Modern agricultural equipment is essential for efficient farming, and understanding the layout of its components is crucial for proper maintenance and operation. Each part plays a vital role in ensuring the machine functions smoothly, making it necessary for operators to be familiar with the overall structure and individual elements.

In this guide, we will explore how different sections of a harvesting tool connect and interact, helping to streamline repairs and replacements. By gaining insight into these relationships, users can quickly address technical issues, improve performance, and extend the lifespan of the equipment.

Whether you’re troubleshooting or planning routine maintenance, having a clear understanding of the equipment’s structure will enhance productivity and reduce downtime. This detailed exploration will assist you in identifying specific areas that may require attention, ensuring smooth and uninterrupted operation.

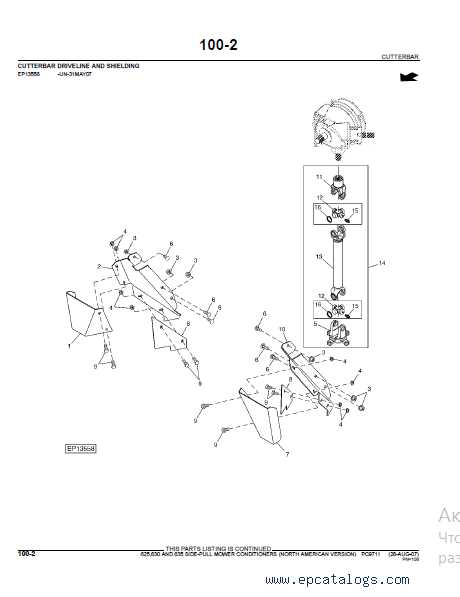

Overview of John Deere 926 Moco Components

This section provides a detailed look at the key elements that make up this advanced agricultural machine. Understanding the core mechanical and functional components allows users to effectively maintain and operate the equipment, ensuring optimal performance and longevity in various working conditions.

| Component | Description | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cutting Mechanism | Designed to efficiently handle various crop types, ensuring clean and precise cuts during operation. | ||||||||

| Drive System | Powerful and reliable, this system ensures smooth transmission of power from the engine to the cutting and conditioning units. | ||||||||

| Conditioning Rollers | Engineered to help reduce drying time by breaking down crop stems, improving overall efficiency in the field. |

| Component | Function |

|---|---|

| Rollers | Used to compress and crimp the material, promoting faster drying and more consistent output. |

| Blades | Responsible for cutting the crop to a desired length, ensuring smooth processing throughout the machine. |

| Drive Belts | Transmit power from the motor to the rotating parts

Understanding the Frame Structure DesignThe frame structure is the backbone of any agricultural machinery, providing essential support and stability for all its components. Its design plays a crucial role in ensuring that the equipment can withstand demanding tasks in tough environments. A well-engineered framework helps distribute the machine’s weight efficiently, contributing to durability and improved performance over time. Structural Integrity: The frame’s strength depends on the choice of materials and the way its elements are connected. Reinforced sections, such as beams and joints, are designed to handle stress and resist bending under pressure, ensuring long-term reliability. Efficiency in Operation: A robust frame design also enhances the machine’s overall efficiency, reducing vibrations and absorbing shocks during operation. This results in smoother handling and less wear on other mechanical Hydraulic System Overview and MaintenanceThe hydraulic system plays a crucial role in the operation and efficiency of agricultural machinery, providing the necessary power for various functions. Understanding its components and maintenance requirements is essential for ensuring optimal performance and longevity. Regular attention to this system not only enhances operational capabilities but also minimizes the risk of unexpected breakdowns. Components of the Hydraulic SystemThe primary components of a hydraulic assembly include pumps, cylinders, valves, and hoses. Each element contributes to the overall functionality, enabling smooth fluid movement and effective force transmission. Pumps are responsible for generating hydraulic pressure, while cylinders convert this pressure into mechanical motion. Valves control the flow of hydraulic fluid, and hoses facilitate the transfer of this fluid throughout the system. Maintenance Practices

Regular maintenance of the hydraulic system is vital for preventing issues and ensuring efficient operation. Key practices include checking fluid levels, inspecting hoses for wear, and ensuring that connections are secure. Additionally, it is important to replace hydraulic fluid according to the manufacturer’s recommendations and to routinely examine the entire system for any leaks or signs of damage. Implementing these measures can significantly extend the lifespan of the hydraulic system and maintain optimal functionality. Exploring the Gearbox AssemblyThe gearbox assembly serves as a critical component in ensuring the effective operation of agricultural machinery. It is designed to facilitate the transfer of power from the engine to the working parts, enabling efficient performance in various tasks. Understanding the layout and function of this assembly is essential for maintenance and troubleshooting. Components and Functionality Within the gearbox, several essential components work in harmony to achieve optimal performance. These include gears, bearings, and shafts, each playing a pivotal role in the overall functionality. The arrangement of these elements dictates how power is transmitted, making it crucial to comprehend their interactions and contributions to the machine’s operation. Maintenance Tips Regular inspection and maintenance of the gearbox assembly can significantly extend the lifespan of the machinery. Ensuring proper lubrication, checking for wear and tear, and promptly addressing any unusual noises can prevent costly repairs and enhance operational efficiency. Familiarizing oneself with the components and their functions aids in effective upkeep. Protecting and Maintaining the PTO ShaftEnsuring the longevity and efficiency of the power take-off (PTO) shaft is crucial for optimal machinery performance. Proper care and preventive measures can help avoid premature wear and potential failures, ultimately leading to improved functionality and reduced repair costs. To safeguard and maintain the PTO shaft effectively, consider the following practices:

Implementing these measures will enhance the performance of the PTO system and contribute to the overall reliability of the machinery. Regular attention to maintenance details can significantly impact operational efficiency and equipment durability. Belt and Pulley Arrangement ExplainedThe configuration of belts and pulleys plays a crucial role in the functionality of various machinery. This system facilitates the transfer of power from one component to another, ensuring smooth operation and efficiency. Understanding how these elements interact can provide valuable insights into maintenance and performance optimization. Understanding the ComponentsIn any belt and pulley setup, the main components include the belts, which are flexible loops, and the pulleys, which are grooved wheels. The belts are looped around the pulleys, creating a tension that drives the connected machinery. The choice of materials and dimensions for these components is vital, as they determine the overall efficiency and durability of the system. Operational DynamicsThe mechanics of a belt and pulley arrangement rely on the principles of friction and tension. When a pulley rotates, it pulls the attached belt, which in turn moves other components of the machine. Adjusting the tension in the belt is essential for optimal performance, as excessive slack can lead to slippage, while too much tension may cause premature wear or breakage. Regular inspections can help maintain the integrity of this vital assembly. Blade Replacement and Maintenance TipsEnsuring optimal performance of your mowing equipment involves regular attention to the cutting elements. Proper care and timely replacement can significantly extend the lifespan of the machinery while improving cutting efficiency. Here are some essential tips for replacing and maintaining the blades:

Following these guidelines will help maintain the cutting elements effectively, ensuring your equipment operates at peak performance throughout its lifespan. Troubleshooting Common Issues with PartsUnderstanding the typical challenges that may arise with equipment components is essential for maintaining optimal performance. Identifying and addressing these issues can significantly enhance the longevity and efficiency of your machinery. One frequent problem involves wear and tear on essential components, leading to decreased functionality. Regular inspections can help detect signs of deterioration early, allowing for timely replacements and minimizing operational disruptions. Another common concern is improper installation of components, which can result in misalignment or ineffective performance. Ensuring that each part is fitted according to specifications can prevent complications and promote smoother operation. Foreign debris or blockages can also hinder the functioning of key elements. Keeping the area clean and regularly checking for obstructions can mitigate these risks and enhance overall efficiency. Lastly, incompatibility between various components may cause unexpected issues. Always verify that replacement items are suitable for your specific equipment model to avoid further complications. |