In the realm of modern farming, comprehending the intricate mechanisms of machinery is crucial for optimal performance. This section aims to illuminate the fundamental elements that contribute to the efficiency and reliability of specific equipment used in agricultural processes.

Visual representations serve as invaluable tools for farmers and technicians alike, allowing them to identify various components and their functions. By exploring these illustrations, one can gain deeper insights into the assembly and operation of the machinery, ultimately leading to better maintenance and troubleshooting strategies.

Furthermore, having a comprehensive grasp of each individual part enables operators to make informed decisions regarding repairs and replacements. As we delve into the specifics, the information presented here will guide you toward achieving the ultimate operational excellence in your agricultural endeavors.

Understanding the John Deere 925 Moco

This section delves into the intricacies of a specific agricultural machine designed for cutting and conditioning crops. With its advanced engineering and user-friendly design, it plays a crucial role in enhancing efficiency on the farm. Grasping its components and functionality is essential for optimizing performance and ensuring proper maintenance.

The machine is known for its robust build and reliability, making it a preferred choice among farmers. It operates seamlessly across various terrains, allowing for effective crop management. Understanding its key features will enable users to maximize productivity while minimizing downtime.

Familiarity with the different elements of this equipment can significantly impact operational success. By comprehending how each part contributes to overall performance, operators can troubleshoot issues and implement best practices in their routine maintenance. This knowledge not only supports longevity but also enhances the machine’s effectiveness in the field.

Key Components of the Moco

The essential elements of this agricultural machine play a crucial role in its functionality and efficiency. Understanding these components allows operators to optimize performance and ensure durability during use.

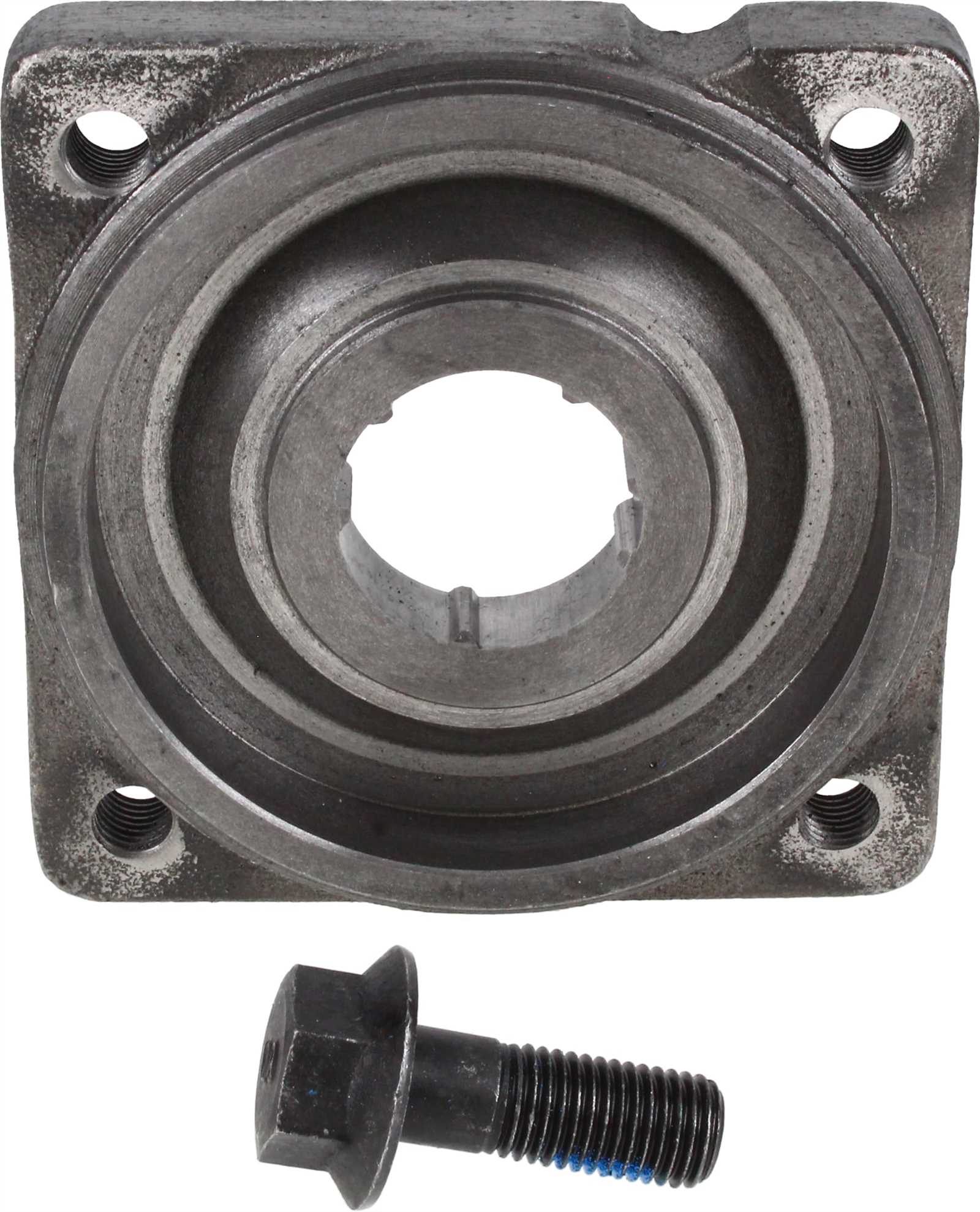

Cutter Bar: This is the primary tool responsible for cutting grass and other crops. Its sharp blades are designed for precision and speed.

Drive System: This mechanism transfers power from the engine to the cutter bar, enabling smooth operation. A reliable drive system is vital for consistent performance.

Frame: The robust structure supports all other components and provides stability during operation. A well-constructed frame enhances the overall longevity of the machine.

Rollers: These components help guide the cut material, ensuring an even distribution and preventing clogging. Properly functioning rollers contribute to efficient workflow.

Safety Features: Incorporating protective mechanisms is essential to safeguard operators and prevent accidents. These features enhance user confidence while operating the equipment.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance offers numerous advantages that enhance performance and longevity. These elements are designed to match specifications precisely, ensuring optimal functionality and reducing the likelihood of malfunctions.

| Advantage | Description |

|---|---|

| Quality Assurance | Genuine components undergo rigorous testing to meet high standards, ensuring reliability. |

| Longevity | These elements are crafted for durability, leading to a longer lifespan for your equipment. |

| Performance | Authentic parts are engineered for seamless compatibility, promoting superior operation. |

| Warranty Protection | Using original components often maintains warranty coverage, safeguarding your investment. |

| Resale Value | Maintaining equipment with genuine parts can enhance resale value, appealing to potential buyers. |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your agricultural machinery requires consistent attention and care. By following a structured maintenance routine, you can significantly extend the lifespan of your equipment while optimizing its performance. Below are essential tips to help you maintain your machinery effectively.

Regular Inspections: Conduct routine checks to identify wear and tear before they escalate into major issues. Look for signs of damage, loose components, or leaks. Addressing small problems promptly can save time and costs in the long run.

Cleanliness: Keeping your machinery clean is crucial. Regularly remove debris, dirt, and residue that can hinder performance. Clean components not only function better but also last longer, as accumulated grime can lead to corrosion and other damages.

Lubrication: Ensure that all moving parts are adequately lubricated according to the manufacturer’s guidelines. Proper lubrication reduces friction and wear, promoting smoother operation and extending the lifespan of crucial components.

Timely Replacements: Pay attention to components that have a defined lifespan. Replace worn-out parts before they fail to avoid unexpected downtime. Staying proactive with replacements can enhance overall reliability.

Seasonal Maintenance: Adapt your maintenance schedule based on seasonal usage. Preparing equipment for storage during off-seasons and ensuring readiness before peak usage periods can prevent potential breakdowns and ensure optimal performance.

Operator Training: Educate operators on proper handling techniques and best practices. Well-trained personnel are less likely to cause unnecessary strain on the machinery, reducing the risk of damage.

By implementing these strategies, you can ensure that your equipment remains in peak condition, minimizing the risk of costly repairs and enhancing operational efficiency.

Common Issues and Troubleshooting

This section addresses frequent problems encountered with agricultural machinery, along with effective solutions to enhance performance and longevity. Identifying these issues early can prevent significant downtime and costly repairs.

Typical Problems

- Poor cutting efficiency

- Unusual noises during operation

- Frequent clogging of components

- Inconsistent hydraulic performance

Troubleshooting Steps

- Check blade sharpness and alignment.

- Inspect for loose or damaged parts.

- Ensure hydraulic fluid levels are adequate.

- Clean any debris that may cause blockages.

Parts Availability and Sourcing

Access to quality components is essential for maintaining equipment performance and longevity. Identifying reliable sources and understanding availability can streamline repairs and reduce downtime.

Finding Reliable Sources

- Authorized dealers: These suppliers provide genuine components, ensuring compatibility and quality.

- Aftermarket suppliers: Alternative options often offer competitive pricing and varied selections.

- Online marketplaces: Websites dedicated to agricultural machinery can provide a wide range of products.

Factors to Consider

- Compatibility: Ensure that the components match your specific model requirements.

- Quality: Verify the reputation of the supplier for high-quality offerings.

- Pricing: Compare costs across different sources to find the best deals.

Comparing Aftermarket vs. OEM Parts

When maintaining agricultural equipment, choosing the right components is crucial for optimal performance. Two primary options exist: original manufacturer items and alternative aftermarket solutions. Each choice has distinct advantages and considerations that can impact efficiency, longevity, and cost-effectiveness.

Advantages of OEM Components

- Quality Assurance: Manufactured to the original specifications, ensuring perfect compatibility.

- Reliability: Often backed by warranties and trusted by professionals in the industry.

- Performance: Designed to work seamlessly with specific machinery, enhancing operational efficiency.

Benefits of Aftermarket Alternatives

- Cost-Effectiveness: Typically available at lower prices, making them more accessible for budget-conscious operators.

- Variety: A wider range of options, allowing for customization based on individual needs.

- Innovation: Many aftermarket providers invest in research, resulting in improved designs and technologies.

Ultimately, the decision between original items and alternatives hinges on personal priorities, including budget, performance requirements, and maintenance philosophy.

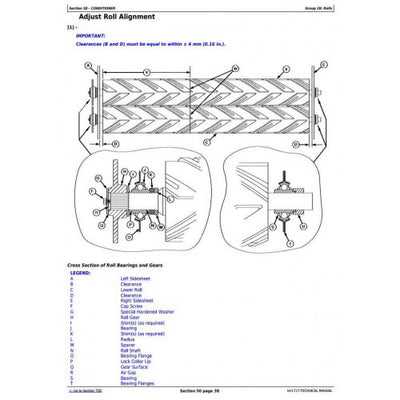

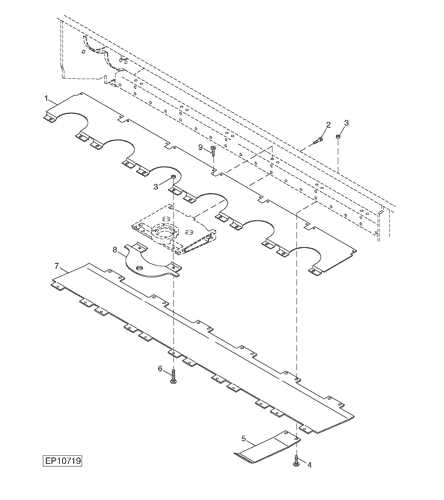

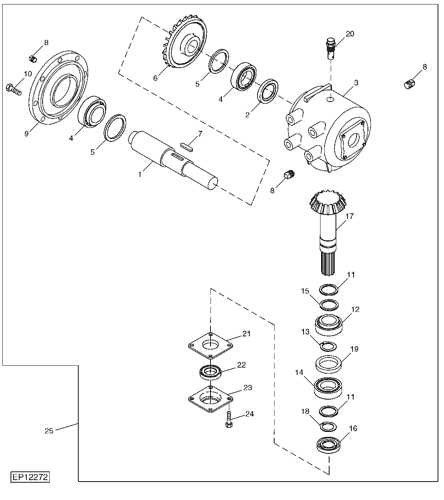

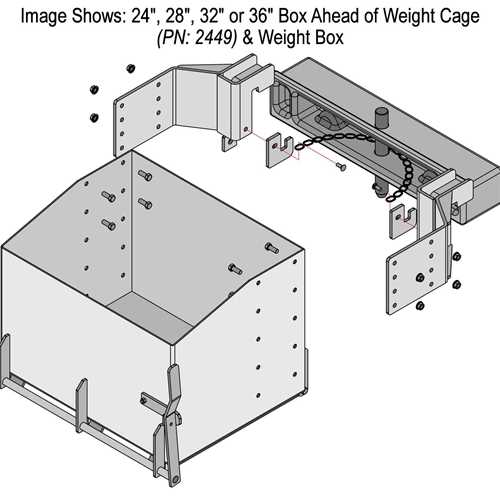

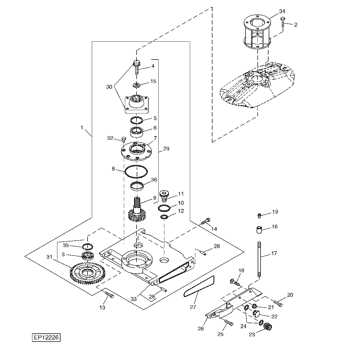

Understanding the Parts Diagram

Comprehending the layout of components within machinery is essential for effective maintenance and repairs. A visual representation provides insights into how individual elements interact and contributes to the overall functionality of the equipment. Familiarity with this schematic can streamline troubleshooting processes and ensure optimal performance.

Key Components Overview

Each section of the representation illustrates specific assemblies and their relationships. Recognizing these sections allows for targeted interventions during service. Here are some critical elements often depicted:

| Component Name | Description |

|---|---|

| Cutter Bar | The primary element responsible for cutting, positioned at the front of the machine. |

| Drive System | Includes the mechanisms that power the unit and ensure smooth operation. |

| Safety Shields | Protective barriers designed to ensure operator safety during use. |

| Adjustment Levers | Controls that allow users to modify the height and angle of the cutting apparatus. |

Utilizing the Schematic for Maintenance

To maintain equipment efficiently, one must refer to the visual guide frequently. Understanding each section not only aids in identifying worn or damaged parts but also enhances the ability to assemble or disassemble units correctly. This knowledge fosters a proactive approach to equipment care, reducing downtime and increasing productivity.

Essential Tools for Repairs

Effective maintenance relies on having the right tools at hand. Each piece of equipment plays a crucial role in ensuring that repairs are completed efficiently and accurately. Understanding which instruments are necessary can significantly enhance the repair process.

Basic Hand Tools

- Wrenches: For tightening and loosening bolts.

- Screwdrivers: Essential for assembling and disassembling components.

- Pliers: Useful for gripping and manipulating parts.

Specialized Equipment

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

- Grease Gun: Helps maintain lubrication in moving parts.

- Diagnostic Tools: Aid in identifying issues quickly.

Safety Precautions During Maintenance

Ensuring a secure environment while performing upkeep is crucial for preventing accidents and injuries. Proper safety measures protect not only the individual conducting the maintenance but also those nearby, creating a safer workplace overall.

Personal Protective Equipment

Always wear appropriate personal protective gear, including gloves, goggles, and helmets. This equipment significantly reduces the risk of injury from sharp objects, chemicals, and moving parts during maintenance tasks.

Equipment Lockout Procedures

Implementing lockout/tagout procedures is essential to prevent accidental machine start-up. Before beginning any work, ensure that the equipment is powered down and secured to eliminate potential hazards.

How to Read a Parts Manual

Understanding a service guide is essential for anyone involved in maintenance or repair of machinery. These manuals provide detailed information that helps users identify components and ensure proper functioning. By familiarizing yourself with the layout and terminology, you can streamline your repair processes and minimize downtime.

Familiarize Yourself with the Structure

A typical service guide is organized into sections that cover various assemblies and components. Start by reviewing the table of contents, which will direct you to specific areas. Each section usually includes diagrams and lists that illustrate different parts and their relationships within the system. Pay attention to section headings and subheadings, as they will help you navigate effectively.

Understand the Terminology

Common terms used in these manuals may include components, assemblies, and hardware. Get comfortable with these terms to accurately interpret the information presented. Additionally, notes and legends may accompany diagrams, providing vital context and specifications. Take time to familiarize yourself with these annotations to enhance your comprehension.

Cost Analysis of Replacement Parts

Understanding the financial implications of substituting components is crucial for efficient machinery maintenance. This analysis offers insights into expenses, helping operators make informed decisions.

- Initial Costs: Assess the purchase price of each component, including variations in quality.

- Long-term Expenses: Consider durability and frequency of replacements, impacting overall investment.

- Operational Efficiency: Evaluate how new components affect performance, potentially reducing downtime.

Ultimately, a comprehensive evaluation ensures that choices align with both budget constraints and operational needs.

Customer Reviews and Experiences

Feedback from users plays a crucial role in understanding the effectiveness and reliability of agricultural equipment. Insights shared by customers not only highlight performance but also showcase real-life experiences that can guide potential buyers.

Many users have praised the durability of the machinery, noting how it withstands various weather conditions and heavy use. One reviewer mentioned that after several seasons of operation, the equipment showed minimal wear and tear, which speaks volumes about its build quality.

On the other hand, some customers expressed concerns regarding maintenance, specifically citing the need for replacement components. However, they appreciated the availability of resources and diagrams that simplified the process, making repairs less daunting.

Overall, the collective experiences of users provide a valuable perspective, enabling prospective buyers to make informed decisions based on real-world performance and reliability.