hydraulic lines and fittings for signs of wear or corrosion is crucial. If leaks are detected, replacing the damaged components promptly can restore system integrity and performance.

Wear and Tear on Cutting Components

Another common problem is the deterioration of cutting elements due to extensive use. Over time, blades and other cutting parts may become dull or damaged, affecting cutting efficiency. To remedy this, regular maintenance, including sharpening or replacing blades, is recommended to ensure consistent performance and optimal results.

Best Practices for Care

Maintaining agricultural equipment is essential for ensuring longevity and optimal performance. Implementing effective care routines not only enhances functionality but also minimizes the risk of unexpected breakdowns. Adopting systematic approaches to upkeep can lead to improved efficiency and reduced maintenance costs over time.

Routine Inspections

Conducting regular inspections is a vital practice for sustaining machinery health. Check for signs of wear and tear, such as frayed belts or loose components. Ensure that all moving parts are properly lubricated to prevent friction-related damage. Addressing minor issues promptly can prevent more significant problems in the future.

Proper Cleaning Techniques

Keeping equipment clean is crucial for maintaining its efficiency. Remove debris and dirt buildup after each use, especially from critical areas like filters and cooling systems. Utilize appropriate cleaning agents that do not harm the surfaces of the machinery. Regular cleaning not only improves performance but also helps identify potential issues early on.

Comparative Analysis with Other Models

This section delves into the evaluation of a specific agricultural machine in relation to its peers within the same category. By examining various functionalities, performance metrics, and design features, we aim to provide a clearer understanding of how this equipment stacks up against alternatives available in the market.

Performance Metrics

When analyzing the operational efficiency, it is essential to compare key performance indicators such as speed, cutting width, and adaptability to different terrains. The model in question showcases impressive capabilities that rival those of leading competitors, ensuring optimal productivity across diverse agricultural tasks.

Design Features and Usability

The usability and ergonomics of machinery play a crucial role in user satisfaction. Notably, this model incorporates innovative design elements that enhance ease of use, making it a strong contender when placed alongside similar options. The intuitive layout and robust construction contribute to a seamless user experience, which is vital for long hours in the field.

Resources for Further Information

For those seeking to enhance their understanding of agricultural machinery and its components, a variety of resources are available. These materials can provide valuable insights into the mechanisms and functionality of specific equipment, ensuring optimal performance and maintenance practices.

Online Communities and Forums

Engaging with online forums dedicated to machinery enthusiasts can be incredibly beneficial. Platforms like discussion boards and social media groups offer a wealth of shared knowledge, user experiences, and practical tips from individuals who work with similar equipment.

Manufacturer and Dealer Publications

Consulting manuals and publications from manufacturers and authorized dealers is another excellent way to gain in-depth information. These documents often include detailed specifications, troubleshooting guides, and maintenance schedules that are crucial for anyone looking to operate and care for their machinery effectively. Always refer to official sources to ensure the information is accurate and reliable.