Understanding the internal makeup of a small engine is key for both maintenance and repair. Whether you’re a seasoned technician or a DIY enthusiast, having a clear picture of how different elements fit together is essential. This knowledge not only helps in identifying potential issues but also streamlines the repair process, making it easier to source replacements and perform accurate fixes.

Each mechanical system is made up of various crucial elements that work in unison to deliver optimal performance. By familiarizing yourself with the layout and function of these key components, you ensure that you’re well-prepared to handle routine upkeep or more complex repair jobs. A thorough breakdown of this information can provide clarity and confidence when working with small engines.

This section will guide you through a detailed overview of critical elements, providing a visual and functional understanding of how each piece contributes to the overall system’s efficiency. With this knowledge, you’ll be better equipped to diagnose issues and ensure everything runs smoothly.

Honda G100 Parts Diagram

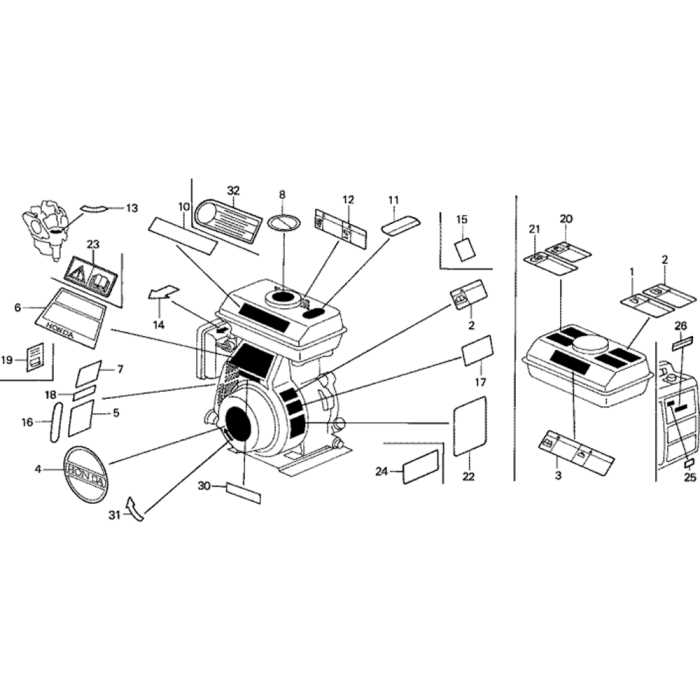

This section provides a detailed view of the individual components and their arrangement within the engine. The illustration offers a clear perspective on how each element connects and interacts, making it easier to identify specific pieces and their function within the system.

- Engine block assembly layout

- Positioning of key mechanical components

- Connections between essential elements

- Arrangement of fuel and air intake systems

- Visualization of internal moving mechanisms

Understanding the structure is crucial for proper maintenance and repair, as it ensures accuracy when handling replacements or adjustments.

Overview of Honda G100 Engine Components

The small internal combustion system in question is known for its durability and efficiency. Designed for compact machinery, this engine combines simplicity with effective performance. Key elements of the unit work together to ensure smooth operation and reliable power delivery. Each part is engineered to serve a specific function, contributing to the overall performance and longevity of the machine.

Core Components

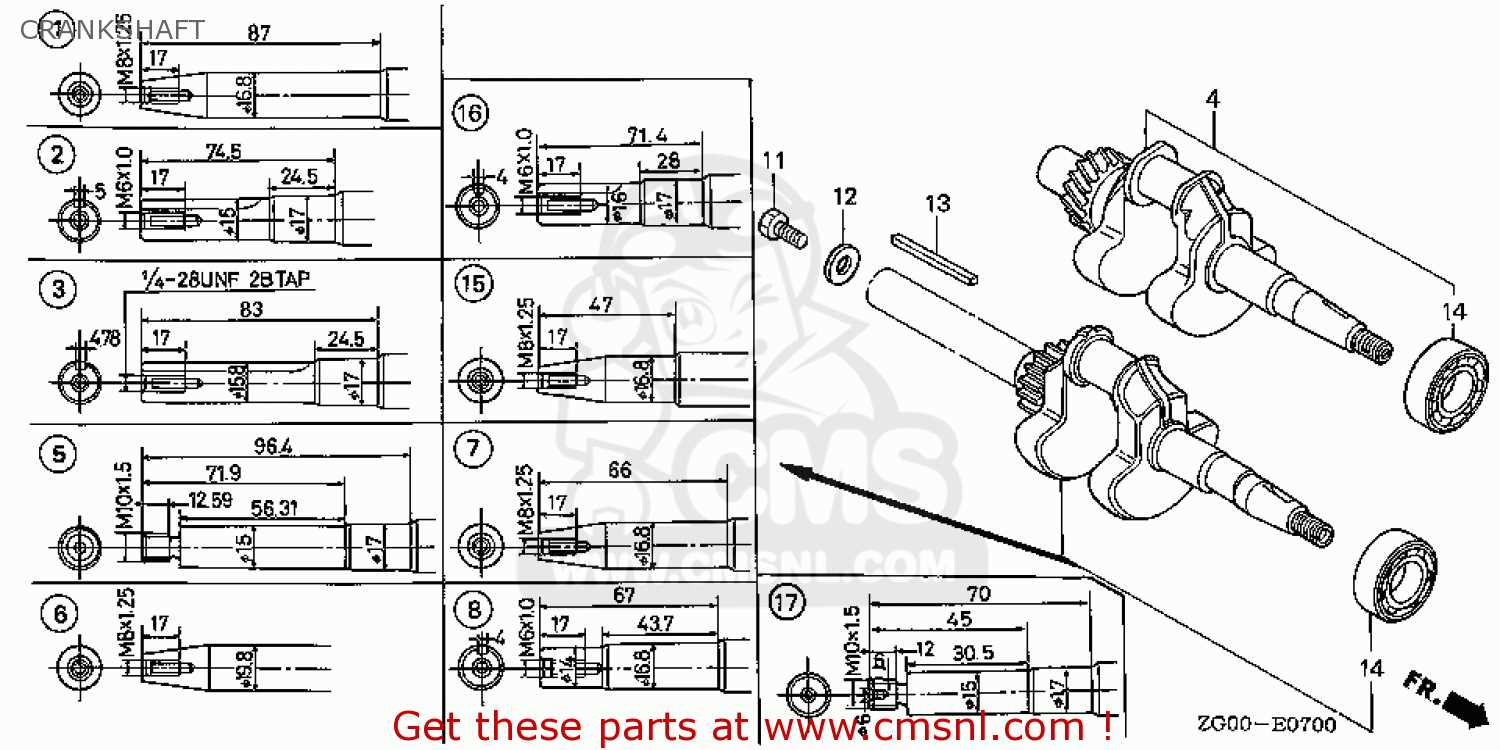

At the heart of the engine lies a robust block that houses several essential mechanisms. The crankshaft is responsible for converting linear motion into rotational energy, while the piston cycles within the cylinder, compressing the fuel-air mixture. The connecting rod links these parts, transmitting motion from the piston to the crankshaft.

Fuel and Ignition System

The fuel system is designed to deliver the precise amount of fuel to the combustion chamber. The carburetor plays a key role in mixing air and fuel in the right proportion, ensuring optimal combustion. Meanwhile, the ignition system ensures that a timely spark ignites the mixture, driving the engine’s power output. The flywheel stores rotational energy, helping to maintain momentum and ensure a consistent running cycle.

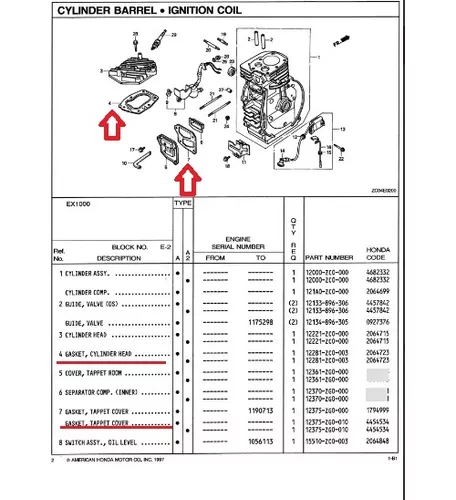

Exploring the Cylinder Block Layout

The design of the cylinder block plays a critical role in the functionality and performance of internal combustion engines. By analyzing the internal structure, we gain insight into how various components interact to support overall engine efficiency and longevity. This section delves into the core elements of the block, focusing on its geometry and key construction features.

Main Structural Components

The central housing, known as the block, contains multiple bores where the pistons move up and down. These cylindrical chambers are precision-engineered to ensure smooth piston movement. Additionally, the block integrates essential pathways for both cooling and lubrication systems, contributing to the thermal stability of the engine.

Material Composition and Durability

Typically cast from aluminum alloys or cast iron, the cylinder block must withstand high thermal and mechanical stresses. The choice of material directly affects weight distribution, heat dissipation, and the overall durability of the engine. A well-engineered block is crucial for managing the intense pressures generated during combustion cycles.

| Component | Function | Material | |||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder Walls | Gui

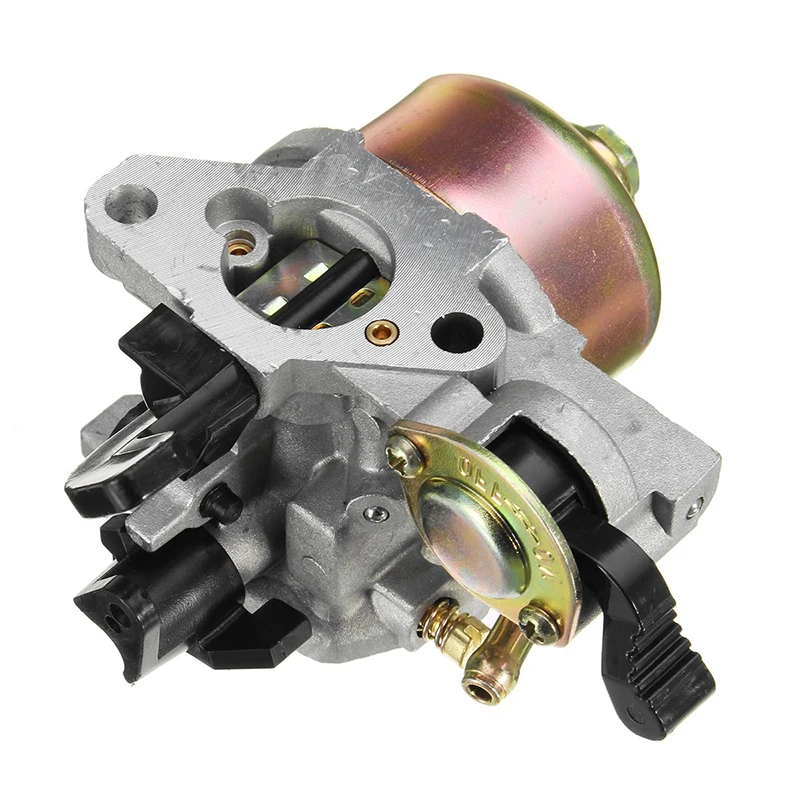

Detailed View of the Carburetor AssemblyThe carburetor assembly is a critical component in the engine’s fuel system, responsible for mixing air and fuel in the correct proportions for combustion. A thorough understanding of its structure and function is essential for maintenance and troubleshooting. Main Components of the Carburetor

The carburetor is composed of several key elements that work together to ensure proper fuel delivery. These components include the throttle valve, choke, float chamber, and various jets, each serving a specific role in regulating the air-fuel mixture.

Adjustments and Maintenance

Understanding the Ignition System StructureThe ignition system is a crucial component that enables the engine to function by igniting the air-fuel mixture within the combustion chamber. Its proper operation ensures efficient performance, stable combustion, and overall engine reliability. The structure involves several interconnected elements, each serving a vital role in the process of generating and controlling the spark necessary for ignition. Main Components

The ignition system is built around key elements that work in unison to deliver the required spark at the right moment. These include:

Functionality OverviewIn essence, the ignition system is designed to generate and control the spark timing. The coil boosts the voltage, while the distributor ensures it reaches the correct cylinder. The spark plug then performs the critical task of igniting the fuel mixture, ensuring the engine runs smoothly and efficiently. Proper synchronization between these components is key for optimal operation. Examining the Fuel Tank and Lines

The fuel reservoir and associated conduits play a crucial role in the overall functionality of the engine system. Understanding their structure and operation is essential for maintaining optimal performance. This section delves into the components involved in fuel storage and distribution, highlighting their significance in ensuring smooth engine operation. The fuel tank is designed to store gasoline securely while preventing leaks and vapor loss. It is typically made from durable materials to withstand various environmental conditions. The fuel lines, on the other hand, transport the fuel from the tank to the engine. Their integrity is vital to avoid blockages or leaks that could disrupt the fuel flow.

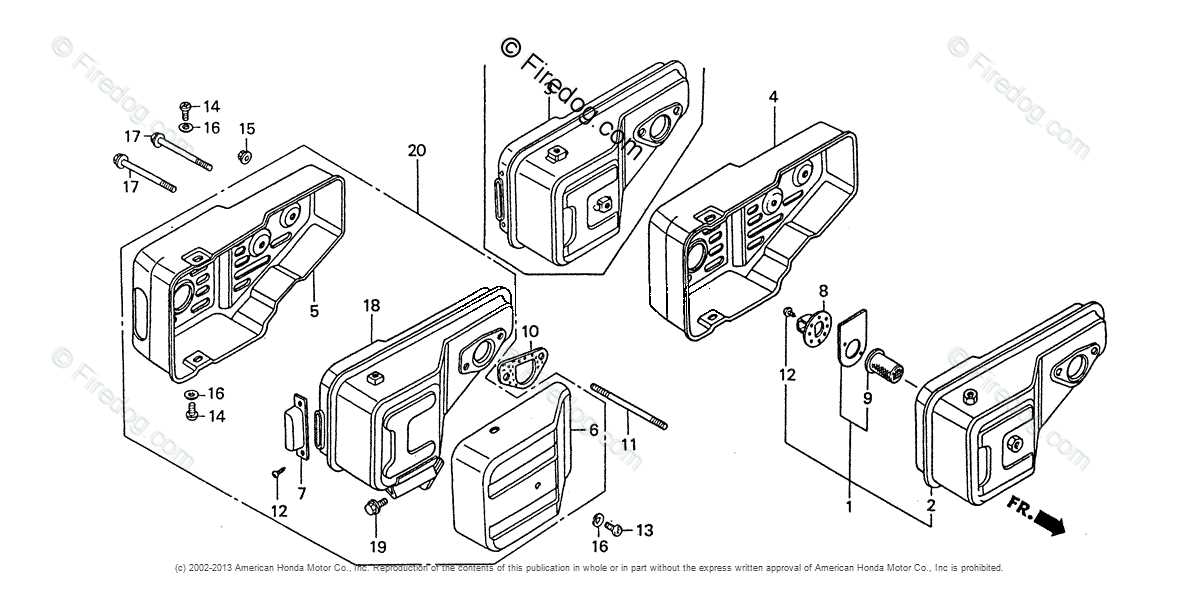

Regular inspection and maintenance of these elements are necessary to ensure a reliable and efficient fuel supply. Any signs of wear or damage should be addressed promptly to prevent performance issues. Honda G100 Exhaust System BreakdownThe exhaust assembly plays a critical role in ensuring efficient operation and optimal performance of the engine. Understanding the components and their arrangement helps in maintaining the overall functionality of the system. This section provides a detailed overview of the elements involved in the exhaust structure, emphasizing their importance and interconnectivity.

Proper maintenance and timely replacement of these components ensure longevity and efficiency of the exhaust system. Regular inspections help identify potential issues before they escalate, leading to smoother operation and improved performance. Internal Engine Cooling Mechanism LayoutThe cooling system within an internal combustion engine plays a crucial role in maintaining optimal operating temperatures. Efficient temperature regulation is vital for performance, longevity, and overall functionality. This section outlines the key components and their arrangement within the cooling mechanism. Key Components of the Cooling System

Flow and Functionality

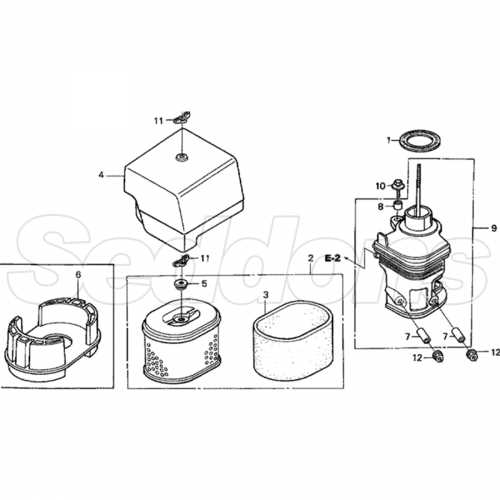

The coolant circulates through the engine, absorbing heat generated during combustion. As the liquid passes through the radiator, it loses heat to the environment. The thermostat opens and closes to control the flow, ensuring efficient cooling under varying conditions. This interplay of components contributes to the overall thermal management of the engine. Air Filter Assembly and Its Components

The air filter assembly plays a crucial role in maintaining the performance and efficiency of an engine. It is designed to prevent contaminants from entering the combustion chamber, ensuring that only clean air mixes with fuel for optimal combustion. Understanding its components is essential for effective maintenance and troubleshooting. Key Components of the Air Filter AssemblyThe primary element of the air filter assembly is the air filter itself, which traps dirt, dust, and other particles. This filter is typically made from paper, foam, or a combination of materials that provide excellent filtration while allowing sufficient airflow. Additionally, the assembly may include a housing that secures the filter in place and prevents unfiltered air from bypassing the filtration system. Maintenance and ReplacementRegular maintenance of the air filter assembly is vital for optimal engine performance. It is recommended to inspect the filter periodically and replace it when it becomes clogged or dirty. A clean air filter not only enhances engine efficiency but also improves fuel economy, making it an essential aspect of engine care. Neglecting the air filter can lead to decreased performance and increased emissions. Understanding the Flywheel and Pulley SystemThe flywheel and pulley system is a critical component in many mechanical devices, playing a vital role in energy storage and transmission. This system works by converting rotational energy into mechanical work, ensuring smooth operation and efficiency. The design typically involves a wheel that rotates around an axis, coupled with a pulley that helps transfer motion and force. Functionality of the flywheel centers on its ability to maintain momentum. When energy is applied, the flywheel accumulates this energy, allowing for a steady output even when the input fluctuates. This characteristic is essential in applications where consistent performance is required. Meanwhile, the pulley system aids in managing power transfer between various components. By altering the direction of force and providing mechanical advantage, pulleys facilitate easier operation of machinery. This interplay between the flywheel and pulley enhances the overall functionality of the system, contributing to improved efficiency and reliability. In conclusion, understanding the dynamics of the flywheel and pulley system is crucial for optimizing performance in mechanical applications. Its ability to store energy and manage power effectively underscores its significance in various engineering solutions. Oil System Parts and Their FunctionsThe oil system of an engine plays a crucial role in maintaining its overall efficiency and longevity. It ensures proper lubrication of moving components, reduces friction, and facilitates heat dissipation. Understanding the various elements within this system and their specific roles is essential for effective maintenance and optimal performance. Key components of the lubrication system include:

Each of these elements works together to create a reliable and efficient lubrication system, contributing to the smooth operation of the engine and prolonging its lifespan. |