In the realm of modern farming, the efficiency and reliability of machinery play a crucial role in maximizing productivity. Familiarity with the intricate elements that constitute these machines is essential for operators and technicians alike. A clear comprehension of how each component interacts can lead to better maintenance practices and informed decision-making regarding repairs and upgrades.

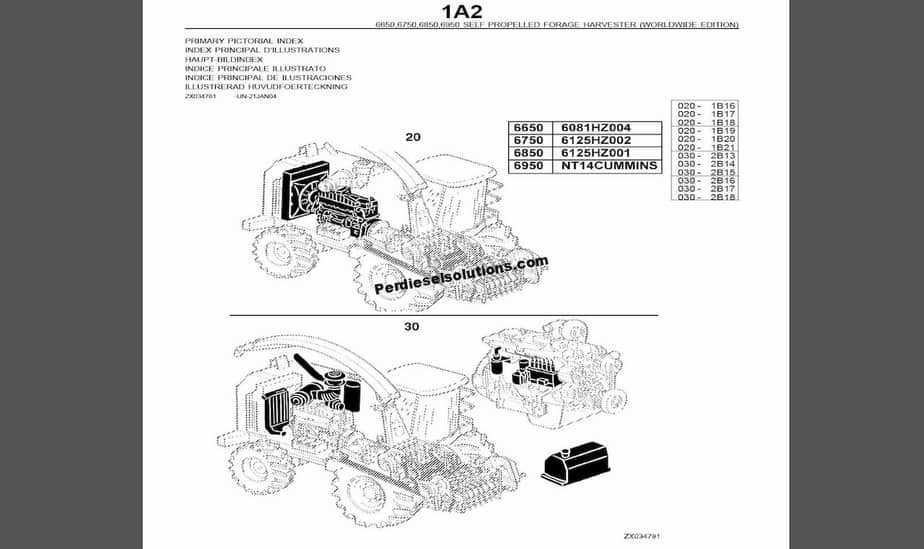

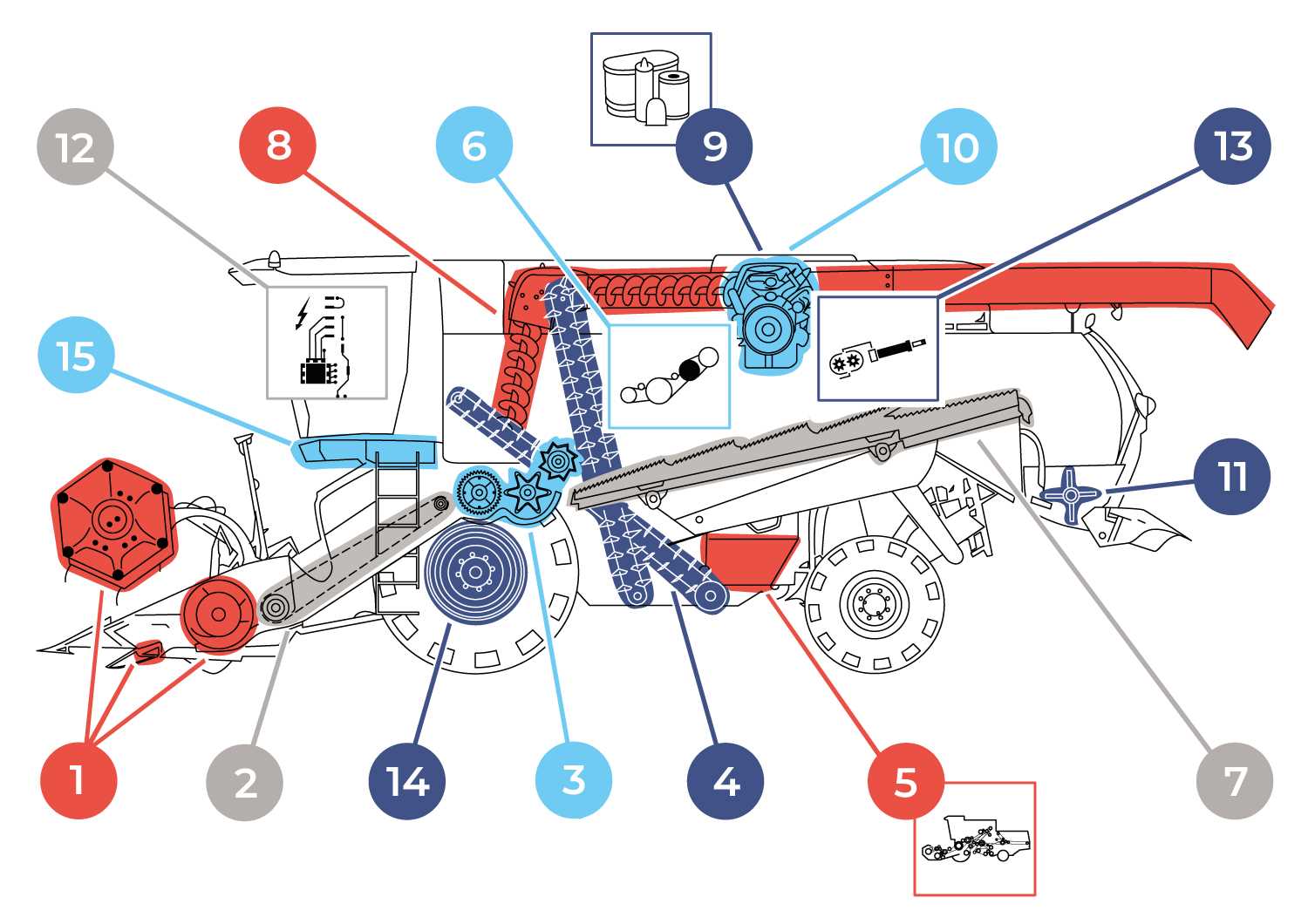

To navigate the complexities of these mechanical systems, visual representations can serve as invaluable resources. They offer a detailed overview of the various sections and functions, allowing users to pinpoint specific features with ease. This understanding not only streamlines the repair process but also enhances the overall performance of the equipment.

Whether you are a seasoned professional or a newcomer to the agricultural industry, delving into the specifics of machinery construction can empower you to take control of maintenance tasks. Armed with the right knowledge, operators can ensure their equipment runs smoothly, reducing downtime and increasing efficiency on the field.

Understanding the John Deere 9600

This section delves into the intricacies of a well-regarded agricultural machine, highlighting its components and functionalities. A thorough comprehension of this equipment is essential for optimal performance and maintenance.

Key features of this model include:

- Efficient harvesting capabilities

- Advanced technology for precision farming

- Robust engine performance

- Durability in various field conditions

When exploring the various components, it’s crucial to consider their roles:

- Engine: Provides the necessary power for operation.

- Transmission: Ensures smooth movement and speed control.

- Harvesting system: Optimizes crop collection efficiency.

- Chassis: Supports the overall structure and stability.

Understanding these elements contributes to better maintenance practices and enhances the lifespan of the equipment. Familiarity with the functionalities allows operators to make informed decisions, ensuring effective use in the field.

Key Features of the 9600 Model

This model stands out for its robust capabilities and innovative design, tailored for efficiency and performance in various agricultural tasks. The combination of advanced technology and user-friendly features makes it a reliable choice for farmers seeking productivity and ease of use.

Performance and Efficiency

- Powerful engine options that enhance operational output.

- Advanced harvesting technology for improved grain handling.

- Efficient fuel consumption, reducing overall operating costs.

User-Friendly Design

- Intuitive control panel for easy operation.

- Comfortable cabin with ergonomic seating and climate control.

- Enhanced visibility for improved safety and maneuverability.

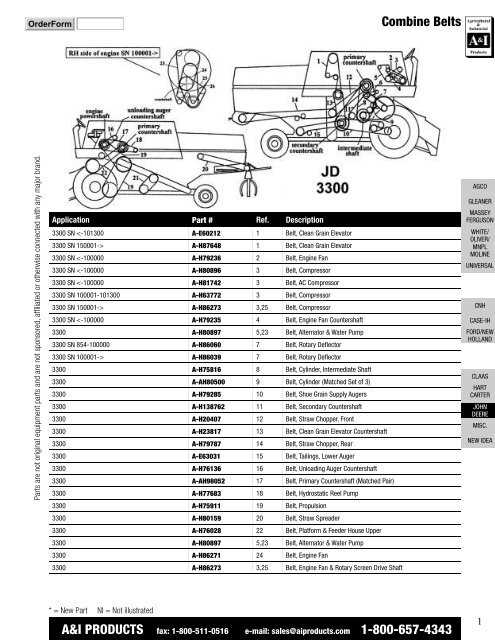

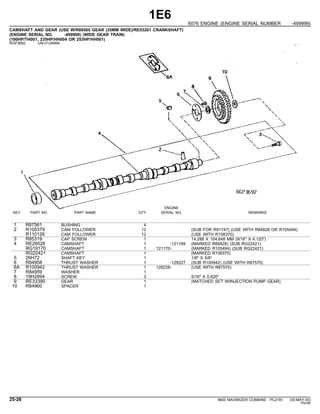

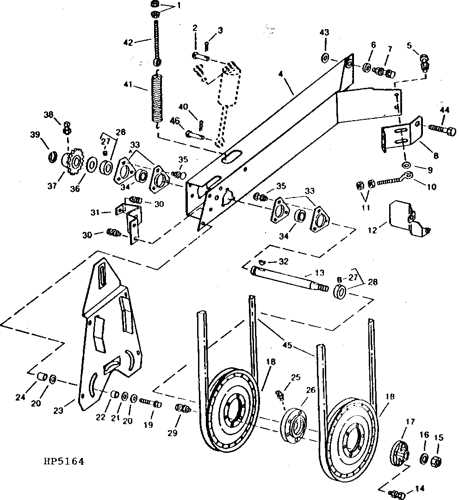

Importance of Parts Diagrams

Visual representations of components are crucial for understanding complex machinery. They serve as valuable tools for both maintenance and assembly, ensuring that users can easily identify and locate essential elements.

- Facilitates quick identification of components.

- Aids in troubleshooting and repairs.

- Enhances communication among technicians.

- Improves efficiency during assembly processes.

- Reduces the risk of errors in installations.

Ultimately, having access to these visual aids promotes effective management of equipment, leading to increased longevity and performance.

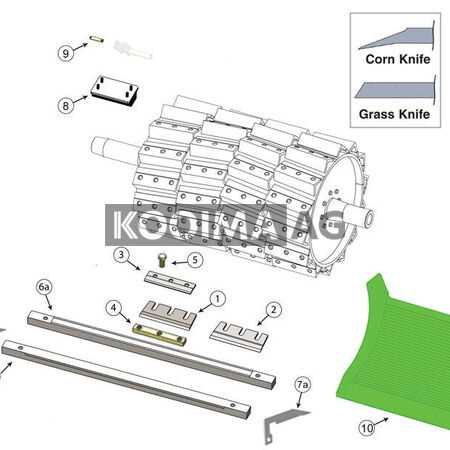

Common Parts and Their Functions

Understanding the various components of agricultural machinery is essential for efficient operation and maintenance. Each element plays a vital role in ensuring the machine runs smoothly, contributing to overall productivity. Familiarizing oneself with these components can aid in troubleshooting and enhance performance.

Key Components

One of the primary elements is the engine, which powers the entire machine. It converts fuel into mechanical energy, enabling various functions. Another important component is the transmission system, responsible for transferring power from the engine to the wheels, facilitating movement across fields.

Auxiliary Elements

Additionally, the cutting system is crucial for harvesting, allowing for precise and effective crop collection. The hydraulic system also plays a significant role, providing the necessary force for various attachments and ensuring smooth operation of moving parts. Understanding these systems is key to maximizing efficiency and minimizing downtime.

Where to Find Diagrams Online

Accessing visual representations of machinery components is essential for maintenance and repairs. Various resources are available online, catering to different needs and preferences. These platforms provide detailed illustrations, allowing users to explore the intricate workings of their equipment.

Popular Websites

| Website | Description |

|---|---|

| Manufacturer’s Official Site | Often offers comprehensive resources, including manuals and visual aids. |

| Online Forums | A community-driven space where users share insights and resources, including images. |

| Third-Party Retailers | Some retailers provide detailed illustrations of components available for purchase. |

Tips for Efficient Searching

Utilize specific keywords related to your equipment when searching. Engaging with forums and communities can also lead to discovering hidden resources and expert advice.

Maintenance Tips for 9600 Components

Regular upkeep of machinery components is crucial for optimal performance and longevity. Implementing a consistent maintenance routine can prevent costly repairs and enhance efficiency. This section provides essential guidance to ensure all elements function smoothly.

Routine Checks

Conducting frequent inspections helps identify wear and tear early. Focus on lubrication, filter cleanliness, and any signs of rust or damage. Keeping a checklist can streamline this process.

Proper Storage

When equipment is not in use, storing it correctly can significantly extend its lifespan. Ensure it is kept in a dry, protected environment to prevent environmental damage.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Lubrication | Every 50 hours | Use recommended lubricants. |

| Filter Replacement | Every 100 hours | Check for blockages regularly. |

| Visual Inspection | Every use | Look for signs of wear. |

Identifying Parts by Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations provide a clear overview, helping users to locate and recognize individual elements quickly. Utilizing these illustrations enhances efficiency, allowing for swift identification and troubleshooting.

Benefits of Using Visual Guides

- Enhanced clarity in understanding complex structures.

- Streamlined communication among technicians and operators.

- Reduced time spent on locating specific components.

- Improved accuracy in ordering replacements.

Steps to Identify Components

- Review the illustration thoroughly to grasp the layout.

- Cross-reference with the manual for additional context.

- Highlight or mark components for easy reference during repairs.

- Keep a record of any identified discrepancies or damages.

How to Order Replacement Parts

Acquiring new components for machinery is essential for maintaining optimal performance and longevity. Understanding the process of sourcing these items can streamline repairs and ensure that your equipment runs smoothly. This guide will help you navigate the steps required to obtain the necessary elements effectively.

Identifying Your Needs

Before placing an order, it’s crucial to identify the specific components required for your machinery. Reference the manual or use online resources to find the exact specifications needed.

Placing Your Order

Once you have identified the components, follow these steps to order:

| Step | Description |

|---|---|

| 1 | Contact your local supplier or visit their website. |

| 2 | Provide the component details and any relevant model information. |

| 3 | Confirm pricing and availability. |

| 4 | Place your order and choose your preferred shipping method. |

Popular Aftermarket Parts Options

Exploring alternative components can greatly enhance the performance and longevity of agricultural machinery. These options often provide superior quality or innovative features that original equipment may lack. Enthusiasts and professionals alike seek reliable substitutes that meet their operational needs.

Filters: High-efficiency filters can improve engine performance by ensuring cleaner air and fuel, reducing wear and tear.

Belts: Upgraded drive belts offer increased durability and resistance to wear, essential for maintaining optimal functionality during heavy use.

Blades: Enhanced cutting edges allow for a more precise operation, leading to better crop management and reduced downtime.

Tires: Selecting robust tires designed for specific terrain can significantly impact traction and overall machine efficiency.

Choosing aftermarket options can lead to remarkable improvements, ensuring that equipment remains competitive and effective in the field.

Repair vs. Replacement Decisions

When faced with a malfunctioning piece of equipment, determining the most effective course of action can be crucial for efficiency and cost management. Understanding the nuances between fixing existing components and acquiring new ones is essential for maintaining optimal performance.

Factors Influencing the Decision

Several elements play a role in this decision-making process. Cost is often a primary concern, as repairs can sometimes be significantly less expensive than purchasing replacements. Additionally, the age and condition of the equipment can affect whether a repair is worthwhile or if a replacement would ultimately be more beneficial.

Long-Term Implications

Beyond immediate expenses, considering the long-term implications of both options is vital. A temporary fix may lead to recurring issues, while a new acquisition could provide enhanced efficiency and reliability. Ultimately, evaluating both short-term and long-term outcomes will guide you in making the most informed choice.

Expert Advice on 9600 Upgrades

When considering enhancements for your machinery, it’s essential to focus on components that improve performance and efficiency. Upgrades can significantly impact productivity and longevity, ensuring your equipment remains competitive in the field.

- Evaluate the current state of your equipment.

- Identify key areas for improvement, such as engine power, harvesting efficiency, or operator comfort.

- Consult with specialists for tailored recommendations.

Ultimately, investing in quality enhancements will pay off in both operational efficiency and reduced downtime.

- Prioritize upgrades based on your specific operational needs.

- Consider integrating advanced technology for real-time monitoring.

- Stay informed about the latest innovations in your industry.

With the right upgrades, your machinery can achieve optimal performance, ensuring you stay ahead of the competition.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and their maintenance, providing clarity to users seeking assistance.

Common Inquiries

- What types of components are essential for optimal functionality?

- How can I identify the correct items for my machinery?

- Where can I find reliable suppliers for these items?

Maintenance Tips

- Regularly inspect components for wear and tear.

- Follow the manufacturer’s guidelines for replacements.

- Keep a record of all parts replaced for future reference.

Resources for John Deere Owners

Owning and maintaining agricultural machinery can be a complex task. Accessing the right materials and information is crucial for ensuring optimal performance and longevity of your equipment. Here are some valuable resources to support enthusiasts and operators alike.

- Online Forums: Engaging with fellow owners can provide insights and solutions to common challenges. Popular forums often feature discussions on troubleshooting and maintenance tips.

- Manufacturer’s Website: The official site offers comprehensive manuals, specifications, and updates that are essential for informed ownership.

- Local Dealerships: Authorized dealers can provide expert advice, genuine components, and servicing options tailored to specific machinery needs.

Additionally, consider these other resources:

- Service Manuals: Detailed guides help users navigate repairs and maintenance.

- Social Media Groups: Platforms like Facebook host communities where members share experiences, tips, and best practices.

- YouTube Channels: Many content creators offer tutorials and demonstrations that can be incredibly helpful for visual learners.

By leveraging these resources, owners can enhance their understanding and care of their agricultural machinery, leading to more efficient and effective operation.